Manufacturing Process of Transverse Slider on Civil Building 3D

Printing Machine

Novi Saksono, Heri Setiawan and Arya Mustova

Polytechnic for Manufacturing Bandung, Indonesia

Keywords: Slider, Manufacturing Process, 3D Printing.

Abstract: The transverse slider is one of the components in the 3D machine civil building printing which serves to help

bring the nozzle to the coordinates according to the desired building design in order to produce the shape

according to the design. 3D machine printing Civil buildings require a device designed to be a carrier for other

components. Transverse slider will carry the nozzle with the help of the motor movement, then with the help

of the control the slider will move according to its coordinates so as to help bring the nozzle to the coordinates

of the building design. The construction of the transverse slider on the Civil Building 3d printing machine is

carried out by machining and fabricating the parts such as lathe, milling, grinding, and welding. After the

Slider is completed and realized at the Bandung Manufacturing Polytechnic Department of Manufacturing

Engineering, it is hoped that the Slider can be used for the manufacture of civil buildings and function properly

and be useful for the Polman academy, and the State of Indonesia.

1 INTRODUCTION

Along with the times, the manufacturing industry is

always developing continuously so that advances in

manufacturing technology can simplify and speed up

the production process, as well as its relation to civil

technology that applies the Additive Manufacturing

method by means of 3D Print for building

construction. Additive Manufacturing is a

manufacturing process by adding material in layers so

that it can form something called finished product,

this building construction can be operated by 3D Print

which processing time is relatively faster compared to

manufacture by human labor.

3D Print building or 3D building concrete casting

machine (3D Concrete Building Printing) has a

working principle similar to 3D Print in general,

namely the FDM type, where the building to be

printed can be formed by adding concrete material

and removing it layer by layer through a nozzle whose

movement is operated by the program. 3D Print this

building requires nozzle for Secrete ingredient

geopolymer which becomes ingredient building, so it

is necessary sliders for bring nozzle to the desired

coordinates so that the designed building could

formed.

The working principle of the 3d printing

transverse slider for civil buildings is that the servo

motor will rotate according to the direction of the

computer. The servo motor will turn the gears on the

rack gear to move Slider according to coordinates.

The slider will bring the nozzle to form the desired

civil building design.

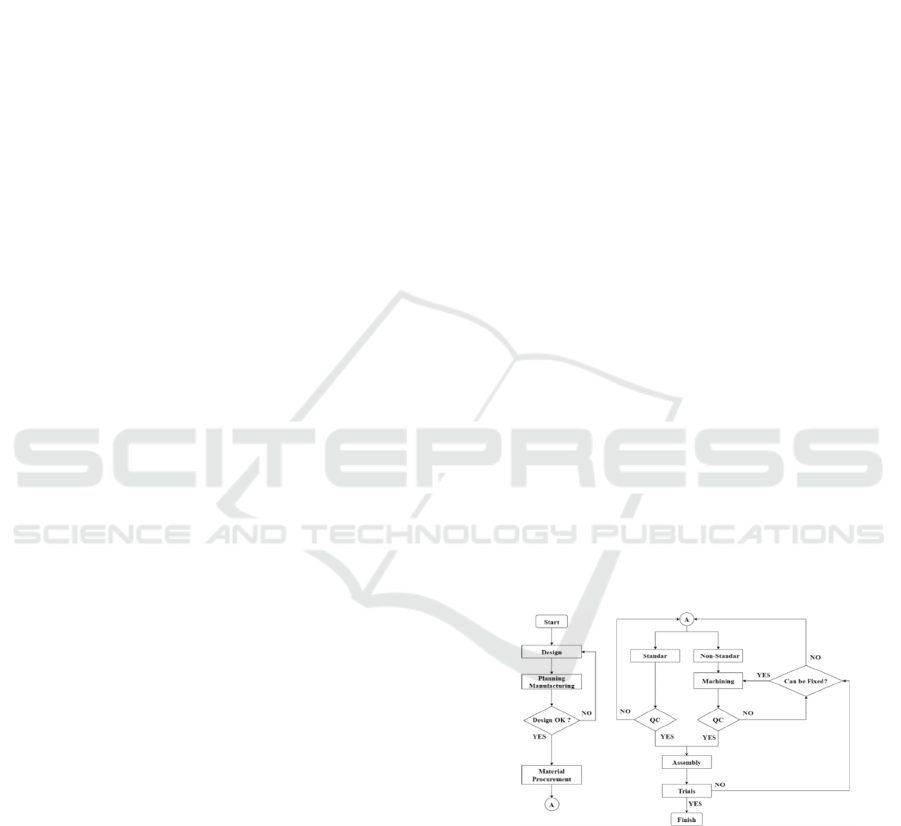

Figure 1: Flowchart manufacturing transverse sliders.

