The Utilization of Solar Cell System Design in the Ship

Danny Faturachman

The Faculty of Ocean Technology, Darma Persada University

Keywords: Energy saving, Ferry, Mechanical cooling system, Lightning equipment, Solar Cel

Abstract: Utilization of solar energy as solar photovoltaic plant in the engineering as a source of electrical energy to

produce no pollution, air pollution and pollution on the surrounding environment. The basic ingredients of

photovoltaics is solar cell. The use of solar cell on a vessel can be used as energy in a variety of electrical

equipment on the ship, due to the relative abundance of Sun energy and never run out because the Sun bathes

the territory Indonesia 10-12 hours a day. In this case the solar cell used to meet the needs of the mechanical

cooling equipment on board the ferry that sails around the region of Indonesia. Expected usage of this solar

energy can reduce the use of fossil fuels oil and can save on operational costs. In this paper will show the

usage of solar cell in the ship for mechanical cooling system and for lighting equipment. All the needs of

electrical power in supply from batteries being replenished by solar panels. Solar power become one of

alternative energy to overcome the presence of the energy crisis especially a reduction in the availability of

petroleum and the more expensive world oil prices. Major problems focused on design of electric system as

power plant resources in the ship. We will see the calculation for solar cell system design for mechanical that

the investment for purchase a solar cell will be more efficient than motor diesel and also that solar cell also

can be used for power lighting in the ship and can saving almost 52.5% by 52.5 % of the generator burden.

1 INTRODUCTION

Be advised that papers in a technically unsuitable

form will be returned for retyping. After returned the

manuscript must be appropriately modified.

There are a variety of alternative energy could be

developed include coal, natural gas, geothermal,

biomass, hydro, wind, wave, solar and nuclear. From

some of the alternative energy, are classified into two

groups, the energy is not renewable and renewable

energy. Renewable energy not including consists of

petroleum, coal, nuclear and gas. While including the

kind of renewable energy include geothermal,

biomass, water, wind, solar, wave and others that are

still open. Renewable energy has the potential to be

superior in comparison to fossil energy. There are

several underlying reasons among others due to the

build-up of the infinite, renewable and

environmentally friendly. Solar energy, water, wind,

biomass, Ocean and other alternative energy sources

are available in abundance in nature, whereas it is

used still little. Remember the sunshine all year round

for availability, then it is right if the solar energy is

harnessed as a provider of electrical energy. With the

layout of the equatorial regions are on Indonesia,

which is at a latitude of 60 North Latitude and 110

South Latitude and 950 East Longitude and 1410 East

Longitude and having regard to the circulation of the

Sun in a year in the area of 23.50 North Latitude and

23.50 South Latitude and the territory of Indonesia

will always in sunlight for 10 until 12 hours in a day.

Because of the layout of Indonesia are on the Equator

then Indonesia has solar radiation level that falls on

the surface of the Earth Indonesia (especially the

West part of Indonesia) averaged approximately 4.5

kWh/m2 monthly variation of about 10%

(Faturachman, et.al, 2013).

The need for increasing energy and depleting

reserves of oil, forcing people to look for alternative

energy sources. Developed countries have also

competed and raced the latest breakthroughs to search

a creating new technologies that can replace

petroleum as an energy source. Depleting his supplies

of energy and also the dependence on one type of

energy in which the fuel oil is very huge and almost

all sectors of life using this fuel, while fuel oil Is a

commodity exports dominant to state revenues. In the

utilization solar energy in Indonesia as an equatorial

and tropical areas with the land area of almost 2

million sq km, endowed with irradiating the sun more

than six hours a day or about 2,400 hours in a year.

Solar energy on Indonesia have intensity between 0.6

Faturachman, D.

The Utilization of Solar Cell System Design in the Ship.

DOI: 10.5220/0010039501290137

In Proceedings of the 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and Technology (ICEST 2018), pages 129-137

ISBN: 978-989-758-496-1

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

129

- 0.7 kW / m2 how its abundance of energy most

wasted this. For solar energy utilization attempts

Indonesia has various advantages such as:

• The energy is available with large numbers in

Indonesia.

• Strongly support the national energy policy of

austerity.

