CONTROL SYSTEM INTERFACE OF SCANNING SONAR FOR

MOBILE ROBOTS

Sv. Noykov and O. Manolov

Laboratory of Mobile Robotics LAMOR, ICSR-BAS, Block 2, Acad. G. Bontchev St., Sofia 1113, Bulgaria

Keywords: Mobile robot, Ultrasonic rang

e-finder.

Abstract: In this work, a simple, low-cost and reliable electronic module for coupling of an ultrasonic range-finder

with a mobile robot’s microprocessor system is presented. A software filter for correct reading of the

ultrasonic data is presented as well. Due to the software filter, a shielding of robot and sonar’s electronic

modules is not required. In this way compactness and low price of the device construction were achieved.

1 INTRODUCTION

Ultrasonic range-finders, referred also as sonars, are

known as robust and cheap distance measurement

devices suitable for various applications (Corrion et

al., 1996), including gathering of information from

environment for real-world modeling as well as for

navigating in mobile robotics (Borenstein et al.,

1996; Cao and Borenstein, 2002; Noykov and

Manolov, 2004). Ultrasonic range-finders don’t

depend on the lighting and brightness of surfaces,

even if they are influenced by the matter in which

the objects are made; they don’t depend on smoke,

and they don’t need cumbersome equipment

(Corrion et al., 1996). These devices provide relative

distance measurements between them and

surrounding obstacles located within their angular

detection range, also called “sonar detection cone”.

The time elapsed between the transmission of a

wave and the reception of its echo allows the

computation of a range reading r.

The current market suggests a variety of

u

ltrasonic range-finders. As is reported in

(Borenstein et al., 1996), the ultrasonic range

finders, based on POLAROID ranging modules, are

the most widely found in mobile robotics literature.

The base series of POLAROID ultrasonic ranging

systems is described in (Borenstein et al., 1996;

Polaroid Corp., 1991; Polaroid Corp., 1981). It

includes transducer and two electronic modules:

ranging circuit board and experimental

demonstration board. This ultrasonic ranging system

is low cost and its parameters satisfy the

requirements of the most applications in mobile

robotics (Borenstein et al., 1996). It is able to

measure ranges from 0.9 feet to 35 feet with

resolution 0.1 feet. The ranging circuit board (RCB)

