A Wearable Vibrotactile Interface for Unfavorable Posture Awareness

Warning

Christian Lins

1

, Sebastian Fudickar

1

, Alexander Gerka

2

and Andreas Hein

1

1

Carl von Ossietzky University, Oldenburg, Germany

2

OFFIS - Institute for Information Technology, Oldenburg, Germany

Keywords:

Wearables, Vibrotactile Interface, Posture Warning, Occupational Ergonomics, Ergonomics Feedback,

Haptics.

Abstract:

We present the concept of a vibrotactile interface with up to 13 tactors (vibration motors) that are distributed

over the full body to warn industry workers when taking unfavorable postures. The developed system is to

be integrated into a motion capture workwear for industry workers to serve as posture feedback system to

prevent unfavorable or even harmful postures. Such postures are a risk factor for musculoskeletal disorders

(MSD), especially among older adults. We evaluated the vibrotactile system with 11 subjects to identify

the optimal notification vibration sequences (regarding pulse length and repetition) and the accuracy of the

location-dependent perception. Results indicate that the optimal pulse length is about 150 ms and is repeated

2 or 3 times within the sequence for maximum attention.

1 INTRODUCTION

Industry workers regularly perform harmful or dan-

gerous postures during their work shifts (as shown

exemplarily in Figure 1). These unfavorable postures

can – when performed regularly – lead to muscu-

loskeletal disorders (MSD) such as chronic back pain,

especially among workers in the second half of life.

Such MSDs are a primary cause of absence from

work due to illness and early retirement in physically

demanding occupations. According to (Punnett and

Wegman, 2004), MSDs are the most significant cate-

gory of work-related illnesses although a direct com-

parison between countries is difficult. The treatment

of MSDs amounts to considerable costs for the public

health systems of various countries, e.g., the Federal

Statistical Office of Germany reports costs of 420 e

per citizen for the year 2015 (Statistisches Bunde-

samt, 2017; Walker et al., 2003).

Even if the causes of MSDs are not always occu-

pational causes, heavy physical work such as manual

handling and lifting is often considered a risk fac-

tor for the emergence of musculoskeletal disorders

(Amell and Kumar, 2001; Hoy et al., 2010; Matsui

et al., 1997). Thus, prevention measurements be-

come a necessity, e.g., as part of the corporate health

management in industrial companies with physically

hard-working employees.

Figure 1: Shipyard welders working in awkward poses.

It is an ongoing task of the corporate health man-

agement to continuously assess psychological and

physical risk factors of every workplace and every

working individual. For the early detection of such

risk factors for occupational diseases of the muscu-

loskeletal system, a measuring suit that includes 15

distributed intelligent sensor nodes has been devel-

oped (Lins et al., 2015). Each of these nodes incor-

porates a 6-DOF inertial measuring unit (IMU) with

accelerometer and gyroscope that together measure

relative linear and angular acceleration. The measur-

ing suit is integrated into ordinary work clothes to not

interfere with the daily work. The nodes are small,

lightweight and can be cleaned with the work clothes

in industrial washing machines. The collected data of

the inertial sensors can be analyzed by occupational

physicians to derive individual risk factors for MSDs

using specialized software. Additionally, the analyz-

178

Lins, C., Fudickar, S., Gerka, A. and Hein, A.

A Wearable Vibrotactile Interface for Unfavorable Posture Awareness Warning.

DOI: 10.5220/0006734901780183

In Proceedings of the 4th International Conference on Information and Communication Technologies for Ageing Well and e-Health (ICT4AWE 2018), pages 178-183

ISBN: 978-989-758-299-8

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

ing software on the node or central unit can identify

critical postures to give the wearer an immediate feed-

back on her or his possibly harmful postures. Then

the employee might be able to actively take a more

ergonomic pose or interrupt the work for a moment to

recover.

