Application of SensorML in the Description of the Prototype Air

Monitoring Network

Mariusz Rogulski

1

and Bogdan Dziadak

2

1

Faculty of Building Services, Hydro and Environmental Engineering, Warsaw University of Technology,

Nowowiejska 20, Warsaw, Poland

2

Faculty of Electrical Engineering, Warsaw University of Technology, Pl. Politechniki 1, Warsaw, Poland

Keywords: Interoperability, Sensor Networks, SWE, Air Monitoring.

Abstract: The aim of this publication is to present the use of OGC standards – SensorML and Observations &

Measurements – to describe the sensor network and measurement process in the prototype of air quality

monitoring network launched in Nowy Sacz in Poland. Standards are used to create structures of relational

databases to achieve interoperability through data collection in an orderly manner in the field of

environmental data and in the description of monitoring process. This is important especially when the

system consists of a number of low-cost measuring devices, that are designed to complement existing

measurement network.

1 INTRODUCTION

There are currently a lot of mobile and stationary

sensors that measure various environmental

parameters, operating independently or as part of a

number of measuring stations and monitoring

networks. Constantly also there are performed

different types of observations and measurements,

both in situ and in laboratories. All these activities

generate huge amounts of data about the state and

quality of the environment on Earth.

To fully benefit from such a huge and diverse

resources, as from global database (knowledge), it is

necessary to provide the possibility of exchanging

and sharing data between different systems, so it

requires to ensure their interoperability.

The concept of interoperability is closely linked

to information technology, especially to information

systems. Interoperability is generally referred to as

“... the ability of two or more components to

exchange information, understand it and use it...”

(Institute of Electrical and Electronics Engineers,

1990). More specifically, it may be defined as “...

the ability of various elements of functional

information systems to communicate, run programs,

or transfer data between them in a way that does not

require from the user any knowledge, or requires

from the user a minimum knowledge on the unique

properties of these elements...” (ISO/IEC 2003).

One way to ensure interoperability, is to provide

the data in a clearly defined schemes available in

specialized for this purpose network services, with

individual communication protocols. This type of

concept, regarding spatial data, is used in the Spatial

Data Infrastructures (SDI). Using SDI allows for a

certain extent to automate the use of shared metadata

and spatial data. An example of the practical

implementation of such a model is INSPIRE,

consisting of SDI of individual EU Member States.

Experiences of the implementation phase of this one

the world’s largest data harmonisation effort of

environmental information infrastructures can be

found in (Kotsev et al., 2015).

The key to ensure interoperability in the field of

environmental data are specifications developed by

OGC (Open Geospatial Consortium) and standards

developed by ISO (International Organization for

Standardization). They provide the basis for the

construction and operation of spatial information

infrastructures, while ensuring technical

interoperability, both in terms of communication of

services and data exchange.

OGC, ISO and other institutions have developed

a number of norms, standards, specifications and

recommendations for description of measuring

processes and sensors (metadata) in order to achieve

interoperability capabilities. As one of the most

important in this regard should be considered

Rogulski, M. and Dziadak, B.

Application of SensorML in the Description of the Prototype Air Monitoring Network.

DOI: 10.5220/0006379903070314

In Proceedings of the 3rd International Conference on Geographical Information Systems Theory, Applications and Management (GISTAM 2017), pages 307-314

ISBN: 978-989-758-252-3

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

307

SensorML. Besides it, important are, among others:

IEEE 1451, ECHONET, Device Description

Language (DDL), and Device Kit (Tang and Yeh,

2001).

The aim of this publication is to present the use

of OGC standard – SensorML – to describe the

sensors and measurement process in the prototype of

air quality monitoring network launched in Nowy

Sacz in Poland. Section 2 summarizes the IEEE

1451 standard dedicated to transmitters service

standardization, and primary elements of the

specification SensorML 2.0. Section 3 describes the

use of specifications Sensor ML to describe the

measuring process of the air quality monitoring

network based on prototype measuring stations.

Section 4 provides a summary.

2 STANDARDS OF SENSORS AND

DATA DESCRIPTION IN

MEASUREMENT SYSTEMS

Speaking about interoperability of measurement

data, we mean primarily final results of the

measuring system, which is properly formatted and

described data block, most often located in a

standardized database or data warehouse. From

there, it can be easily downloaded and processed by

other systems. However, it should be noted that the

standardization of measurement data recording can

be done from the very beginning of the measurement

process.