controls both the transmit and receive operating

modes of the transducer. The experimental

demonstration board (EDB) is designed especially

as a user interface to the RCB. The EDB contains all

the necessary electronic circuitry to convert the

transmit/receive time interval into a figure indicating

distance, in feet, and present it on a three digit light

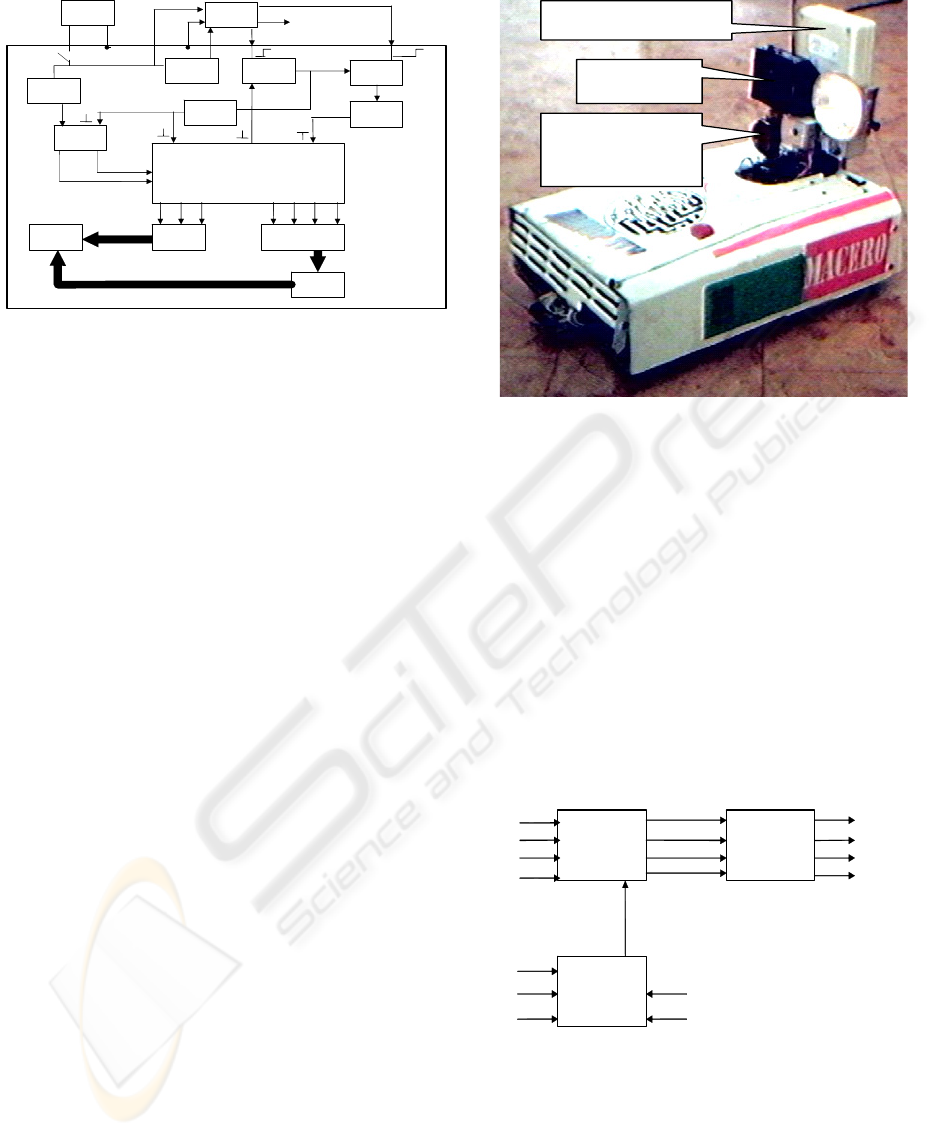

emitting diode (LED) display. The block diagram of

the EDB, given in (Polaroid Corp., 1981), is shown

in Fig. 1. The output of the EDB is a three digit

display (9) with a numeric output range of 0.9 to

35.0 in increments of 0.1 feet. The multiplexed

display is controlled by a three-digit binary counter

(8) with strobed digit-select lines DS1, DS2, DS3. It

uses a single binary-coded decimal (BCD) to-7-

segment decoder (11). Unfortunately, this

multiplexed display output does not allow direct

coupling with external microprocessor system. For

this purpose, an additional interface circuitry is

required. Such interface equipment, given in

(Ciarcia, 1980), was manufactured and tested in

Laboratory of Mobile Robotics LAMOR, ICSR-

BAS. Unfortunately, it was established that this

interface circuitry did not work properly.

245

Noykov S. and Manolov O. (2005).

CONTROL SYSTEM INTERFACE OF SCANNING SONAR FOR MOBILE ROBOTS.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Signal Processing, Systems Modeling and

Control, pages 245-250

DOI: 10.5220/0001164302450250

Copyright

c

SciTePress

RCB

POWER

+6V

GND

VDD

transducer

VSW XLG FLGGND

ON/OFF

1

2

SET

RES

RES

SET

3

4

LE

7

DLE

6

5

CLK RES

A1 A7

OF

178 ms

LC

SR

RES LATCH

ENABLE

SCANNING CLOCK

CLK INPUT

8

DS3 DS2 DS1 Q3 Q2 Q1 Q0

9 10

11

12

Sonar’s

transducer

Camera

Radiomodem

Figure 1: Block diagram of the Polaroid Experimental

Demonstration Board

In this work, hardware and software devices,

which enable an external microprocessor system to

read correctly the information from a POLAROID

ultrasonic ranging system, are presented.

Figure 2: The mobile mini-robot LAMOR-1TV.

2 THE SCANNING ULTRASONIC

RANGE-FINDER

In the LAMOR Lab, ICSR – BAS, the mobile robot

LAMOR-1TV has been created for experimental

research and education. LAMOR-1TV, shown in Fig.

2, is described in (Noykov and Manolov, 2004).

