Formulation and Characterization of Cosmetic Serum Containing

Argan Oil as Moisturizing Agent

Budiasih S.

1

*, Masyitah I.

1

, Jiyauddin K.

1,2

, Kaleemullah M.

1

, Samer A. D.

1

,

Mohd Fadli A.

1,2

and Eddy Y.

1,2

1

School of Pharmacy, Management & Science University, Selangor Darul Ehsan, Malaysia

2

International Center for Halal Studies, Management & Science University, Selangor Darul Ehsan, Malaysia

Keywords: Cosmetic Serum, Argan oil, moisturizer, stability

Abstract: Nowadays, cosmetics are becoming more high demand in daily life and it was used frequently by many of

people per year. Moisturizing serum is a bland of oleaginous substances that are applied to the skin by

rubbing which used to replace natural skin oil, to cover tiny fissures in the skin and to provide a soothing

protective film. Argan oil is a plant oil that produced from Argan tree (Argania spinose) which become one

of the main roles in the dermocosmetic field due to higher in moisturizer contents. The main objective of the

research is to evaluate the characteristics of cosmetic serum and to identify the best formulation of cosmetic

serum containing Argan oil as moisturizing agent. Five formulations of cosmetic serum (F1, F2, F3, F4 and

F5) with different concentration of Argan oil have been developed. They were evaluated for its physical

appearance, pH, rheology, spreadability, skin moisturizing, stability test and analysed by using ANOVA

single factor. The product was milky white, rose cheek smell, non-greasy, non-oily and homogen. The result

showed that pH of five formulations have shown significant different (p<0.05) and was fall into acceptable

range (pH 5-6). Stability study at low and room temperature shown all formulation were stable except for

high temperature (at 40°C) only F2 after week 1. Statistical result indicated that there was significant

different between all formulations in moisturizing effect (p<0.05) and F3 gave higher percentage of

moisture rising. Rheological analysis shows all five formulations were pass over 30% of torque point.

Formulation 2, 3 and 4 gave more than 50% of spreadability percentage compared with formulation 1 and 5.

In this study, it can be concluded that the F2 of formulated cosmetic serum are stable and could delivered

high moisturizer effect on the skin.

1 INTRODUCTION

The cost increase in worldwide living standard has

created a rise in demand for cosmetic products. The

cosmetic industry established in Malaysia is one of

the important economic sources. The importance of

cosmetics has increased as many people want to

stay young and attractive.

Cosmeceutical refers to the combination of the

cosmetics industry with the pharmaceutical

industry. Cosmetics companies produce cosmetics

and pharmaceutical ones produce medicines.

Cosmeceuticals are skincare products that combine

cosmetics and medicines. What this means to the

consumer is that they actually work (DeHaven,

2007). “Cosmetic Product” by definition from

Guideline on The Control of Cosmetic Products,

Health Science Authority, Revised in 2014, is any

product that is intended to be placed in contact with

the various external parts of the body, such

epidermis, hair system, nails, lips, eyes, teeth and

the mucous membranes of the oral cavity and

external genital organs with purposes mainly to

cleaning, perfuming, changing their appearance,

correcting body odours, protecting or keeping them

in good condition (Authority, 2011).

The available cosmetic products are classified

mainly in five classes which are skin care products,

hair care products, colour cosmetic products,

personal care products, and fragrances (T. Mitsui,

1993). The skin care and maintenance are included

moisturizers, massage oils, creams, fairness creams,

petroleum gels, sunscreens, anti-itching creams, and

antiseptic ointments.

Budiasih, S., Masyitah, I., Jiyauddin, K., Kaleemullah, M., Samer, A., Fadli, A. and Yusuf, E.

Formulation and Characterization of Cosmetic Serum Containing Argan Oil as Moisturizing Agent.

DOI: 10.5220/0009846300002406

In Proceedings of BROMO Conference (BROMO 2018) - Symposium on Natural Product and Biodiversity, page 1

ISBN: 978-989-758-347-6

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1

Serum is one of the cosmetic products with very

high concentration of active ingredient in their

formula for providing intensive nutrition to the

deeper skin layer and non-greasy finish product

which suitable for skin.

Cosmetic serum was classified based on its rate

of absorption and the ability to penetrate into the

deeper layers of the skin. This research was planned

to develop an ideal cosmetic serum containing

Argan oil as a moisturizing agent to the skin. Serum

are differ from others moisturizers in that serum do

not “make room” for emollients or thickener.

Likewise, serum will not contain sunscreen active

like daytime moisturizer would but serum preserve

the extra space for other beneficial ingredients or

even more antioxidants than any others product.