• Verified and equitable energy.

• Allow built in remote areas because it does not

require the transmission of energy or

transportation of energy resources.

• Solar energy is an environmentally friendly

energy source.

While in Indonesia should actually solar cells get

special attention, this because indonesia which is the

tropics and is in the equatorial region and indonesia

has the characteristics of the wind to a less well ( very

fluctuates ) in an appeal with the characteristics of the

wind in the western countries but it was very

profitable to solar energy average get a sunburn six

hours a day on the weat. An effort to search for new

energy sources should meet requirement that produce

the amount of energy quite strong the cost of

economical and not have a negative impact on the

environment. Hence search- are in direct in the use of

solar energy either directly or indirectly by the use of

a panel that solar cell that can change solar energy

into electrical energy in call of solar cell are very

supportive (Shariman, et. all, 2014).

Solar cells or in the international world is more

known as a solar cell or photovoltaic cell, is a

semiconductor that has a surface of divasi and consists

of a series of p and n type diodes, which able to

convert the energy of sunlight into electrical energy.

Figure 1. Solar Cell

Solar Cell application in Marine Engineering:

1. The use of solar cells on a supertanker.

2. Solar boat.

3. Japan first cargo ship sets.

Figure 2. Solar Cell in Tanker

To build a solar energy system (photovoltaic) that

can operate properly then needed some major

constituent components are: a. the Solar Panel, b.

Charge controller, c. Inverter, d. Battery.

Photovoltaic (PV) is the technology that serves to

change or convert solar radiation into electrical

energy directly. The word is derived from the

language of Greece, photos which means light and

volt mean voltage. PV is usually packaged in a unit

called the module. In a solar module consists of many

solar cells that can be arranged series or parallel.

Whereas the definition of solar is a semiconductor

element that can convert solar energy into an electric

photovoltaic effect on the ground. The core of PV job

is edit or convert energy from solar radiation into

electrical energy. Some of the components used is a

semiconductor element called solar cells, and then

organized into a solar module.

Solar systems photovoltaic common worn for

lighting is a system individuals or that more often

known as the solar home system (SHS). This system

has voltage 12 V dc, consisting of one module

photovoltaic, batteries, instrument controller and 3

lamp and a stop contact. (Abu Bakar, 2006).

Figure 3. Module Solar Cell System Block

Diagram

From the diagram above can explain that the

energy in sunlight into electrical energy by the

convert module will be channeled to a charge

controller to adjust the charging electrical energy in

the battery. From this controller charger can also

directly use to load DC or go directly to the inverter

to change the current air conditioning Next electrical

energy in the battery will generate in convert by direct

current (DC) to alternating current (AC) so it can be

used in the load.

Charge of controller on the system (solar power

stations) can as a brain because of their functions as

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

130

officers electric current good against the current

enters or current out / used.

Inverters in principle, photovoltaic generates a

current of DC (unidirectional). When the required AC

currents (alternating), then it can be met by installing

a tool modifiers, electronic equipment that works

very efficiently is called an inverter. Inverter

specification is not the same i.e., depending on the

extent of the power consumption of the entire

electrical equipment. The greater the need for power,

then the power inverter capacity also grew.

Battery is a device that converts the chemical

energy directly into electrical energy. A battery

consisting of voltaic one or more cells and every

voltaic cell consisting of two half cells connected in

series by electrolyte conductive containing the anion

(negative ions) and cation (positive ions). In

oxidation reaction reduction, battery power reaction

reduction (the addition of electrons) to cation

happens, at the cathode while oxidation reaction

(electrons deleted) to anion happening anode.

Electrodes not interconnected, but connected

electrically by an electrolyte which may be either

solid or liquid. Battery is a source of electricity

obtained through a chemical process to get electrical

energy by long time it takes plate positive and

negative plate enough. Positive and negative plate

prepared gregarious then sealed each other and made

no relation one against another.

2 PROBLEM STATEMENT

In the utilization of solar energy photovoltaic are used

to directly convert solar energy into electrical energy.