LAMOR-1TV is a mobile mini-robot with differential

steering. LAMOR-1TV has a length of 400 mm, a

width of 260 mm and a height of 220 mm. As part of

sensor subsystem of the robot, a scanning ultrasonic

range-finder (shortly sonar) was developed. The

sonar is based on an ultrasonic ranging system from

the base series of POLAROID. To enable scanning,

the transducer of the sonar is mounted on the axle of

a stepper motor. The home angular position of the

sonar’s transducer is 0º, i.e., the sonar’s transducer is

directed to the robot’s front in its home position. The

scanning range of the sonar is 244.8º, starting from -

122.4° to +122.4° in the horizontal surface. The

minimum scanning angle step of the sonar is 1.8º.

The described in the next section interface module

IM is used for coupling of the sonar with the

LAMOR-1TV microprocessor system.

3 INTERFACE MODULE FOR

CONNECTION OF AN

ULTRASONIC RANGING

SYSTEM TO AN EXTERNAL

MICROPROCESSOR SYSTEM

The suggested in (Ciarcia, 1980) interface circuitry

was modified and new interface module for coupling

of an ultrasonic ranging system from the base series

of POLAROID with an external microprocessor

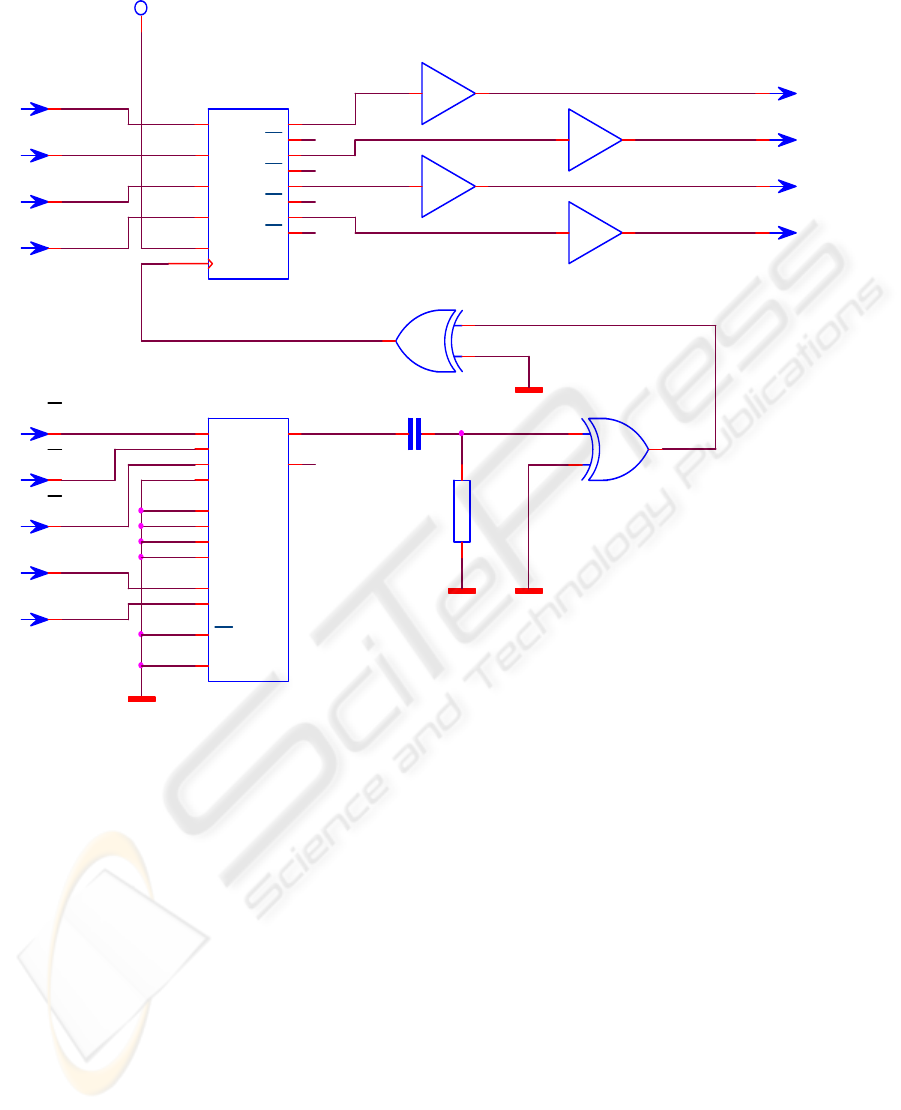

system was developed. The block diagram of the

Q0

Q1

Q2

Q3

BIT3

BIT2

BIT1

BIT0

DS3

DS1

DS2

BIT1

BIT0

X0

X1

X2

B

A

D0

D1

D2

D3

CK

1

23

O

UTPU

T

BIT1 BIT0 LIN

E

0 0 DS1 (LSD)

