Composition Ratio of Lactose and Corn Starch in Granule Capsule

Formulation of 70% Ethanol Extract Justicia Gendarussa Leaves as

Male Contraceptive

Bambang Prajogo EW

1

, Esti Hendradi

2

,and Pramudita Riwanti

1

1

Pharmacognosy Department, Faculty of Pharmacy, Airlangga University, Surabaya

2

Chemical Pharmacy Department, Faculty of Pharmacy, Airlangga University, Surabaya

Keywords: Justicia gendarussa, lactose, corn starch.

Abstract: The objective of this study were to make a good physical properties of Justicia gendarussa granules with

lactose and corn starch as filler. Optimizations were made into 3 formulas. The difference of each formula

was in the ratio of corn starch and lactose. Formula 1 used ratio 3:7 for corn starch and lactose, Formula 2

used ratio 1:1 for lactose and corn starch, Formula 3 used ratio 7:3 for corn starch and lactose. Physical

evaluation was held to evaluate and choose the best granule like flowability, fines content, angle of repose,

moisture content, compressibility. The result for granules optimization, flowability formula 1 was 3,29 ±

1,08 g/s, formula 2 was 6,04 ± 1,80 g/s, formula 3 was 6,48 ± 1,32 g/s. Angle of repose for F1,2 and 3 were

30,54 ± 1,14o, 29,98 ± 0,34oand 26,98 ± 0,00o. Compressibilty index were 12,00% , 10,00% and 11,99%.

Moisture content 1,82%, 2,08% and 2,75%. Fines content were above 20%. From the evaluation, F2 was

selected as the best formula.

1 INTRODUCTION

Justicia gendarussa is a tropical plant which grow

in tropic land including Indonesia. This plant have

been used by society of Papua as male

contraceptive

30

. Major components from genus

Justicia are alkaloid, lignan, flavonoid and

terpenoid. Gendarussa leaves also contain tannin,

kalium, volatile oil.calcium oxalate and also

alkaloid (justicina) which is toxic.

8

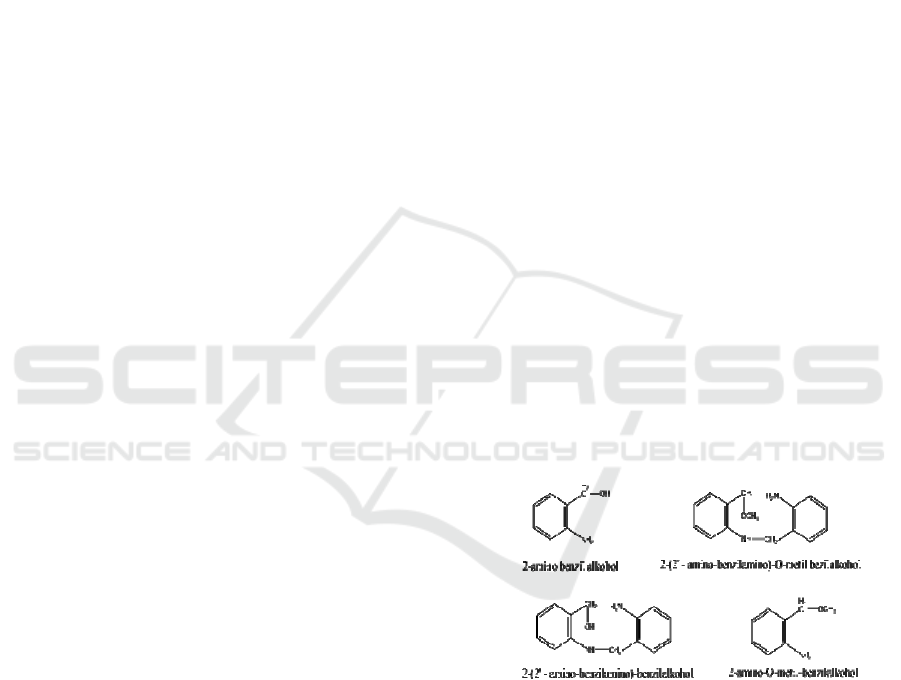

Alkaloid have been isolated from J.gendarussa

leaves are 2-amino benzyl alcohol; 2-amino-o-

metyl benzyl alcohol; 2-(2’-amino-benzilamino)

benzil alcohol; 2-(2’amino-benzil)-o-metil-benzil

ackohol (Figure.1).

