Definition of Experience Feedback Sheet for Eco-design

Nada Matta

1

, Carlos Delagado

1

, Tatiana Reyes

1

and Guillaume Jouanne

2

1

University of Technology of Troyes, Institut Charles Delaunay, 12 Rue Marie Curie CS 42060, 10004 Troyes, France

2

AlterMaker, 2 rue Gustave Eiffel, 10430 Rosières-Près-Troyes, France

Keywords: Experience Feedback, REX Method, Eco-design.

Abstract: In this paper, we propose a Knowledge to use experience feedback techniques in order to keep track of eco-

design decisions. The integration of eco-design in industries is becoming more and more considered as a

necessary condition of Sustainable development. Even sustainable rules become to be defined as norms, but

the application of these rules in design still difficult. Firstly, eco-design criteria are extracted from documents

in order to help the definition of experience feedback sheets main points. CommonKADS generic models are

also used in order to define adequate sheets to reasoning and task types linked to eco-design phases.

1 INTRODUCTION

The integration of eco-design in industries is

becoming more and more considered as a necessary

condition of Sustainable development. It should be

noted that the consideration of environmental issues

in design can modify the objectives, outputs,

resources, processes and performance indicators of a

company. Eco-design goals (using of renewable

materials, recycling, reducing energy, etc.) coupled

with economic and social objectives (implication of

stakeholders, sharing knowledge, considering culture

aspect, etc.) are more or less considered in proactive

or prescriptive way. These approaches lead to

develop innovative solutions (circular economy,

hybrid energy production, etc.). We can note that eco-

design joins the environmental innovation logic

(Depret and Hamdouch, 2009; Michelin et al, 2014)

allowing to reduce material and energy impact. Even

some rules are identified for sustainability but the

application of these rules still no common in

industries. Each industry try to understand these rules

and apply some of them in companies.

In order to answer this problem, we use two types

of approaches: extracting criteria from documents

related to sustainability studies and keeping track of

eco-design activity using experience feedback sheets.

This paper presents this work and especially how

extracted criteria can be used as an index of

experience feedback sheets in order to facilitate their

reuse.

2 EXTRACTING CRITERIA

FROM DOCUMENTS

As first steps of this study, design indicators can be

identified from analysing experience feedback.

Therefore, expertise documents gathered in a young

company, containing design data about materials and

processes, are analysed. We show in this section how

the features defining these materials and processes

have been identified.