The use of photovoltaic energy plants as a source of

electricity can be said to produce no pollution, air

pollution and noise pollution to the surrounding

environment. Based on these considerations, it

appears that photovoltaic conversion of sunlight into

electrical energy will be the main energy source in the

future. In addition, the price of conventional energy

sources will continue to be higher and its preparation

is also very limited, while photovoltaic prices

gradually going down as a raw material abundant on

the Earth. Electrical energy is generated from

photovoltaic can be used for a variety of uses. And to

ensure the continuous provision of energy is then

used as energy storage batteries. Electric motors

become increasingly practical and economically after

the number of discoveries on the technology of solar

panels, battery and charger are better. Electric motor

maintenance and cost effective in the work.

For solar panel treatment more easily enough

cleaned once a week. Installation of electric motors is

simpler and also does not require refrigeration. All

electrical power needs in the supply from the battery

is recharged by solar panels. With this system is

expected to reduce fossil fuels. But now the problem

is confined to the ship, and to apply this system

needed a place. In this final project will examine the

effectiveness of solar cells. Where the obtained

results expected are references to the ability of solar

cells in generating electrical energy where the final

result is expected to be aware concerning the

efficiency of solar cells.

The need for electricity in a ship must provide by

the generator and its immense power available is very

dependent on operational the ship. The generator

choices is specialized of idealizing systems in this

role for planning because it involves tecno-economy

problem. The requirement or common rules

electricity a ship between other:

1. Supply electricity to vessels needs. System neutral

body of ship grounded on may not except:

Zinc anode protection system must be a

cathode or the outer part body of ship;

System limited or local ground as system

starting and starting motor in motor fuel

combustion;

A measuring monitor insulator instrument to

the current that circulated no more than 30 mA

in the worst of conditions;

High voltage neutral ground to avoid

dangerous areas were defined in requirements.

2. Power supply and distribution.

Generator, switch board and battery must be in

a separate location from the fuel tank and oil

pump, with a cofferdam or with sufficient

distance.

Cable that may be open to steam and gas needs

to be protect with insulation in accordance,

with the possibility of reducing corrosion.

Some requirements in the form of cable for

installation on board based on the position where the

cables will be placed, adapted to the structure of the

ship so that the installation and buffer plate avoid of

strains/stresses possibility. Stages of electricity ship

system from the genset generator with his drive that

serves as power plants that supply all the needs of

electric power on board. Then the flows in the

channel generate main switch board (the main liaison

panel) which is a main panel that combines the power

of some existing genset for distributed the junction

was then in the forward to all components of each

junction. Junction power is a terminal of some

The Utilization of Solar Cell System Design in the Ship

131

existing equipment on board that require a three-

phase electric power:

a) Junction lighting is a terminal for the power

supply to be used as a means of lighting

(lights) on the ship.

b) the Junction is a communication terminal for

the power supply being used as

communication tools on board.

c) Monitoring the terminal Junction is to supply

electric power to be used as a monitoring tool.

After using the genset, ships can use the power of

the land through shore connection which is usually in

use at the time of the ship's docking. If the genset is

not active then the emergency source of electrical

power (power source) is usually in the form of

battery. Due to the nature of the emergency then only

certain equipment and very important in the supply

by the emergency source of electric power for

example his lights, lamps, navigation, gangway

lighting appliances, and others. Emergency power

source will be stored automatically through the

emergency switch board if all the genset is not active.

3 RESULT

3.1 For Power Lightning Equipment

The following are the main data from the main

Ferry Ro-Ro 500 GRT:

Length Over All LOA = 45,05 m

Length between Perpendicular LPP = 40,15 m

Length of Water Line LWL = 42,00 m

Breadth B = 12,00 m

Height H = 3,20 m

Draft T = 2,15 m

Velocity Vs = 11 knot

Main Engine = 2 × 800 HP

Auxiliary Engine = 2 × 80 kVA

Gen set emergency = 25 kVA

Power lighting needs:

a) For the main lighting lights used fluorescent and

neon lights.

b) For emergency lighting lamps mounted at the

steering wheel, desk maps, alleys, stairs, engine

room, and locations that are considered important

or in accordance with the requirements of the

BKI.

c) Lighting lights for engine room, bathroom/toilet,

kitchen and rooms open from types that are

waterproof (water tight).

