PRIMOS – A NOVEL CONCEPT TO PROGRAM COMPLEX

ASSEMBLY PROCESSES

Markus Ehrmann, Jochen Schlick, Marc Seckner, Detlef Zuehlke

Institute for Production Automation, Kaiserslautern University of Technology,

P.O. Box 3049, 67653 Kaiserslautern, Germany

Keywords: Robot programming, visual programming, micro assembly, interference handling.

Abstract: Over the past years requirements and size of robot programs have continuously increased. Especially

assembly processes increasingly integrate sensors and sensor-based positioning methods to ensure safe

processes. Until now programming is realized in manufacturer-dependent text-oriented or graphic-supported

simulation systems. If such complex processes have to be realized, both methods result in various

disadvantages: Text-oriented programs loose their overview and simulation systems are in need of entire

environment models. Due to these reasons, a new concept has been developed in order to improve and

simplify the programming of complex sensor based assembly processes. The main objectives of the concept

are reducing complexity of robot programs, facilitating clearness for users, supporting diagnostics and

handling of trouble during programming. Therefore the technique of visual programming is used and the

program is described in an abstract manner by linking graphical symbols. They represent movement of

robots and positions of endeffectors. To execute various tasks, so called actions are assigned to the program

flow. Further on a concept for handling occurring troubles is integrated. So called exceptions are user-

defined and consist of various types of troubles. If an exception is triggered, the program flow will be

interrupted and reactions take place. For validation, the concept has been successfully implemented in a

tool, named PRIMOS (P

rogramming Robots with an Interference Handling Motion Orientated System). It

has been positively evaluated by programming a sensor based assembly process of flanges on optical fibres.

1 INTRODUCTION

Industrial robots constitute an important factor in

factory automation (Wörn, 2003). They are used in a

various fields and applications. Up to now most of

them are installed in mass-productions like the

automotive industry (Krause, 1998; Wörn, 1998;

Weck, 2001). In modern automotive plants they are

commonly used for welding and component

handling (Wörn, 1998). While offering high

potential for cost reduction in automated

manufacturing, they are a considerable expense

factor. Capital investment and maintenance costs can

be estimated easily, but the expenses for

programming are difficult to assess (Denkena, 2004;

Zäh, 2004).

Programming includes generating program code,

optimizing program code, teaching point

coordinates, adapting programs and of course

educating robot programmers (Denkena, 2004;

Blume, 1996). Consequently the time needed for

programming is an important cost factor.

Investigations figured out that the ratio of

programming time to production time can rise up to

50% (Zäh, 2004). An important influence to the

programming time needed is the complexity of the

program which is affected by the requirements of the

task and the amount of integrated devices like

sensors or other robots (Rosenbusch, 2003; Weck,

2003).

The complexity of robot programs keeps increasing

during the past years. This is due to rising demands

to geometrical tolerances, reliability, cycle times etc.

To fulfil these demands intelligent devices, sensors

and sensor-based positioning methods are used

(Hirziger, 1999). The complexity of the program

code rises because control-loops, synchronization

with external intelligent devices and device access

functions have to be implemented. In most cases the

code is very problem specific and can’t be reused in

other programs.

The complexity of the process and the program code

lead to a certain susceptibility to troubles. Hence a

concept for interference handling has to be

107

Ehrmann M., Schlick J., Seckner M. and Zuehlke D. (2005).

PRIMOS – A NOVEL CONCEPT TO PROGRAM COMPLEX ASSEMBLY PROCESSES.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 107-112

DOI: 10.5220/0001162801070112

Copyright

c

SciTePress

integrated in the programs to ensure safe processes.

However this increases the complexity of the

program code even more.

In this paper a new concept for programming robots

is presented, which helps to reduce the complexity

of the program code and helps to keep an overview

of the program. The advantages of visual

programming are combined with an intuitive and

easy way to integrate sensors, control-loops and

sensor based positioning methods. A major

component that settles on top of the sensor

integration is an exception handling concept. So,

inevitable trouble during the process can be easily

handled. The concept has been implemented in a

tool named PRIMOS (P

rogramming Robots with an

I

nterference Handling Motion Orientated System).