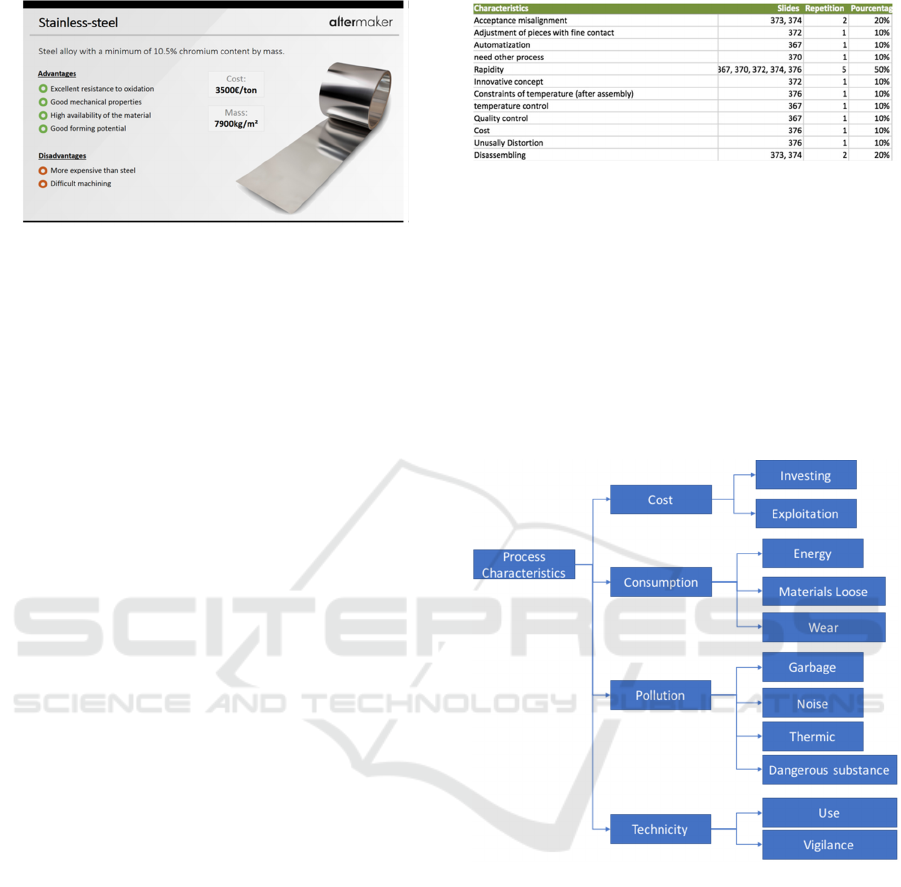

2.1 Eco-design Documents

Altermaker is a young start-up specialized in software

development to support design for sustainability. The

company led analysis on industrial materials and

processes used in mechanical engineering. The results

are stocked as MsPowerpoint documents in which

several elements are defined for each material or

process: advantages, disadvantages, short description

and specific comparisons. In these documents

(0), several features are interesting to consider and

other ones need more analysis. Our study aims at

analysing these documents in order to define the

concepts that show the main features of given

materials and processes.

Matta N., Delagado C., Reyes T. and Jouanne G.

Definition of Experience Feedback Sheet for Eco-design.

DOI: 10.5220/0006488501010107

In Proceedings of the 9th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (KMIS 2017), pages 101-107

ISBN: 978-989-758-273-8

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Example of Altermaker documents (material

card).

2.2 Analysing Approach

Knowledge engineering techniques (Studer and al,

1998) are used to analyse Altermaker documents. In

this type of approach, expertise documents can be

analysed in order to identify the role that elements can

play in problem solving related to a specific domain,

what is called concepts. Several techniques can be

used in documents analysis, we note especially

TextMining (Feldman and al, 2007) that is based on

repetition of words and on relations between words.

In this study, each slide presents a specific material or

process. Therefore, using automatic TextMining tools

cannot be interesting in our case: documents should

be analysed manually.

80 slides are analysed for materials and 157 for

processes. Processes documents are already classified

on manufacturing, assembling and cutting. But there

is no classification of materials slides. Analysing

steps, the procedure can be summarised as:

1. Characteristics are identified from description,

advantages and disadvantages.

2. The number of occurrences of characteristics

are counted.

3. Results are then presented to two mechanical

eco-design experts of Altermaker in order to

eliminate noise, conflicts and to validate the

relevance of each characteristic.

4. Characteristic categories are detailed and split

in sub-groups.

5. Groups are then validated by the eco-design

experts.

6. Finally, analysing of omissions in order to

possibly complete classifications (0).

Figure 2: Results of process documents analysing.

