Real-time HiL for Hydraulic Press Control Validation

J. Rodríguez

1

, C. Calleja

1

, A. Pujana

1

, I. Elorza

1

and I. Azurmendi

2

1

IK4 – IKERLAN Technology Research Centre, 20500 Arrasate-Mondragon, Gipuzkoa, Spain

2

KONIKER S. KOOP., Apdo. 18, San Andres auzoa, 20, 20500 Arrasate-Mondragon, Gipuzkoa, Spain

Keywords: Real-time, Virtual Commissioning, Hydraulic Press, Hardware-in-the-Loop, Low Cost, High Fidelity,

Simulation.

Abstract: Hydraulic press control validation often competes for access time with other logistical and production

needs. This can result in significant costs due to down times, longer delivery periods and sub-optimal

control adjustments. Reduction of said costs has traditionally been pursued via some degree of virtual

commissioning, i.e. control validation away from the press, via a model. All such models require a

compromise between cost, fidelity and simulation time. Here, we present a case study in which we have

achieved a low-cost, high-fidelity, real-time hydraulic press model, with a flexible methodology which

allows model creation in parallel with the engineering stage, as well as easy model refinement and

modification during the entire press lifecycle.

1 INTRODUCTION

Commissioning results in a non-negligible part of

the overall cost of hydraulic presses, due to the

considerable number of man-hours and factory floor

occupancy it incurs. This is only exacerbated by its

taking place at the end of press deployment

projects - or even years later, when retrofitting or

improvements are carried out - and largely on site,

often thousands of miles away from the

manufacture's infrastructure (Vilacoba, D.

a

et al.,

2016 and Qiu, X. et al., 2016).

It is currently possible to considerably reduce the

cost and risk of commissioning via software tools

which allow different levels of hydraulic design and

controller validation. However, further integration

and streamlining of the design, validation and

commissioning processes are yet worth seeking, in

order to avoid costly and error-prone model and

controller refactoring, as well as closing the gap

between simulations and real press operation.

Real-time capability on the part of reasonably

high-fidelity hydraulic models is a necessity for

virtual commissioning. Solutions exist in which

controller execution times are slowed down to

synchronise with slower than real-time models.

However, this makes it difficult to account for

communication delays and processing times during

validation.

It is also essential for virtual commissioning that

it be possible to build models at the systems

engineering level, i.e. based on component

specifications, rather than constructive details or

undocumented physical properties. This is typically

catered to via component model catalogues

compiled by component manufacturers. However,

this results in considerable fragmentation of

component modelling efforts and makes it all the

more difficult for the systems engineer to model

circuits combining components from manufacturers

whose component model catalogues have different

formats.

A methodology is therefore sought for real-time

capable, component manufacturer independent,

hydraulic circuit modelling at the systems

engineering level, which provides sufficient fidelity

for virtual commissioning and spans the entire

product lifecycle.

Hydraulic circuit modelling is widely present in

the literature, where the most common approach is

based on Modern Control Theory. (Zadeh, L. et al.,

1963, Jung, D.

a

et al., 2014 and Respondek, J.S.,

2010). This theory was employed to develop

hydraulic circuits with complex nonlinear equations,

far away for the idea to create low complexity and

data-sheet level hydraulic components.

OpenModelica provides a systematic and

convenient way to manage this sort of nonlinear

equations. The model equations were not designed

126

Rodríguez, J., Calleja, C., Pujana, A., Elorza, I. and Azurmendi, I.

Real-time HiL for Hydraulic Press Control Validation.

DOI: 10.5220/0006440201260133

In Proceedings of the 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2017), pages 126-133

ISBN: 978-989-758-265-3

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

for a full hydraulic circuit, instead each component

has its own set of equations. The hydraulic circuit

model was achieved combining these individual

components following the press schematic on the

blueprints.

Once the hydraulic circuit has been modelled, it

is time to start the control design and the validation

process. The virtual representation of the press and

industrial PC controller compound has been

achieved connecting the model ports to the input and

output ports of the controller.

On a Software in the Loop (SiL) validation the

reaction between the hydraulic models and the

controller will be tested in order to debug them. On a

Hardware in the Loop (HiL) validation, the

controller will be embedded on the hardware,

verifying how it will react during the

commissioning.

This paper discusses the steps to develop from

the controller design to the virtual commissioning.

After this explanation, the focus will be centred in

analysing the real-time modelling, validating the

hypotheses first with a simple hydraulic press and

second with a more complex industrial press. Finally

on the conclusions, we will discuss the final results

and set out the future work in this virtual

commissioning study.