7

Figure.1 : Chemical structure aromatic amin substituted

isolated from J.gendarussa leaves.

7

Flavonoids from Justicia gendarussa Burm. f.

are 6,8-di-C-α-L-arabinosil-4', 5,7 trihydroxy-

flavon or 6,8-di-C-α-Larabinosilapigenin and this

compound called gendarusin A, C-α-L-

arabinopiranosil-4 ', 5,7 - trihydroxy-8-C-β-D-

silopiranosilflavone or 6-C-α-L-arabinosil- 8-C-β-

D-silosilapigenin and this compound called

gandarusin B. Other flavonoids are gandarusin C,

D and E. Gandarusin A is major component,

steroid, volatile oil, alkaloids and other flavonoids

Composition Ratio of Lactose and Corn Starch in Granule Capsule Formulation of 70 .

DOI: 10.5220/0009844200002406

In Proceedings of BROMO Conference (BROMO 2018) - Symposium on Natural Product and Biodiversity, page 1

ISBN: 978-989-758-347-6

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1

(gandarusin B,C,D and E) are minor components

in 70% ethanol extract Justicia gendarussa Burm.f.

31

J.gendarussa extract have an antifertility effect

that can inhibit spermatozoa penetration in-vitro

with inhibit of hyaluronidase enzyme.

29

Therefore,

J.gendarussa was developed into phytopharmaca

drug. Phytopharmaca drug must be produced based

on required standar to ensure the quality of

product. The production process must conform the

standards of GMP. GMP’s requirement including

raw material, equipment, sanitation and hygiene.

Further development of 70% ethanol extract

J.gendarussa leaves into phytopharmaca drug,

need formulation which have been conducted by

several researchers. Granules formulation from

water extract J.gendarussa leaves with avicel and

lactose as filler made by wet granulation gave poor

results because of the tablet hardness and slow

disintegration time (almost 20 minutes). Based on

that results, the filler change into lactose and corn

starch and gave good results

39

, the hardness of

tablets and disintegration time were decreased. The

addition of non-ionic surfactant,tween 80 is also

made to improve the physical requirements and the

dissolution rate of gendarusin A in the granules

formula.

2

Then developed further by replacing

Tween 80 with Poloxamer 188 as surfactant. In

this study, the surfactant used is sodium lauryl

sulfate. Replacement poloxamer 188 (non-ionic)

with sodium lauryl sulphate which are anionic

surfactants is based on research conducted by

Alkhamis et al. (2003) who found that non-ionic

surfactant demonstrated the ability solubilization

smaller than the anionic and cationic surfactants on

solubilization glikazid. Additionally, poloxamer

188 has a relatively expensive price so that less

effective if will be developed later. This formula

then regarded as the chosen formula by

considering the parameters that can produce good

product as an infertility drug.

Table 1 : Relationship between % compressibility and

flowability

40

%

Compres

s

ibilit

y

Flowability

5-12 Perfect

12-16 Good

18-21 Moderate

23-28 Poor

28-35 Poor

35-38 Very poor

> 40 Ver

y

-ver

y

poo

r

(cohesive)

2 MATERIALS AND METHOD

2.1 Materials

Lactose (Lactose Monohydrate, Leprino USA),

Corn starch (Amylum Maydis, Cargill Bio-

Chemical China, Cab-o sil (Pluronic F-68, Sigma

Life Scine USA), Sodium Lauryl Sulfate (SLS),

Methanol p.a (Merck), Ethanol 70% Nylon

membrane 0,2 µm (Whatman), Filter holder

(Millipore), Aquadest.

2.1.1 Standarized Simplicia of J.Gendarussa

Nine months of J.gendarussa leaves have been

harvested. Fresh leaves then made into simplicia

by sortation (remove mechanical parts except leaf

that are not needed like bark, stem, etc) and then

washed and dried in drying cabinet at tempertaure

below50°C. Dried simplicia then milled to a

powder with a certain size

12

2.1.2 Extraction

Gandarussa leaves powder extracted with

macseration using ethanol 70% (1:10) for 24 hours.