2 METHODOLOGY

2.1 Materials

Argan oil, Squalane light (Chem Soln), Triglyceride

(Sigma), Glycerin USP (Chem Soln), Hyaluronic

acid HMW, Sodium EDTA, PEG-100, PEG-12

Dimethicon, Sodium acrylate, Phenoxyethanol-SA,

distilled water.

2.2 Apparatus and Equipments

Rheometer (Brookfield® R/S CP), pH meter

(Hanna®), Moisture Checker (Scalar®),

homogenizer (Ultra Turrax), beaker, glass rod, filter

paper (Whatman), syringe with needle, aluminium

foil, dropper.

Table 1: Formula of cosmetic serum

Materials

Quantity (%)

F1

F2

F3

F4

F5

PHASE A

Water

73.8

EDTA

0.2

Hyluronic acid

HMW

2

PHASE B

PEG-12

4

Squalene light

6

5

4

3

2

Argan oil

1

2

3

4

5

Triglyceride

3

PHASE C

Glycerin USP

5

PEG-12

Dimethicon

3

Sodium acrylate

1

Phenoxyethanol-

SA

1

2.3 Preparation of Cosmetic Serum

All the ingredients were weighed according to the

different percentage listed (Table 1). The net weight

of all formulated serum was 100g. Add water and

EDTA into a disinfected glass beaker and stir, until

EDTA has dissolved. Add hyaluronic acid and mix

thoroughly with a stick blender or homogenizer

until phase A is free of lumps. Add phase B to

phase A, stir well after each ingredient has been

added. Mix with stick blender. Add phase C to

phase A/B, again, stirring well after each ingredient.

Especially after sodium acrylate uses the stick

blender. Serum should be free of any lumps.

Viscosity can be adjusted by adding, 2.5% of the

sodium acrylate, if needed.

2.4 Organoleptic, Physicochemical and

Stability Testing of Cosmetic

Serum

The properties and stability testing of cosmetic

serum were carried out for the five different

formulations of cosmetic serum. The observation

were recorded on day one of preparation, week one,

week two, week three, week four and two month

after preparation for determination of organoleptic

properties, pH, homogeneity, rheological, skin

moisture and stability study.

2.4.1 Physical Appearance

Observe the color of the serum formulation sample

which should be in white milky and glossy

appearance. Next, feel some serum formulation

sample on the skin to access the texture which

should smooth homogeneous texture and non-

greasy finish.

2.4.2 pH Test

The pH test will be determined by using Digital pH

meter. Dipper of digital pH will be deep into the

sample of serum formulation and the pH value will

be recorded. The pH of the formulation should

having acidic pH as the skin is having an acidic pH

of around 4–6.

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

2

2.4.3 Homogeneity

This will be confirmed by spread some of the serum

formulation on the transparent glass and observe it.

The formulation should produce uniform

distribution of serum.

2.4.4 Rheological Study

Viscosity of the formulation is determined by

Brookfield® Viscometer at 100rpm, using spindle

type model S64.5 ml of the serum. The serum will

placed in a big mouth container with the spindle

dipped in it for about 5 minutes before the

measurement.

2.4.5 Spreadability Test

The product spreads on the skin or affected area and

denotes the extent of area to which the serum was

applied. Some sizes of filter paper are chosen and

each filter paper is measure the total area of filter

paper (A1) and weighing of each filter paper (W1).

Choose the formulation to be tested and draw

several milliliters into the B-D 5mL syringe and

drawn onto the center of filter paper for 20 drops.

When latest drop hits the filter paper, start a timer

or stopwatch to count down for exactly 10 minutes.

During the 10 minute test, the liquid will spread in a

relatively uniform circular pattern over the filter

paper. After 10 minutes, cut exactly on the line

between saturated spread and dry filter paper by

using scissor. Weigh the remaining dry

(unsaturated) filter paper. Record this weight as

W2. Measure the diameter of the saturated portion

of filter paper. If the spread was not a perfect circle,

then take several diameter readings around the

spread area and determine an average diameter.

Record this measurement as A2.

% Spread by Area = (A2/A1)100

2.4.6 Skin Moisture Test

Skin moisture will be measure by using Scalar

moisture checker after applying cosmetic serum on

the skin. The scale will show the moisture of the

skin after using the cosmetic serum.

2.4.7 Stability Test

It is to determine physical and chemical stability of

the product with accelerated stability analysis which

subjects the material to elevated temperatures. Short

term accelerated stability study was carried out for

the period of 3 months for the formulation. The

samples were stored at different storage conditions

of temperatures and samples are withdrawn on

monthly interval and analyzed.

3 RESULTS AND DISCUSSION

3.1 Physical Appearance

Physical appearance was evaluated by observation

on the texture, color and smell of the formulated

cosmetic serum. All formulations gave milky white

finish products with non-greasy and non-oily

properties after 4 weeks observation. The rose smell

of formulation 1 and 4 started to disappear after

week 2 while formulation 2, 3 and 5 after week 3.