2 FROM CONTROLLER DESIGN

TO VIRTUAL

COMMISSIONING

Simulink

®

is an interesting controller design tool,

especially due to a growing number of control

hardware manufacturers supporting code generated

directly from Simulink

®

projects. This allows

seamless verification at every stage of the

engineering and commissioning processes:

• Design: during the design phase, the press

model is integrated within the same Simulink

®

project as the control blocks. This allows

flexible and dynamic testing of new algorithms

and architectures.

• SiL Validation: once the control algorithms are

ready for validation, the press model is taken

out of the Simulink

®

project, and the control

algorithms are tested as a stand-alone piece of

software, which communicates with the press

model for co-simulation. This provides a

software-in-the-loop validation framework.

• HiL Validation: once the control algorithms

are validated, the Simulink

®

project is

embedded in an industrial controller, while the

press model is run in real time and

communicated with said controller. This

provides a hardware-in-the-loop validation

framework (Crǎciun, O.

a

et al., 2014).

• Virtual Commissioning: once the controller is

validated, it is wired to a real-time target

running the press model, e.g. via a field bus or

analog signals. This provides a framework for

controller commissioning, after which it may be

directly wired to the physical press. At this

point, any further necessary adjustments come

from unmodelled press properties.

This controller lifecycle requires a press modelling

methodology which allows model creation based on

drawings and specifications, and integrates well with

Simulink

®

during the design phase. It must also

result in real-time-capable models, which can be

directly used during HiL validation and virtual

commissioning.

3 REAL-TIME MODELLING

The modelling of hydraulic presses at the system

level is most conveniently done with sets of

algebraic differential equations, which are given by

classical mechanics and hydraulics. Multiple

software tools are currently available which aid this

modelling process, as well as solving the resulting

sets of equations. Said tools are based on component

libraries, elements from which are combined and

linked to define full models (Skoglund, T.

ab

et al.,

2007 and Winter, M.

a

et al., 2015).

We have chosen to work with OpenModelica

(Fritzson, P., 2011), due to its being Open Source,

which provides good cost-effectiveness, flexibility

and price stability. It will also be shown that it

provides every feature we need for our virtual

commissioning methodology (Linköping, 2014).

Regarding component libraries, the same reasons

may have driven us to choose the standard Modelica

library, or another of the available free ones.

However, they have one or more of the following

disadvantages:

• Excessive Complexity: e.g. the standard

Modelica library uses multi-phase fluids. This is

necessary to model refrigerators, but little more

than a computational burden when modelling

hydraulic presses.

Real-time HiL for Hydraulic Press Control Validation

127

• Constructive Parameters: e.g. valves are often

modelled based on passage areas. This is useful

to design valves, but impractical when

modelling full hydraulic circuits based on

commercial components. As a result, models

based on these libraries require a backward-

engineering process, in which nominal

component flow characteristics are reproduced

via trial-and-error adjustment of constructive

parameters.

• Excessive fidelity: e.g. valves are often

modelled for fidelity with both laminar and

turbulent flows (Gavrilakis, S., 1992). This

results in full circuit models whith a sort of

fidelity which is very difficult to validate when

designing said circuits, because component data

sheets do not provide the information that would

be necessary to determine the critical flow rate.

It also results in very slow models.

As a result of these disadvantages, we have chosen

to write our own OpenModelica library, to fit the

specific needs of our use case. We have then used

that library to model a state-of-the-art hydraulic

press.

3.1 Hydraulic Component Library

We seek a library with the following characteristics:

• Low complexity: the library must be easy to

use, and therefore made of high level hydraulic

components, such as valves, pumps, cylinders

and pipelines. Low level details such as pilot

lines must be abstracted. This will allow high-

level integration of complex models at the

system design phase, rather than component

design.

• Datasheet-level Parameters: components must

be configurable by simple inspection of data

sheets. Passage areas and other constructive

details must be abstracted, because they are not

easily deduced from data sheets. This will allow

direct component configuration at the system

design phase, and avoid modelling via reverse

engineering.

• Datasheet-level Fidelity: components must

behave as specified by data sheets. Fidelity

beyond the level specified by data sheets must

be avoided. This will allow model validation via

direct comparison with parameters, and

minimise computation time for the maximum

level of fidelity which is verifiable at the system

design phase.