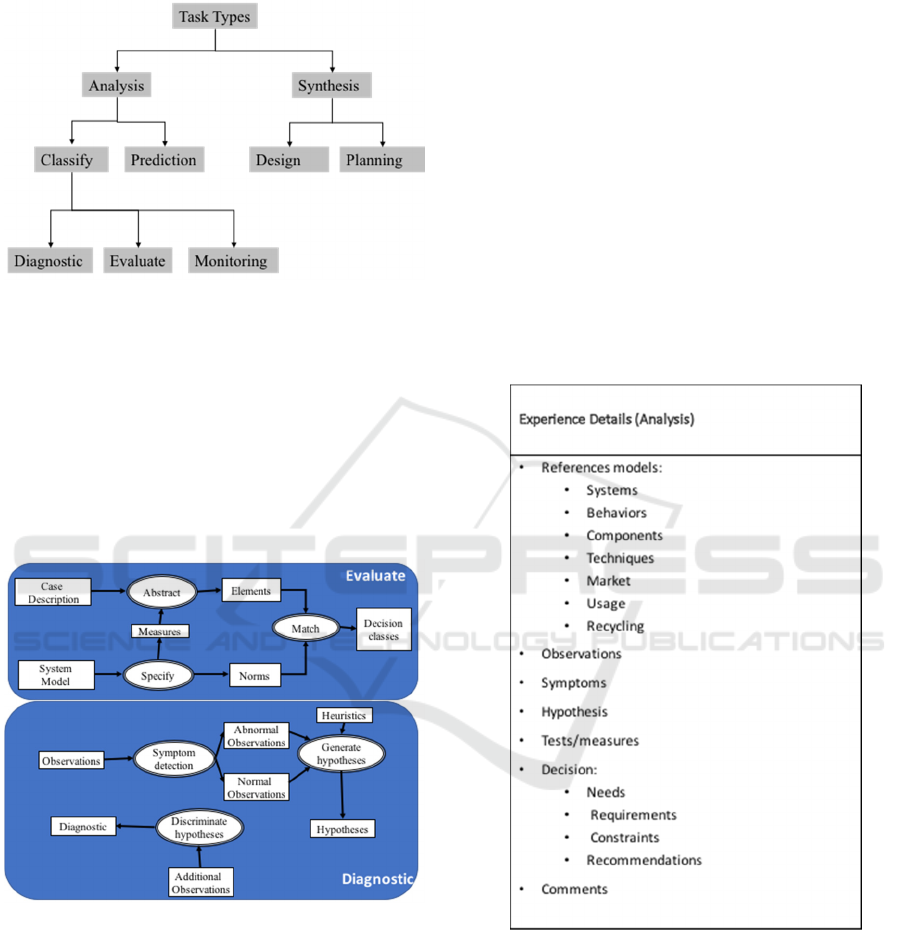

2.3 Characteristics Classifications

Repetition of characteristics is then used in order to

classify them. On one hand, our classification aims at

emphasizing the impact of process and materials on

the environment and, on another hand, at helping

designers to deal with process and materials in eco-

design. For instance, the main process characteristics

are identified as: cost, consummation, pollution,

technicality, etc. (0).

Figure 3: Example of Process characteristics.

For materials, we identify: Resistance, compacity,

disassembling, modification, etc. (0). Then, for each

process type (assembling, drilling, welding,…)

values are associated to these classifications.

Figure 4: Example of Materials characteristics.

These identified characteristics and classifica-

tions allowed us to build a database of processes and

materials with technical, organisational and economic

data. These characteristics are then linked to

environmental ones and ready to be implemented in

the “ECODESIGN STUDIO”

1

software to support

decision making of environmental experts.

To complete this study, we use REX method

(Malvache and Prieur, 1993) in order to extract

knowledge from eco-design activity.

3 KEEPRING TRACK OF

ECO-DESIGN ACTIVITY

3.1 REX Method

The REX method enhances capturing and structuring

of daily knowledge (Malvache and Prieur, 1993). In

this method, an actor has to fulfil an experience

feedback sheet as a report of his daily activity. Each

form is structured in order to show the definition of a

problem and how the actor solves it (0).

A lexicon that offers an easy access to these forms

indexes experience feedback forms. Forms can be

also organized and indexed using different

viewpoints in order to reflect the domain diversity in

an organization.

The definition of these sheets must correspond to

the type of the activity. That helps actors to answer

expertise key elements integrated in these sheets.

REX sheets are used especially in diagnosis

________________________________________

1

http://www.altermaker.com/fr/

Figure 5: Example of a REX Sheet.

applications for radio and sound company (Renaud et

al, 2008), for design applications in Prowhy tool

2

(Kuntz et al, 2016). In our work, we try to use these

sheets for other types of task. So before defining REX

sheets for eco-design, lets us study the different types

of tasks of this activity.