2.1 IEEE 1451 Standard

In order to standardize communication protocols and

use of intelligent sensors, standard IEEE 1451

(Saponara et al., 2011; Kim et al., 2011) has been

established. The origins of the work on the standard

dates back to the late twentieth century. Then the

leading manufacturers of sensors, and IEEE and

NIST, began the work associated with the

standardization of smart sensors use. The result of

this work is a family of standards under the title

IEEE 1451 Standards for a Smart Transducer

Interface for Sensor and Actuators (Dziadak et al.,

2011; Lee, 2007). In this standard, an intelligent

sensor is able to measure the acquisition, pre-process

it, format the data and send them, using an available

network, to a higher level in the measurement

system. The definition of a smart sensor is broad and

includes both sensors and actuators with a controller

chip enabling network communications or with the

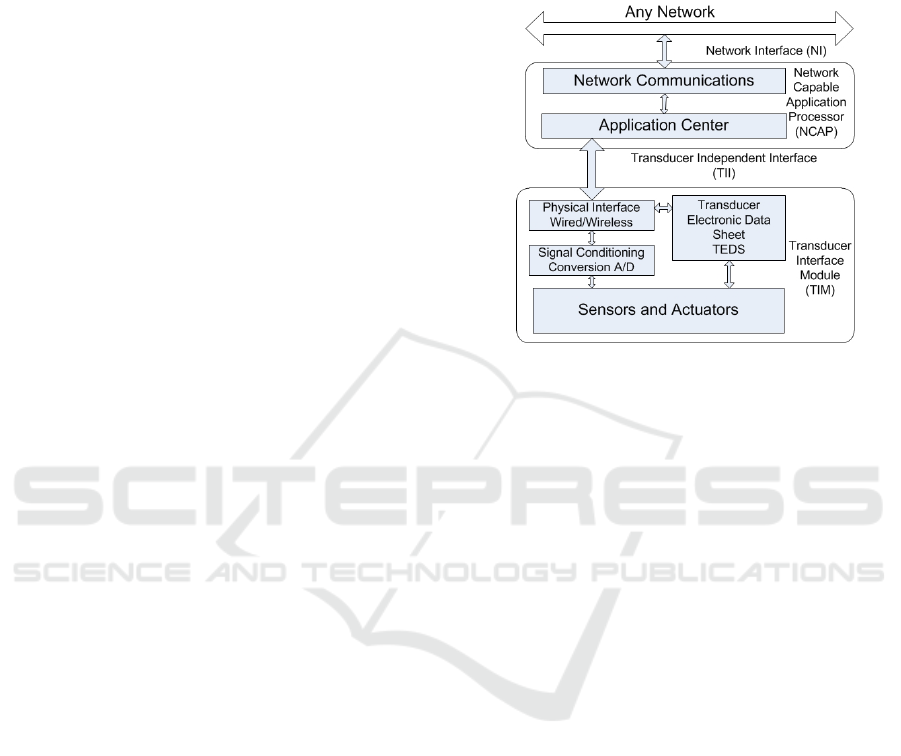

controller. Block structure of the transmitter,

compatible with the present standard, is shown in

Figure 1. We can distinguish two main blocks: -

Transducer Interface Module (TIM) and Network

Capable Application Processor (NCAP).

Figure 1: Structure of the smart transmitter in accordance

with IEEE 1451.

Transducer Interface Module consists of sensors or

actuators, conditioning and processing block A/D of

TEDES base and interface. It is responsible for

proper installation and operation of the sensor and

for the performance of measurement. Sensors should

be operated in a plug and play mode. Data for the

sensor installation in the measurement system are

downloaded from an electronic database TEDS.

Base TEDS is an electronic catalog card of the

sensor which contains all the necessary information,

such as: sensor type, measuring range, resolution,

accuracy, sensitivity, response time, and

identification data.