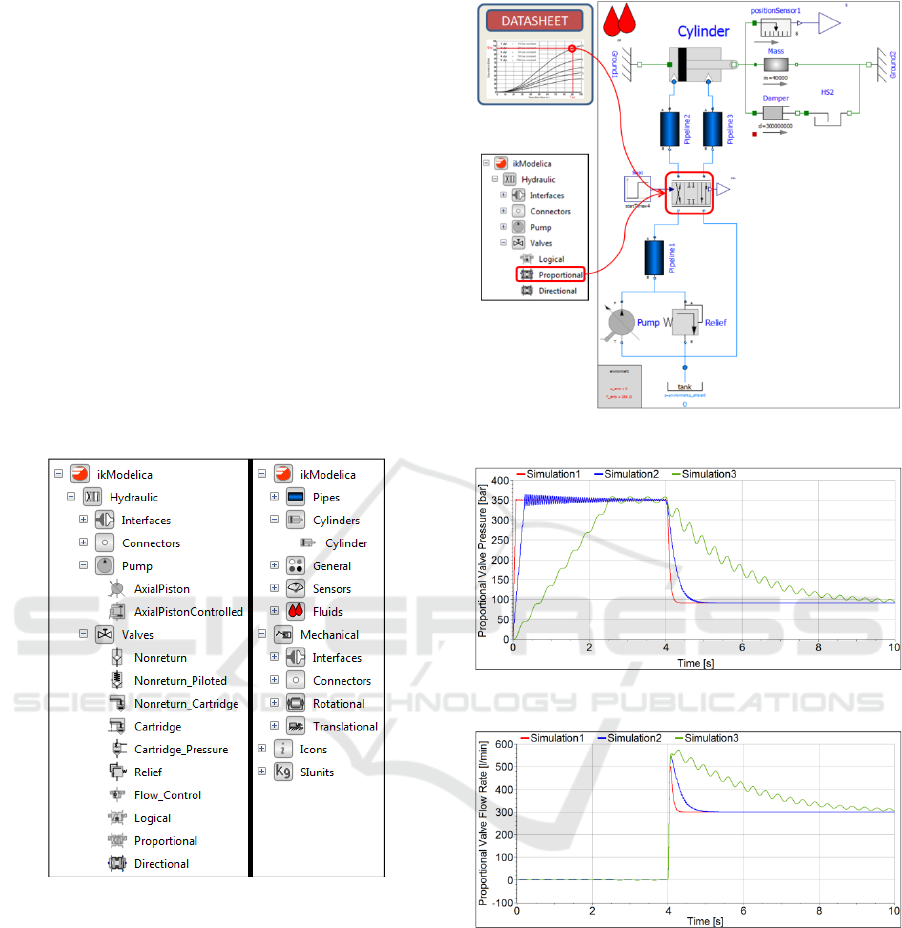

We develop and maintain a library for

OpenModelica with these characteristics (Figure 2).

The library models the main hydraulic and

mechanical components we typically find in

industrial presses, such as cylinders, valves,

pipelines and pumps (Adiprasetya, M.H., 2012).