Homogeneity of all formulations were uniformly

distributed of contents while observing serum on

the transparent glass slide.

The use of fragrance in cosmetic serum is to

cover the unpleasant smell of Argan oil. The 1 part

of concentrated rose cheek fragrance was diluted

into 10ml distilled water to get 0.1% fragrance

before used in all five formulations. The diluted

fragrance used in formulation made them less smell

and unstable to stand in longer time. Thus, all

smelling of five formulations started to disappear at

week 4.

Fragrance is not always readily detected in

cosmetics either often masking agents are used to

disguise the natural smell of the active ingredients

(which often have really unpleasant smells). These

masking agents so “clean” smell that often

consumers think the product is fragrance-free (Dan

Thompson, June 2014).

3.2 pH Evaluation of Cosmetic Serum

The result shows on the day 1, pH of five

formulations are fall within the range of pH 5 to pH

6. This is because in the outer layers of the stratum

corneum, the moisture barrier has a slightly acidic

pH (4.5 to 6.5). These slightly acidic layers of the

moisture barrier are called the acid mantle. The

acidity is due to a combination of secretions from

the sebaceous and sweat glands. The acceptance

range for the effectiveness of a dermocosmetic

product is lies between pH 4 to pH 6 (Shan

Sasidharan, 2014). After two months, the pH of

these formulations rises gradually, which closed to

the neutral pH (pH 7). However, all formulation

was considerably fulfilling the pH requirement as a

dermocosmetic product. The distribution of pH test

Formulation and Characterization of Cosmetic Serum Containing Argan Oil as Moisturizing Agent

3

between formulation 1, 2, 3, 4 and 5 showed no

significantly different (p< 0.05).

3.3 Rheological Study of Cosmetic

Serum

From the test, the torque value of all five

formulations were more than 30% which mean the

resulted value of viscosity is in the acceptable

viscometer range.

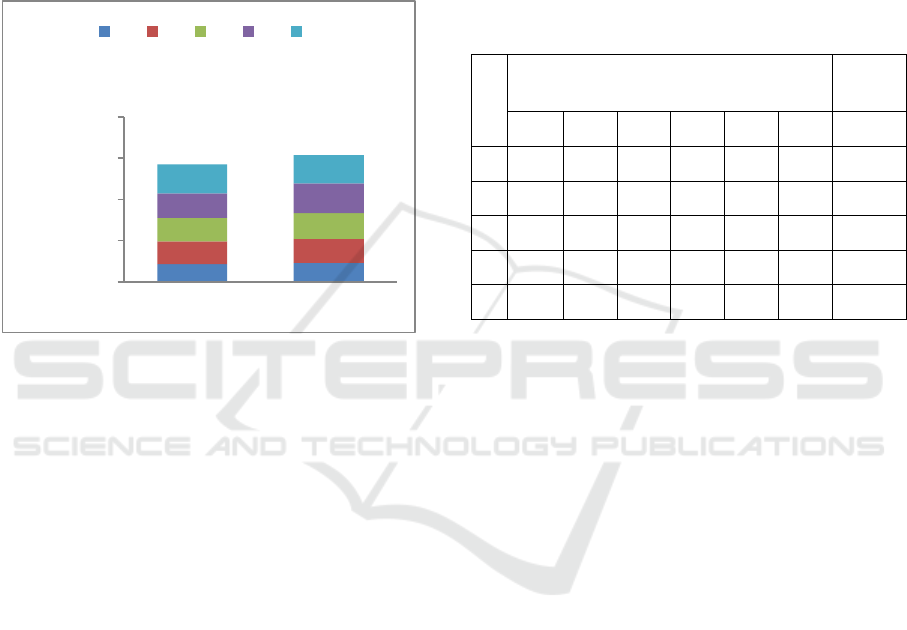

Figure 1: Viscosity study of the formulation

Viscosity of all formulation 1, 2, 3, 4 and 5 are

gradually increased after 4 weeks placed in the

room temperature (25±2) from 214.696, 276.15,

286.018, 296.537 and 351.828 to 232.759, 292.096,

310.566, 359.57 and 344.924 respectively.

Since the F1, F2, F3, F4 and F5 having an

increasing in emollient which are 1%, 2%, 3%, 4%

and 5% of Argan oil, the viscosity of these

formulation are increasing from day 1 to week 4. A

product viscosity is determined by its structure and

the greatest impact on it has the continuous phase;

eg water. The effect on the viscosity is depending

on the size, shape and concentration of the

suspended particles and how they are interact with

the continuous phase (Tharwat F. Tadros, 2013).