Re-extraction until three times. After extraction,

the solvents were allowed to evaporate using rotary

evaporator. Thus the highly concentrated ethanol

extract were obtained. The extract then stored in

refrigerator at 4

o

C for further use for formulation

process.

2.1.3 Formulation

Optimization were held with 3 formulas.

J.gendarussa leaves granules were prepared by wet

granulation method. Corn starch, lactose were used

2

as filler, sodium lauryl sulfate 1% was used as

surfactant and cab o sil was used as glidant. The

difference for each formula was on the ratio

between lactose and corn starch. Formula 2 used

ratio 1:1 for lactose and corn starch, Formula 1

used ratio 3:7 for lactose and corn starch, Formula

3 used ratio 7:3 for corn starch and lactose.

Physical evaluation is held to evaluate and choose

the best granule.

2.2 Evaluation of Granules

2.2.1 Flow Rate and Angle of Repose

The angle of repose was determined by allowing

granules to flow through a funnel and fall freely

onto a graph paper on a horizontal surface. The

time taken for the weighed granules to flow out

completely was recorded

5

. This was performed in

triplicate.

Flow rate was obtained by the equation below:

Flow rate = weight of granules / time

The height and diameter of the resulting cone were

measured and the angle of repose is calculated

from this equation:

tan Ø =h/r

Where :

h is the height of the powder cone and r is the

radius of the powder cone

2.2.2 Bulk Density

The bulk density (ρ

b

) of granules was determined

by filling the material into a tarred graduated

cylinder to the 100 ml mark. The graduated

cylinder was weighted and the bulk density

calculated as the ratio of the sample weight to

sample volume

ρbulk= W / V

Where :

ρbulk = Apparent bulk density,

W = Weight of the sample,

V = Apparent volume of powder

2.2.3 Tapped Density

A suitable amount of granules was placed in a 100

ml measuring cylinder. After absorbing its initial

volume, the sample was tapped 500 times initially

followed by an additional taps of 750 times until

the difference between succeeding measurement is

less than 2% and then tapped volume, was

measured, to the nearest graduated unit. Tapped

density was calculated using

equation

ρtab = W / Vf

Where :

ρtab = Tapped Density,

W = Weight of the sample,

Vf = Tapped volume of powde

2.2.4 Moisture Content

Moisture content determination using Ohauss

electronic Moisture balance 45 with place about

0,5-1g sample in sample pan. The sample pan must

lie flat in the pan handler. Then, press the start

button to start analyze. After ten minutes, %

moisture content can read.

2.2.5 Fines Content

The determination of fines is done by inserting 100

grams of granules into a sieve with a hole diameter

of 140 mesh (the equivalent of 100 micrometers).

Then sieve vibrated for 20 minutes at a speed of 10

rpm. Weigh the amount of powder that escaped

sieve (Wade and Weller, 1994). The amount of

fines should not more than 20%. Particles that are

larger than 250 μm is relatively free flowing,

whereas particles have a size below 100 μm (fines)

cause problems in the flow properties due to the

occurrence of a large cohesive force.

3

2.2.6 Statistical Analysis

Data analysis was performed on the physical

parameters of the granules and then performed

statistical analysis by one-way ANOVA (One-Way

ANOVA). To determine whether there were

significant differences between the formula, then

followed by the Tukey-HSD test to determine any

formula that provides a meaningful difference.

Statistical analysis includes flow rate, angle of

repose, moisture content and% compressibility

with 95% confidence level (α = 0.05). When

Asymp. Sig. α < (0.05), then Ho is rejected and Ha

accepted.

Composition Ratio of Lactose and Corn Starch in Granule Capsule Formulation of 70

3

3 RESULTS AND DISCUSSION

J.gendarussa leaves extract have a viscous

consistency therefore need filler composition like

corn starch and lactose that can improve the

physical properties of granules. With a viscous

consistency and large water content, granulation

process carried out by wet granulation to improve

the flowability and compactibilty of granule mass.