All components are configurable via parameters

typically found in data sheets, such as nominal flow

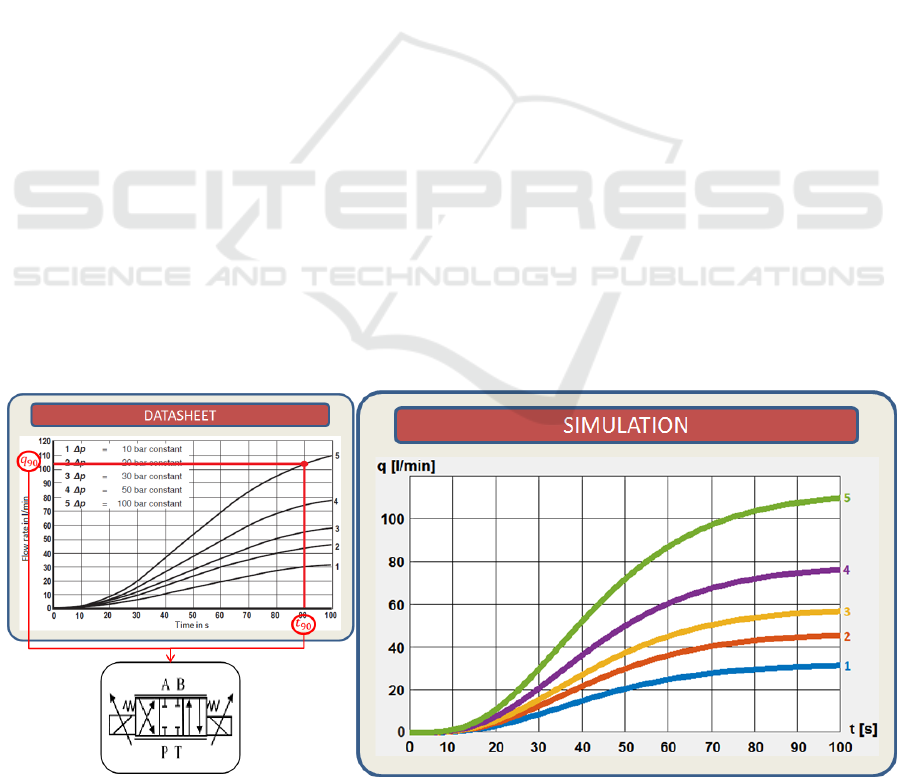

rates, piston areas or response times. Figure 1 shows

a flow rate diagram given by a proportional valve

data sheet. A single point taken from said diagram is

enough to configure our corresponding component,

which results in the simulation also show in the

figure.

Figure 1: Proportional valve model configuration and simulation results.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

128

3.2 Model Assembly

A simple case study is presented here to illustrate

circuit model assembly from the components in our

OpenModelica library. Figure 3 shows a model with

a cylinder, a proportional valve, a constant

displacement pump, a relief valve and three

pipelines. The cylinder pushes on a considerable

mass and, when extended sufficiently, comes in

contact with a damper, which may be a simple

representation of a deep drawing process. Model

assembly is done by dragging and dropping

components from the library, and configuration is

done from data sheets (Madin, B.

a

, 2016).

Although this model is rather simple compared

to typical hydraulic presses, it will give a taste of the

fidelity which is achievable with our library, while

still maintaining real-time capabilities with complex

models, as will be shown in section 0.

Figure 2: Our OpenModelica library.

Figure 4 shows the pressure at the P port of the

proportional valve during three different 10 second

simulations, the difference between which is the

length of the pipeline coming from the pump.

Simulations 1, 2 and 3 correspond to pipeline

lengths of 1, 10 and 100 meters, respectively. Note

that the pressure is initially 0 and, since the

proportional valve is closed, it grows as the pump

compresses oil into the pipeline. The pressure

stabilises at 350 bar, where the relief valve opens to

limit it. As pipeline length grows, pressure takes

longer to build up and oscillations appear.

4 seconds into the simulations, the proportional

valve is fully opened to make the cylinder extend.

Figure 3: Simple model.

Figure 4: Proportional valve port P pressure.

Figure 5: Proportional valve port P flow rate in litres per

minute.

Then, oil flows from the pump to the cylinder, and

pressure at port P goes down to the pressure

differential needed to get the pump's nominal flow

rate through the valve. Again, pressure drops slower

and in a more oscillating way as pipeline length

grows. This is due to the pipeline acting as a

pressurised reservoir, which requires more oil to

flow through the valve to drop a given pressure, as

shown by Figure 5.

Real-time HiL for Hydraulic Press Control Validation

129

Figure 6: Cylinder displacement.

Figure 6 shows the cylinder displacement.

Initially, it is fully retracted and, 4 seconds into the

simulations, when the valve opens, it extends. The

pipeline going from the pump to port P on the valve

acts as an accumulator, and provides an initial boost,

which gets larger as the pipeline gets longer. The

cylinder subsequently settles to a constant speed,

dictated by the pump's nominal flow rate.

Figure 7 shows what happens afterwards. The

cylinder continues to extend until it makes contact

with the damper. This results in the cylinder

extension slowing down to a speed dictated by

maximum pump pressure and valve flow

characteristics. Note that pressure buildup in the

longer pipeline requires a longer time, which results

in the cylinder displacement in simulation 3 again

getting closer to that of simulations 1 and 2.

4 VALIDATION CASE STUDY

4.1 Press Model

For the case study presented here, a hydraulic press

circuit based on a commercial press has been

modelled, which uses a subset of the components in

the library described by section 0.

The model has been assembled exactly as the

circuit design drawings are, i.e. by placing all

components on a graphical interface and connecting

the ports. Component parameters have then been

directly taken from publicly available component

data sheets. Without further abstraction or

simplification efforts, the model is real-time capable

and provides as much fidelity as is possible to

validate with the available design data.

The press model features 9 cylinders, 9

proportional valves, 2 pumps, multiple non-return,

pressure relief and cartridge valves and multiple

pipelines.