Viscosity is a measurement of internal fluid

friction which is resistance to flow when one layer

of fluid is forced to move in over another layer and

typically measured with Brookfield Viscometer. A

fluid may be made up of molecules that vary in size,

shape, and cohesiveness or a single type of

molecule. As these molecules are forced to move or

flow past each other, the molecular properties will

determine just how much force is required to move

them past each other. The force required to cause

movement is referred to as shear. Shear force are

importance in cosmetic product in order to

determine the packaging of pumping product during

manufacturing and also the spreading of serum on

the skin.

According to an article, most of cosmetic

products mostly categorize under shear thinning for

suspensions and emulsions, where their viscosity

decreases with increasing shear rate. This behavior

is also referred to as pseudoplastic and is the result

of structural breakdown within the fluid (Kelly

Dobos, 2017).

Table 2: pH result of the formulation

Mean ± Standard deviation (N=3)

Mean ±

Standard

deviation

Day 1

Wk 1

Wk 2

Wk 3

Wk 4

Wk 8

F1

5.87

±0

5.89

±0.01

6.03

±0.02

6.03

±0.05

6.14

±0.02

6.89

±0.01

6.13

±0.02

F2

6.01

±0.01

5.98

±0.01

6.04

±0.01

6.08

±0.01

6.06

±0.01

6.21

±0.01

6.06

±0.01

F3

6.01

±0.01

6.01

±0.02

5.99

±0.01

6.05

±0.02

6.14

±0.02

6.52

±0.01

6.12

±0.004

F4

5.86

±0.01

5.88

±0.01

5.87

±0.01

5.92

±0.01

5.95

±0.01

6.22

±0.01

5.95

±0.002

F5

5.90

±0.01

5.90

±0.02

5.93

±0.02

5.91

±0.01

5.95

±0.02

6.18

±0.02

5.97

±0.005

3.4 Spreadability Study of Cosmetic

Serum

Spreadability indicates the area on which a semi-

solid topical formulation spreads on application to

the skin. This parameter plays a key role in

determining both the efficacy and the consumer

acceptance of the product. A poor spreadability may

result in an uneven distribution of the formulation

on the skin, thus affecting the amount of the dose

applied and the efficiency of active ingredient(s)

skin permeation. On the other hand, consumers

perceive a poor spreadability as a weakness of the

product, which could lead to the choice of other

products with a better performance, independently

on their actual efficacy.

214,696

232,759

276,15

292,096

286,018

310,566

296,537

359,57

351,828

344,925

0

500

1000

1500

2000

DAY 1 WEEK 4

VISCOSITY (pa)