2 MOTION ORIENTED

PROGRAMMING

To guarantee an easy and intuitive use,

programming is carried out with the technique of

visual programming. This technique is used in a lot

of software applications and offers various

advantages (Möbius, 1996; Schiffer 1998; Schröder

2000; Bischoff 2002; Zühlke, 1997). Visual

programming represents elements in an abstract

manner by graphical symbols. Compared to

graphical programming there is no need for CAD-

models of the environment. The program to be

created is displayed with a focus on the robot’s

motions and the endeffector’s positions. The motion

flow of the robot is described by linking positions

and motions.

To identify the beginning of a program the element

start is used. It can’t be deleted and exists only once

in every program. The element start has to be linked

with a motion. Motions have to be specified by the

programmer by defining parameters like velocity

and acceleration and the type of movement like

point-to-point or linear.

When the endeffector is moved to a certain position,

specific tasks can be fulfilled. These tasks are called

actions. Examples are gripping parts, analyzing

camera data or executing closed-loop fine-

positioning routines. The number of assignable

actions to one motion or one position isn’t limited.

All actions are managed in a kind of library.

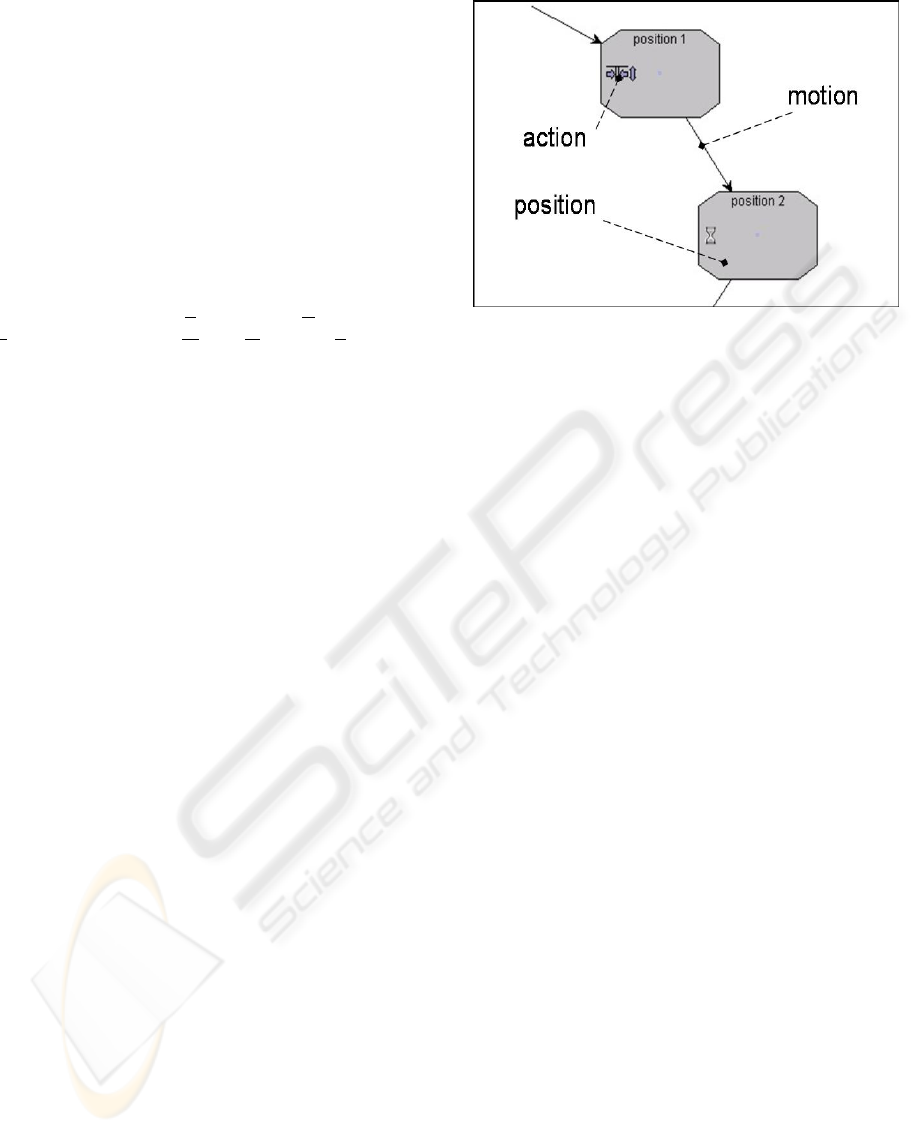

Figure 1

illustrates the coherence of positions, motions and

actions.

Figure 1: motion flow in the visual programming system,

consisting of positions, motions and actions

To realize iterations, so called containers are used. A

container groups several motions and positions

together. It has a well-defined starting and exit point.

A fixed number of iterations can be given by the

user, in order to repeat the program part in the

container a defined number of times. Further on

containers fulfil exception handling. Exceptions are

triggered by specific sensor data. The kind of sensor

data that triggers an exception can be defined by the

user. When an exception occurs, the program flow is

interrupted and continued at a well-defined point in

the program code. Concerning robot programming,

it is very important to consider the next movement

of the endeffector after the program is interrupted. A

safe movement has to be done in order to avoid

collisions.

In the visual programming system exceptions are

bound to a container. Every exception triggered in

the container leads to a new entry point where the

program will continue. The exception which is

triggered by the interference is handled. To assist the

user while moving the endeffector out of the danger

zone when reacting on interferences a specific type

of motion can be set. Every exception has a user-

defined name and is declared inside a container.

Exceptions consist of input signals, internal or

external states and interferences. The content of each

exception is defined by the user and depends on the

integrated sensors. To define exceptions logical

expressions and Boolean operators are used.