In this work, we present a vibrotactile interface

(VTI) that is integrated into workwear together with

this unobtrusive motion capture sensor suit (Lins

et al., 2015) so that wearers are alerted whenever per-

forming unfavorable postures. Our approach here en-

ables wearers to be aware of potential harmful pos-

tures so that they can decide to improve their pose by

themselves. Most approaches rely on a tight-fitting

connection between the body and the tactile interface

so that it can be assumed that the dampening effect

of the clothes is minimal. This is a valid approach

for a controlled experimental setting. We pursue a

more practical approach and deliberately integrate our

VTI into the loosely-fitting workwear. For such ap-

proach, necessary parameters as well as localization-

dependent perception accuracies are missing, which

we investigate in this work. Also, it is challenging

to integrate a VTI with a non-trivial number of tac-

tors (that are required for sufficient precision) unob-

trusively into the workwear and at the same time make

the system electrically stable, robust and mobile us-

able a full workday. The availability throughout the

day may suffer if the vibration motors are frequently

used as every motor requires 150 mA while vibrating.

Thus, to improve the runtime of the VTI, an energy ef-

ficient (short and recognizable) vibration pattern and

well-suited positioning of the VTIs must be identified.

The outline of this paper is as follows: In Section

2 we inspect some of the related work conducted re-

garding the applicability and efficient use of vibrotac-

tile interfaces. In Section 3, we introduce our concept

and the prototype in detail. In Section 4, we present

the first results of our experiment to identify the opti-

mally perceived vibration parameters (length and rep-

etition of pulse codes) as well suited positioning in

terms of perception accuracy. In Section 5, we dis-

cuss our findings critically and give an outlook and

identify further steps in Section 6.

2 RELATED WORK

Vibrotactile interfaces have been used in various

fields, e.g., to guide people. For instance, (Kerde-

gari et al., 2016) have implemented a helmet for

firefighters that helps them to navigate in smoky ar-

eas. Piateski and Jones have created a tactile display

with a 16-element tactor matrix and have evaluated

different patterns for navigation (Piateski and Jones,

2005). Also, (Alahakone and Senanayake, 2010) and

(Gopalai and Arosha Senanayake, 2011) have devel-

oped and evaluated a back belt containing sensors and

tactile actuators for postural control feedback in reha-

bilitation. In principle, they use inertial sensors to get

the back’s orientation and generate a tactile feedback

with varying strength dependent on the difference in

the optimal back orientation. Carvalho et al. present a

closely fitting system integrated into a vest (Carvalho

et al., 2017). The system incorporates inertial sensors

and tactors and can be used to recognize unfavorable

poses of the spine.

Due to the practicability of tactile interfaces as

an undisturbing notification mechanism, the core pa-

rameters for optimizing tactile interfaces are well

known: These parameters of vibrotactile percep-

tion are amplitude, frequency, timing and location

(Van Erp, 2002). However, coding information by

amplitude variations is difficult because the range be-

tween comfort and pain is small and typically allows

only four different levels (Van Erp, 2002; Brell and

Hein, 2007). While the sensitivity to frequency is

optimally perceived in a range between 150 Hz and

300 Hz (Jones and Sarter, 2008), coding information

through frequency-variations is difficult as only nine

different levels of frequency are recommended for vi-

brotactile interfaces (Van Erp, 2002). Coding infor-

mation in temporal patterns (pulses) gains more pre-

cision if the gap and pulse lengths are at least 10 ms

long (Van Erp, 2002). Kaaresoja and Linjama have

investigated the subjective perception of various pulse

lengths of a vibration motor and found that in this par-

ticular case the ideal pulse length is 50 ms to 200 ms

for getting attention (Kaaresoja and Linjama, 2005).

Longer pulses were perceived as annoying. Spatial

resolutions for vibrations on the skin is at least 4 cm

which should be sufficient for limb-aware warning

(Van Erp, 2002).

Many physiological parameters about vibration

and tactile perception are well known, and a com-

prehensive overview about the spatial and temporal

sensitivity of the human skin is available through Le-

derman (Lederman, 1991).

3 SYSTEM DESIGN

The complete system consists of the Motion Capture

(MoCap) sensor suit integrated into workwear, a De-

cision Support System (DSS), and the Vibrotactile In-

terface (VTI).