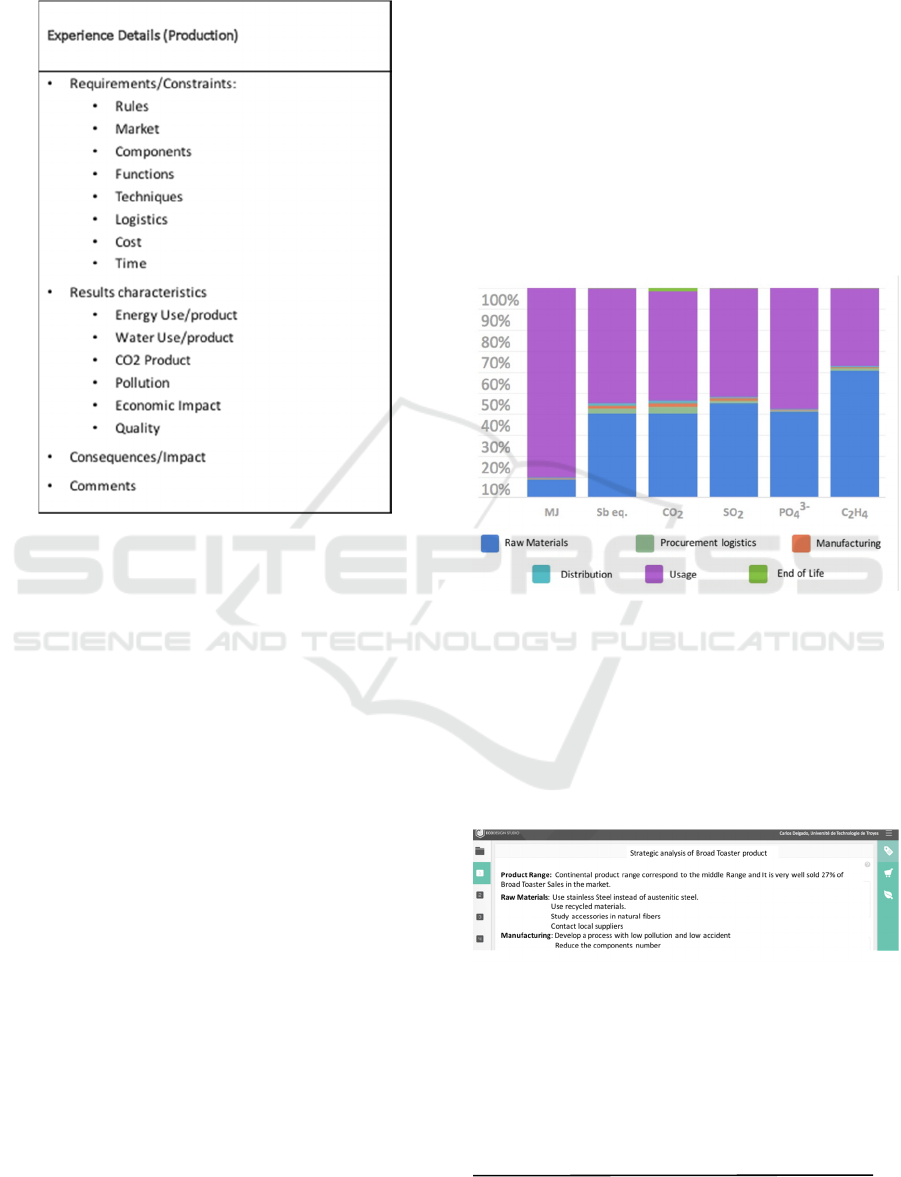

3.2 Eco-design Task Types

Several studies in eco-design tends to integrate

environmental consideration in the whole design

process. We note especially studies of Victor Papanek

in his book 'Design for the Real World: Human

Ecology and Social Change' (Jackson, 1993). The

method is based on the whole life-cycle of the

product: from the raw materials extraction to the end-

of-life treatment of the product, considering as well

the steps of supplying, production, distribution, use

and maintenance (Knight and Jenkins, 2009). This

methodology is now part of the ISO14000

environmental management standard since 2006. In

our work, we consider the main phases of this process

as first step of our analysis:

1. Need analysis and requirement definition

2. Specification and design of artefact

3. Test and Manufacturing

4. Product using and recycling

The reasoning type used in each phase is then

identified based o cognitive studies; Clancey tree

(Clancey, 1985) and the application of this tree (0) in

knowledge engineering approach especially

CommonKADS (Schreiber, 2000). In fact, Clancey

2

http://www.prowhy.org/

tree help to distinguish analysis from synthesis

reasoning.