Network Capable Application Processor is a

block providing control of the measurement process

and communication between the block of TIM

transmitters and higher layers of the measurement

system. Most often, NCAP is a controller/computer

with the appropriate hardware and computing

capabilities allowing for translations of interfaces

and coordination of the process. NCAP can also

provide Web services and APIs dedicated to data

receivers (Higuera and Polo, 2012). Communication

with both the TIM block and the network, can be

implemented using a variety of techniques and

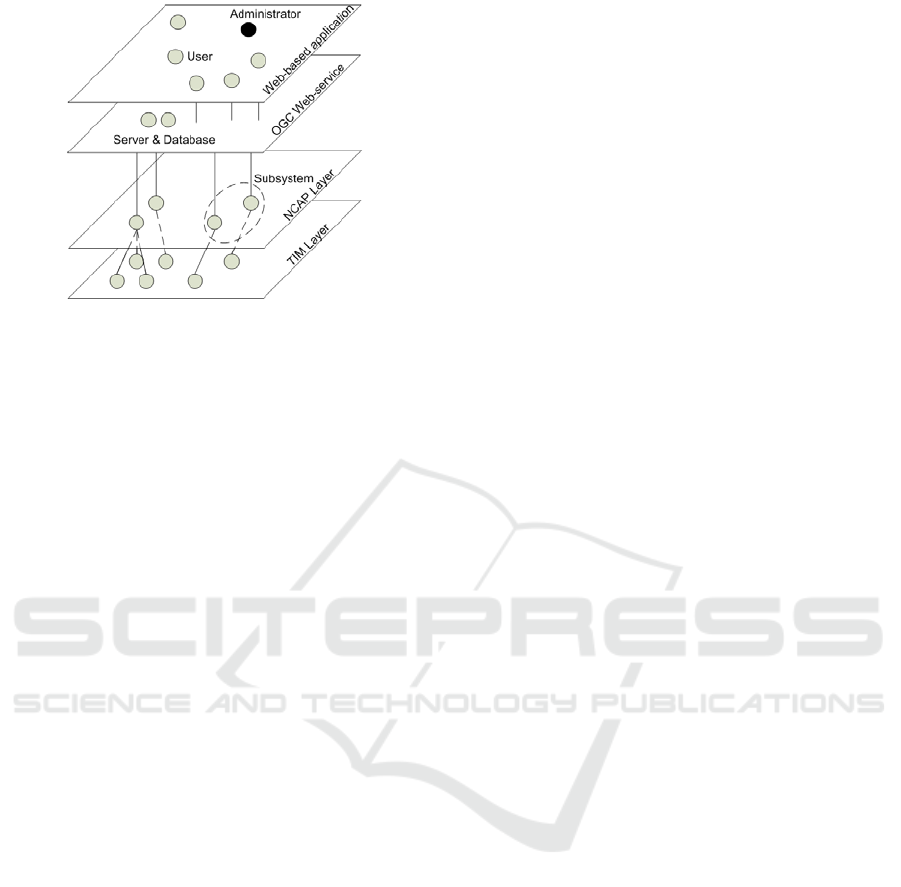

technologies (Pu et al., 2016). The coupling between

the IEEE 1451 standard and the standards of upper

layers of the OGC model, is shown in Figure 2.

GISTAM 2017 - 3rd International Conference on Geographical Information Systems Theory, Applications and Management

308

Figure 2: Structure of the smart transmitter in accordance

with IEEE1451.

The IEEE1451 standard is used to operate smart

sensors in the network for monitoring surface water

quality in the Sado Estuary Natural Reserve in

Portugal. In this network the communication

between the block of TIM transmitters and the

NCAP block is carried out with the use of RFID

(Postolache et al., 2011). Another example is air

quality monitoring system measuring NO

2

, SO

2

, CO,

O

3

, in which the authors in the controller ADuC812

realized the TIM block with a complete base of

TEDS for used sensors (Kularatna and Sudantha,

2008). In the authors' system, the standardization of

the sensor description operates at the network level,

however, the modularity of the sensor is assumed.

2.2 SensorML V2.0

SensorML v2.0 is a specification for describing

functional model of the sensors activity and

associated measurement processes. Using SensorML

can be described a wide range of sensors, including

both mobile and stationary sensors, and performing

measurements "in-situ" or remote. In addition, this

language allows for, among others: description of

algorithms needed to manage sensors, location of the

observation made by means of sensors, etc.

This language is one of the components

developed by OGC as part of the specification

Sensor Web Enablement (SWE) and the Sensor Web

initiative (Liang et al., 2005). SWE focuses on

developing specifications to cover all types of

sensors and making them accessible, usable and

controllable via the Web (Bröring et al., 2011). For

this reason, some elements (data types, classes, etc.)

are connected between the various components of

the project.