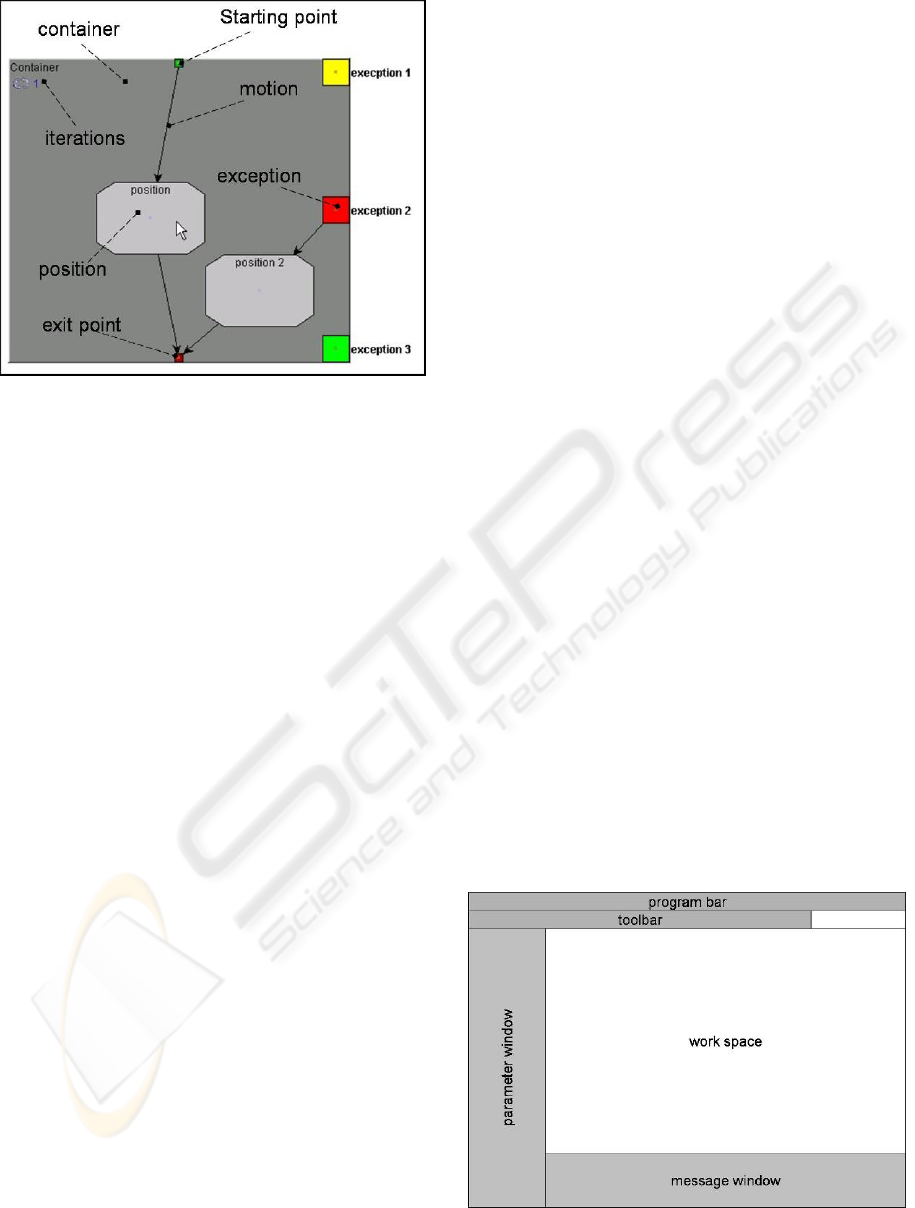

Figure 2 exemplifies the coherence of containers and

exceptions. The defined starting and exit point of the

container can be seen as well. The number of

iterations is located at the upper left corner of the

container.

ICINCO 2005 - ROBOTICS AND AUTOMATION

108

Figure 2: Usage of containers to handle exceptions

A short example points up the meaning: A container

includes two positions which are linked with

motions. To grip a part at the first position the action

grip is assigned to it. At the second position the part

has to be fit in a hole. Thus the action peg in hole is

added to the position. The gripper is equipped with a

force-torque-sensor which detects the interferences

collision during gripping, collision during peg in

hole and collision during motion. Inside the

container two exceptions are declared: assembly

collision and motion collision. One handles the

collision during motion and the other during

gripping and peg in hole. The user combines the two

interferences collision during gripping and collision

during peg in hole with the logical expression or for

the exception assembly collision. If one of these two

interferences occurs the same exception will be

triggered. The reaction is the same in both cases.

Inside a container any exception is allowed. They

are valid for the whole program flow inside the

container. Apart from the definition of exceptions

for the whole container, local exceptions can be

defined. They refer to single positions or motions.

The reaction on the occurrence of exceptions is

defined inside the container as well. Six different

reaction types exist:

– The entire program is aborted.

– The current position including all actions is

repeated.

– The last action is repeated.

– The program flow jumps to the starting point of

the container and starts again.

– The program flow inside the container aborts,

jumps to the exit point of the container and the

next cycle starts.

– The user defines a reaction which includes

positions, motions and actions.

For each reaction type several actions can be added.

To modify the program flow elements can be

shifted, deleted or inserted. The completed program

can be stored in a platform independent format or

translated to a specific robot code. It is possible to

generate several programs for different robots

starting from the same program flow. To run the

program the generated robot code has to be

transferred to robot controller and started.