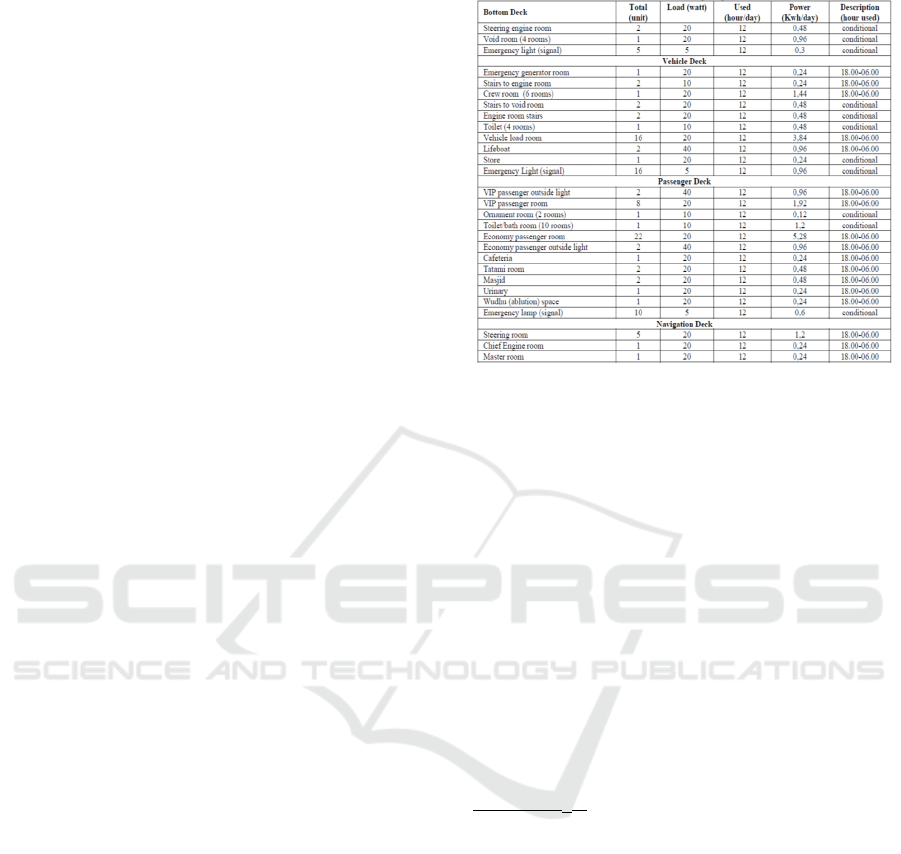

Table 1. Power lighting needs

Solar cell specification:

FV Energy, FVG 240P − MC:

Power peak : 240 W

Efficiency : 14,6 %

Tension module : 30,50 V

Current module : 7,88 A

Open circuit tension : 37,60 V

Short circuit current : 8,28 A

From the selection of the solar panels, it can be

calculated how many pieces of solar panels needed to

meet the needs of power for lighting load. For

conditions in Indonesia, even though the duration of

the sun shines for 8 hours/day (08.00-16.00), but the

effectiveness of the photon beam obtained solar

panels during the day is 5 hours. Thus the number of

panels to meet the needs of power of 33600 W

h

as

much:

33600 W

h

= 28 solar cell

240 W x 5 hr

In this case will be installed as many as 35 solar

panels, where the addition of a number of solar panels

as much as 7 units as backup power when the solar

intensity less than 1000 W/m2. With extensive

consideration of the deck platform is still able to

accommodate the number of solar panels, in addition

to the power generated will be greater or in other

words the addition of solar panels directly also adds

to the amount of power generated. The amount of

power generated by the solar panels in one hour: 35

hours x 240 Watt = 8400 Watt hour. The amount of

power generated by the solar panels is in 5 hours is:

8400 W x 5 hours = 42000 Watt hour = 40 kWh of

solar panel quantity, then solar panels chosen is FV

energy, FVG 240P-MC model with consideration to

address the needs of the power load of information. It

has solar panels power largest so enough to area on

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

132

the bridge deck 20 m x 8 m = 160 m

2

and is installed

with a slope of 150.