2 SOLUTION METHODS

In this solution method, it begins by making design

based on found references. After To do planning start

the planning process making about how sliders this

will made. After planning done so start at stage

material procurement, material procurement is

806

Saksono, N., Setiawan, H. and Mustova, A.

Manufacturing Process of Transverse Slider on Civil Building 3D Printing Machine.

DOI: 10.5220/0011890000003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 806-812

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

divided into 2, namely standard materials and non-

standard materials. On standard materials done QC

for knowing can the material used for construction

sliders machine 3d printing Building Civil. On non-

standard materials apply machining process for make

the desired part, after that then the part already

through the machining process enter Step QC for be

measured can parts used in construction sliders.

After all parts collected so start assembly process

is carried out or assembly for shape construction

sliders transverse. After the construction is done

assembled, a trial is carried out on the slider

construction to find out whether the slider can

function properly or not.

Slider already experience trial stage and test

results obtained that sliders could used for

construction machine 3d printing building Civil , then

the manufacturing process sliders transverse done.

2.1 Design

Slider transverse is the slider that brings the nozzle to

the required coordinates, the placement of the

transverse slider on the construction of a 3d printing

machine for civil buildings as in the following

picture:

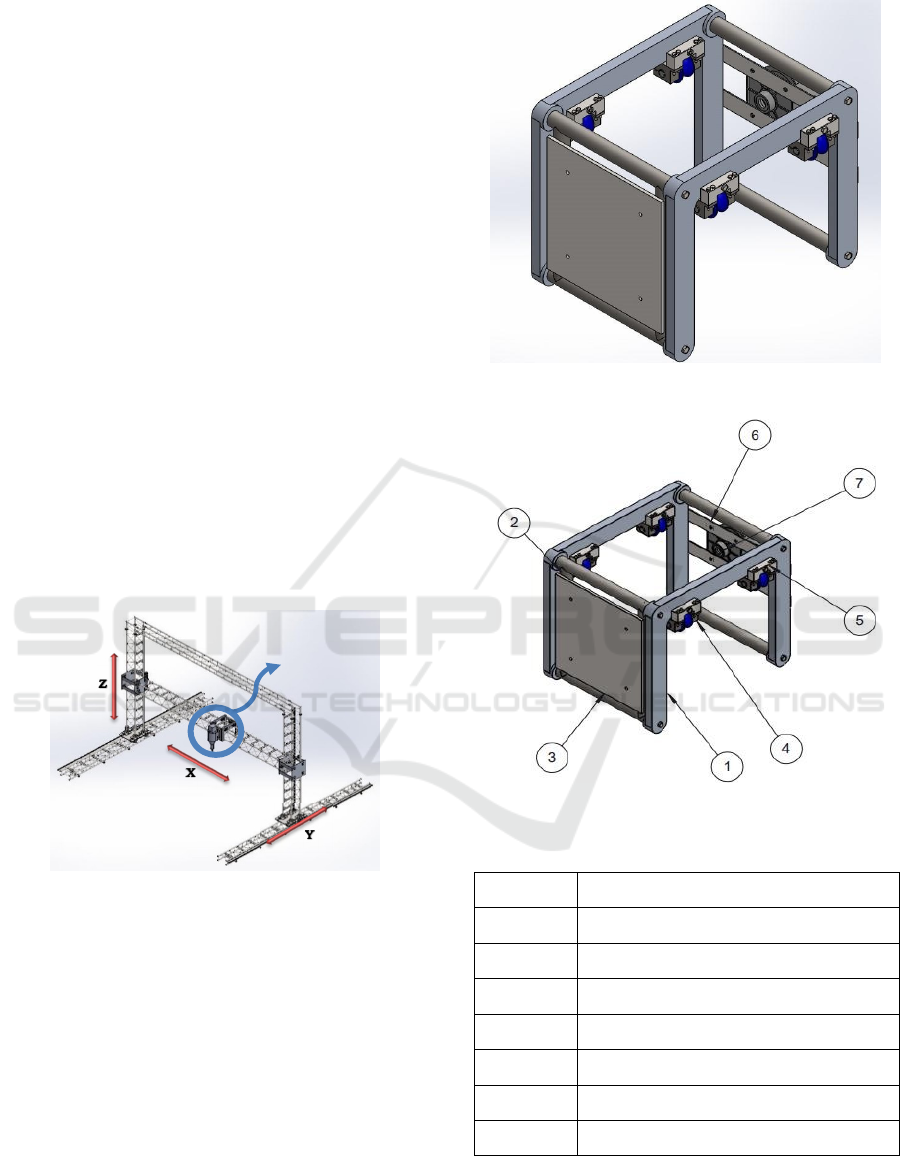

Figure 2: Construction machine 3d printing.

slider is on the x-axis carrying the nozzle to direct the

nozzle to print the geopolymer according to the

desired design.

The design for the transverse slider is made as

follows:

Figure 3: Design slider.

Figure 4: Parts slider.

Table 1: Part names Slider.

No Part Component Name

1 Slider Frame

2 Bracket Mount Pipe

3 Bracket Plate Nozzle

4 Wheel Assy

5 Wheel Spacers

6 Servo Motor Bracket

7 Gearbox Nema

Manufacturing Process of Transverse Slider on Civil Building 3D Printing Machine

807

design frame Sliders:

Figure 5: Parts frame sliders.

Table 2: Part names frane sliders.

No Part Name

1 U- frames

2 Connecting Pipe

3 Shaft cover

design assy Wheels:

Figure 6: Parts wheel assy.

Table 3: Part names wheel.

No Part Component Name

1 U Groove Wheel

2 Wheel axle

3 Spacers

4 Bearing SKF 6004

5 Shaft Support

2.2 Material

2.2.1 Standart Material

Table 4: Standard components.

No

Part

Name

Specification

Picture

1

Bearing SKF 6004

2

Shaft

Support

SHTCMN

20

3 Bolt

7000454

7040172

7040140

7000182

DIN933

2.2.2 Non-Standard Material

Table 5: Components non-standard.

No

Part

Name

Specification Picture

1

Frames

Slider

Junk

aluminum

2

Retainin g

Pipe

S45C

3

Shaft

Cover

ST37

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

808

Table 5: Components non-standard. (cont.)