F1 F2 F3 F4 F5

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

4

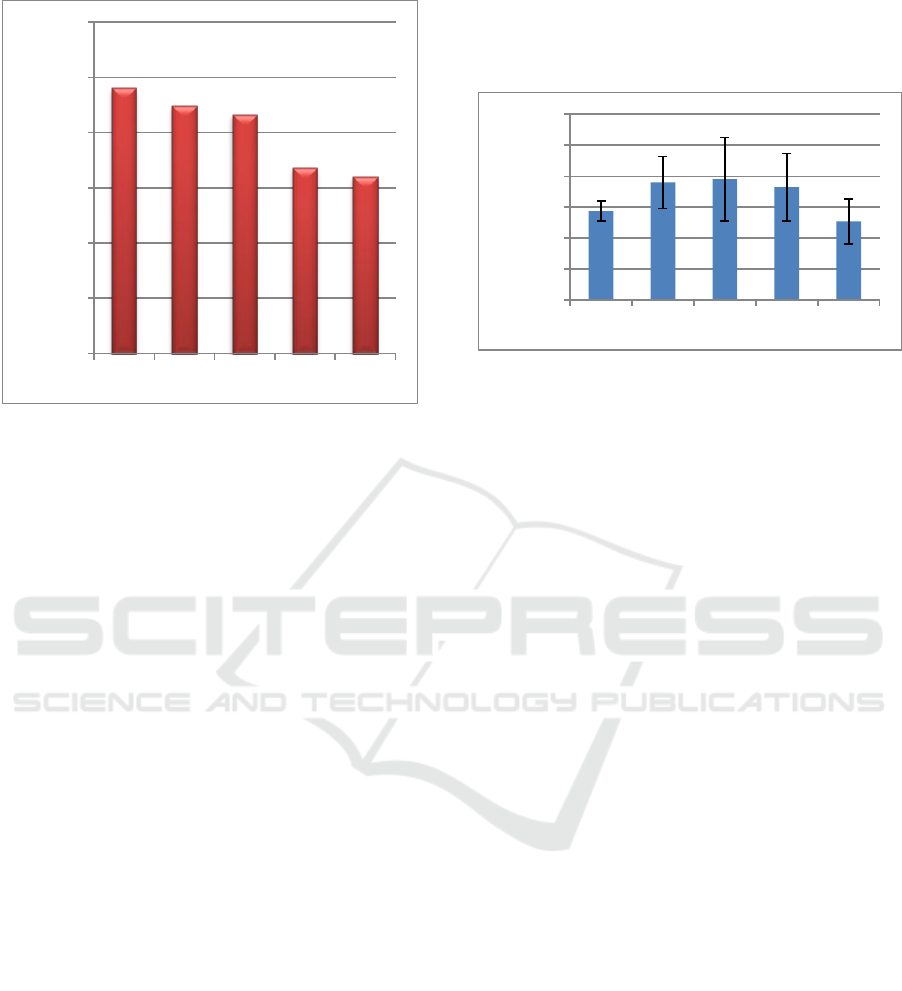

Figure 2: Percentage spreadability of the formulation

From the result of evaluation, it is showed that

formulation 1 give the higher percentage of

spreadability with 24% compared to other

formulations. Secondly, the formulation 2 and 3

also showed more than 20% percent of spreadability

during the test carried out while formulation 4 and 5

only give 16.8% and 16% of spreadability

respectively. Thus, it was assumed that formulation

1 had a good spreadability and consumer

satisfaction when compared to others formulation.

Other authors reported a linear relationship between

viscosity and spreadability for topical formulations,

as the lower the viscosity of a lotion, the lower the

surface tension and the higher the spreadability on

the skin (Lardy F, 2000). When compare with the

viscosity test, formulation 1 having lowest

viscosity, thus it affect its spreadability which

having the highest percentage of spreadability.

For the rheological study and spreadability,

there are having linear relationship between

viscosity and spreadability, as the lower the

viscosity, the lower the surface tension and the

higher the spreadability on the skin.

3.5 Skin Moisture Study of Cosmetic

Serum

A total of 15 volunteers, ages ranging from 18 to 25

years old were included in the study. The volunteers

are healthy with no preceding skin diseases. Non-

invasive skin moisture measurements were carried

out using Scalar moisture checker at 1 minute, 5

minutes and 10 minutes to determine the short term

improvement in skin moisture properties after a

single application of cosmetic serum. Five different

cosmetic serums containing different concentration

of emollient (Argan oil) which are 1%, 2%, 3%, 4%

and 5% were used in this evaluation.

Figure 3: Percentage of moisture increase of the

formulation

From the moisture test of formulation 1,

moisture increment in volunteer 1, 2 and 3 are

14.81%, 12.57% and 15.70%. The total percentage

increment is 14.36 % (±1.61). In the formulation 2,

moisture increment in volunteer 1, 2 and 3 are

21.28%, 14.16% and 21.57%. The total increment

of formulation 2 is higher than formulation 1, 4 and

5 which is 19.00 % (±4.20) and slightly lower by

0.67% from the formulation 3. The formulation 3

shows the highest percentage of moisture increment

in all three volunteers which is 19.67 % (±6.49).

While in the formulation 4, total increment of

moisture from the individual’s volunteer 1, 2 and 3

(23.99%, 13.13%, 17.57%) is 18.23% (±5.46).

lastly, formulation 5 show the least moisture

increment in the volunteer 1, 2 and 3 (16.83%,

11.40% and 9.88%) with the total moisture

increment is 12.70% (±3.65). Thus from the result,

formulation 3 show the highest moisture levels

raised compared to others formulation.

According to the one way ANOVA using data

percentage of moisture increment for 15 volunteer

at 1 minute, 5 minutes and 10 minutes for all

formulation, all data show high significant different

(p<0.05) among each volunteer. The moisture level

of each volunteer varied due to the different

thickness of skin between male and female,

environment condition and lifestyle of volunteers.

This proven that Argan oil contains higher

contents of triglyceride which mainly act as

moisturizing agent through the percentage of

moisture rising after first application. Emollients

provide some occlusivity and improve the

appearance of the skin by smoothing flaky skin

cells. There are many different types of emollient

esters and oils available. Emollients are generally

24,00

%

22,40

%

21,60

%

16,80

%

16,00

%

0,00%

5,00%

10,00%

15,00%

20,00%

25,00%

30,00%

F1 F2 F3 F4 F5

0,00%

5,00%

10,00%

15,00%

20,00%

25,00%

30,00%

F1 F2 F3 F4 F5

Formulation and Characterization of Cosmetic Serum Containing Argan Oil as Moisturizing Agent

5

grouped by their ability to spread on the skin. By

combining emollients with the different spread

rates, it can tailor the skin feel of a moisturizer. In

this cosmetic serum formulation, three types of

emollient were used such as Argan oil, squalene and

triglyceride. Additionally, emollient lipids similar to

those naturally found in the skin may also increase

the rate of barrier repair (Dobos, 2016). Thus, by

increasing the percentage of emollient would be

increasing the skin’s moisture level.