Materials used as filler are lactose and corn

starch. Lactose in the tablet formulation excipients

serves as good as it can condense the mass of

granules in the wet granulation or direct

compression and can improve the flow properties

because the lactose has a large specific gravity.

24

It

is also the most widely used filler because it does

not react with almost all of the ingredients.

Generally, formulation with lactose showed a good

rate of drug release, quick dry granules,

disintegration time is not very sensitive to changes

in the tablet hardness.

25

However, lactose may

increase the hardness of the tablet therefore need a

disintegrant to overcome. Corn starch has a lower

specific gravity than the lactose that can help the

bonds between the extract particles is not too

strong so the combination of this two excipients

lactose and corn starch can improve the physical

quality of granules extract (J. gendarussa) as

phytopharmaca drug.

The solubility of J.gendarussa extract that

partially soluble caused a slow release of the active

ingredients therefore the absorbtion and effect will

be slow. Materials with low water solubility caused

bad wetting because of their interfacial tension

between the water phase, vapor phase and solid

phase. As a result, drug will be difficult

dissolved.

25

This requires the addition of a

surfactant to improve the solubility.

In this study, the surfactant used was sodium

lauryl sulphate (SLS). With the addition of this

SLS, can reduce the surface tension between the

particles, which occurs damping effect that makes

the contact between the granules with media is

large so the active substance is easier to get out of

the granule and dissolve into the media. SLS as a

wetting agent can also improve the dissolution rate

of the drug due to its mechanism.

3

The result of granules can be seen in figure.2,

and evaluation of each formulas can be seen in

table 2.

Figure.2: Granules formula 1,2,3 resulted from

optimization

From the results in table 2.2, the flow rate of

the granules, formula 1 was 3.28 ± 1.08 g / s,

formula 2 was 6.04 ± 1.80 g / s, formula 3 was

6.48 ± 1.32 g / s. Based on the statistic results

using ANOVA, there was no significant difference

in flow rate between formula 1,2 and 3. formula

granule flow velocity is considered good if it is in

the range of 4-10 g/s. Formula 2 and 3 meet these

requirements, while the formula 2 has a flow rate

of <4 g/s so it can be considered to have difficult

flow properties.

3

The flowability can also be viewed from the

angle of repose. Angle of repose resulting from

formula 1 was 30.54 ± 1.14

o

, formula 2 was 29.98

± 0.34

o

and formula 3 was 26.98 ± 0,00

o

. From

the results of statistical tests on granules extract (J.

gendarussa) , there was a significant difference

between the angle of repose formula 1 and 3,

Formula 2 and 3 on the confidence level of 0.95%

(α = 0.05). Angle of repose illustrate the magnitude

of the frictional forces between the particles, so

4

can demonstrate the flow properties of a

granular indirectly.

6

Based on the angle of repose,

all of

granules formula were meets the criteria of the

granules with good flow properties, which have the

angle of repose between 20-30

o

.

44

Good flow

properties will make the die filling fulfilled evenly

so the weight of the capsule is not distorted.

25

Granule flow properties also have a

relationship with compressibility. Granules have a

perfect flow properties (granule flow freely) if it

has a range of 5-12% compressibility.

40

In formula

1,2 and 3 the compressibility respectively were

12.07%, 9.68% and 13.11%. All formula meets the

compressibility range with perfect flow properties.

Formula 3 had the highest % compressibility. It

can be related to the high moisture content 2.75%.

Moisture content can affect the compressibility

index and flowability because the moist powder

mass will result in less free flowing powder.

High moisture content of the F3 can also be

caused by the amount of corn starch higher than

other formulas. Corn starch is hygroscopic so the

granules will be more humid. The results of each

formula met the requirements as good granules, the

moisture content of the granules were in the range

of 2% - 4%. These results can guarantee the

granules are stable during storage. Humidity of a

granule will affect the stability of the granules. The

higher the humidity, the higher the potential for

microbes to live so stability become shorter. When

the moisture content too much can lead to sticky

and hard flowing granules, but small water

content will produce a dry granule and easy fragile.