3 IMPLEMENTATION

To demonstrate the novel concept the tool PRIMOS

is realized. It is developed in the programming

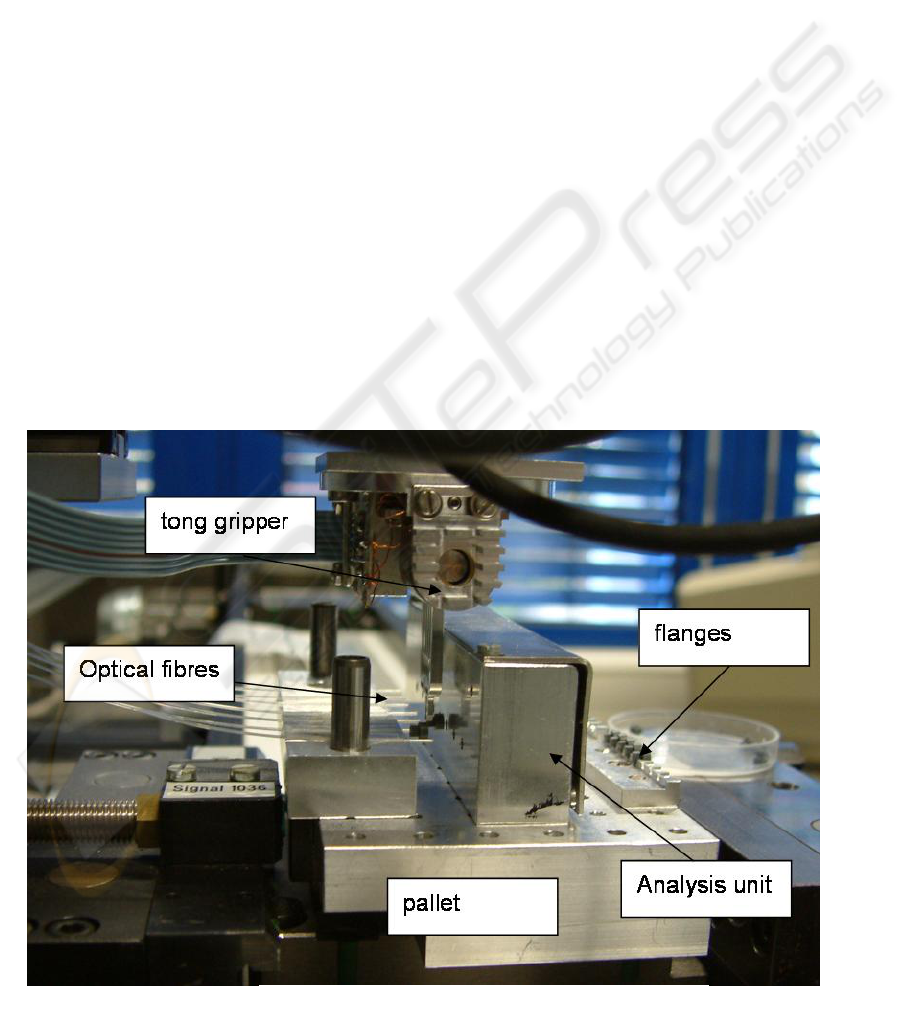

language JAVA. A GUI including the visual

programming surface and the elements of the

concepts is implemented. The GUI is divided into

different areas: program bar, toolbar, work space,

parameter window and message window.

In the program bar all important administration

functions, like save, open or compiling the code to a

specific robot language can be found. The tool bar

includes icons to create the elements container,

position and actions. They can be added to the

program in the work space by drag and drop. Further

on functions to zoom inside the work space are

integrated in the tool bar. The work space includes

the visual programming surface to develop the

programs. Elements of the concept can be shifted,

deleted or inserted. In the parameter window

specific setting can be done. E.g. the reference point

coordinates or the including exceptions and tasks of

a position can be found in the parameter window of

a position. The message window displays errors

during the programming process. E.g. a message

will be shown if a motion is not connected to a

position or a container. In

Figure 3 the screen

segmentation can be seen.