4

Mount

bracket

pipe

S45C

5

Bracket

Plate

nozzle

ST37

6

Servo

Motor

bracket

ST37

7

Wheel

PTFE

8

Shaft

ST37

9

Spacers

ST37

10

Top

wheel

spacer

ST37

2.3 Calculation

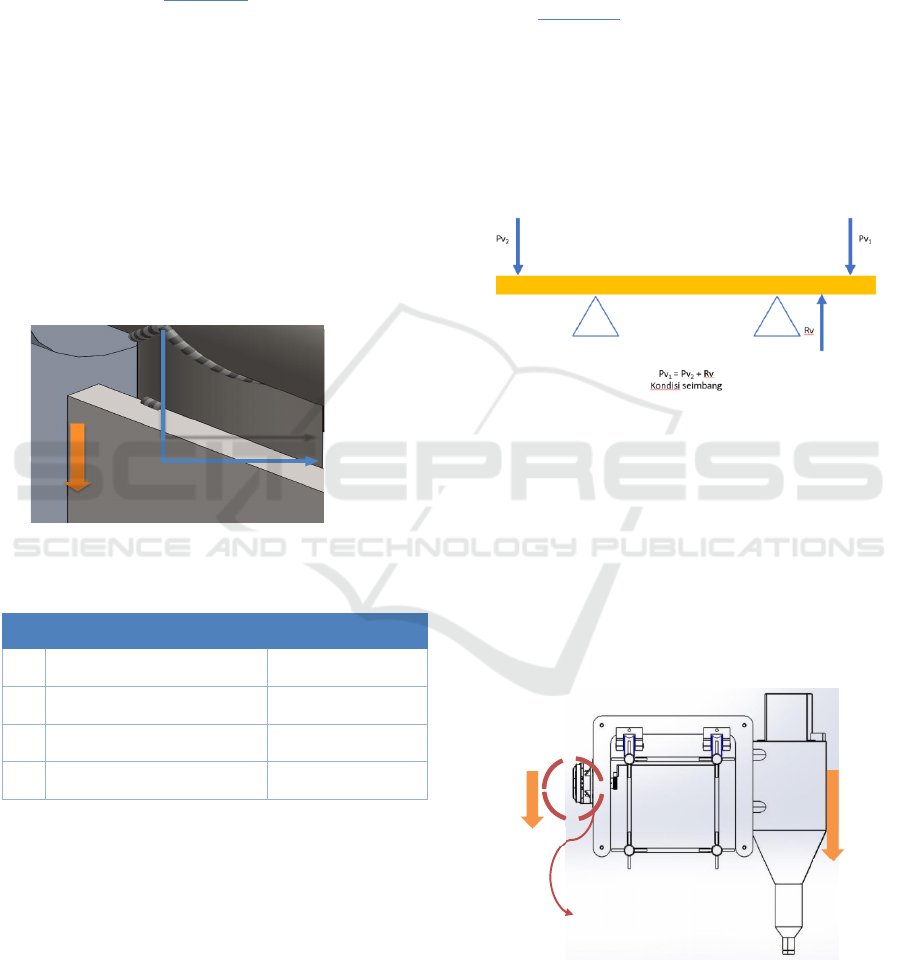

Figure 7: Load from nozzle.F.

Figure 8: Forces acting on bolts.

Known:

Table 6: Nozzle Technical Information.

No Technical Information Score

1 Nozzle Mass 107.82 Kg

2 Yield strength ST 37 250 MPa

3 Sectional area M10 bolt 52.30mm2

σ

pm

= R e / S f

τ

pm

= 0.7 x σpm

(1)

= 250 / 2

= 125 N/mm

2

= 0.7 x 125 N/mm

2

= 87.5 N/mm

2

Description

σ

pm

=

Voltage pull

/normal clearance (N/mm

2

)

Re = Resistant

extension (N/mm

2

)

τ

pm

= Permissible shear

stress (N/mm

2

)

Sf = Safety factor

Manufacturing Process of Transverse Slider on Civil Building 3D Printing Machine

809

⁂Safety Factor for static loading = 1.2 – 2

• Maximum load of M10 baut bolt

τ = F / A (2)

F= τ x A

= 87.5 x 52.30

= 4576.25

N

(3)

The force from the nozzle is 1078 N, it can be said

that 1 M10 bolts are able to withstand the nozzle load

However, with all considerations, 4 M10 bolts are

used.

Description

τ = sheer stress (N/mm2)

A = Cross-sectional area (mm2)

• Determining the shear stress received by the

bolt.

F = 1078 N

Loading divided by 4 bolts

F = 1078 N/4 = 269.5 N

= F / A

= 269.5 N / 52.30 mm

2

= 5.15 N/mm

2

(4)

W

elde

d

p

ar

t

Figure 9: Force on welding.

Table 7: Welding technical information.

No Technical Information Score

1 Permit voltage σ 125 N/mm

2

2

Coefficient γ

2

0.5

3

Welded length (l

1

)

160.45 mm

4 Hem welding

3 mm

• Welding clearance voltage.

σpm = Re/Sf

= 250 / 2

=125 N/mm

2

σ

w

pm = γ

2

x σpm

= 0.5 x 125

= 62.5 N/mm

2

(5)

Description

σ

pm

= Tensile

stress/normal allowable

(N/mm

2

)

Re = Resistant

extension (N/mm

2

)

σ

w

pm = Allowable

weldin

g

stress (N/mm

2

)

sf = Safety factor

⁂Coefficient γ2 for weld seams that have not been

tested = 0.5

• Welding area

L = l

1

– 2A

=160.45 – 2 (3)

= 160.45 – 6

= 154.45 mm

Aw = L x A

= 154.45 x 3

= 463.35 mm

2

m

(6)

• The stress that occurs in the weld seam

σ = F / Aw

= 539 N/463.35 mm

2

= 1.16 N/mm

2

≤ σ

w

izin

≤ 62.5 N/mm

2

≤ 62.5 N/mm

2

(7)

⁂The force given by the nozzle is 1078 N, welding

is carried out on 2 pipes as a support, then the load is

divided on both pipes into F = 1078 / 2 = 539 N

Figure 10: Balance.