A Wearable Vibrotactile Interface for Unfavorable Posture Awareness Warning

179

3.1 Motion Capture Sensor Suit

Technically, the suit consists of 15 sensor nodes in-

corporated in the workwear. The nodes are placed

in the work clothing so that sufficient coverage of

all limbs is achieved. The individual sensor nodes

are connected via a wired bus system with a small

central unit, which makes the necessary calculations

and records the movement data on a memory card.

The cables are integrated with the sensor nodes in the

clothing so that they are usually not noticed by the

wearer. The central unit is about the size of a pack of

cigarettes and can be easily stored in a jacket pocket

(Lins et al., 2015).

Each sensor node consists of two sensors, which

measure the linear acceleration in three dimensions

(accelerometer) and the angular velocity (gyroscope)

(6-DOF IMU). This sensor data of all sensor nodes

are combined by sensor fusion software such that the

movement of the wearer can be derived (Wenk and

Frese, 2015). In contrast to other measurement suits,

the sensors are not directly placed on the skin, which

means that the movement of the limb in the suit and

the wrinkling of the clothing will cause deviations

from the actual movement.

3.2 Decision Support System for

Posture Warning

DSS

Motion

Capture

Data

Posture

Classifier

Vibro-

tactile

Posture

Warning

Figure 2: Basic structure of the decision support system.

Diamond shapes represent input/output data.

To notify workers in case of unfavorable postures,

we aim to integrate a Decision Support System (DSS)

into the sensor suit. The DSS is the software compo-

nent of the vibrotactile feedback system (see Figure

2). It analyses the posture of the suit wearer and gen-

erates pulse sequences at appropriate positions on the

body. In our concept, the DSS does not yet gener-

ate possible alternative poses as in other approaches

but warnings of unfavorable postures. It is more ap-

propriate to train the staff so that it is capable of in-

dependently taking the most sensible posture, instead

of generating alternative postures by an – albeit ad-

vanced – computer system.