Figure 3: layout of the user interface

PRIMOS – A NOVEL CONCEPT TO PROGRAM COMPLEX ASSEMBLY PROCESSES

109

After completing a program, code for the robot

controller is generated. Before producing

manufacturer-dependent code a syntax and

feasibility check is carried out. Up to now the

compiler for the robot language V

+

from Adept is

realized.

4 VERIFICATION

The prototype of PRIMOS is used to program a

micro assembly process. The goal of the process is

to assemble seven flanges on the end of seven

optical fibre cables which have a diameter of 500

micrometers. One of the main problems is to find

and to position the flange on the maximum of the

coefficient of coupling. For assembling a micro

robot and an intelligent gripper are available. The

intelligent gripper is featured with integrated sensors

to measure gripping width and gripping force. Based

on the sensor data a classification into grip situations

and appropriate interferences is provided. The

programming language of the micro robot controller

is V

+

.

The assembly process can be divided into four steps.

First a flange which is positioned on a magazine has

to be gripped. Then it is positioned between the end

of an optical fibre cable and an analysis unit which

measures the intensity of the passing light.

The goal is to figure out the point coordinates with

the maximum intensity. While the flange is moved

in a definite manner the intensity is continuously

measured. To finish the assembly process the

gripped flange is mounted on an optical fibre cable.

