A HIERARCHICAL FUZZY-NEURAL MULTI-MODEL

An application for a mechanical system with friccion identification and control

Ieroham Baruch, Jose Luis Olivares

CINVESTAV-IPN, Dept. of Aut. Control, Ave. IPN 2508, Col. Zacatenco, A.P. 14-740, C.P. 07360 Mexico D.F., Mexico

Federico Thomas

IRI-UPC, Technological Parc of Barcelona, Edif. U, Llorens Artigas str. 4-6, 2-nd floor, 08028 Barcelona, Spain

Keywords: Inverse model adaptive neural control, Dire

ct adaptive neural control, Systems identification, Fuzzy-neural

hierarchical multi-model, Recurrent trainable neural network, Mechanical system with friction.

Abstract: A Recurrent Trainable Neural Network (RTNN) with a two layer canonical architecture and a dynamic

Backpropagation learning method are applied for identification and control of complex nonlinear

mechanical plants. The paper uses a Fuzzy-Neural Hierarchical Multi-Model (FNHMM), which merge the

fuzzy model flexibility with the learning abilities of the RNNs. The paper proposed the application of two

control schemes, which are: a trajectory tracking control by an inverse FNHMM and a direct adaptive

control, using the states issued by the identification FNHMM. The proposed control methods are applied for

a mechanical plant with friction system control, where the obtained comparative results show that the

control using FNHMM outperforms the fuzzy and the neural single control.

1 INTRODUCTION

Recent advances in understanding of the working

principles of artificial neural networks has given a

tremendous boost to identification and control tools

of nonlinear systems, (Narendra and Parthasarathy,

1990; Hunt et al., 1992; 1995, Miller et al., 1992;

Omatu et al., 1995). Most of the current applications

rely on the classical NARMA approach, where a

feedforward network is used to synthesize the

nonlinear map, (Narendra and Parthasarathy, 1990;

Hunt et al., 1992). This approach has some

disadvantages, (Hunt et al., 1992), like that: the

network inputs are a number of past system inputs

and outputs, so to find out the optimum number of

past values, a trial and error must be carried on; the

model is naturally formulated in discrete time with

fixed sampling period, so if the sampling period is

changed the network, must be trained again;

problems associated with stability, convergence and

rate of convergence of this networks are not clearly

understood and there is not a framework available

for its analysis in vector-matricial form, (Gupta et

al., 1994; Jin and Gupta, 1999); it is a necessary

condition, that the plant order has to be known.

Besides to avoid these difficulties, a new Recurrent

Neural Networks (RNN) topology, and a

Backpropagation (BP) like learning algorithm,

(Baruch et al., 2001a, 2002), has been designed.

This RNN model is a parametric one, permitting the

use of the obtained parameters during the learning

for control systems design. Furthermore, the

designed RNN model is a system state

predictor/estimator, which permits to use the

obtained system states directly for state-space

control. The designed RNN model has the advantage

to be completely parallel, so its dynamics depends

only on the previous step and not on the other past

steps, determined by the systems order which

simplifies the computational complexity of the

learning algorithm with respect to the sequential

RNN model of (Frasconi, Gori and Soda, 1992).

For complex nonlinear plants, the authors of

(Bar

uch et al., 1998, 2001b) proposed to use a

fuzzy-neural multi-model, which is applied for

systems with friction identification and control. This

model explore the ideas of (Takagi and Sugeno,

1985), using in the right hand side of the fuzzy rules

static or dynamic functions (see Babushka and

230

Baruch I., Luis Olivares J. and Thomas F. (2005).

A HIERARCHICAL FUZZY-NEURAL MULTI-MODEL - An application for a mechanical system with friccion identification and control.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics, pages 230-235

DOI: 10.5220/0001174702300235

Copyright

c

SciTePress

Verbruggen, 1997), the multiple neural approach

(see Eikens and Karim, 1999), and further a

recurrent neural network multi-models (see Baruch,

et al., 1998; Mastorocostas and Theocharis, 2002).

The difference between the used in (Mastorocostas

and Theocharis, 2002) fuzzy neural model and the

approach of (Baruch, et al., 1998), is that the first

one uses the (Frasconi, Gori and Soda, 1992) FGS-

RNN model, which is sequential one, and the second

one uses the Recurrent Trainable NN (RTNN) model

(Baruch et al., 2001a, 2002), which is completely

parallel one.