From the regulator or charge controller

specification that is, the maximum current that can be

issued charge controller is 60.0 Ampere. Whereas

current generated by a solar panel voltage with a

30.50 volt is 7,88 Ampere, so one charge controller is

used only for: 60/7.88 = 7 units of solar panels. Total

charge (n) = total amount solar panel/7 = 5 units.

Output current for 1 charge controller:

I = 7,88 A × 7 solar panel

= 55,16 A ( maximum current released by charge

controller 60,0 A )

Output for 6 charge controller:

I

output

= I × (n)charge

= 60 A × 5

= 300 A

Charger capacity = output charge current × total

charger × used time

= 60 A × 5 × 12 hours

= 3600 Ah

Power produced for 5 chargers :

I

output

= 300 A

V

output

= 12 V

Power = I

output

× V

output

= 300 A × 12 V

= 3600 Watt = 3,6 kW

To ensure that the system can operate properly

and in accordance with good and suits the needs of

load need planned design of the battery system. Note

the overall burden of the solar panels of 42 kW

h

battery planned to use Marine Batteries, Rolls Series

5000 type with a capacity of 370 A

h

(according to

spec). The resulting power battery:

Battery power = battery capacity × battery voltage

= 357 A

h

× 12 V

= 4284 W

h

= 4,284 kW

h

Total battery for needed the total power 42 kW

h

:

Total battery (n) = total power / power battery

Total battery (n) = 42 kWh / 4,284 kWh = 9,80 ≈ 10

units

Battery capacity for 8 units :

Q

total

battery = 357 Ah × 10 units

= 3570 Ah

Battery power :

Battery power = 3570 A

h

× 12 V

= 42840 W

h

= 42,84 kW

h

After determining the number of batteries

required, the next step is to calculate the length of use

of the battery. Where known:

Battery capacity = 357 A

h

Battery voltage = 12 Volt

Long Used = 12 hours

So:

Power per hour = battery power / long used

= 357 A

h

x 12 V

12 hours

= 357 W

h

Battery used = power battery / power per hour

= 357 A

h

x 12 v

357 W

h

= 12 hours

Battery charge = battery power x total battery

solar cell over all power

= 357 A

h

x 13 V x 10 batteries

42000 watt

= 1.02 hour

In the design of this solar panel system, the current

is generated from solar panels is direct current or DC

(Direct Current). While the current required for the

lighting system is current on his boat back and forth

turning or AC (Alternating Current). To change the

DC to AC inverter needed inverter. Planned use of

Xantrex inverter sine wave type, then the number of

inverters needed is:

Number inverter = solar cell overall power/ power

output inverter

= (42000 W)/(4000 W) = 10, 5 ≈ 11

units

In the plan the placement of solar panels on the

deck of the bridge and the solar panel system

components in the void or empty space under the deck

of the vehicle with a total area of 12.4 m x 12 m =

148,8 m

2

. As for the number of each component and

its size:

a) Charger controller, amount: 5 unit, dimensions:

37 cm x 15 cm x 15 cm, weight: 0.45 Kg/unit

b) Battery (12 Volt 74 A

h

), amount: 10 unit,

dimensions: 55.9 cm x 17.8 cm x 6 cm, weight:

123.4 Kg/unit

c) Inverter amount: 11 unit, dimension: 53.4 cm x

38,1 cm x 22,86 cm, weight : 16 Kg/unit

Then the total weight of the whole solar system of

solar panels and other components in the

completeness of 2054.75 Kg.

3.2 Power Need Analysis for Cooling

System

Words like “is”, “or”, “then”, etc. should not be

capitalized unless they are the first word of the title.

Power need for the ship's cooling system Ro-Ro

ferry is used for Steering Room, Passenger Rooms,

Cabin Crew Rooms and the Control Room, installed

air conditioning (AC) machine in the form of AC

The Utilization of Solar Cell System Design in the Ship

133

Split in each room. AC Blower must be arranged so

that every part of the room to get the same

temperature influence. Engine/generator AC should

be placed outdoors and protected from direct weather

influences and the sea air or given a construction for

protection against the weather. For AC generators

placed on vehicle load space must be given a

protective fender, or construction to protect the

generator from the possibility of a collision with a

vehicle.