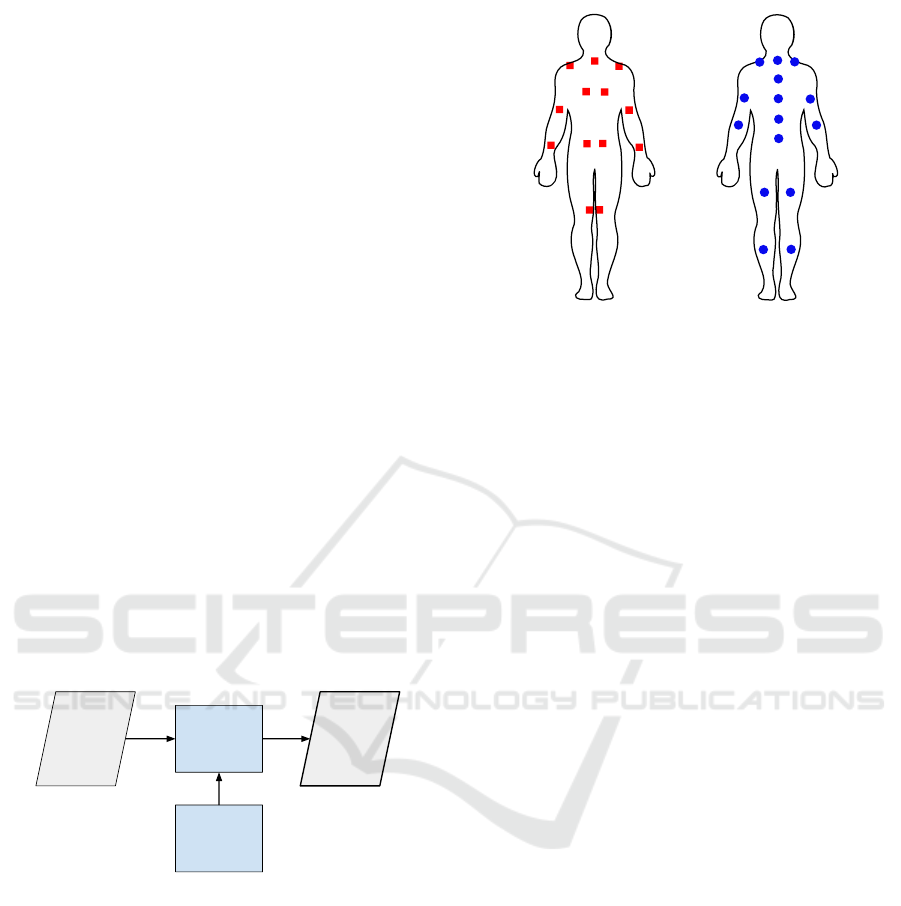

Figure 3: Placement of the tactors (red squares, left) and

motion sensors (blue circles, right) on the body (backview).

The system gets the skeletal motion capture data

from the suit’s sensor fusion component. At first,

the motion data is segmented into both movements

and static postures (Lins et al., 2018). The postures

are then risk rated using a predefined pose classifier,

e.g., based on common posture assessment methods,

in our case the Ovako Working Posture Analysis Sys-

tem (OWAS) (Karhu et al., 1977).

An improved version of the DSS as outlined in

Figure 2 may include a module that can - based on

the posture and the current work - guide the wearer to

a less awkward position through a custom vibrotactile

code. Spelzman et al. have developed such system for

snowboard training (Spelmezan et al., 2009).

3.3 Vibrotactile Interface

Our tactile display used in this work consists of 13

tactors placed next to joints and anatomic references

where the skin is relatively thin and location sensitive

(see Figure 3). The anatomical points for the tactor

placement are the neck, shoulders, elbows, wrists, the

lower end of shoulder blades, left and right of the lum-

bar spine, and on the inner side of the knees. Due

to the possibly higher perception of vibration near

bones, they might be used as a resonance body and

thus strengthen the perception of the vibration.

The vibration motor type used here is a rototac-

tor (type EKULIT VM 0610 A 3.0) that runs at a

fixed vibration frequency of 167 Hz, which is within

the optimal perception range (Jones and Sarter, 2008).

The vibration motors heads can rotate freely. There-

fore they are encased before their integration into the

workwear suit. For this reason, we 3D-printed fitting

plastic caps (see Figure 4 on the right) that cover the

spinning head and most of the motors. The caps are

fixed on the motors, so they are not vibrating within

the caps, but the head can spin freely.

ICT4AWE 2018 - 4th International Conference on Information and Communication Technologies for Ageing Well and e-Health

180

Figure 4: Opened prototype of the central unit (left) and a

vibration motor with its plastic cap (right).

Figure 5: Integration of the tactors into regular workwear.

The complete vibrotactile interface is integrated

into standard industrial workwear (rofa Beklei-

dungswerk) with cable canals and velcro closures for

the tactors. Some tactors are additionally fixed with

tape. Every tactor is connected to the central unit

(see Figure 4 on the left) using phone jack connectors.

Hence it is relatively easy to connect and disconnect

the central unit from the suit.

4 EVALUATION

The experiment aimed to determine the optimal range

of the following two vibration parameters to achieve a

high perceptional accuracy. These parameters are the

number of repetitions n of a single pulse P within a

warning sequence S as well as the optimum length p

t

of these individual pulses (see Figure 6). The pause

interval between pulse repetitions was chosen to be p

t

as well.

The experiments were carried out as part of a short

pilot study with a total of 11 subjects (8 male, 3 fe-

male).

1 2 3

p

t

p

t

Figure 6: A pulse sequence S consisting of one to three

pulses P each having length and pause interval p

t

.

4.1 Experimental Setup

Subjects were standing upright on two legs (OWAS

112) and had to determine the stimulating position.