0 1 DS2

1 0 DS3 (MSD)

Figure 3: Interface module for connection of an ultrasonic

ranging system POLAROID to an external micro

p

rocesso

r

system: block diagram

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

246

IC3C CD4050

7

6

IC2 CD4052

12

14

15

11

1

5

2

4

6

10

9

13

3

7

X0

X1

X2

X3

Y0

Y1

Y2

Y3

EN

A

B

X

Y

VEE

DS2

IC4B

CD4070

5

6

4

Q3

BIT1 out

Q0

IC3B CD4050

5

4

DS1

IC3D CD4050

9

10

Q2

BIT0 out

BIT3 out

C1 100pF

IC3A CD4050

3

2

BIT0 in

BIT2 out

IC1 CD4042B

4

7

13

14

5

6

3

9

12

15

2

10

11

1

D0

D1

D2

D3

CLK

POL

Q0

Q1

Q2

Q3

Q0

Q1

Q2

Q3

IC4A

CD4070

1

2

3

DS3

+5V

BIT1 in

Q1

R1

10k

Figure 4: Interface module for connection of an ultrasonic ranging system POLAROID to an external microprocesso

r

system: schematic diagram

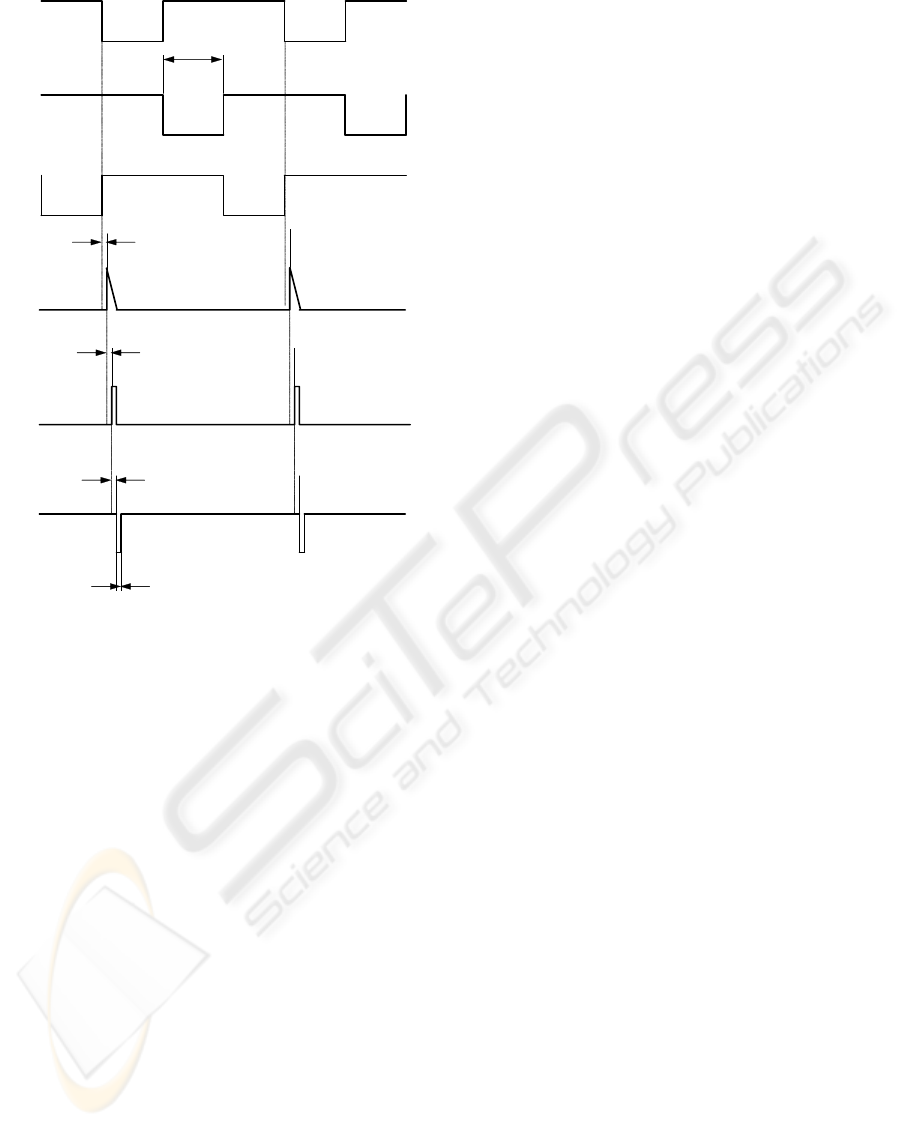

interface module (IM) in Fig. 3, its schematic

diagram in Fig. 4, and its timing diagram in Fig. 5,

are shown.

The block diagram of the interface module (IM)

includes three blocks. Block 1 includes three-input

demultiplexer (IC2) and logic circuits for a strobe

signal generating (IC4). Block 2 includes a 4-bit lach

(IC1), and Block 3 includes an output buffer (IC3).

When the MSD (most-significant digit) of the LED

display is energized, the DS3 line is low. The data

on Q0 thru Q3 at this tame form the BCD value of

that number. Similarly, when DS2 goes low, the data

lines will hold the second digit value. IC2 is a 4-to-

1-line demultiplexer with the three digit strobes as

inputs. A 2-bit TTL compatible parallel output from

the reading external microprocessor system

determines which of these channels is routed though

the multiplexer. To get DS1, the LSD (least

significant digit), the input code to the EDB

interface would be 00. A binary code of 10 would