Specifications for AC and its placement are:

- The engine control room : 1 x ½ PK

- Medical Room : 1 x ½ PK

- Mess Room : 1 x ½ PK

- Captain and Engine Room Operators : 1 x ½

PK

- Mosque Room : 1 x ½ PK

- Passenger Executive Room : 4 x 1½

PK

There are 3 factors to consider when determining

the need for PK of AC power conditioners, namely

AC power (BTU/hour), electrical power (Watts), and

PK of the AC compressor. Actually number PK on

AC power is a unit on the AC compressor, not AC

cooling power, so to decide on the power need, we

must look from the specification of AC.

Table 2. Power Need

Room’s

Name

Unit AC

Power

( PK)

AC

Power

(BTU/h)

AC

Power

(Watt)

Engine

Roo

m

1 1/2 ± 5000 220

Captain &

Engine

Room

Operato

r

1 1/2 ± 5000 220

Passenger

Executive

Roo

m

4 11/2 ± 12000 1560

Medical

Roo

m

1 1/2 ± 5000 220

Mosque

Roo

m

1 1/2 ± 5000 220

Mess

Roo

m

1 1/2 ± 5000 220

Total 2660

According to the table 2, it needs power for air

conditioner on board during the cruise of 10 hours is

2660 x 10 = 26,600 W 26.6 Kwh.

In determination of solar panels which will be

used, there are parameters that serve as a reference.

The parameters in selection solar panels are:

General rule in passenger vessels. It is used as

a reference by which solar panels this can be

mounted on board, because not all parts of a

passenger ship can be mounted by solar

panels.

Room available on a passenger ship. Solar

panels selected for planning power plant will

be adjusted with a common plan (general

arrangement) a vessel ferry Ro-Ro, so they

will be known how many panel that can be

attached on board.

Based on data of the irradiating sun from several

locations in Indonesia, solar radiation in Indonesia

can be classified as follows [9]:

to western region Indonesia around 4.5

kwh/m

2

day with variations monthly about

10%.

to eastern Indonesia around 5.1 kwh/m

2

day

with variations monthly about 9 %.

wind speed average in Indonesia about 4.8

kwh/m

2

day with variations monthly 9 %.

From calculation of the total solar module above

then we chosen brands of solar cell to be used is type

FVG 240P – MC with the specifications:

Power peak : 240 watt peak

Efficiency : 14.6 %

Voltage of module (max) : 30.50 V

Current of module (max) : 7.88 A

Current of short circuit : 8.28 A

Voltage open circuit : 37.60 V

Dimension : l × b × h

(1650 × 990 × 35) mm

From selection of the solar panels, it can be

calculated how many pieces of solar panels needed to

meet the power for cooling load. For conditions in

Indonesia, even though the duration of the sun shines

is 8 hours/day, but the effectiveness of the photon

beam obtained solar panels during the day is only 5

hours.

With so many panel to meet the needs of power

equal to 26600 watt as many as the efficiency of solar

panel hence: 240 x 14.6 % = 204.96 W.

The number of panel = (26.600 Wh) / (204.96 W

x 5 hour) = 25,956 ≈ 26 solar panels. This solar panel

will be installed as many as 26 solar panels with

consideration of the bridge deck is still able to

accommodate the number of solar panels, Besides all

the power produced will be higher than or in other

words the number of solar panels directly also

increased the amount of resources resulting.

The amount of power generated by the solar panel

in 1 hour is: 26 x 204.96 Watts = 5328.96 Wh. The

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

134

magnitude of the power generated by the solar panels

all over in 5 hours is: 5328.96 x 5 = 26644.8 Wh.

Then solar panels chosen is FVG 240P-MC model

with consideration to address the needs of load power

lighting. It has solar panels, power and sufficient for

the largest area on the deck of the bridge 20 x 8 = 160

m

2

.

For the placement of solar cell will be placed on

deck wheel house and the installation is done in

parallel in order to optimize the absorption of solar

energy.

Figure 4. The Placement of Solar Panel in Deck House

From the existing controller charger

specifications, the maximum current that can be

issued charger controller is of 60 A. Whereas current

generated by a solar module with voltage of 30.5 V is

7.88 A. So that one charger controller was only able

to be used for 7 pieces of solar modules.