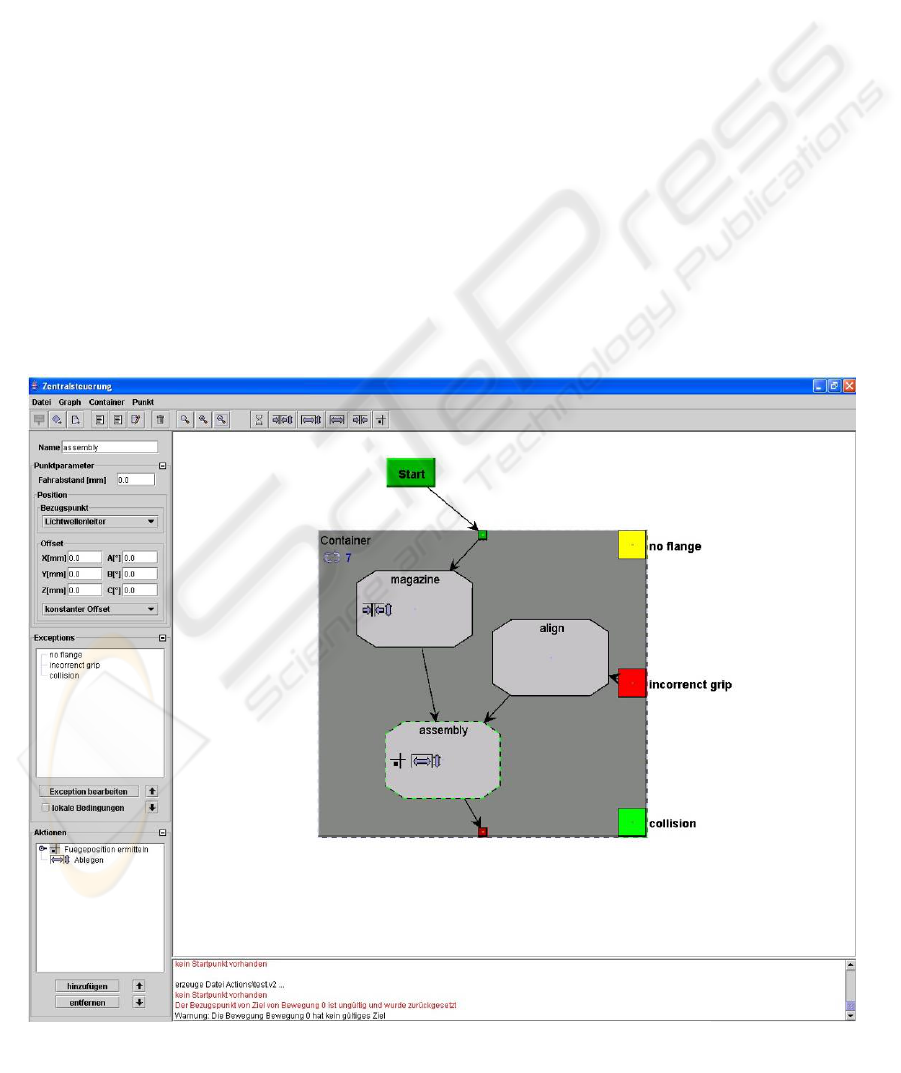

Figure 4 shows the setup of the assembly cell. On

the left side the optical fibres can be seen which are

fixed on a panel. On the right side the magazine with

the unused flanges can be found. In front of the

optical fibres the analysis unit is installed. At the top

of the picture the tong gripper can be seen. The

magazine, the analysis unit and the flanges are

mounted on a pallet which can be seen at the bottom

of the picture.

The assembly process can be interfered in several

ways. The used sensors detect the following ones.

On each detected interference type a specific

reaction takes place.

– If no flange is gripped, the assembly cycle will

be skipped and the next flange will be gripped.

– If a flange gets lost during the assembly process,

the assembly cycle will be skipped and the next

flange will be taken.

– If the flange is gripped incorrectly or

eccentrically, the flange will be aligned on a

specific surface and the assembly cycle is

continued.

– The assembly process will be aborted if a

collision is detected.

Figure 4: assembling flanges on optical fibres

ICINCO 2005 - ROBOTICS AND AUTOMATION

110

To program the process with PRIMOS a container is

inserted and connected with a motion to the program

start. The container includes two positions and three

motions. The first position is named magazine. It is

parameterized by the point coordinates of the flange

on the magazine. The action grip is added. The

second position is named assembly. It contains the

point coordinates between the cable and the

analyzing unit. The actions maximum finding and

mounting and ungrip are added.

The first motion connects the starting point of the

container and the first position magazine. The

second motion links the two positions magazine and

assembly. The third motion connects the position

assembly with the exit point of the container.

The container includes three exceptions. The first

exception, named no flange threads the situation if

no flange is gripped or a gripped flange gets lost.

The second exception, named incorrect grip handles

incorrectly gripped flanges. The third exception,