set channel 3, allowing DS3 to go through. A

summary of the codes is given in the table showed in

Figure 2.2a. When we have selected which digit we

want to read by setting the proper multiplexer-input

code, that digit value will be latched into IC1 and

available as a BCD value to the reading external

microprocessor system. IC3 buffers the CMOS

voltage levels of the EDB to the TTL level required

by some microprocessor systems. To obtain the

distance indication, it is necessary to add the three

values:

DISTANCE = (MSD)*10+(2

nd

digit)*1+(LSD)*0.1

CONTROL SYSTEM INTERFACE OF SCANNING SONAR FOR MOBILE ROBOTS

247

4 THE SOFTWARE FILTER FOR

CORRECT READING OF THE

SONAR INFORMATION

During preliminary experimental gathering of

information from laboratory environment by the

mobile robot LAMOR-1TV, equipped with the

presented in Section 2 sonar, we found that the

robot’s microprocessor system did not read sonar

data correctly, due to the mutual influence of the

electromagnetic fields of the near located circuit

boards of the robot, circuit boards of the sonar, IM,

and stepping motors. Instead of shielding, we

developed a software filter for correct reading of the

sonar information by the robot’s microprocessor

system. The objectives that we had to achieve were

compactness and low price of the construction.

Initially we accomplished number experimental

readings by the sonar. Afterwards we analyzed the

stored in robot’s memory sonar information, read by

robot’s microprocessor system. It was found that this

information contained alternated sequences of

correctly and wrongly received data. The durations

of these sequences were analyzed. Afterwards, on

the basis of obtained results, a software filter was

developed, and implemented as executable code,

written in the on-board EPROM memory of the

robot.