Throughout the experiment, subjects had to point or

mention the limb (for example ”left shoulder”), which

were perceived as the most prominent source of vibra-

tion. The equality of the perceptions is also a valid an-

swer. The experimenter records the side on which the

subject perceived a stronger or more pronounced vi-

bration and the number of the tactor, which the subject

has perceived. The sequence of the VTI stimulation

positions is defined by a random repetitive vibrational

pattern (generated via pseudo-random number gener-

ator of the Arduino-based central unit) is used to max-

imizes the variance of the tested patterns and elimi-

nate potential biases due to the predictability of vibra-

tion location. To determine the optimal pulse length

and the optimal number of pulse repetitions per alarm

sequence, the central unit has been programmed such

that a random pair of pulses (e.g., knee left and knee

right) are recorded every 10 seconds with a random

pulse sequence. Pulse frequency and amplitude were

constant. The subject wore headphones listening to

pink noise to prevent them identifying the position

based on motor-sounds.

4.2 Results

In total we collected 539 evaluable left-right percep-

tions, each stated as SP = {S

L

, S

R

}, of 11 subjects.

Of these perceptions 306 samples were with a clearly

stronger left or right perception (S

L

> S

R

or S

R

> S

L

),

further called S

max

.

For all S

max

we summarized their number of repe-

titions and pulse lengths (see Table 1 and 2).

Table 1: The ratio of particular pulse sequence repetitions

within the strong perceptions, i.e. how many of the S

max

are

sequences with one, two or three repetitions.

Pulse repetitions 1 2 3

Ratio 22.9% 36.9% 40.2%

Table 2: The ratio of particular pulse lengths within the

strong perceptions, i.e. how many of S

max

are sequences

with pulse lengths of 25, 50, 100 or 150 milliseconds.

Pulse lengths 25 ms 50 ms 100 ms 150 ms

Ratio 12.7% 20.9% 27.8% 38.6%

These preliminary results show that a pulse se-

quence with two or three individual pulses, each with

a pulse length of 150 ms, is most clearly perceived.

This is also in line with the literature values, which

were tested directly on the skin (Van Erp, 2002).

However, the exact position of the vibration could

be localized correctly only in about 60.8% of the

A Wearable Vibrotactile Interface for Unfavorable Posture Awareness Warning

181

cases. The vibrations on the back were difficult to

perceive properly. In particular, the vibration motors

in the lumbar region were not perceived at all. The

reason for this is likely the loose jacket.

84.7%

65.9%

78.9%

74.1%

2.2%

56.4%

Figure 7: Percentage of correct localizations of the differ-

ent tactor groups (shoulders, upper arm, wrist, upper back,

lower back, knees). The values refer two both left and right

side.

Figure 7 shows the accuracy with which the vi-

brations at the individual body positions could be cor-

rectly localized.

5 DISCUSSION

In principle, a vibrotactile interface is suitable for un-

favorable posture warning. However, for the vibrotac-

tile interface, which has been tested here, the place-

ment of the tactors is not yet optimal (about 60% cor-

rect localization). As one can see, the perception is

good at the shoulders and wrists, slightly worse on

the arms and the upper back (see Figure 7). The lower

back tactor integrated into the jacket is not correctly

recognized in nearly every case. Sometimes the sub-

jects report undifferentiated vibrations somewhere on

the back. This is probably caused by the jacket that

is too loosely on the skin. A similar situation is at

the knees but not to this extent. So we can say the

vibrations, which were triggered by tactors close to

the skin, were perceptible in most cases. If the tactor

is only loosely on the skin due to folds or dampen-

ing effects of the fabric, the perception is significantly

worse. This issue is of great importance if the vibro-

tactile feedback should communicate postural change

hints to the wearer. If the VTI is not precise enough to

allow the wearer identify the limbs at risk, a change

hint will not be correctly perceived either.

In our pilot study, we have investigated the ef-

fect of varying the pulse lengths together with length-

adapted pause intervals between two pulses, i.e., p

t

=

pause. The follow-up study should investigate various

pause intervals as well.

Finally, it must be noted that further usability tests

are necessary, especially in combination with the pre-

viously untested connection to the decision support

system, i.e., to address the issue of alarm fatigue

(Wilken et al., 2017).