Examples of the use of SWE standard, along

with a brief description of the individual components

of this specification, can be found in (Conover et al.,

2010). In (Chen et al., 2013), the authors described

the use of SWE to create a Web directory service,

based on directory service OGC, allowing for

location, access, retrieval of parameters and use of

sensors and algorithms describing the sensors.

Technologies and standards included in the SWE

were also used to create an event-based service

receiving spatial data “on-demand” (Fan et al.,

2013). In (Kotsev et al., 2016) OGC specifications

are used in the AirSensEUR open software/hardware

multi-sensor platform for measuring ambient air

quality.

In turn, (Chen et al., 2012) using BPEL and

processes chains from SensorML, proposed a

method to create workflows for the so-called e-

science, that is those fields of science, which require

calculations in highly distributed network

environments or using huge data sets processed in

grid environments. In (Hu et al., 2014) proposed a

model of sensors description for satellite remote

sensing based on the object- and language-oriented

paradigm of SensorML. In (Jiménez et al., 2014),

the SensorML specification, with standards ISO

19156 and ISO 19115, were used to enhance the

interoperability of data in the field spectroscopy

scientific community. In (Hu et al., 2015) presented

a different perspective on geospatial data processing

and on the basis of the language of SensorML

(which is an event-driven technology) created

TaskML, which is the task-driven technology.

SensorML was also used as a framework for many

applications (Bröring, 2012), among others: EU

directive INSPIRE, EU-funded projects SANY,

South Africa AFIS project, and US OOSTethys

community Project. In (Jirka et al., 2012) is

presented a lightweight profile for the OGC Sensor

Observation Service that ensures the necessary

interoperability for environmental data provided by

the EEA’s member states. The possible applications

of SensorML in Polish SDI was proposed in

(Rogulski and Rossa, 2015).

An overview of the currently developed norms

and standards can be found in (Sánchez López,

2011). The authors discuss there, among others,

standards created by ISO (ISO/IEC 18000) or IEEE

(IEEE 1451). SensorML and O&M can also be used

in one of the newest OGC specifications – OGC

SensorThings API, created for the integration of

sensors, processes and results of observations and

measurements within the Internet of Things (IoT)

(Huang and Wu, 2016).

The basic idea of modelling using SensorML

specifications is to create measurement processes for

Application of SensorML in the Description of the Prototype Air Monitoring Network

309

which it is possible to determine the inputs, outputs,

parameters and additional information characterizing

individual steps of the process. These steps may be

other processes, measuring devices or sensors used

for measurements and observations. In its simplest

form, the measurement process may consist of a

single step. It is possible to create many different

types of processes relating to any components of the

environment. All of them are based on certain

common attributes present in the base process. The

processes can follow both the physical processes

associated with the measurements and observations,

as well as processes other than physical (e.g.

associated with a numeric processing of the

measured values or with modelling).

The core of SensorML specification is made of

the following two abstract classes, on which other

classes inherit:

DescribedObject – a class that provides basic,

common characteristics for classes of processes

(components), inherit from this class. Among

them we find a lot of descriptive characteristics

relating to general information about the process

(e.g. keywords, classifications), limitations (e.g.

validity period, access, intellectual property),

classifications (characteristics and parameters),

references (contacts and documentation), and

history. Some of them are grouped in code lists

providing the ability of easy analysis,

AbstractProcess – basic abstract class that

inherits from DescribedObject, offering

additionally attributes associated with inputs,

outputs and process parameters, indicating the

purpose of the process, as well as with the further

development of more sophisticated (e.g.

descriptively) derivatives processes.

On the basis of abstract classes following classes

are designed:

SimpleProcess – for indivisible processes, that is,

the implementation of which is treated as a

whole, consisting of one step. This class contains

additional properties that allow to describe the

methodology used in the process,

AggregateProcess – for complex, multi-step

processes, with the possibility of mapping data

flows between steps, that is determining that the

output of the step are input of the next step,

PhysicalComponent – to describe real, simple,

physical devices or sensors (processes

components), for which is important to define

spatial coordinates and time,

PhysicalSystem – used to model physical

devices, more complex than in the case of

Physical Component, as the processes for which

the location in the real world is known and

important,

Processes with Advanced Data Types – class

offering support for more advanced data types

than those offered by abstract class

AbstractProcess (e.g. DataArray, Matrix,

DataStream and Choice).