The number modules of 1 charger = (charger

power) / (power module) = 60/7.88 = 7.61 7 pieces,

so for 1 charger controller accommodates up to 7

panels.

To determine the amount of controller charger:

charger = (number of modules) / 7 = 1/7 = 3.28 4

controller charger.

Current output for 1 charger controller:

l = 7.88 x 7 = 55.16 A (the current maximum of 60 A

controller charger issued)

Current output 4 controller charger for 10 hours :

o

utput

= l x (n) charger = 60 x 4 x 10 = 2400 A

The Total power generated by charger controller: 60

× 4 × 24 V = 5760 Watt

To determine the battery used:

Battery capacity = 1104 Watt, battery voltage = 4

Volt.

Battery current: 1104 x 4 = 4416 Wh 4,416 Kwh

Then the number of batteries needed to load total:

Number of the battery = (total load needs) / (battery

power) = 26600/4416 = 6.023 6 battery

Battery capacity for 6 units is: Q

batt

= 1104 x 6 = 6624

Ah

Total battery capacity is: Q

tot

= 6624 bat x 4 = 26496

Wh = 26.496 KWh

Battery charging time = (battery power) / (power

solar cell)

= (1104 x 4 x 6)/(26 x 204,96) = 4.97 hour.

Battery operating Time = (operational length of

battery power)/(total load power that needs)

= (26496 x 10)/26600 = 9.96 h.

In designing this solar cell system, the current

resulting from the solar module is the current DC.

While the current that is used to drive the compressor

using the flow of AC current to change DC, needs

inverter current. Planned use type XANTREX model

SW3024E with the specification:

- Power : 3300 watt

- Voltage : 24 V

- Efficiency: 94%, so 94% x 3300 watt = 3102 watt

The amount of inverter need:

Total inverter = Inverter produced / Inverter power

= 26644.8 / 3102

= 8.59 ≈ 9 inverter

The amount of resources which are borne generator

is:

VA = 80,000 – 26,496 = 53,504 the amount of power

and the savings could be done is:

Saving energy = (the load early - the load after) / (the

load early) x 100 %

= 80,000 / 53,504 x 100 % = 1.49 %

Analysis of driving force system between diesel

engine and solar cell:

Ship propulsion system component:

with motor diesel:

- 1 unit auxiliary 80 kVA

- Tool kit engine

with solar cell:

- Use solar cell 26

- 4 controller charger

- 6 battery

- 9 inverter

The calculation of fuel consumption using generator

power planned 80 kVA, for 10 hours cruise:

W

fo

: 80 x 210 x 10 x 10

-6

x 0.6 = 0.1008 tons

The volume of fuel:

W

fo

/ γ

fo =

0.10 / 0,85 = 0.11 m

3

= 110 liter

The price of diesel fuel for the total fuel shipping is

110 liter and the price of 1 liter of marine diesel is Rp

8,500,-

The calculation for motor diesel:

Investment for the purchase of diesel

- Generator 1 unit: Rp. 43.000.000,

- Tool kit-engine 1 set: Rp. 2,000,000,-

The Utilization of Solar Cell System Design in the Ship

135

Operations:

The fuel for the 5 trip for 1 day needs 110 liters.

- 1 day cruise 110 liters x Rp 8,500 = Rp 935,000

- For a year Rp 935,000 x 365 days = Rp. 341,275,000

- For 5 years Rp. 341,275,000 x 5 =: Rp.

1,706,375,000,-

- For 10 years = Rp. 1.706.375.000,-

For 10 years usage performed 4 times engine

maintenance and costs Rp 6,000,000 x 10 : Rp

60,000,000.-

Investment for the purchase of solar cell:

- Using 26 units solar cell @ Rp.

3,139,500- = Rp. 81,627,000,-

- 4 pieces charger controller @ Rp.

6,490,000,- = Rp. 25,960,000,-

- 6 batteries @ Rp. 9,093,500,- = Rp. 54,561,000,-

- 9 inverter @ Rp. 34,950,000 = Rp. 314,550,000,-

- 1 tool kit set engine: Rp. 2,000,000,

Operational battery backup 6 pieces @ Rp.