DS1

DS2

DS3

IC4A,

p

in 1

IC4A,

p

in 3

IC4B,

p

in 4

t

p,IC2

t

p,IC4A

t

p,IC4B

t

W

t

DS

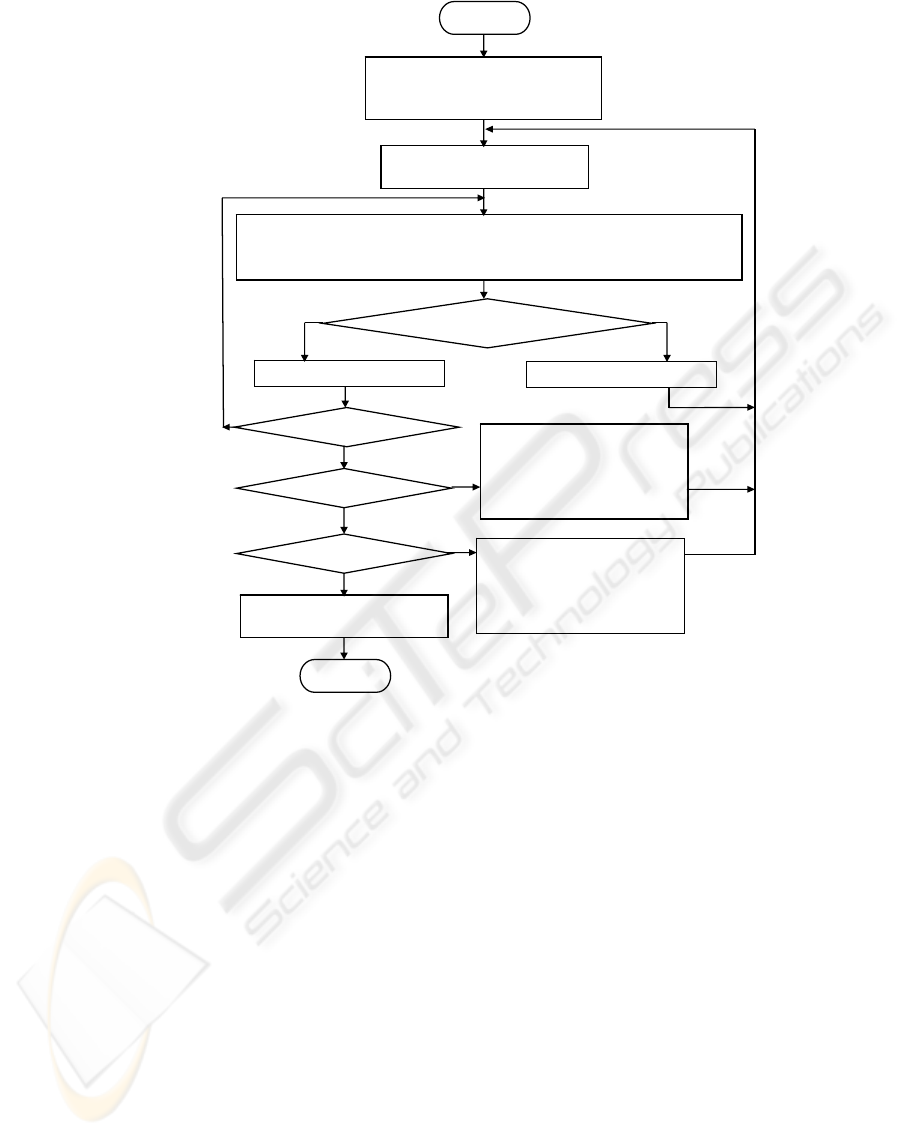

The algorithm of the software filter is

represented in Fig. 6. The calling subprogram

requires LSD, 2

nd

digit, and MSD of sonar data from

the called subprogram consecutively. The called

subprogram reads the data of required digit

repeatedly. To validate the read digit, a coincidence

of 100 consecutive readings is required. After the

read digit is validated, the called subprogram sends

it to the calling subprogram. A single reading takes

34 µs; therefore 100 consecutive readings take 3.4

ms. In the best case (i.e., in case without wrongly

read data) the acquiring of all three sonar digits will

take 3*3.4=10.2 ms. We found that in the worst case

the acquiring of all three sonar digits will take 19.1

ms.