named collision covers every kind of collision.

The reaction on no flange is to abort the cycle inside

the container and to start with the next one. On the

occurrence of the exception incorrect grip a user

defined reaction is triggered. The incorrectly gripped

flange is adjusted. Therefore a position align is

inserted in the container. The position contains the

point coordinates of the specific surface where the

flange is aligned. The position align is connected

with motions to the exception and leads to the

position assembly. The reaction on the third

exception collision is the abortion of the entire

program.

The complete GUI of PRIMOS and the program

flow of the whole assembly process in the work

space can be seen in

Figure 5 .

5 CONCLUSION

A novel concept to program sensor based assembly

processes has been presented. The motion flow of

the robot has to be defined by the user, by specifying

the sequence of positions of the endeffector and the

moves of the robot. Hence, it is orientated at the

mental model of the user.

To reduce complexity as well as abstraction and to

improve clarity the programming takes place in a

visual programming environment. The visual

programming provides various advantages compared

to text-orientated programming systems and to

graphic-supported systems. Compared to graphic-

supported simulation systems is no need for a

Figure 5: programming the assembly process with PRIMOS

PRIMOS – A NOVEL CONCEPT TO PROGRAM COMPLEX ASSEMBLY PROCESSES

111

precise and complex environment model. In relation

to text-oriented programming systems an improved

clarity can be achieved.

Furthermore complexity is reduced by using only

five different types of elements to generate the

program: positions, motions, actions, containers and

exceptions.

In particular action elements capsulate and hide

complexity. Additionally action elements deliver the

task orientated character of the concept, because

huge program structures are reduced to self-

configuring modules. An example can be found in

the programming of the presented assembly process.

The action maximum finding and mounting is

available as a module.