6 CONCLUSIONS AND FUTURE

WORK

We presented the concept and the first prototype of a

wearable vibrotactile interface (VTI) that is intended

for the usage in occupational environments to warn

its wearer of unfavorable or even dangerous postures.

The VTI can work in conjunction with IMU-based

sensor suits that can capture the motion and postures

of the user.

As a first step towards a closed-loop sensor and

feedback suit for preventing unfavorable postures at

work, we built a prototype of VTI and integrated

it into standard workwear. We conducted a pilot

study to identify the most strongly perceived vi-

bration parameters (length and repetition of pulse

codes). Additionally, we evaluated the location ac-

curacy of the perceived vibrations. We recommend

a pulse sequence of two 150 ms pulses for posture

warning. A third pulse would not increase the per-

ceptions much but cost additional energy. A pulse

length of 200 ms could improve the perception of an

alert, which should be verified in an additional study.

Longer pulses would probably irritate the users as

noted by Kaaresonja and Linjama (Kaaresoja and Lin-

jama, 2005).

Our findings indicate that the accuracy of such

VTI within the workwear vary substantially on the

body, so we propose changes for an improved version

of the VTI. First, the tactors of the lumbar back must

be integrated into the waistband of the suit’s trousers,

because the current placement on the jacket’s back has

proved itself practically useless (see 2.2% in Figure

7). Then, the number of tactors on the back can be re-

duced to minimize the complexity of the system in re-

gards to cabling. Finally, we will investigate the pos-

sibility to encode guidance information through vi-

brotactile codes (pulse lengths, repetitions, and varia-

tions in the pause interval), which guide users to better

ICT4AWE 2018 - 4th International Conference on Information and Communication Technologies for Ageing Well and e-Health

182

manual handling and avoidance of constrained pos-

tures.

ACKNOWLEDGMENTS

This work was partly funded by the German Ministry

for Education and Research (BMBF) within the joint

research projects SIRKA (grant 16SV6243). The au-

thors would like to thank all participants who par-

ticipated in the experiment. The photographs of

Figure 1 are used with courtesy of Meyer Werft

GmbH & Co. KG, Papenburg, Germany. This work

was additionally supported by the funding initiative

Nieders

¨

achsisches Vorab of the Volkswagen Founda-

tion and the Ministry of Science and Culture of Lower

Saxony as a part of the Interdisciplinary Research

Centre on Critical Systems Engineering for Socio-

Technical Systems II.

The authors would like to thank the anonymous

reviewers for their helpful comments.

REFERENCES

Alahakone, A. U. and Senanayake, S. M. N. A. (2010). A

real-time system with assistive feedback for postural

control in rehabilitation. IEEE/ASME Transactions on

Mechatronics, 15(2):226–233.

Amell, T. and Kumar, S. (2001). Work-related muscu-

loskeletal disorders: Design as a prevention strategy.

a review. Journal of Occupational Rehabilitation,

11(4):255–265.

Brell, M. and Hein, A. (2007). Positioning tasks in mul-

timodal computer-navigated surgery. IEEE MultiMe-

dia, 14(4):42–51.

Carvalho, P., Queir

´

os, S., Moreira, A., Brito, J. H., Veloso,

F., Terroso, M., Rodrigues, N. F., and Vilac¸a, J. L.

(2017). Instrumented vest for postural reeducation. In

5th International Conference on Serious Games and

Applications for Health. IEEE.

Gopalai, A. A. and Arosha Senanayake, S. M. N. A. (2011).

A wearable real-time intelligent posture corrective

system using vibrotactile feedback. IEEE/ASME

Transactions on Mechatronics, 16(5):827–834.

Hoy, D., Brooks, P., Blyth, F., and Buchbinder, R. (2010).

The epidemiology of low back pain. Best practice &

research Clinical rheumatology, 24(6):769–781.

Jones, L. A. and Sarter, N. B. (2008). Tactile displays:

Guidance for their design and application. Human

Factors, 50(1):90–111. PMID: 18354974.