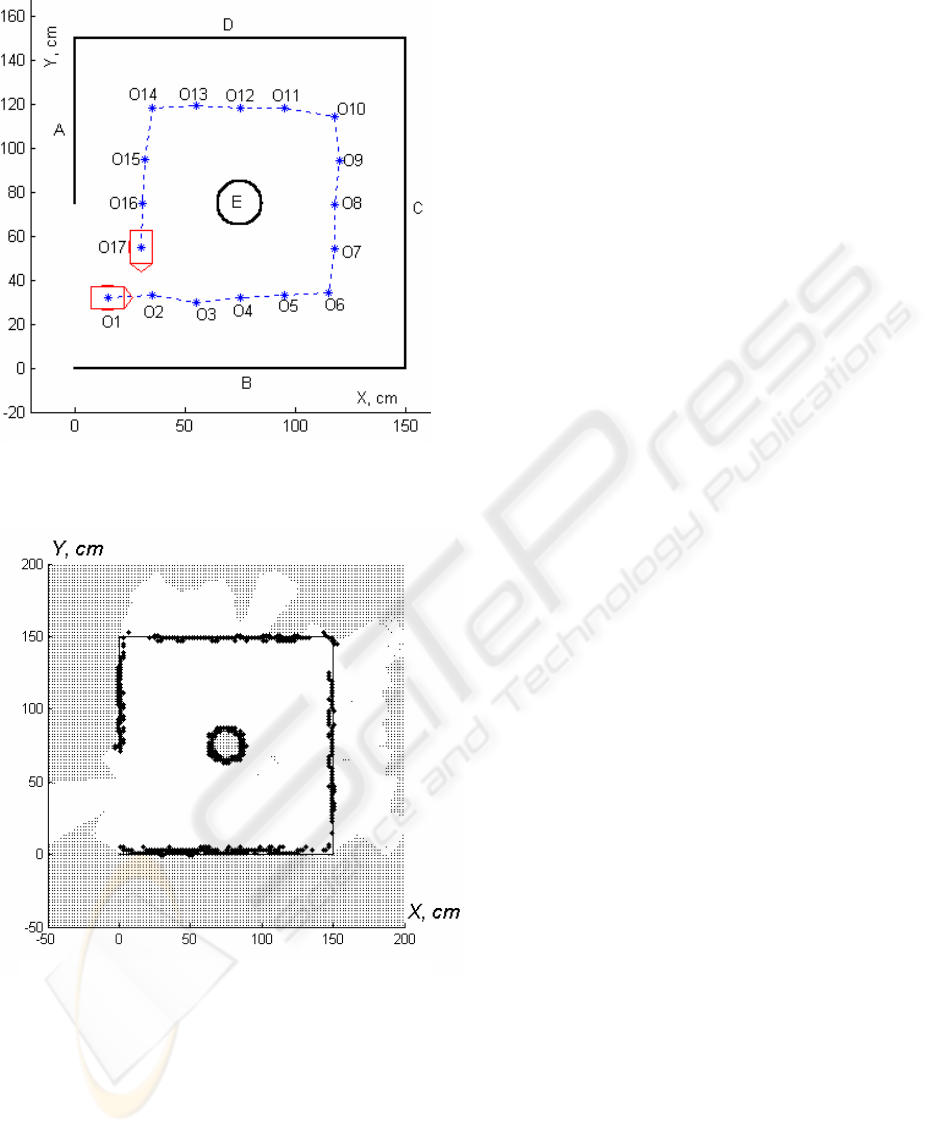

5 IMPLEMENTATION

In (Noykov and Manolov, 2004), we proposed a

modified method for occupancy grid map building

by a mobile robot and a scanning ultrasonic range-

finder. The map building process consists of two

phases: 1) Gleaning of information from

environment, and 2) Sonar data processing. For

sonar data processing the proposed modified method

combines: 1) statistical approach for probability

sonar model building; and 2) application of the

fuzzy logic theory for sonar data fusion. For

experiments, the mobile robot LAMOR-1TV,

equipped with the scanning sonar, is used. The

experimental laboratory environment is presented in

Figure 7. The experimental laboratory environment

is characterized by two book shelves A and B, with

rough surfaces, which may cause a smooth sonar

echo, and two walls C and D, with flat surfaces,

which may induce multiple reflections. The

environment involves also a stationary cylindrical

object E. The executed robot path is depicted by

dotted line. Successive positions, where the robot

stops and collects information from environment by

scanning range finder, are O

1

, O

2

... O17. They are

labelled by stars. The robot is shown in its both start

position O

1

and end position O

17.

Figure 5: Interface module for connection of an

ultrasonic ranging system POLAROID to an external

microprocessor system: timing diagram

The algorithm for gleaning of information from

environment by moving mobile robot and scanning

ultrasonic range finder is as follow:

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

248

N

Y

Y

N

N

Y

N

Read sonar data digit according to value of CODE. Compera read digit

DATA

new

with last read value DATA

old

DATA

new

== DATA

old

?

Clear counter COUNT:

COUNT= 0

DATA

old

= DATA

new

COUNT= COUNT+1

COUNT==100?

In

p

ut

Establish code for LCD reading:

CODE= 0

CODE==0?