Figure 6: Task Types Tree.

CommonKADS approach presents primitives in

order to help to distinguish the type of knowledge

used related of each reasoning types. For instance, in

diagnosis task, actor try to identify symptom from

observations, generates hypothesis based on his

experience and discriminate these hypotheses by

testing them in order to find the default. 0 presents

main CommonKADs, we used in order to define REX

sheets.

Figure 7: CommonKADS evaluation and diagnostic generic

models.

3.3 Eco-design REX Sheet Definition

To define REX sheet types, we need from one hand

to identify expertise activity types and from the other

hand, to adapt sheets elements with the expert. For

each main phase in eco-design, the type of reasoning

is identified as follows:

Need, usage and recycling analysis can be

considered as evaluation reasoning type, when actor

try to identify the main parameters of a situation and

identify needs by comparing these parameters to

situation models he knows. So, main elements

characterizing knowledge used and produced in this

step can be:

• Reference models: Systems, behaviours,

Components, techniques, market, usage, etc.

• Observations: systems, components,

behaviours, market, usage, etc.

• Decision: Needs, requirements, constraints,

recommendations, etc.

Actors use diagnosis sometimes in order to detect

problems and discrepancies in existing systems,

market and especially recycling products. So, some

points can, be added to the sheet like: symptoms,

problems hypothesis, discrimination tests and

measures (0).

Figure 8: Analysis sheet type.