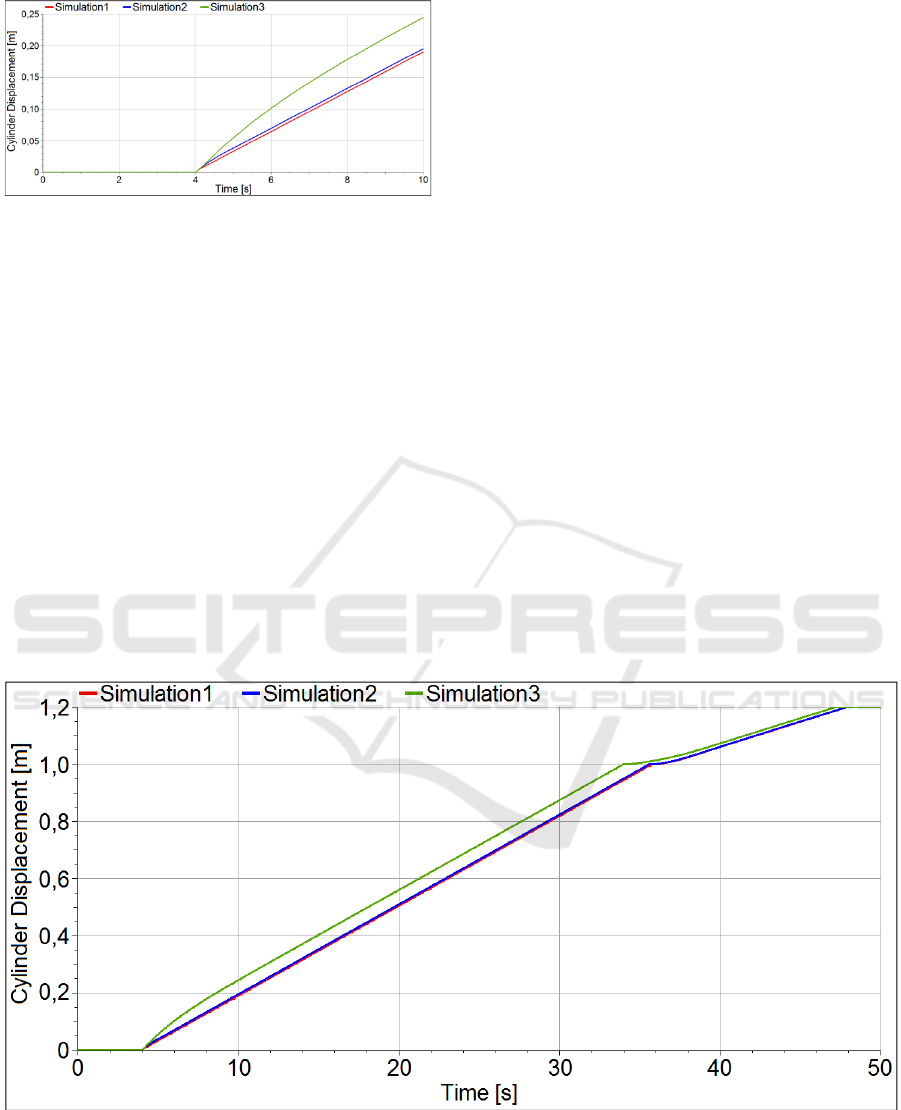

A controller has been implemented in Simulink

®

,

based on the original press controller, which is

implemented on traditional motion control hardware.

This has allowed the parallel model and controller

development described in section 0.

Figure 7: Cylinder displacement until contact is made with damper.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

130

Figure 8: Software in the Loop validation.

The press model has been included in the Simulink

®

project via a functional mock-up unit (FMU) for co-

simulation (Chen, W.

a

et al., 2011). The Simulink

®

control algorithms have then been run in parallel

with the press model, and adjusted based on control

response until the latter has been considered

appropriate.