Fines content (particle size <100µm) from all

formulas were more than 20%. From all that

formula, the best formula chosen was determined

based on the evaluation has been done. Formula 2

was chosen formula because the formula 3 had a

high moisture content, it is feared the stability of

the granules is getting shorter. While the formula 1

and 2 based on the results of the statistical analysis,

flowability and angle of repose did not provide a

significant difference but in terms of the yield

obtained, compressibility and flowability, formula

2 was better than formula 1. Thus formula 2 with

ratio 1:1 for lactose and corn starch was a best

formula and chosen to do the next process.

CONCLUSION

Granules with filler ratio 1:1 for lactose and corn

starch can result in good physical properties of

granules.

REFERENCES

1. Ansel, H. C., Popovich, N. G., and Allen, L.

V. 1995. Pharmaceutical Dosage Form and

Drug Delivery System, 6

th

ed., Malvern:

Williams and Wilkins, p. 60-65.

2. Arifani, G. 2012. Pengaruh Tween 80

Terhadap Laju Disolusi Gendarusin A dalam

Granul Ekstrak Etanol 70% Daun Justicia

gendarussa burm. f. Untuk Sediaan Kapsul.

Skripsi. Fakultas Farmasi Universitas

Airlangga.

3. Aulton, M. E. 2002. Pharmaceutics : The

Science of Dosage Forms Design. London :

Churchill Livingstone

4. Banker, G. S. and Anderson, N. R. 1989.

Tablet, In: Lachman, L., Lieberman, H. A.

And Kanig, J. L. (Eds). Teori dan Praktek

Farmasi Industri, edisi ketiga, Vol II, Jakarta:

Universitas Indonesia.

5. Bhagawan, W.S. 2015. Formulasi dan Uji

Disolusi Granul Ekstrak Etanol 70%

Terfraksinasi Daun Gendaarusa. Thesis.

Fakultas Farmasi Universitas Airlangga.

6. Carstensen. 1977. Pharmaceutics of Solid

and Solid Dosage Forms. New York: John

Willey and Sons.

7. Carstensen, J.T. and Rhodes, C.T., 2000, Drug

Stability Principles and Practices, Third

Edition, Revised and Expanded, Marcel

Dekker, Inc., New York : 238 – 381.

8. Chakravarty, A. K., Dastiar, P. P. G., and

Pakrashi, S. C. 1982. Simple aromatic amines

from Justicia gendarussa 13C NMR Spectra

of the bases and their analogues. Tetrahedron.

Elsivier, 18 (12):1797-1802.

Table 2 : Physical Evaluation of Granules

Evaluation Formula 1 Formula 2 Formula 3 Requirement

Flowability (g/s) *3.28±1.08 6.04±1,80 6.48±1,32 4-10

g

/s (Good flowabilit

y

)

Angle of repose (

o

) *30.54±1.14

o

29.98±0,34

o

26.98±0,00

o

20-30

o

(Good flowabilit

y

)

fines (%) 24.15 25.97 21.09 < 20%

Compressibility (%) 12.00 10.00 11.99 5-12% (Perfect flowabilit

y

)

Moisture content (%) 1.82±0,02 2.08 ± 0,04 2.75 ± 0,02 2-4%

Yield (%) 61.63% 71.08% 78.40% -

Composition Ratio of Lactose and Corn Starch in Granule Capsule Formulation of 70

5

9. Dalimartha, S. 2001. Atlas Tumbuhan Obat

Indonesia, Jilid 1, Jakarta: Trubus Ariwidya.

10. Departement of Health. 2002. British

Pharmacopoeia. London: The Stationary

Office. p. 1003, A 241-242.

11. Departemen Kesehatan RI. 1995. Farmakope

Indonesia. Edisi IV. Jakarta : Dirjen POM.

12. Departemen Kesehatan RI. 1995. Materia

Medika Indonesia. Jilid VI. Jakarta:

Departemen Kesehatan RI.

13. Departemen Kesehatan RI. 2000. Parameter

Standar Umum Ekstrak Tumbuhan Obat.

Jakarta: Departemen Kesehatan RI.