Some of the attributes belonging to the above

classes of SensorML specification, link to SWE

Common 2.0 components, as well as to the types and

structures defined in standards, in particular those

from ISO 19XXX series.

3 APPLICATION OF SENSORML

IN THE NETWORK OF AIR

QUALITY MONITORING

DEVICES

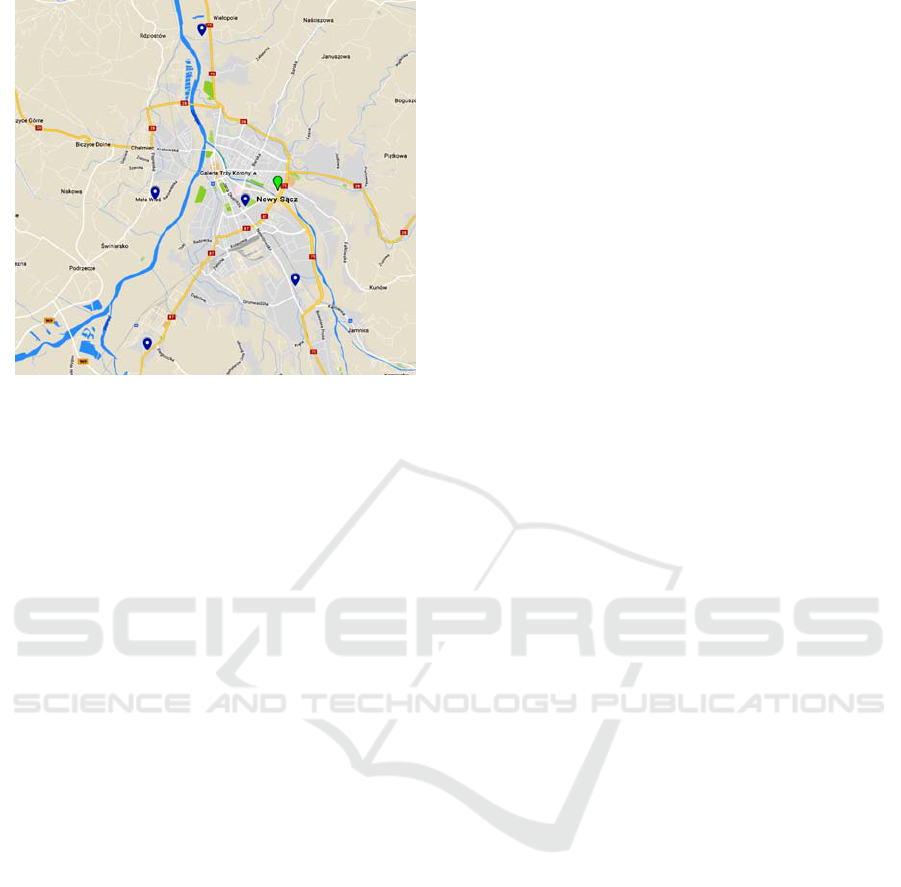

SensorML specification was used to design

structures in a relational database, where are stored

the data on the measurement network built using

prototype measuring devices in the city of Nowy

Sacz in the southern Poland. The devices were

designed by a team of researchers of the Faculty of

Electrical Engineering of Warsaw University of

Technology, and the measurement network was

established with the participation of scientists from

the Faculty of Building Services, Hydro and

Environmental Engineering of Warsaw University of

Technology. Measuring devices measure basic

meteo parameters, concentration of PM

1

, PM

2.5

,

PM

10

and CO. Prototype devices were installed in

September of 2016 and became operational in five

locations in Nowy Sacz. Installation locations

(shown in Figure 3) have been established by the

city authorities.

The purpose of the devices installation is

densification of the existing measurement network

for the area of Nowy Sacz, which consists of one

professional measurement device, owned by the

Regional Inspectorate for Environmental Protection

(RIEP). Another measuring station belonging to

RIEP is located in Szymbark near of Gorlice

(approx. 28 km in a straight line, but it does not

measure PM), and next in Tarnow (approx. 45 km in

a straight line). In the Małopolska Voivodeship, a

higher density of measuring stations occurs only in

and around Kraków, what is quite a considerable

distance from the city of Nowy Sacz. The city of

Nowy Sacz has more than 80 thousand residents,

and throughout Nowy Sacz County – approx. 200

thousand.