Save in memory LCD.

Establish code for 2

nd

digit

reading:

CODE= 1

Save in memory 2

n

d

digit.

Establish code for MCD

reading:

CODE= 2

Save in memory MCD

Out

p

ut

Y

CODE==1?

Figure 6: The algorithm of the software filter.

1) The robot stops in the point О

к

. The sonar rotates

in its end right angular position (-122.4°) and takes a

measurement

. The counter is established i= 1.

k

i

r

2) The counter is incremented, i= i+1. The sonar

rotates one step to the left and takes a

measurement

.

k

i

r

3) Step 2 repeat while sonar reaches its end left

angular position (+122.4°).

4) The sonar rotates in its home position (0º) and the

robot goes to the next path point, O

k+1

.

5) Algorithm 1) - 4) repeated while the robot reaches

the end of the planned path.

A program, written in the EPROM of the on-

board microprocessor control unit, carries out the

immediate servicing and control of the LAMOR-1TV

sensors and motors. This program accomplishes also

the communication with external PC through RS232

interface, where the high-level robot control

program is written in C. The high-level robot control

program enables the user to program the robot’s

path, co-ordinates of the positions, where the robot

must stop and collect information from environment,

scanning angle step of the sonar, etc. Range finder

data are collected in the robot’s frame of reference

by scanning a space around the robot’s instant

position O

i

, passed to the external PC, and stored

there into a text file.

One of the experimentally obtained cell maps of

the environment from Figure 5 is presented in Figure

8. The occupied cells are labelled by thick black

crosses and small points label the indeterminate

cells. It can be seen, that: 1) regardless of the

different roughness of the object surfaces, the

thicknesses of the object contours are approximately

equal; and 2) the wrong measurement results due to

multiple reflections are rejected.

CONTROL SYSTEM INTERFACE OF SCANNING SONAR FOR MOBILE ROBOTS

249

6 CONCLUSION

In this work, hardware and software devices, which

enable a robot’s microprocessor system to read

correctly the information from scanning sonar, based

on a POLAROID ultrasonic ranging system, are

presented. The interface includes a simple, low-cost

and reliable electronic module for coupling of the

ultrasonic ranging system with the robot’s

microprocessor system, and a software filter for

correct reading of the information passing between

them. Due to the software filter, a shielding of robot

and sonar’s electronic modules is not required. In

this way compactness and low price of the device

construction were achieved.

REFERENCES

Borenstein, J., H.R.Everett, L.Feng, 1996. "Where am I?”

Sensors and Methods for Mobile Robot Positioning.

Technical Report. The University of Michigan.

Cao, A., and J. Borenstein, 2002. Experimental

Characterization of Polaroid Ultrasonic Sensors in

Single and Phased Array Configuration. Presented at

the UGV Technology Conf. at the 2002 SPIE

AeroSense Symp., Orlando, FL, April , 1-5.

Figure 7: Gleaning of information from

environment by moving mobile robot and scanning

ultrasonic range finder: experimental laboratory

environment and robot path.

Ciarcia, S., 1980. Home In on the Range! An Ultrasonic

Ranging System. Byte Publications Inc.

Corion, O., A.M.Desodt, D.Jolly, 1996. Using Ultrasonic

Means for the Recognition of a Real Space. Proc. 6th

International Symp. on Int. Measurement

Confederation “Eurotech ‘96”, Brussels, 9-11 May,

pp. 415-420.

Noykov, Sv., O. Manolov, 2004. Environment Map

Building Using Mobile Robot and Ultrasonic Range

Finder. In 5-th IFAC Symposium on Intelligent

Autonomous Vehicles, Lisbon, Portugal, July 5-7, CD-

ROM paper No 388.

Polaroid Corporation, 1991. Ultrasonic Ranging System.

Product Literature, Polaroid Corporation, 784

Memorial Drive, Cambridge, MA 02139, 617-386-

3964.

Polaroid Corporation, Commercial/Battery Division, 1981.

Polaroid Ultrasonic Ranging System. Handbook

Application Notes/Technical Papers.

Figure 8: An experimentally obtained integrate

d

occupancy grid map of the environment, represented i

n

Figure 7. The empty cells are leaved by white; thic

k

black crosses label the occupied cells; and small points

label the indeterminate cells.

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

250