2 MODELS DESCRIPTION

2.1 Recurrent Neural Model and

Learning

The RTNN model is described by the following

equations, (see Baruch et al., 2001a, 2002):

X(k+1) = JX(k)+BU(k) (1)

Z(k)=S[X(k)] (2)

Y(k) = S[CZ(k)] (3)

J = block-diag (Ji); ⏐Ji⏐< 1

(4)

Where: X(k) is a N - state vector; U(k) is a M- input

vector; Y(k) is a L- output vector; Z(k) is a L-

auxiliary vector; S(x) is a vector-valued activation

function with compatible dimension; J is a weight-

state diagonal matrix with elements J

i

; the equation

(4) is a stability condition, imposed on the weights

J

i

; B and C are weight input and output matrices

with compatible dimensions and block structure,

corresponding to the block structure of J. As it can

be seen, the given RTNN model is a completely

parallel parametric one, with parameters - the weight

matrices J, B, C, and the state vector X(k). The

controllability, observability and stability of this

model are considered in (Baruch et al., 2002). The

general BP learning algorithm is given as:

W

ij

(k+1) = W

ij

(k) +η ∆W

ij

(k) +α ∆W

ij

(k-1)

(5)

Where: W

ij

(C, J, B) is the ij-th weight element of

each weight matrix (C, J, B) of the RTNN model to

be updated; ∆W

ij

is the weight correction of W

ij

; η,

α are learning rate parameters. The weight updates

∆C

ij

, ∆J

ij

, ∆B

ij

of C

ij

, J

ij

, B

ij

are:

∆C

ij

(k) = [T

j

(k) -Y

j

(k)] S

j

’(Y

j

(k)) Z

i

(k)

(6)

∆J

ij

(k) = R

1

X

i

(k-1)

(7)

∆B

ij

(k) = R

1

U

i

(k)

(8)

R

1

= C

i

(k) [T(k)-Y(k)] S

j

’(Z

j

(k)) (9)

Where: T is a target vector with dimension L; [T-Y]

is an output error vector also with the same

dimension; R

1

is an auxiliary variable; S

j

’(x) is the

derivative of the activation function, which for the

hyperbolic tangent is S

j

’(x) = 1-x

2

. The stability of

the learning algorithm is proved in (Baruch et al.,

2002), and it is applied for a DC motor control.

2.2 Hierarchical Fuzzy-Neural

Multi-Model

For complex dynamic systems identification, the

fuzzy rule of (Takagi and Sugeno, 1985) admits to

use in the consequent part a crisp function, which

could be a static or dynamic (state-space) model.

Some authors, referred in (Baruch, et al., 1998;

Mastorocostas and Theocharis, 2002), proposed as a

consequent crisp function to use a NN function. In

(Baruch et al., 1998, 2001b), it is proposed as a

consequent crisp function to use the RTNN model.

The fuzzy rule of the proposed model is given by:

R

i

: IF x is A

i

THEN y

i

(k+1)= N

i

[x(k), u(k)],

i=1,2,..,P

(10)

Where: N

i

(.) denotes the RTNN model, given by

equations (1) to (3); i -is the model number; P is the

total number of models, corresponding to Ri. In the

case when the intervals of the variables, given in the

antecedent parts of the rules are not overlapping, the

output of the model is a simple sum of the rule

consequences, and this simple case, called fuzzy-

neural multi-model, has been considered in (Baruch

et al., 1998, 2001b). In the general case, when the

membership functions are overlapping, the output of

the fuzzy neural multi-model system is given by the

following equation:

Y= Σ

i

w

i

y

i

= Σ

i

w

i

N

i

(x,u)

(11)

A HIERARCHICAL FUZZY-NEURAL MULTI-MODEL: An application for a mechanical system with friccion

identification and control

231

Where w

i

are weights, obtained from the

membership functions, (see Baruch et al., 2001b).