14. Dhirendra, K., Lewis, S., Udupa, N., and Atin,

K. 2009. Solid Dispersion, India, Manipal

College of Pharmaceutical Science. p. 234-

246.

15. EMEA., 1999. Working Part on Herbal

Medicinal Products (HMPWP), Stability

testing of HD (Herbal Drug), HDP (Herbal

Drug Preparation), and HMP (Herbal

Medicinal Product), Guidelines 25 : 48.

16. Feher, M., and Schmidt, J. M. 2003, Property

Distributions: Differences Between Drugs,

Natural Products, And Molecules From

Combinatorial Chemistry, J. Chem. Inf.

Comput. Sci. 43, 1, 218-227

17. Gordon, R. E., Rosanske, T. W., Fonner, D. E.,

Anderson, N. R., and Banker, G. S. 1990.

Granulation Technology and Tablet

Characterization. In: Lachman, L.,

Lieberman, H. A., Schwartz, J. B. (Eds),

Pharmaceutical Dosage Forms: Tablets, 2

nd

ed,

Vol. 2, New York: Marcel Dekker, Inc.

18. Gunsel, W. C. and Kanig, J. L. 1976. Tablet,

In: Lachman, Lieberma, H. A. and Kanig J.

L., The Teory and Practice of Industrial

Pharmacy, 2

nd

Ed., Lea and Febiger,

Philadelphia.

19. Gupta, R. S., and Sharma, R. 2006. A Review

on Medicinal Plants Exhibiting Antifertility

Activity in Males. Natural Product

Radiance. Vol. 5 (5), p. 389-410.

20. Handa, S. S., Khanuja, S. P. S., Longo, G., and

Rakesh, D. D. 2008. Extraction Technologies

for Medicinal and Aromatic Plants. Itali:

International centre for science and high

technology. pp.21-25.

21. Harborne, J. B., 1987. Metode Fitokimia

Penuntun Cara Modern Menganalisis

Tumbuhan, Edisi kedua. Bandung: Institut

Teknologi Bandung Press.

22. Heyne. 1987. Tumbuhan Berguna

Indonesia. Jilid III. Terjemahan Badan

Litbang Kehutanan. Jakarta: Yayasan Sarana

Wana. hal 1759.

23. Kiren, Y., Deguchi, J., Hirasawa, Y., Morita,

H., and Prajogo, B. 2014. Justidrusamides A-

D, new 2-aminobenzyl Alcohol Derivatives

from Justicia gendarussa. Journal of Natural

Medicines. Vol. 68, pp. 754-758.

24. Kusumahyuning, R., Soebagyo., Sulihtyowati,

S. 2005. Pengaruh Laktosa dan Povidon dalam

Formula Ekstrak Kaempferia galanga L.

Secara Granulasi Basah. Majalah Ilmu

Kefarmasian. Vol. II, No. 16, 110-115.

25. Lachman, L., Lieberman H.A., Kanig J.L.

1994. Teori dan Praktek Farmasi Industri

edisi III. Jakarta : UI Press.

26. Lieberman, H.A., Lachman, L., Schwartz, J.B.

1990. Pharmaceutical Dosage Forms. New

York : Marcel Dekker.

27. Ncube, N. S., Afolayan, A. J., and Okoh, A. I.

2008. Assessment Techniques of

Antimicrobial Properties of Natural

Compounds of Plant Origin: current methods

and future trends. African Journal of

Biotechnology. Vol 7, pp.1797-1806.

28. Prajogo, B. E. W., A. Khoiril, IGP Santa dan

Soeharno. 1997. Efek Ekstrak Diklormetan

dan Ekstrak Metanol Daun Gendarussa

vulgaris Ness pada Spermatogenesis tikus,

Simposium PERHIPBA IX, Universitas

Gadjah Mada, Yogyakarta.

29. Prajogo, B. E. W., NS. Matty, IGP. Santa and

PS. Onny. 1998. Efek Ekstrak Diklormetan

dan Ekstrak Metanol Daun Gendarussa

vulgaris Ness pada Aktivitas Enzim

Spermatozoa Kelinci. Symphosium

POKJANAS TOI 8 VIII Universitas Brawijaya,

Malang.