GISTAM 2017 - 3rd International Conference on Geographical Information Systems Theory, Applications and Management

310

Figure 3: Locations of prototype devices. For comparison

by a different colour indicated also station of RIEP (based

on: Google Maps).

The devices operate 24 hours a day. Every minute,

they send a message to the server with the values of

measurements and basic meteo parameters. Data

transmission from the devices is done using the

built-in modems and GPRS. On the server side

works a software to collect (listening service written

in Java) and storage of data (database MySql).

Data from the various additional devices are

available to residents at: http://www.nowysacz.pl/

pomiary-powietrza, making it possible to check the

air quality in the various districts. Ultimately, based

on data obtained from measurements and on

forecasts, an air quality index will be determined.

In connection with the planned development of

measurement network throughout the region of

Nowy Sacz and with the desire to achieve

interoperability of data to describe the devices and

the measurement process, SensorML 2.0 language

has been used.

The measurement process, modelled using

SensorML, consists of the following steps:

1. Collecting data using physical sensors gathered

in the measurement stations.

2. Automatic verification of data, or verification by

the operator.

3. Determination of indicator of air quality by the

appropriate algorithm (phase in progress).

The first stage was modelled as the Physical

Component, since it is made of components whose

location in the real world is known and of

importance. At this step there is the measurement of

air parameters (pollutions) and basic meteo

parameters. This is accomplished by sensors

concentrated in the measurement stations that sense

air and provide digital numbers representing the

measures of a property of that environment.

For the other two steps, their location is not

important and they are not implemented by the

physical measuring devices, therefore they are

modelled as the Simple Process. In the second step

takes place the verification of measurements results -

automatic and by a human. In the case of, for

example, sensor failure, the measurements results

can be classified as erroneous and do not take them

to the air quality assessment in the third step.

In the third step, on the basis of measurements of

pollution, meteorological data and forecasts, will be

determined air quality index, as the most affordable

for the residents. An appropriate algorithm will play

here a main role.

All three steps of data acquisition and processing

are combined in a multi-step measurement process

using class AggregateProcess.

For the first step, the most important parameters

involved in the process described herein are

following:

Process type: Physical Component,

Inputs: temperature, humidity, pollutions,

Outputs: weather (temperature, humidity),

pollutions (PM

1

, PM

2.5

, PM

10

),

System Location: locations of measuring points

(as shown in Figure 3),

System Components: Temperature sensor,

Humidity sensor, Pollution sensor.

For the second step, the most important

parameters involved in the process described herein

are following:

Process type: Simple Process,

Inputs: weather (temperature, humidity),

pollutions (PM

1

, PM

2.5

, PM

10

),

Outputs: weather (verified temperature and

humidity values), pollution (verified PM

1

, PM

2.5

and PM

10

values),

System Components: verification of pollutants,

verification of meteo parameters.

For the third step, the most important parameters

are as follows:

Process type: Simple Process,

Inputs: weather (verified temperature and

humidity values), pollutions (verified PM

1

, PM

2.5

and PM

10

values),

Outputs: air quality index,

System Components: determination of air quality

index.