As it could be seen from the equation (11), the

output of the approximating fuzzy-neural multi-

model is obtained as a weighted sum of RTNN

functions, given in the consequent part of (10). The

output of the upper level of the Fuzzy-Neural

Hierarchical Multi-Model (FNHMM) is a complete

weighted sum, given by (11), and the weighted

summation is performed by a RTNN model, which

introduced some kind of filtration of the outputs of

the lower level RTNN’s. So (11) is converted in the

next discrete-time nonlinear dynamic equation:

Y(k+1) = N[x(k), (Σ

i

w

i

y

i

(k))] =

N[x(k), (Σ

i

w

i

N

i

(x

i

(k), u

i

(k)))]

(12)

3 ADAPTIVE FUZZY-NEURAL

CONTROL SCHEMES

3.1 An Inverse Model Adaptive

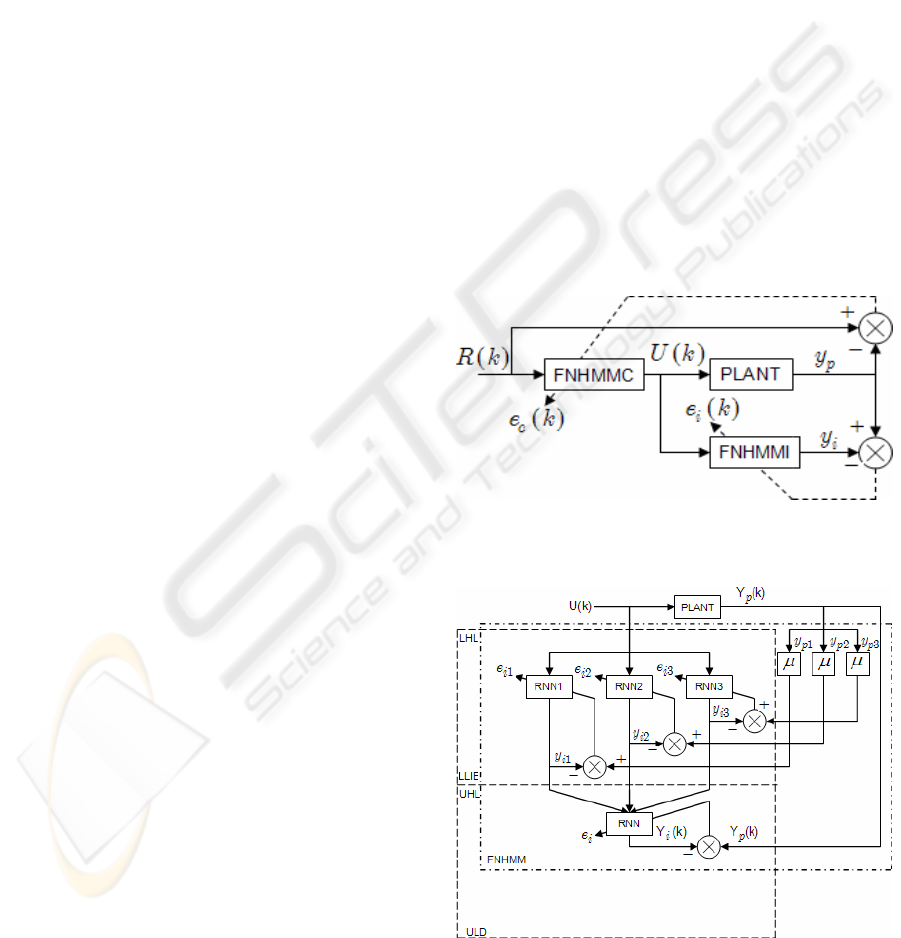

FNHMM Control Scheme

The main control objective here is to build an

inverse model of the plant in such a way that the

output of the plant tracks the system reference. It is

obvious that the control here as an open loop

feedforward learning control. The block-diagram of

this control is given on Figure 1. It contains a

FNHMM identifier (FNHMMI), which identifies the

Jacobean of the plant, and a FNHMM feedforward

controller (FNHMMC). The output of the plant and

the reference signal are normalized in the interval

[+1, -1] and divided in the same three overlapping

intervals corresponding to its membership functions

(positive, negative, and zero). The structure of the

FNHMM identifier is given on Figure 2. The local

and global errors of identification and control used

for RTNNs learning are given by the following

equations:

e

i

(k) = y

Pi

(k) - y

ii

(k); e(k) = y

p

(k) - y

i

(k) (13)

e

ci

(k) = R

i

(k) - y

Pi

(k); e

c

(k) = R(k) - y

p

(k) (14)

The FNHMMI has two levels – Lower Hierarchical

Level (LHL), and Upper Hierarchical Level (UHL).