9,093,500,- = Rp. 54,561,000,-

Maintenance costs for 10 years @ Rp. 2,000,000/yrs

= Rp. 20,000,000,-

Table 3. Total Investment

Yea

r

Generato

r

Solar cell

1 R

p

. 341,275,000,- R

p

. 434,329,500,-

5 Rp.1,706,375,000,- Rp. 10,000,000,-

10 Rp.1.706.375,000,- Rp. 20,000,000,-

After 10

y

ears

Rp. 60.000.000,- Rp. 54,561,000,-

Total Rp. 3,814,025,000,- Rp. 553,259,000,-

4 CONCLUSIONS

1. From an analysis of existing loads needs, the design

of utilization of power lighting equipment on the 500

GRT Ferry needs:

a) Early loads generator = 80 kVA

b) Necessity after loads = in because of loads

42000 VA supplied by solar system, that

generator load is:

80000 - 42000 = 38000 VA = 38 kVA

c) Energy savings can be done is:

= early load – after loads × 100 %

= × 100 %

= 52,5 %

d) The amount of a solar panel that can be

mounted on the deck of the bridge with a

total area of 160 m2 as much as 35 solar

panel considering the rules applicable to the

Ro-Ro Ferry ships.

e) The other amounts is: 5 unit charger

controller, 10 unit batteries, and 11 unit

inverter.

2. Total overall resources for 5 trips Merak-

Bakaheuni cruise trip is 26.6 kWh. This value is

calculated based on 1 trip cruise for 2 hours. Based on

the data above, the planning of solar cell for the

cooling system are as follows: The module used is

type FVG 240 P-MC with:

a) Power peak specifications: 250 Watts

b) Efficiency: 14.6%

c) Voltage module (max): 30.50 V

d) Flow module (max): 7,88 A

e) Short circuit Currents: 8,28 A

f) Open circuit Voltage: 37,60 V

g) Dimensions: p l t (1650 x 990 x 35) mm

h) Output power panel : 204,96 Watts

The amount of the planned solar cell is 26 units

with the effectiveness of the Sun for about 5 hours, so

that the total power output is obtained by 26,496

kWh. The overall surface area of panels for

installation planning 37,57 m

2

solar cell placed on the

wheel house decks with a total area of 160 m2.

ACKNOWLEDGEMENTS

If any, should be placed before the references section

without numbering.

REFERENCES

Allocca, A. John, “Emergency Power”, 2003.

Biro Klasifikasi Indonesia, 2009.

Fauzi, Farit, “Pemanfaatan Sel Surya Sebagai Catu Daya

Peralatan Penerangan Kapal Di Kapal Tanker”, 2010.

Faturachman, Danny. Muslim, Muswar. Mustafa,

Shariman, “The Utilization of Solar Power for

Lightning Equipment on Ferry”, EnCon 2013, 6th

Engineering Conference, "Energy and Environment"

2nd -4th July 2013, Kuching Sarawak

Haesin, A. Nia, “Listrik Dinamis I”, Materi Pelajaran

Fisika, 2003.

Lunde, J. Peter, “Solar Thermal Space Heating and Hot

Water System”, John Wiley and Sons, 1994.

Matsushita Battery Indrustrial Co.,Ltd, “Solar Cells

Technical Handbook”, 1998/1999.

Mustafa, Shariman, Faturachman, Danny. Arya, Dewanto

Yoseph. Muslim, Muswar, Solar Cell System Design

for Mechanical Cooling System on the Ferry 500 GT

International Journal of Mining, Metallurgy and

Mechanical Engineering (IJMMME), 2 (2). pp. 57-61.

ISSN 2320-4052 (print); 2320-4060 (online).

Peter, J.Lunde, “Solar Thermal Engineering Space Heating

and Hot Water System”.

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

136

Rahman. A, “Ketrampilan Elektronika”, Gajahmada

University, 1995.

www.cool-ship.org

www.celsias.com

www.fvenergy.com

www.solarnavigator.net

www.indonesiannoor.com/index2.html

The Utilization of Solar Cell System Design in the Ship

137