3.6 Stability Study of Cosmetic Serum

The sample of formulations were stored at three

different storage conditions and withdrawn weekly

to analyze the physical stability.

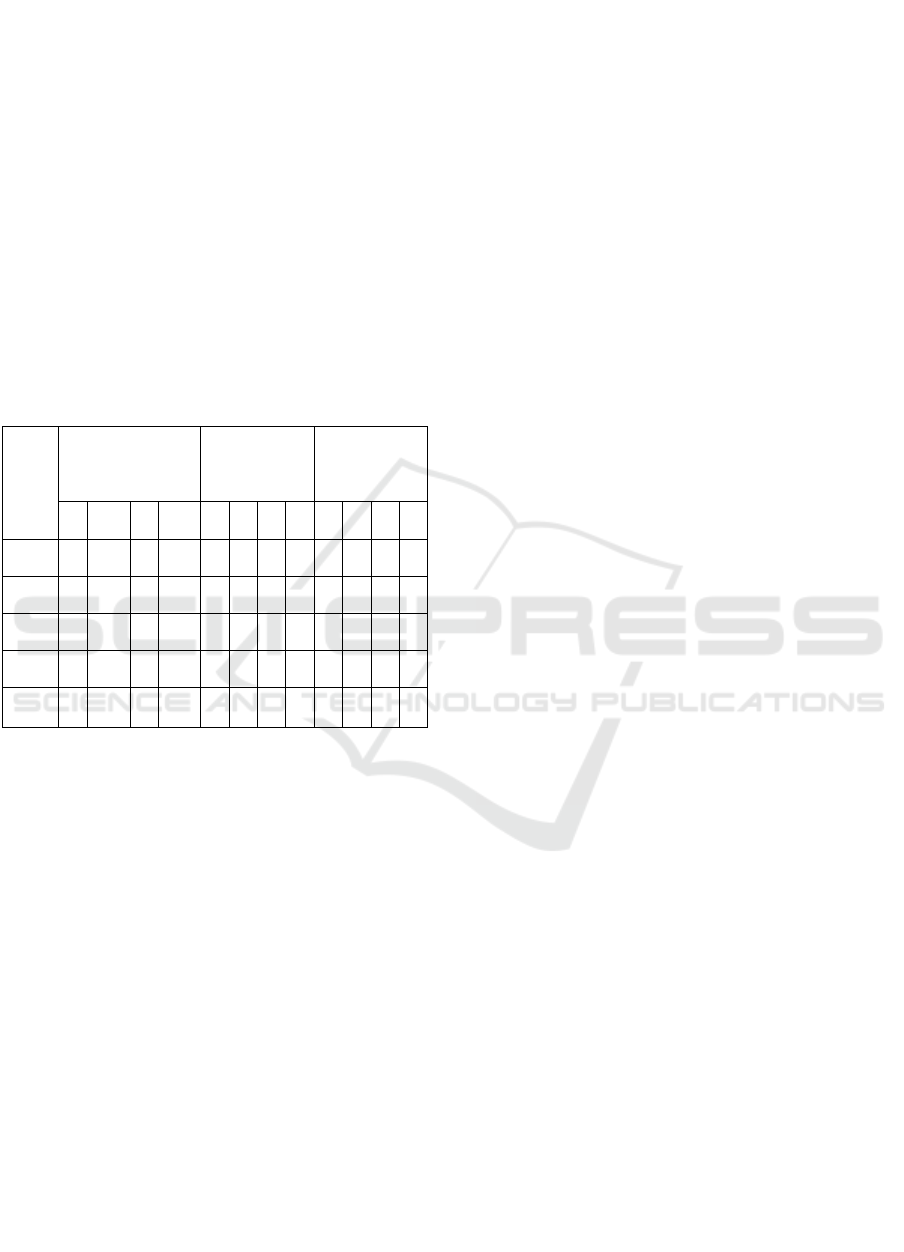

Table 3: Stability studies of the formulation

Room

temperature

(25°C±1)

Cold room

(2-3°C)

Oven

(40°C)

W

1

W

2

W

3

W

4

W

1

W

2

W

3

W

4

W

1

W

2

W

3

W

4

F1

X

X

X

X

X

X

X

X

/

/

/

/

F2

X

X

X

X

X

X

X

X

/

/

/

/

F3

X

X

X

X

X

X

X

X

X

/

/

/

F4

X

X

X

X

X

X

X

X

/

/

/

/

F5

X

X

X

X

X

X

X

X

/

/

/

/

X : No phase separation

/ : Phase separation

All 5 formulations were stable at room

temperature (25°C±2) and cold room (2-3°C) for a

month without having any phase separation. At the

high temperature storage (40°C), all 5 formulations

show stable during first three days. After that,

formulation 1, 3, 4 and 5 started to have phase

separation while formulation 2 stable for a week

and become unstable at the week 2. This process

results from the external forces usually gravitational

or centrifugation. When such forces exceed the

thermal motion of droplets, a concentration gradient

builds up in the system with the larger droplets

moving faster to the top or bottom of container

depends on their density (Tharwat F. Tadros, 2013).