The handling of trouble is enabled by the use of

exceptions. They are user defined and any kind of

reaction can be determined. Any detectable

interference by the sensors can be used.

The concept has been successfully implemented in

the tool PRIMOS. Its operability has been tested by

programming an exemplary sensor based assembly

process. Diagnostics and the handling on occurring

interferences have been tested with positive results.

In ongoing researches there are still some aspects to

consider. Up to now merely the manufacture specific

language V

+

is supported. To demonstrate the

platform independent character, additional back ends

are necessary. As yet just a few actions elements are

realized in the prototype. To improve the work

capability further actions like camera analysis have

to be realized.

The prototype does not support the teaching of point

coordinates after generating the code so far. It is

necessary to expand the tool within the next steps by

this requirement.

The new programming concept and the

corresponding programming tool PRIMOS

significantly reduce the complexity of program code

for sensor based assembly processes. The tool offers

a way to implement complex processes focusing

process safety instead of handling the complexity of

the program code.

REFERENCES

Bischoff, R.; Kazi, A.; Seyfarth, M., 2002. The MORPHA

Style Guide for Icon-Based Programming. In Proc. of

the 11th IEEE Int. Workshop on Robot and Human

interactive Communication, ROMAN2002, Berlin,

Germany, September 25-27, pp. 482-487.

Blume, C., Früauf, P., 1996. Standardization of

Programming Methods and Languages for

Manipulation Industrial Robots. In: Proceedings of the

27

th

International Symposium on Industrial Robots, 6.-

8.October 1996, Milan, Italy, page 677-682.

Denkena, B., Wörn, H., Apitz, R., Kowalski, P., Mages,

D., 2004. Vereinfachte Programmierung von

Industrierobotern. In: wt Werkstattstechnik online, page

442-446.

Hirziger, G., 1999. Es gibt noch viel zu tun – Gedanken

zur Entwicklung der Robotik. In: Schweizer

Maschinenmarkt Nr. 26, pp. 94-88.

Krause, F.-L., Uhlmann, E., 1998. Stand und

Entwicklungstendenzen in der Robotertechnik.

München. Carl Hanser Verlag.

Möbius, F., 1996. Visuelle Programmierung von

Industrierobotern: Ein Beitrag zur bedienergerechten

Gestaltung von Programmiersystemen. Düsseldorf,

VDI Verlag.

Rosenbusch, T., 2003: Forschung für die Robotik von

morgen. In: wt Werkstattstechnik online, pp. 638-643.

Schiffer, S., 1998. Visuelle Programmierung –

Grundlagen und Einsatzmöglichkeiten. Bonn. Addison-

Wesley-Longman.

Schröder, C., 2000. Integration von Sensorik in die

visuelle Roboterprogrammierung. Disseration.

Universität Kaiserslautern – Fachbereich

Maschinenbau,

Weck, M., Gottschald, J., 2001: Place & Play-Roboter. In:

wt Werstattstechnik online.

Weck, M., Almeida, C., 2003. Unscharfe Roboter-

Programmierung. In: wt Wertstattstechnik online, pp.

627-631.

Wörn, H., Wurll, C., Henrich, D., 1998. Automatic off-

line programming and motion planning for industrial

robots. In: Proceedings of the 29

th

International

Symposium on Robotics, 27.-30. April 1998,

Birmingham, Great Britain.

Wörn, H., 2003. Tendenzen in der Fabrikautomation. In:

VDI Berichte Nr. 1756.

Zäh, M.F., Vogl, W., Munzert, U., 2004. Beschleunigte

Programmierung von Industrieroboter. In: wt

Werkstattstechnik online , page 438-441.

Zühlke, D., Möbius, F., Schröder, C., 1997: Symbols

facilitate programming of industrial robots. In:

Proceedings of the 1997 IEEE International

Conference on Robotics and Automation, Albuquerque,

New Mexico, pp. 3037-3042.

ICINCO 2005 - ROBOTICS AND AUTOMATION

112