The LHL is composed of three parts: 1)

Fuzzyfication, where the plant output signal is

divided in three intervals µ : positive [1, -0.5],

negative [-1, 0.5], and zero [-0.5, 0.5]; 2) Lower

Level Inference Engine (LLIE), which contains three

(Takagi and Sugeno, 1985) TS - fuzzy rules, given

by (10), and operating in the three intervals, and

three RTNNs, learned by the local errors of

identification (13); 3) Upper Level Defuzzyfication

(ULD) which consists of one RTNN, learned by the

global error of identification (13). This RTNN

performs a filtered weighted summation of the

outputs of the lower level RTNNs. The learning and

functioning of both levels is independent.

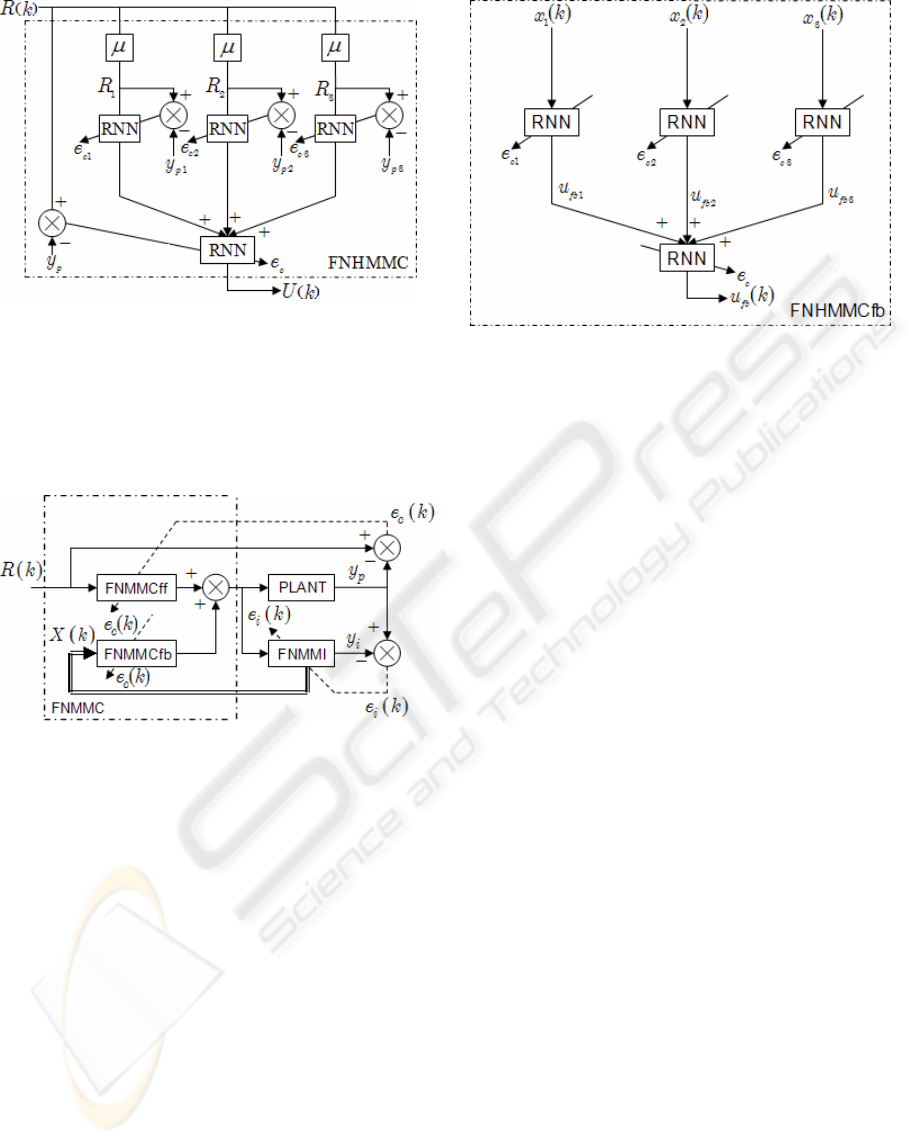

The block-diagram of the FNHMM feedforward

controller is given on Figure 3. During the learning,

the control errors are attenuated by the inverse of the

identified plants gain. The FNHMM feedforward

controller contains the same elements as the

FNHMM identifier. They are: fuzzyfication of the

plant output and the reference signal; lower level

inference engine, which contain the same number of

rules and RTNNs, learned by the local errors of

control (14); upper level defuzzyfication done by an

upper level RTNN, learned by the global error of

control (14).