Oil in water emulsion is considered to be special

liquid-liquid colloidal dispersions. The kinetic

stability is a consequence of small droplet size and

the presence of n interfacial film around the oil

droplets and is caused by stabilizing agent or

emulsifiers. In the serum formulation, polyethylene

glycol-100 (PEG-100) had been used as oil in water

emulsifier to form a homogenous mixture by

keeping water and oil together. These stabilizers

suppress the mechanisms that would involve in the

breakdown of emulsion such as sedimentation,

aggregation, coalescence and phase inversion.

These serums are stabilized by films that form

around the oil droplets at the water-oil interface.

Temperature can affect emulsion stability

significantly. Temperature affects the physical

properties of oil, water, interfacial films, and

surfactant solubilities in the oil and water phases.

These, in turn, affect the stability of the emulsion.

Perhaps the most important effect of temperature is

on the viscosity of emulsions because viscosity

decreases with increasing temperatures. This

decrease is mainly because of a decrease in the oil

viscosity. In this evaluation, temperature of the

oven (40°C) increases the thermal energy of the oils

droplets and, therefore, increases the frequency of

drop collisions. It also reduces the interfacial

viscosity, which results in a faster film-drainage

rate and faster drop coalescence.

The effect of temperature on crude oil/water

interfacial films was studied in some detail by

Jones et al., who showed that an increase in

temperature led to a gradual destabilization of the

crude oil/water interfacial films. However, even at

higher temperatures, a kinetic barrier to drop

coalescence still exists. Temperature influences the

rate of buildup of interfacial films by changing the

adsorption rate and characteristics of the interface.

It also influences the film compressibility by

changing the solubility of the crude oil surfactants

in the bulk phase.

4 CONCLUSIONS

The formulated cosmetic serum was successfully

developed and evaluated using different standard

parameters including skin moisture rising

properties. Based on all cosmetic serum

formulations studied, all F1, F2, F3, F4 and F5

formulation showed significantly different in rising

of skin moisture level (p<0.05). On the evaluation

of the finished serum’s texture, all formulations

give a milky white in color, non-greasy, non-oily

and homogeneous contents. Without any pH

adjustment, all the formulations gave the pH value

within the limits of normal skin pH range. Besides

that, in the stability study of cosmetic serum, all

formulations stable until 4

th

week in the room

temperature (25°C±1) and cold room (2-3°C) but

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

6

unstable in the oven (40°C) after the first 3 days

except for F2 which stables for a week before

undergo phase separation.

Thus, from the studied, the F2 is the best

formulation of cosmetic serum as it is the most

stable formulation and could give highest

percentage of moisture increased.

Besides that, further studies are warranted to

prove safety and efficacy of the formulated

cosmetic serum and extend formulation to gel and

cream formulation.

ACKNOWLEDGEMENTS

This dissertation would not be possible without

guidance and the help of Supervisor Mdm Sri

Budiasih, colleagues and family. I would like to

take this opportunity to express gratitude to

Management & Science University (MSU) for

allowing me to conduct the research study by

providing the necessary equipment and materials.

Thank you.

CONFLICT OF INTEREST

Declare none

REFERENCES

Ambikar R. B., Powar P. V., Singh C. K., Sharma

P. H., Formulation and Evaluation of

Moisturizer Prepared from Natural Sources,

Asian Journal of Pharmaceutical Technology &

Innovation, 02 (08); 2014.

André O. Barel, M. P. (2014). handbook of cosmetic

science and technology. CRC Press.

Balazs, E. a. (1984). Hyaluronic acid. Its structure

and use. Cosmet Toilet, 65–72.

Chemical of the Week -- Chelates and Chelating

Agents. (n.d.). Retrieved

fromhttp://scifun.chem.wisc.edu/chemweek/chel

ates/chelates.htmlDan Thompson. (2014, June

25). Fragrance and Cosmetics: Pretty Smells

Equal Big Reactions :: YummyMummyClub.ca.

Retrieved from

http://www.yummymummyclub.ca/blogs/dan-

thompson-beauty-busted/20140625/fragrance-

and-cosmetics

Diana Draelos, Z. (2000). THERAPEUTIC

MOISTURIZERS. Dermatologic Clinics, 18(4),

597-607. doi:10.1016/s0733-8635(05)70210-2

Dal'Belo, S. E., Rigo Gaspar, L., & Berardo

Gonçalves Maia Campos, P. M. (2006).