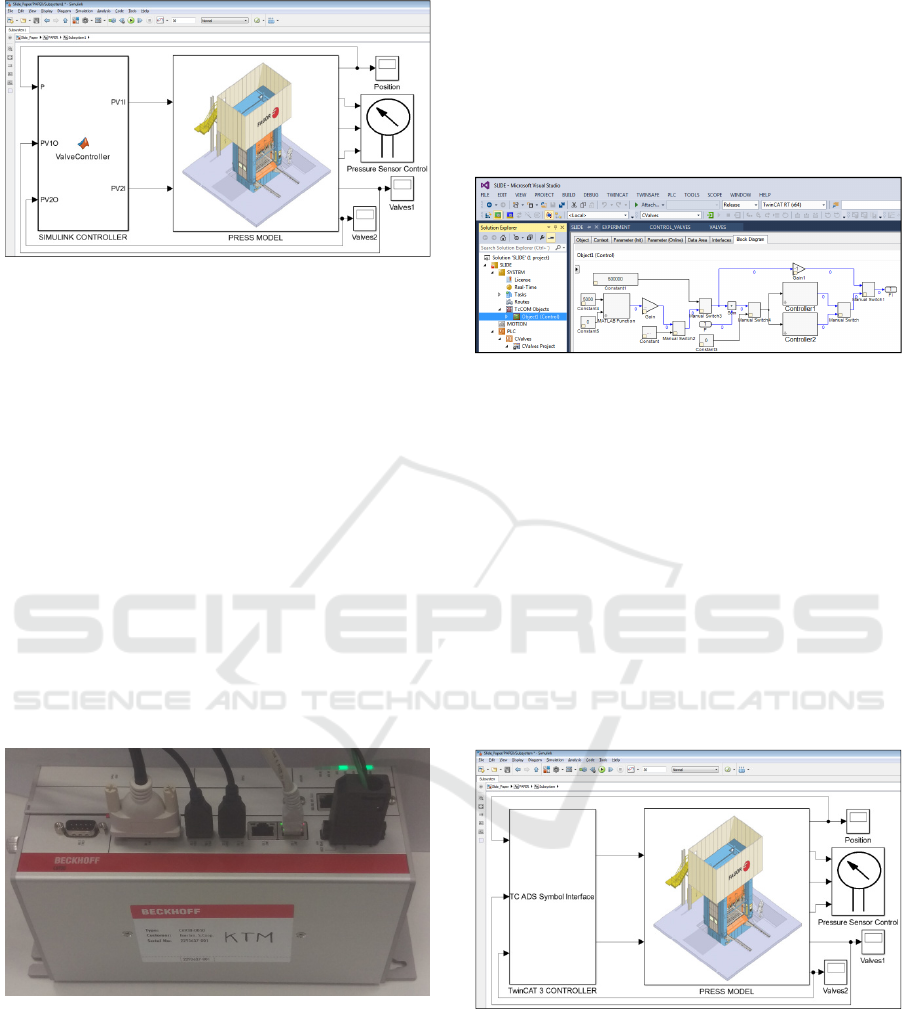

4.2 Hardware-in-the-Loop

The validated Simulink

®

control algorithms have

been embedded in the Beckhoff industrial PC shown

by Figure 9, via its real-time system TwinCAT 3.

This would be their definitive form for

commissioning. However, HiL validation is

possible, due to the press model's real-time

capability (Sun, P. et al., 2002; 2005; 2006 and

Ferreira, J.A.

a

et al., 1999).

Figure 9: Industrial PC used for HiL validation.

The press model has been separated from the control

algorithms, and communicated with the latter via

TwinCAT's ADS blocks. Running on the Windows

CPU of the industrial PC, it keeps up with the real-

time execution of the control algorithms on

TwinCAT, and generates the sensor signals based on

the press dynamics and the commands it receives

from the controller.

A Simulink

®

project has been created to build the

TcCOM object and export the controller from this

software into TwinCAT. This method connects

Simulink

®

blocks directly to the PLC syncrhonizing

both clocks in real-time. The controller was exported

as a S-Function with a similar behaviour of the

initial control (Figure 10).

Figure 10: TcCOM Object with the controller developed

in Simulink

®

and embedded in TwinCAT 3.

TwinCAT is capable of executing this module in

real-time assigning a task. This process is similar to

the one followed by the PLC to create and run the

Program Organization Units (POU’s) and the main

program. The TcCOM Object execution time was

configured in the task, and has to be similar to the

one selected in Simulink

®

during the design stage.

The HiL methodology was developed connecting

the TcCOM Object with the Simulink

®

simulation.

In this project, the controller was replaced with a

“TC ADS Symbol Interface” capable of

communicating Simulink

®

simulation with the

controllers running in TwinCAT (Figure 11).

Figure 11: Hardware in the Loop validation.