Figure 1: Block diagram of the inverse plant model control

using FNHMM identifier and FNHMM feedforward

controller

Figure 2: Block diagram of the Fuzzy Neural Hierarchical

Multi-Model identifier

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

232

Figure 3: Block diagram of the FNHMM feedforward

controller

3.2 A Direct Adaptive FNHMM

Control Scheme

The structure of the system is given on Figure 4.

Figure 4: Block diagram of the direct adaptive neural

control scheme using FNMMI, FNMMCfb and FNMMCff

It contains a FNHMM identifier (see Figure 2),

FNHMM feedforward (see Figure 3) and feedback

(see Figure 5) controllers. The FNHMM identifier

and the FNHMM controllers contain fuzzyfier, a

Fuzzy Rule-Based System (FRBS), a set of RTNN

models and a RTNN used as defuzzyfier. The

control fuzzy rules applied and the total control,

issued by the FNMM control system are:

R

i

: If x is A

i

then u

i

= U

i

(k), i=1, 2 ,.., L (15)

U

i

(k) = - N

fb,i

[x

i

(k)] + N

ff,i

[r

i

(k)] (16)

U(k)= Σ

i

w

i

U

i

(k)

(17)

Where: r(k) is the reference signal; x(k) is the

system state; N

fb,I

[x

i

(k)] and N

ff,I

[r

i

(k)] are the

Figure 5: Block diagram of the FNMMC feedback

controller

feedforward and feedback parts of the fuzzy-neural

control, performed by RTNN functions, and w

i

are

weights, obtained from the membership functions,

corresponding to the rules (15). As it could be seen

from the equation (17), the control could be obtained

as a weighted sum of controls, given in the

consequent part of (15). In the case when the

intervals of the variables, given in the antecedent

parts of the rules, are not overlapping, the weights

obtain values one and the weighted sum (17) is

converted in a simple sum. From Figure 5 it is seen

that the FNHMM identifier approximates the plant

using three RTNNs, working in three overlapping

intervals, corresponding to the three membership

functions (positive, negative, and zero). The state

vector issued by each RTNN is entry of a feedback

FNMM controller and the FNHMM feedforward

controller complements the control part. The

defuzzification level of both control parts is

performed by RTNNs (see Figures 3 and 5).

4 SIMULATION RESULTS

Let us consider a DC-motor - driven nonlinear

mechanical system, taken from (Baruch, et al.,

2001b), which has the following friction parameters

(Lee and Kim, 1995): α = 0.001 m/s; F

s

+

= 4.2 N ;

F

s

-

= - 4.0 N; ∆F

+

= 1.8 N ; ∆F

-

= - 1.7 N ; v

cr

= 0.1

m/s; β = 0.5 Ns/m. Let us also consider that the

position and the velocity measurements are taken

with period of discretization To = 0.01 s; the system

gain is ko = 8; the mass is m = 1 kg, and the load

disturbance depends on the position and the velocity

(ld(t) = ld

1

q(t) +ld

2

v(t); ld

1

= 0.25; ld

2

= - 0.7). So

the discrete-time model of the 1-DOF mass

mechanical system is:

A HIERARCHICAL FUZZY-NEURAL MULTI-MODEL: An application for a mechanical system with friccion

identification and control

233

x

1

(k+1) = x

2

(k)

x

2

(k+1)=-0.025x

1

(k)-

0.3x

2

(k)+0.8u(k)-0.1fr(k)

(18)

v(k) = x

2

(k) - x

1

(k) (19)

y(k) = 0.1 x

1

(k) (20)