Kaaresoja, T. and Linjama, J. (2005). Perception of short

tactile pulses generated by a vibration motor in a mo-

bile phone. In First Joint Eurohaptics Conference and

Symposium on Haptic Interfaces for Virtual Environ-

ment and Teleoperator Systems. World Haptics Con-

ference, pages 471–472.

Karhu, O., Kansi, P., and Kuorinka, I. (1977). Correcting

working postures in industry: A practical method for

analysis. Applied Ergonomics, 8(4):199–201.

Kerdegari, H., Kim, Y., and Prescott, T. J. (2016). Head-

mounted sensory augmentation device: Designing

a tactile language. IEEE Transactions on Haptics,

9(3):376–386.

Lederman, S. J. (1991). Skin and touch. Encyclopedia of

human biology, 7:51–63.

Lins, C., Eichelberg, M., R

¨

olker-Denker, L., and Hein,

A. (2015). SIRKA: Sensoranzug zur individu-

ellen R

¨

uckmeldung k

¨

orperlicher Aktivit

¨

at. In 55.

Wissenschaftliche Jahrestagung 2015 der Deutsche

Gesellschaft f

¨

ur Arbeitsmedizin und Umweltmedizin

e.V., M

¨

unchen, pages 301–303. Deutsche Gesellschaft

f

¨

ur Arbeitsmedizin und Umweltmedizin (DGAUM)

e.V.

Lins, C., M

¨

uller, S. M., Gerka, A., Pfingsthorn, M., Eichel-

berg, M., and Hein, A. (2018). Unsupervised temporal

segmentation of skeletal motion data using joint dis-

tance representation. In Proceedings of the 11th Inter-

national Joint Conference on Biomedical Engineering

Systems and Technologies (BIOSTEC/HEALTHINF

2018). SCITEPRESS Digital Library.

Matsui, H., Maeda, A., Tsuji, H., and Naruse, Y. (1997).

Risk indicators of low back pain among workers in

japan: association of familial and physical factors

with low back pain. Spine, 22(11):1242–1247.

Piateski, E. and Jones, L. (2005). Vibrotactile pattern recog-

nition on the arm and torso. In First Joint Eurohaptics

Conference and Symposium on Haptic Interfaces for

Virtual Environment and Teleoperator Systems. World

Haptics Conference, pages 90–95.

Punnett, L. and Wegman, D. H. (2004). Work-related mus-

culoskeletal disorders: the epidemiologic evidence

and the debate. Journal of Electromyography and Ki-

nesiology, 14(1):13 – 23. State of the art research

perspectives on muscoskeletal disorder causation and

control.

Spelmezan, D., Jacobs, M., Hilgers, A., and Borchers, J.

(2009). Tactile motion instructions for physical ac-

tivities. In Proceedings of the SIGCHI Conference

on Human Factors in Computing Systems, CHI ’09,

pages 2243–2252, New York, NY, USA. ACM.

Statistisches Bundesamt (2017). Krankheitskosten: Kosten

2015 nach Krankheitsklassen und Geschlecht in Euro

je Einwohner.

Van Erp, J. B. (2002). Guidelines for the use of vibro-tactile

displays in human computer interaction. In Proceed-

ings of eurohaptics, volume 2002, pages 18–22.

Walker, B., Muller, R., and Grant, W. (2003). Low back

pain in australian adults: the economic burden. Asia

Pacific Journal of Public Health, 15(2):79–87.

Wenk, F. and Frese, U. (2015). Posture from motion. In

2015 IEEE/RSJ International Conference on Intelli-

gent Robots and Systems (IROS), pages 280–285.

Wilken, M., H

¨

uske-Kraus, D., Klausen, A., Koch, C.,

Schlauch, W., and R

¨

ohrig, R. (2017). Alarm fatigue:

Causes and effects. Studies in health technology and

informatics, 243:107–111.

A Wearable Vibrotactile Interface for Unfavorable Posture Awareness Warning

183