Note;

Pv

1

= Load from nozzle

Pv

2

= Load of motor

Rv = Resistance vertical from the strength of

resistance M6 bolt shear stress in the rack along

the pillar

Pv

1

= Pv

2

+ Rv (8)

1078N = 23N + Rv

Rv = 1055N

Figure 11: Balance on the slider.

mo

1Rac

k

is hel

d

using 6 M6 Bolts,

on the X-axis

ill 6

m

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

810

τ = F / A F = τ x A

(9)

= 87.5N/mm

2

x 17.89mm

2

= 1565.37 N

≥ 1055

N

≥ 1055 N

≥ 1055 N

≥ 1055

N

(10)

The force from the nozzle is 1078 N, it can be said

that 1 M6 bolt is able to withstand the nozzle

load.While the pillars are installed 24 M6 bolts.

2.4 Machining Process

Information :

F = Foundry CML = CNC Milling

HG = Hand Grinder BW = Bench Work

BS = Bend Saw ML = Milling

BO = Bor GC = Grinding Cut

L = Lathe QC = Quality control

Table 8: Stages of the construction process Slider.

No.

Part Name

Qty

( p c s )

Stages of the Working

Process

1 2 3 4 5

SM-01-

01

U-frames

2

F

CML QC

SM-01-

02

Connecting Pipe

4 GP HG QC

SM-01-

03

Shaft Cover

8 BS L QC

SM-02

Bracket Mount

Pipe

2 GC HG QC

SM-03

Bracket Plate

N

ozzle

1 HG BO QC

SM-04-

01

U Groove Wheel

4 BS BW L QC

SM-04-

02

Shaft

4 L QC

SM-04-

03

Spacers

4 GC BW L BO QC

SM-05

Spacers top

wheel

8 ML BO QC

SM-06

Servo Motor

Bracket

2 HG BO QC

Information :

EW = Electric Welding Th = Adjustment/Thread HG

= Hand Grinder QC = Quality control

Table 9: Stages of the process of working on sub- assembly

parts.

No.

Part Name

Qty

( pcs )