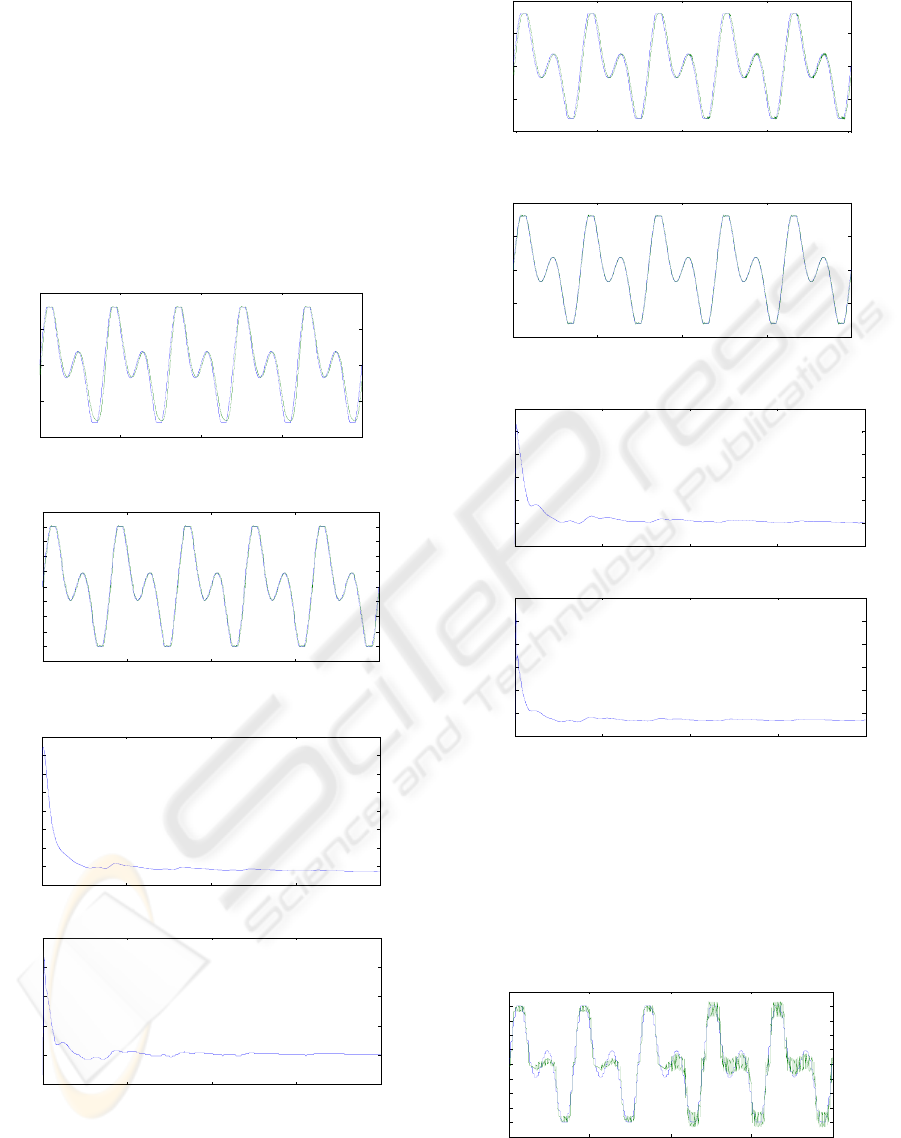

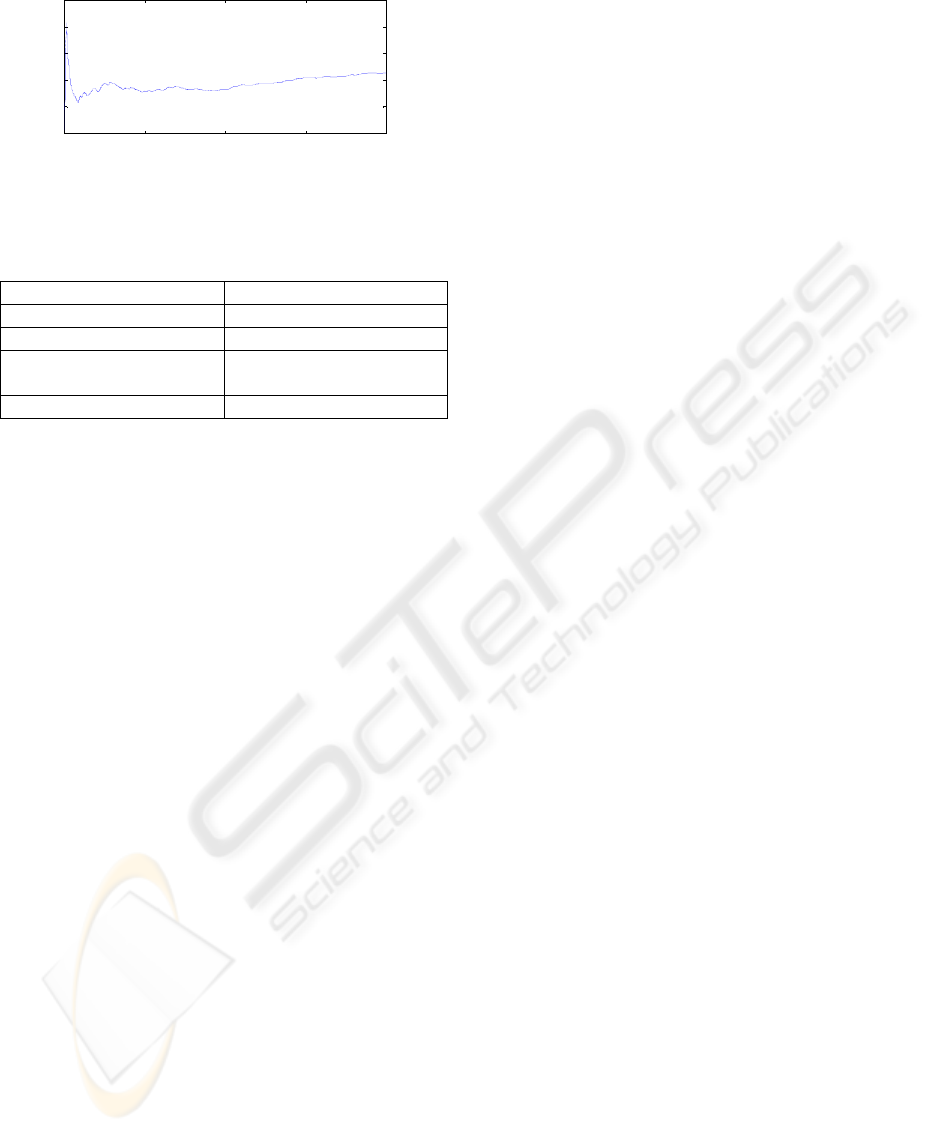

Where fr(k) is the friction force. Comparative results

of plant control for both schemes, obtained using

single RTNNs and that - using FNHMMCs, are

given on Figure 6 a,b,c,d and Figure 7 a,b,c,d. For

sake of comparison, simulation results obtained

using a fuzzy controller, are given on Figure 8 a,b.

0 5 10 15 20

-1

-0 .5

0

0.5

1

a) Comparison of the reference signal and the output of the

plant controlled by one RTNN.

0 5 10 15 20

-1

-0 .8

-0 .6

-0 .4

-0 .2

0

0.2

0.4

0.6

0.8

1

b) Comparison of the reference signal and the output of

the plant controlled by FNHMMC.

0 5 10 15 20

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

c) MSE of RTNN control.

0 5 10 15 20

0

0.5

1

1.5

2

2.5

x 1 0

-3

d) MSE of FNHMM control.

Figure 6: Trajectory tracking control results obtained with

one RTNN feedforward controller and with a feedforward

FNHMMC

0 5 10 15 20

-1

-0 .5

0

0.5

1

a) Comparison of the reference signal and the output of the

plant, using single RTNN controllers.

0 5 10 15 20

-1

-0 .5

0

0.5

1

b) Comparison of the reference signal and the output of

the plant using FNHMMC.

0 5 10 15 20

0

0.002

0.004

0.006

0.008

0.01

0.012

c) MSE of control with single RTNN controllers.

0 5 10 15 20

0

0.2

0.4

0.6

0.8

1

1.2

x 10

-3