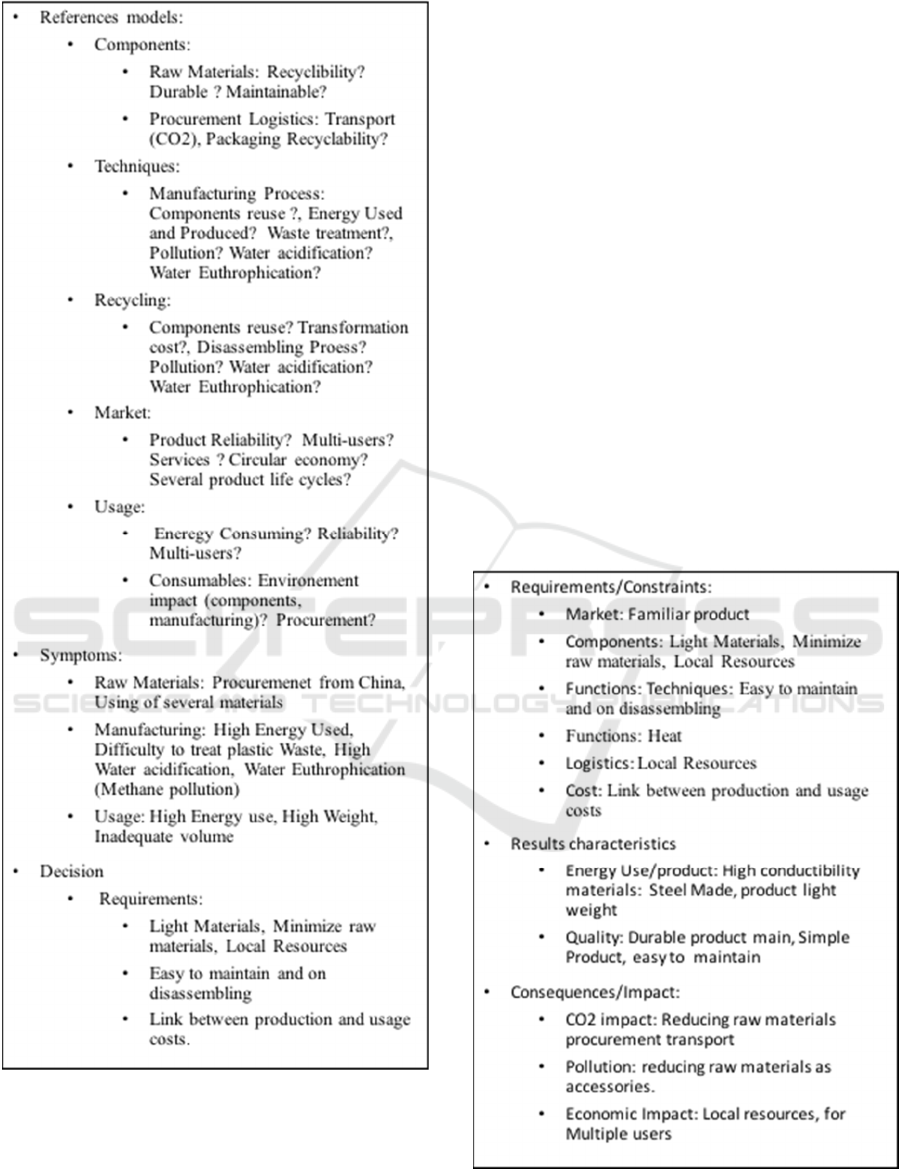

For design and Manufacturing, requirements,

components, and evaluation results with

argumentation must be described (0). Tests is the

prediction of future behaviour of the system.

Based on eco-design parameters, environmental

parameters must be added to these sheets like:

Energy, water, CO2, pollution, resources and

economic Impacts. These elements can so be added to

description of each systems, components and

behaviours (0).

Figure 9: Design and Manufacturing sheet type.

These REX sheets will be integrated in the eco-

design actors’ environment, for instance in PLM and

environmental tools like the “ECODESIGN

STUDIO”

3

, as first page or summary of documents

produced at each phase in eco-design.

Characteristics we try to define (section 1) can be

used to give a cognitive index of these sheets adding

to main keywords extracted from them. So, the access

to knowledge embedded in this type of sheets can be

through a tree summarizing main characteristics

(Section 1.) or with simple keyword research.

Inference engine like Protege (Noy et al, 2001) or

CORESE (Corby et la, 2004) can be used for that.

These techniques can be directly integrated as a

Knowledge Based Engineering system (Chapman et

al, 1999) already used in design. These techniques

can use REX sheet instead of rules bases.

We illustrate in the following an example of the

application of REX sheet in eco-design.

________________________________________

3

http://www.altermaker.com/fr/

4 EXAMPLE OF REX SHEETS

IN BREAD TOASTER

ECO-DESIGN

A group of students in our university had to redesign

a bread toaster with eco-design needs. They plan their

work in: strategic, functions, component analysis and

eco-design recommendations. They use

“ECODESIGN STUDIO”

4

in this analysis. In the

strategic analysis, they study the impact of the current

product in the environment under several criteria: raw

material, Procurement logistics, manufacturing

process, distribution, usage and end-of-life (0).

Figure 10: Bread Toaster Strategic analysis for the current

product.

Even, there is a number of criteria showed in this

analysis, but how and why these analysis is driven are

not described. Main comments they note about that

was only about the choice of the product range to

analyse. There was nothing about how they analyse

these criteria (0).

Figure 11: Comments about Bread Toaster Strategic

Analysis.

To push actors to make explicit their choices and

their analysis, Analysis REX sheet can be used. As

we note above, in this type of sheet, actors have to

identify the reference models that they compared the

4

http://www.altermaker.com/fr/

Figure 12: Bread Toaster need analysis REX Sheet.

observations with. Different criteria categories like

Market, Manufacturing Techniques, Components,

Recycling, and Usage help actors to structure their

answers and write clear sentence usable for learning.

For instance, in needs and market analysis (0)

choosing steel is important to reduce energy in

product usage. Reducing Raw materials numbers is

important to have a light product and for minimize

manufacturing pollution impact and product

recycling. Light Product is important to reduce

energy in product usage. The cycle of materials

procurement is important to study in order to reduce

CO2 impact. Putting reference models and decision

in the same sheet, is very important to push actors to

answer main elements to consider in eco-design and

help learners to understand choices by comparing

reference model’s characteristics to observed

symptoms and decisions. For product design, how

choices answers eco-design requirements is

emphasized by inviting learners to compare

requirements with results characteristics and impact

(0). We can note that inviting actors to comment their

decisions using dedicated REX sheets put on from

one side, main elements used in their reasoning to

obtain these decisions and from the other side help to

structure their comments (instead of sentences in

which different elements are mixed) in a clear way

avoiding the confusion of natural language sentence

and the omissions of criteria.