Stages of the

Working Process

1 2 3 4

SM-01-00 Slider Frame 1 EW HG Th QC

SM-04-00 Assy Wheel 1 Th QC

2.5 Assembly

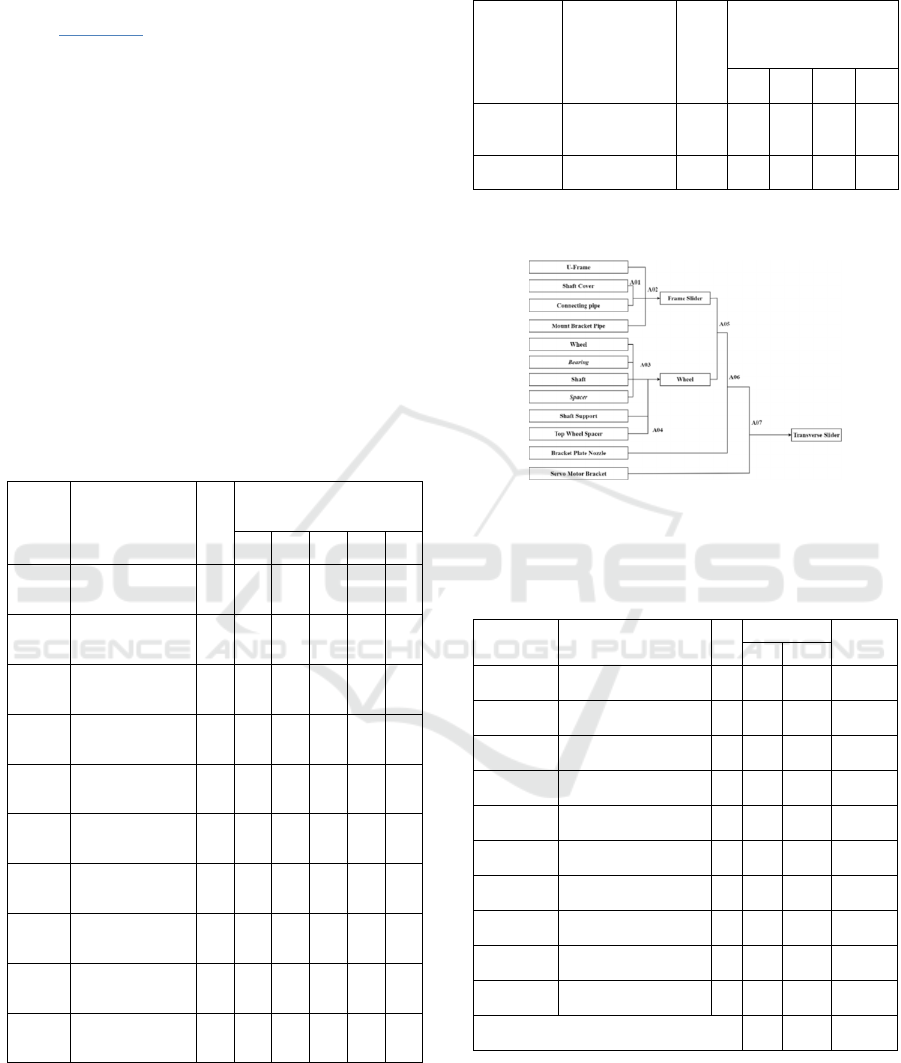

Figure 12: Assembly Diagram.

2.6 Estimated Time

Table 10: Estimated Time.

No.Part Part Name Qty

Estimate

Total

(Minute)

TNC TC

SM-01-01 Frame 2 85 90 175

SM-01-02 Connecting pipe 4 17 0,94 17,94

SM-01-03 Shaft cover 8 57 49,6 106,6

SM-02-00 Bracket Mount Pipe 2 11 7,72 18,72

SM-03-00 Bracket Plate Nozzle 1 20 80,3 100,3

SM-04-01 Wheel 4 25 100 125

SM-04-02 Shaft 4 35 55,4 90,4

SM-04-03 Spacer 4 16 9,4 26,4

SM-05-00 Top Wheel Spacer 8 41 95 136

SM-06-00 Servo Motor Bracket 2 19 95,3 114,3

Total : 326 583,66 910,66

Adding with 33.95 welding time, the estimated

machining process = 944.61 Minutes

Manufacturing Process of Transverse Slider on Civil Building 3D Printing Machine

811

2.7 Estimate Cost

Table 11: Estimation Cost.

No. Detail cost Total cost

1 Machining Process Rp 458.100

2 Operator (man power) Rp 227.415

3 Standart Part Rp 4.114.876

4 Non standart part Rp 2.244.590

5 Overhead cost Rp 1.426.996

Total Cost : Rp 8.561.977

3 CLOSING

1. The construction have dimensions 540 x

568.30 x 720.50 mm with weight 56 Kg, using

4 wheels, 2 pieces frame, 4 connecting pipes,

motor bracket on the side right and nozzle

bracket on the side left . Materials used in the

form of aluminum, carbon steel and PTFE.

2. In machining process moment making