d) MSE of control with a FNHMMC

Figure 7: Trajectory tracking control results obtained with

single RTNN feedforward/feedback control and with a

feedforward/feedback FNHMMCs

Values of the Means Squared Error of identification

and control using FNHMMs, single RTNNs, and

fuzzy control, are given on Table 1.

0 5 10 15 20

-1

-0.8

-0.6

-0.4

-0.2

0

0. 2

0. 4

0. 6

0. 8

1

a) Comparison of the reference signal and the output of the

plant.

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

234

0 5 10 15 20

0

0.5

1

1.5

2

2.5

b) MSE of control.

Figure 8: Trajectory tracking control results obtained

using a fuzzy controller

Table 1: Mean Squared Error of identification and control

Name FNHMM vs. single RTNN

Systems identification: 0.08% vs. 0.27%

Feedforward control: 1.5% vs. 2.3%

Feedforward plus feedback

direct adaptive control:

0.41% vs. 2.7%

Fuzzy control: 5.8% (does not use NNs)

From Figures 6, 7, 8 and the MSE% data from Table

1, we could conclude that: the systems identification

using FNHMM gives better results than that using

only one RTNN; the control schemes which use

FNHMMC works better than that using one RTNN;

the FNHMM feedforward/feedback direct adaptive

control gives better results with respect to the

FNHMM feedforward control; the fuzzy control is

worse with respect to the neural control, especially

when the friction parameters changed.