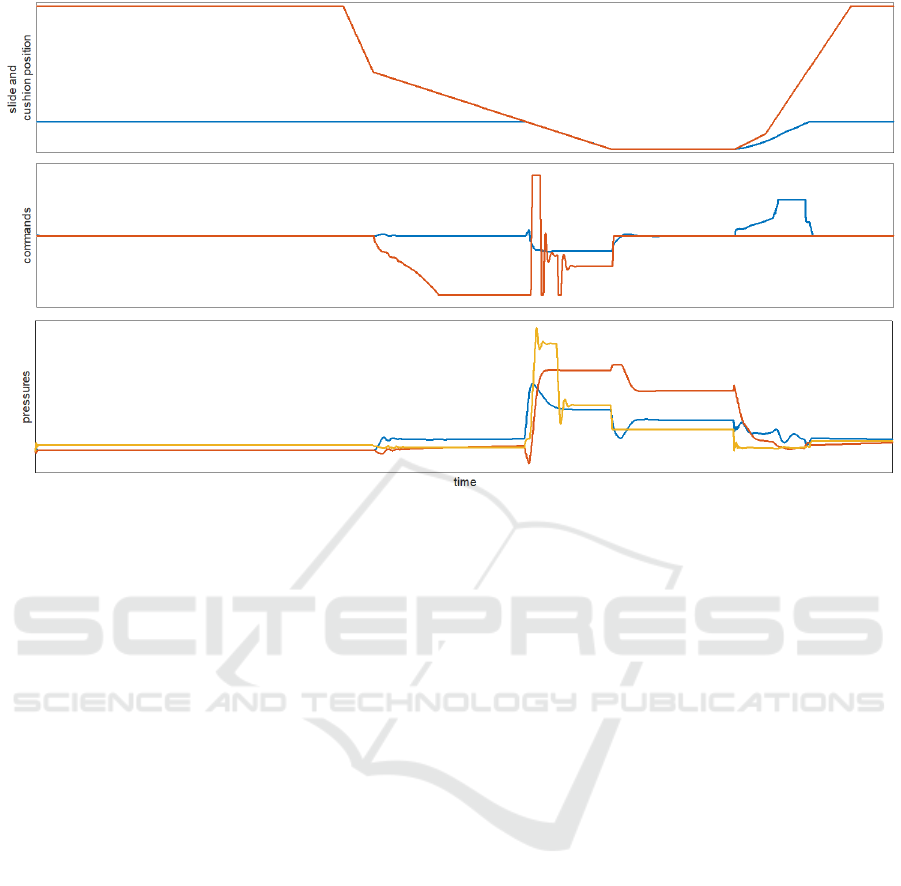

The results of both SiL and HiL validations are in

this case similar, as expected. Some variables are

shown by Figure 12 and Figure 13. Note that

pressure response times and oscillations are

determined by valve response times, pipe

dimensions, oil compressibility, head losses and, in

general, by all the circuit characteristics which are

specified by the hydraulic design documentation.

Real-time HiL for Hydraulic Press Control Validation

131

Figure 12: Validation results.

After this HiL validation, the controller is ready

for deployment on the press, pending the configu-

ration of the industrial PC for communication with

its instruments. However, a virtual commissioning is

possible, in which the press model is moved to a

system capable of physically replicating all the

sensor and actuator communications and signals.

This, due to its relative cost in terms of input and

output cards necessary for said system, has been

excluded from this case study, and is reserved for

actual press commissioning processes, where the

savings generated by the virtual commissioning

outweigh its cost.

5 CONCLUSIONS

A modelling methodology is sought for hydraulic

press virtual commissioning. Full integration with

engineering processes and real-time capabilities are

the primary requirements.

It has been argued here that said methodology

can profit from existing physical modelling

packages, among which is OpenModelica. Existing

component libraries are however not generally

focused on virtual commissioning and systems

engineering needs, and do not therefore typically

fully accomodate said requirements.

We develop and maintain an OpenModelica

library which specifically targets virtual

commissioning and allows high-fidelity modelling

of hydraulic presses, based on publicly available

data sheet parameters, at every stage of the

development cycle, including real-time HiL

validation.

Some of said libary's characteristics and

capabilities have been presented here, and a case

study has been described, in which a commercial

hydraulic press model has been run on a Beckhoff

industrial PC for controller HiL validation.

This methodology integrates well with the

controller development cycle. However, it requires

an additional effort to model presses in

OpenModelica. As it has been argued, said effort is

moderate, it accomodates the systems engineering

skillset and provides a sufficient reward in terms of

cost and risk reduction. However, it fragments the

systems engineering efforts, because circuit design is

duplicated, since OpenModelica is not sufficient to

produce all the necessary system documentation, e.g.

hydraulic drawings.

Further integration is therefore sought with the

system design tools, in order to draw circuit design

details from a centralised repository and produce

models automatically, thus reducing specific

modelling efforts during press development and

eliminating error-prone manual configuration. In

future works,we will reinforce this metholodgy by

means of automatizing the process with

OpenModelica Python Interface.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

132

ACKNOWLEDGEMENTS

This work was supported in part by the Basque

Country Government (Research Project

ELKARTEK 2016, ALCON 4.0, KK-2016/00016

ALCON4.0).

This work was supported in part by the Guipuzkoa

Provincial Council (Research Project CONAMON

4.0, OF 215/2016 ES).

REFERENCES

Vilacoba, D.

a

, Perez, P.

a

, Gracia, A.

a

, Weber, P.

b

, 2016.