30. Prajogo, B. E. W. 2002. Aktivitas Antifertilitas

Flavonoid Daun Gendarusa Vulgaris Ness.

Penelitian Eksperimental Pencegahan

Penetrasi Spermatozoa Mencit dalam Proses

Fertilisasi In Vitro. Disertasi. Program Pasca

Sarjana Universitas Airlangga Surabaya.

31. Prajogo, B. E. W., Dudi, S., dan Mulya, H. S.

2007. Analisis Gendarusin A pada tanaman

Budidaya Justicia gendarussa Burm f. Jurnal

Farmasi Indonesia. 3: 176-180.

32. Prajogo, B. E. W., Pramesti, D., Musta’ina, S.,

Winarso, H., Radjaram, A., Suharjono., Zaini,

N. C., Flourisa, J., Anggraeni, M. 2011.

Clinical Trial: The Use of Justicia

gendarussa Burm. f. as Male Contraception.

APCRSHR 6. Yogyakarta: Indonesia.

33. Prajogo, B. E. W. 2014. Autentik Tanaman

Justicia gendarussa Burm. f. Sebagai Bahan

Baku Obat Kontrasepsi Pria. Surabaya:

Airlangga University Press dengan LP3

UNAIR.

34. Pratama, B. O. 2012. Penentuan Standar

Umum Ekstrak Etanol 70% Daun Justicia

gendarussa Burm. f. Skripsi. Fakultas Farmasi

Universitas Airlangga.

35. Radji, M., Oktavia, H., Suryadi, H. 2008.

Pemeriksaan Bakteriologis Air Minum Isi

Ulang Di Beberapa Depo Air Minum Isi Ulang

6

di Daerah Lenteng Agung dan Srengseng

Sawah Jakarta Selatan. Majalah Ilmu

Kefarmasian, Vol 5(2) : 101-109

36. Rajakumar, N., and Shivana, M. B. 2009.

Ethno-medical Application of Plants in the

Eastern Region of Shimoga Distric. Journal

Ethnopharmacology. Vol 126, pp.64-73.

37. Rizqa, O, D., 2010. Standardisasi Simplisia

Daun Justicia gendarusssa Burm f. Dari

Berbagai Tempat Tumbuh (Daerah

Mojokerto lahan 1, Mojokerto Lahan II,

dan Ponorogo). Skripsi, Fakultas Farmasi

Universitas Airlangga, Surabaya.

38. Rowe, R. C., Paul, J. S., Sian, C. O. 2009. The

Handbook of Pharmaceutical Excipients. 6

th

Ed, London: Pharmaceutical Press and

American Pharmacist Association.

39. Sari, M.A. 2010. Pengembangan Formula

Granul Ekstrak Etanol 70% Daun Justicia

gendarussa Burm.f. Sebagai Sediaan

Fitofarmaka. Skripsi, Fakultas Farmasi

Universitas Airlangga, Surabaya.

40. Staniforth, J. N. 1988. Powder Flow. In:

Aulton, M., Pharmaceutica: The Science

Dosage Form Design, New York: Churchill

Livingstche.

41. Sucker, H. 1982. Test Methods for

Granulates, In Pharm Ind, 44

th

Ed, number 3,

Switzerland.

42. United State Pharmacopoeia Convention.

2003. The United State Pharmacopeia 26-

National Formulary.

43. United States Pharmacopeia Convention.

2002. The United State Pharmacopeia 25-

National Formulary.

44. Wells, J. L. and Aulton, M. E. 1988.

Preformulation, in Aulton, M. E., Editor,

Pharmaceuticals The Sciences Dosage Form

Design. London: Churcill Livingstone.

45. WHO. 1999. WHO Monograph on Selected

Medicinal Plants. Vol.I, Geneva: WHO.

46. Zheng, Jack. 2009. Formulation and

Analytical Development for Low Dose Oral

Drug Products. New Jersey: John Wiley &

Sons, Inc.

Composition Ratio of Lactose and Corn Starch in Granule Capsule Formulation of 70

7