6 CONCLUSIONS

A FNHMM for identification and control of

complex nonlinear plants is proposed. Two control

schemes of FNHMM has been experimented and

compared with a respective single-RTNN and fuzzy

control. The comparison of identification results for

a 1 DOF mechanical system with friction show that

the FNHMM identifier has a better performance

with respect to the identification using one RTNN.

The same is valid for the schemes of control. The

better control is the feedforward/feedback control

and the worse control is the fuzzy control.

REFERENCES

Babushka, R., and H. B. Verbruggen, 1997. Fuzzy

modeling: principles, methods and applications. In

Proc. of the Int. Workshop on Intelligent Control

INCON'97, Sofia, Bulgaria, Oct. 13-15, Bulgarian

Union for Automation and Informatics, pp. 1-23.

Baruch I., and E. Gortcheva, 1998. Fuzzy neural model for

nonlinear systems identification. In: Proc. of the

AARTC IFAC Workshop, Cancun, Mexico, April 15-

17, p.p. 283-288.

Baruch I., Flores J.M., Thomas F., and R. Garrido, 2001a.

Adaptive neural control of nonlinear systems. In Proc.

of the Int. Conf on NNs, ICANN 2001, Lecture Notes

in Computer Science, vol. 2130, Springer-Verlag,

Berlin, Heidelberg, N. Y., p.p. 930-936.

Baruch, I., Flores, J.M., and R. Garrido, 2001b. A fuzzy-

neural recurrent multi-model for systems identification

and control. In Proc. of the Europ. Contr. Conference,

ECC’01, Porto, Portugal, Sept. 4-7, p.p. 3540-3545.

Baruch I., Flores J.M., Nava F., Ramirez I.R., and B.

Nenkova, 2002. An advanced neural network topology

and learning, applied for identification and control of a

D.C. motor. In Proc. of the 1-st Int. IEEE Symp. on

Intelligent Syst., Varna, Bulgaria, Sept., pp. 289-295.

Eikens, B., and M.N. Karim, 1999. Process identification

with multiple neural network models. Internat.

Journal of Control, vol. 72, No 7/8, pp. 10-20.

Frasconi, P., Gori, M., and G. Soda, 1992. Local feedback

multilayered networks. Neural Computation, vol. 4,

pp. 120-130.

Gupta, M., Nikiforuk, P., and L. Jin, 1994. Adaptive

control of discrete time nonlinear systems using

recurrent neural networks. IEE Proc. Control Theory

and Applications, vol. 141, No 3, pp. 169-176.

Hunt, K.J., Sbarbaro, D., Zbikowski, R., and P. J.

Gawthrop, 1992. Neural network for control systems

(A survey). Automatica, vol. 28, pp. 1083-1112.

Hunt, K.J., Irwin, G.R., and K. Warwick, 1995. Neural

network engineering in dynamic control systems.

Springer Verlag, London.

Jin, L., and M. Gupta, 1999. Stable Dynamic

Backpropagation Learning in Recurrent Neural

Networks. IEEE Transactions on Neural Networks,

vol. 10, pp. 1321-1334.

Lee, S.W., and J.H. Kim, 1995. Robust adaptive stick-slip

friction compensation. IEEE Trans. on Ind. Elect., vol.

42 , No. 5, p.p. 474-479.

Mastorocostas P.A., and J.B. Theocharis, 2002.A recurrent

fuzzy-neural model for dynamic system identification.

IEEE Transactions on Systems, Man and Cybernetics,

Part B: Cybernetics, vol. 32, pp. 176-190.

Miller III, W.T., Sutton, R.S., and P.J. Werbos, 1992.

Neural networks for control. MIT Press, London.

Narendra K. S., and K.Parthasarathy, 1990. Identification

and control of dynamical systems using neural

networks. IEEE Transactions on Neural Networks,

vol. 1, No. 1, pp. 4-27.

Omatu, S., Khalil, M., and R. Yusof, 1995. Neuro-control

and its applications. Springer Verlag, London.

Takagi, T., and M. Sugeno, 1985. Fuzzy identification of

systems and its applications to modeling and control.

IEEE Trans. Systems, Man, and Cybernetics, vol. 15,

pp. 116-132.

A HIERARCHICAL FUZZY-NEURAL MULTI-MODEL: An application for a mechanical system with friccion

identification and control

235