Conference Paper, Optimized press line orchestration

through virtual prototyping: A successful story in,

IEEE International Conference on Industrial

Technology, ICIT 2016, IEEE Xplore.

Qiu, X., Xiao, C., Tan, H., Hou, Y., Zhou, Y., 2016.

Article. Multi-software co-simulation for a large

robotic automatic stamping production line, in China

Mechanical Engineering.

Zadeh, L., Desoer, C., 1963, Linear System Theory: The

State Space Approach. McGraw Hill, New York.

Jung, D.

a

, Kang, D.

b

, Kang, M.

c

, Kim, B.

c

, 2014. Article.

Real-time pump scheduling for water transmission

systems: Case study, in KSCE Journal of Civil

Engineering, Springer.

Respondek, J.S., 2010. Article. Numerical simulation in

the partial differential equation controllability analysis

with physically meaningful constraints, in

Mathematics and Computers in Simulation Volume 81,

Issue 1 September 2010 Pages 120-132, Elsevier.

Crǎciun, O.

a

, Florescu, A.

a

, Munteanu, I.

b

, Bacha, S.

a

,

Radu, D.c, 2014. Article. Hardware-in-the-loop

simulation applied to protection devices testing, in

International Journal of Electrical Power and Energy

Systems, Science Direct.

Skoglund, T.

ab

, Dejmek, P.

a

, 2007. Article. A dynamic

object-oritented model for efficient simulation of fluid

dispersion in turbulent flow with varying fluid

properties, in Chemical Engineering Science Volume

62, Issue 8, April 2007, Pages 2168-2178.

ELSEVIER.

Winter, M.

a

, Taube, J.

a

, Froeschl, J.

b

, Herzog, H.-G.

a

,

2015. Conference Paper. From Simulation to

Testbench Using the FMI-Standard, in 12

th

IEEE

Vehicle Power and Propulsion Conference. IEEE.

Fritzson, P., 2011. Conference Paper. Modelica A cyber-

physical modeling language and the OpenModelica

environment, in 7

th

International Wireless

Communications and Mobile Computing Conference,

IEEE Xplore.

Linköping, 2014. Modelica

®

- A Unified Object-Oriented

Language for Systems Modelling, Modelica

Association, Version 3.3 Revision 1.

Gavrilakis, S., 1992. Article. Numerical simulation of low-

reynolds-number turbulent flow through a straight

square duct, in, Journal of Fluid Mechanics, Journal of

Fluid Mechanics.

Adiprasetya, M.H., Prihatmanto, A.S., 2015. Conference

Paper. Design and implementation of real time

simulator with Modelica, in 2012 International

Conference on system Engineering and Technology.

IEEE.

Madin, B.

a

, Ausiin, R.

b

, 2016. Conference Paper. Case

studies of the design and performance of one-way

surge tanks in pumped water and wastewater pipelines,

in 12

th

International Conference on Pressure Surges,

BHR Group Limited.

Chen, W.

a

, Huhn, M.

a

, Fritzson, P.

b

, 2011, Conference

Paper, Pages 19-24. A generic FMU interface for

modelica, in Proceedings of the 4

th

International

Workshop on Equation-Based Object-Oriented

Modelling Languages and Tools, EOOLT 2011.

Sun, P., Talaia, P.M., Rocha, A.M., Grácio, J.J., Ferreira,

J.A., 2002, Conference Paper. Experimental device

about automatic control of a hydraulic press, in

Proceedings of Asian Simulation Conference/the 5

th

International Conference, Proceedings of Asian

Simulation Conference.

Sun, P., Grácio, J., Ferreira, J.A., 2005. Conference Paper.

New experimental device of evaluating springback in

sheet metal forming, in Materials Science and

Technology 2005 Conference, Materials Science and

Technology.

Sun, P., Grácio, J.J., Ferreira, J.A., 2006. Article. Control

system of a mini hydraulic press for evaluating

springback in sheet metal forming, in Journal of

Materials Processing Technology, ELSEVIER.

Ferreira, J.A.

a

, De Oliveira, J.E.

b

, Costa, V.A.

a

, 1999.

Article. Modeling of hydraulic systems for hardware-

in-the-loop simulation: a methodology proposal, in

Fluid Power Systems and Technology – 1999 (The

ASME International Mechanical Engineering

Congress and Exposition). ASME.

Ferreira, J.A., De Almeida, F.G., Quintas, M.R., 2002,

Article, Pages 237-248. Semi-emprirical model for a

hydraulic servo-solenoid valve, in Proceedings of the

Institution of Mechanical Engineers. Part I: Journal of

Systems and Control Engineering, SAGE journals.

Real-time HiL for Hydraulic Press Control Validation

133