Moisturizing effect of cosmetic formulations

containing Aloe vera extract in different

concentrations assessed by skin bioengineering

techniques. Skin Research and

Technology, 12(4), 241-246.

doi:10.1111/j.0909-752x.2006.00155.x

DeHaven, C. (2007). isclinical. Retrieved April 3,

2016, from Delivery of cosmetic ingredients to

the skin:

http://www.isclinical.com/whitepapers/delivery-

costmetic-ingredients.pdf

Dobos, K. (n.d.). Chemists Corner. Retrieved April

3, 2016, from How Do Skin Moisturizer Work:

http://chemistscorner.com/how-do-skin-

moisturizers-work/

Dom Guillaume, Z. C. (2011). Argan Oil.

Alternative Medicinal Review, 275-279.

Dominique Guillaume, Z. C. (April 2011). Argan

oil and other argan products: Use in

dermocosmetology. European Journal of Lipid

Science and Technology, 403-408.

Dow Answer Center. (2016, April 15). Retrieved

from

http://dowac.custhelp.com/app/answers/detail/a_

id/1845/~/procedure-for-emulsification-of-oil-

in-water-using-surfactants

Dr. Leslie S. Baumann Dermatologist. (2014).

News and Research on Argan Oil. Retrieved

from http://www.arganlifeproducts.com/argan-

publications2.html

Farris, P. K. (n.d.). NU Skin. Retrieved April 3,

2016, from Skin Anatomy and Physiology:

https://www.nuskin.com/en_ZA/corporate/comp

any/science/skin_care_science/skin_anatomy_an

dphysiology.html

Gabriella Baki, K. S. (2015). Introduction to

Cosmetic and Formulation. John Wiley & Sons,

Inc., Hoboken, New Jersey.

Garg, A.; Aggarwal, D.; Garg, S.; Singla, A.K.

Spreading of semisolid formulations: An

update.Pharm. Technol. 2002, 26, 84–105.

Golmohammadzadeh, S., Mokhtari, M., &

Jaafari, M. R. (2012). Preparation,

characterization and evaluation of moisturizing

and UV protecting effects of topical solid lipid

nanoparticles. Brazilian Journal of

Pharmaceutical Sciences, 48(4), 683-690.

doi:10.1590/s1984-82502012000400012

Formulation and Characterization of Cosmetic Serum Containing Argan Oil as Moisturizing Agent

7

Jones, T.J., Neustadter, E.L., and Whittingham,

K.P. 1978. Water-In-Crude Oil Emulsion

Stability And Emulsion Destabilization By

Chemical Demulsifiers. J Can Pet

Technol 17 (2). PETSOC-78-02-

08. http://dx.doi.org/10.2118/78-02-08.

Kapoor, S., & Saraf, S. (2010). Formulation and

Evaluation of Moisturizer Containing Herbal

Extracts for the Management of Dry

Skin. Pharmacognosy Journal, 2(11), 409-417.

doi:10.1016/s0975-3575(10)80024-0

Kelly Dobos. (2017). Fluid Viscosity for the

Formulation Chemist – Chemists Corner.

Retrieved from http://chemistscorner.com/fluid-

viscosity-for-the-formulation-chemist/

Lardy, F.; Vennat, B.; Pouget, M.P.; Pourrat, A.

Functionalization of hydrocolloids: Principal

component analysis applied to the study of

correlations between parameters describing the

consistency of hydrogels. Drug Dev. Ind.

Pharm. 2000, 26, 715–721.

LAURA JOHANNES. (2012, June 11). The Health

and Cosmetic Benefits of Argan Oil - WSJ.

Retrieved from

http://www.wsj.com/articles/SB1000142405270

2303768104577460504019108684

L.L. Schramm ed. 1992. Emulsions: Fundamentals

and Applications in the Petroleum Industry,

Advances in Chemistry Series No. 231.

Washington, DC: American Chemical Society.

Paepe, K. E., & Rogiers, V. (2009). Glycerol as

Humectant in Cosmetic Formulations. Basic and

Clinical Dermatology, 279-294.

doi:10.3109/9781420070958.017

Rawlings, A., & Matts, P. (2007). Dry Skin and

Moisturizers. Dermatologic, Cosmeceutic, and

Cosmetic Development, 339-371.

doi:10.3109/9780849375903-22

Vinchy. (2011, September 14). hello magazine.

Retrieved April 3, 2016, from all you ever

wanted to know about cosmetic serum:

http://www.hellomagazine.com/healthandbeauty

/skincare-and-

fragrances/201109146118/cosmetic-serum-

know-how/

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

8