Transverse slider through various machining

and fabrication processes like milling, lathe,

grinding, and welding.

3. Estimate time needed to make Transverse

slider on machine 3d printing of buildings

civil is 15.74 Hours

4. Estimate cost required for make Transverse

slider on machine 3d printing of buildings

civil is Rp8.561,977

REFERENCES

Goeritno Wahjoe; Wikanda Uli; and S.Ecep. 2000. Standar

polman Seri 0 Bandung; Bandung Polytechnic of

Manufacturing.

Elemen Mesin 3 Perhitungan Elemen Mesin; Bandung

Polytechnic of Manufacturing.

Pendidikan Dosen, 2. 2022. Transmission is. July 19, 2022

accessed from Transmission are – Functions, Types,

Components & Working Methods (dosen

Pendidikan.co.id)

Waloeyo, Gamawan A. 2021. Biaya Dasar PPC. Bandung;

Bandung Polytechnic of Manufacturing.

Susanti O. 2021. DESIGN AND CONSTRUCTION

OF TAILSTOCK ON MINI 2 AXIS CNC

LATHE MACHINE AT MANUFACTURING

POLYTECHNIC, BANDUNG. (BANDUNG

MANUFACTURING POLYTECHNIC)

Gallavotti, Giovanni. The elements of mechanics. Springer

Science & Business Media, 2013. Mechanics and

Elements PDF Engine (Free 220 Pages)

(pdfdrive.com); July 15, 2022; accessed from

pdfdrive.com

Hashim, Jasmi. The production of metal matrix composites

using the stir casting technique. Diss. Dublin City

University, 1999. Casting Technique Metal &

Treatment Hot PDF (196 Pages) (pdfdrive.com); July

16, 2022; accessed from pdfdrive.com.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

812