Figure 13: Beard Toaster design REX sheet.

5 CONCLUSION

There is still no experience feedback techniques used

in eco-design. Each company try to answer norms and

rules by using own techniques. The aim of our work

is to enhance learning between these company using

their experience feedback. Keeping track of

experience using REX sheet and memory is proposed

in this paper. REX sheet types are defined related to

different phases of eco-design: analysis, design,

manufacturing, test, usage and recycling. Eco-design

criteria are also extracted from documents analysis

that help to index REX sheets and give a cognitive

access to these experience traces. REX Sheets can be

integrated in eco-design tools as argumentation and

notes of each decision making and propositions.

We tend to apply these sheet in other eco-design

application in order to validate and complete their

descriptions. These sheets and criteria will be

integrated in eco-design environments like

“ECODESIGN STUDIO”. First tests can be done by

our students in their eco-design projects. Finally, tests

with students will be done, in order to analysis REX

sheet writing and use possibilities. Finally, REX

sheets can then be compared and classified in order to

identify lessons from experiences as it is used for

project memory (Dai et al,2014).

REFERENCES

Corby, O., Dieng-Kuntz, R., and Faron-Zucker, C. (2004,

August). Querying the semantic web with corese search

engine. In Proceedings of the 16th European

Conference on Artificial Intelligence (pp. 705-709).

IOS Press.

Chapman, C. B., and Pinfold, M. (1999). Design

engineering—a need to rethink the solution using

knowledge based engineering. Knowledge-based

systems, 12(5), 257-267.

Clancey, W. J. (1985). Heuristic classification. Artificial

intelligence, 27(3), 289-350.

Dai X, Matta N., Ducellier G., Cooperative knowledge

discovery in design projects, in IC3K, Knowledge

Management and Information System Conferences,

Rome, October, 2014

Depret, M. H., and Hamdouch, A. (2009). Quelles

politiques de l'innovation et de l'environnement pour

quelle dynamique d'innovation environnementale ?

Innovations, (1), 127-147.

Feldman, R., and Sanger, J. (2007). The text mining

handbook: advanced approaches in analyzing

unstructured data. Cambridge University Press.

Jackson, F. (1993). Design for the Real World: Human

Ecology and Social Change. Journal of design history,

6(4), 307-310.

(Knight and Jenkins, 2009) Knight, P., and Jenkins, J. O.

(2009). Adopting and applying eco-design techniques:

a practitioner’s perspective. Journal of cleaner

production, 17(5), 549-558.

Kuntz, E., Reubrez, E., Geneste, L., Romero, J. C., Llamas,

V., and de Valroger, A. Traceability in Problem

Solving Processes. Daily Knowledge Valuation in

Organizations, Matta N., Atifi H., Ducellier G., Willey

2016, 215-233.

Michelin, F., Vallet, F., Reyes, T., Eynard, B., and Duong,

V. L. (2014). Integration of environmental criteria in

the co-design process: case study of the client/supplier

relationship in the French mechanical industry. In

Proceedings of the DESIGN 2014 13th international

design conference. Dubrovnik (pp. 1591-1600).

Malvache, P., and Prieur, P. (1993, October). Mastering

corporate experience with the Rex method. In

Proceedings of ISMICK (Vol. 93, pp. 33-41).

Noy, N. F., Sintek, M., Decker, S., Crubézy, M., Fergerson,

R. W., and Musen, M. A. (2001). Creating semantic

web contents with protege-2000. IEEE intelligent

systems, 16(2), 60-71.

Renaud J., Morelo B., Fushs B., Bonjour E., Matta N.

Retour d'expérience et connaissances industrielles:

Outils et démarches, AFNOR, 2008.

Schreiber, G. (2000). Knowledge engineering and

management: the CommonKADS methodology. MIT

press.