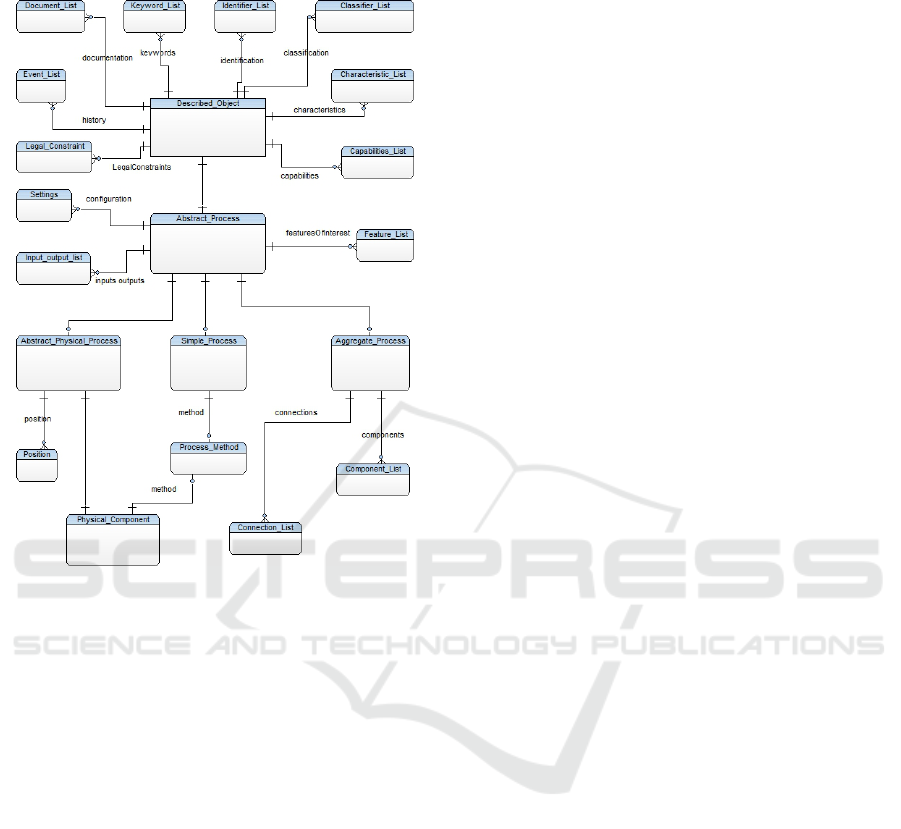

To enable the collection and storage of data on

sensors and measurement system, according to the

SensorML specification, application diagram was

brought to a relational database schema. The

Application of SensorML in the Description of the Prototype Air Monitoring Network

311

conceptual diagram of the most important entities is

shown in Figure 4.

Figure 4: ERD diagram based on SensorML.

Described_Object is a basic entity in the model,

corresponding to the class of DescribedObject from

SensorML. Complex class attributes, attributes that

are different data types, or cardinality more than 1,

are modelled as separate entities:

Keyword_List – keywords describing sensors

and various stages of the measuring process,

Identifier_List – a list of generic identifiers

describing sensors (names of sensors,

manufacturers, models, serial numbers) and the

successive stages of data processing,

Classifier_List – list of classifiers describing

sensors (e.g. dust sensor, sensor measuring

temperature, humidity), and the various stages of

the measurement process (manual correction of

the measurement results by the operator,

automatic determination of the air quality index),

Legal_Constraint – information about intellectual

property of used tools and algorithms – based on

ISO 19115 (intellectual property of measuring

station design, its software and algorithms used

in the subsequent phases belongs to the scientists

from the Warsaw University of Technology),

Characteristic_List – a detailed description of

used sensors and measuring stations (including

dimensions, connection method of individual

components) and the parameters of the

algorithms used in the subsequent stages of the

process,

Event_List – a history of changes to the system

parameters (e.g. information of sensors

replacements, repairs of measuring stations,

configuration changes, etc.),

Document_List – documentation of sensors

(from external suppliers), measuring station and

software used for the collection and transmission

of data, and documentation of developed

software tools used in the subsequent stages of

data processing.

Abstract_Process is an entity related to the class

AbstractProcess. Complex class attributes or

attributes, which are other types of data, were

modelled as separate entities:

Settings – information about the current settings

of individual components,

Feature_List – a list of objects for sensors

observation (e.g. atmosphere surrounding an air

monitoring station – in the case of sensors, air

quality in Nowy Sacz – in the case of

algorithms),

Input_Output_List – entity corresponding to the

attributes of 'inputs' and 'outputs' – contains a list

of inputs and outputs of specific steps.

Aggregate_Process is an entity related to the

class AggregateProcess, it ties all measurement

process steps. It includes:

Connection_List – connections between outputs

and inputs of individual steps,

Component_List – connections between the

elementary steps that make up the aggregate

process.

Abstract_Physical_Process is an entity related to

the class AbstractPhysicalProcess. It includes:

Position – information about the location of

individual sensors and the time of which they

were installed in a given location.

Physical_Component is an entity related to the

class PhysicalComponent. It includes:

Process_Method – a description of the

methodology of the measurement or processing

by algorithms.

Complete list of attributes in the individual

entities have resulted primarily from a list of

attributes (properties) of each class of specifications

of SensorML 2.0, SWE Common 2.0 and ISO 19115

standard. In addition, the model includes columns

relating to the physical implementation of the

relational schema in the database.

In order to record measurement results and bind

GISTAM 2017 - 3rd International Conference on Geographical Information Systems Theory, Applications and Management

312

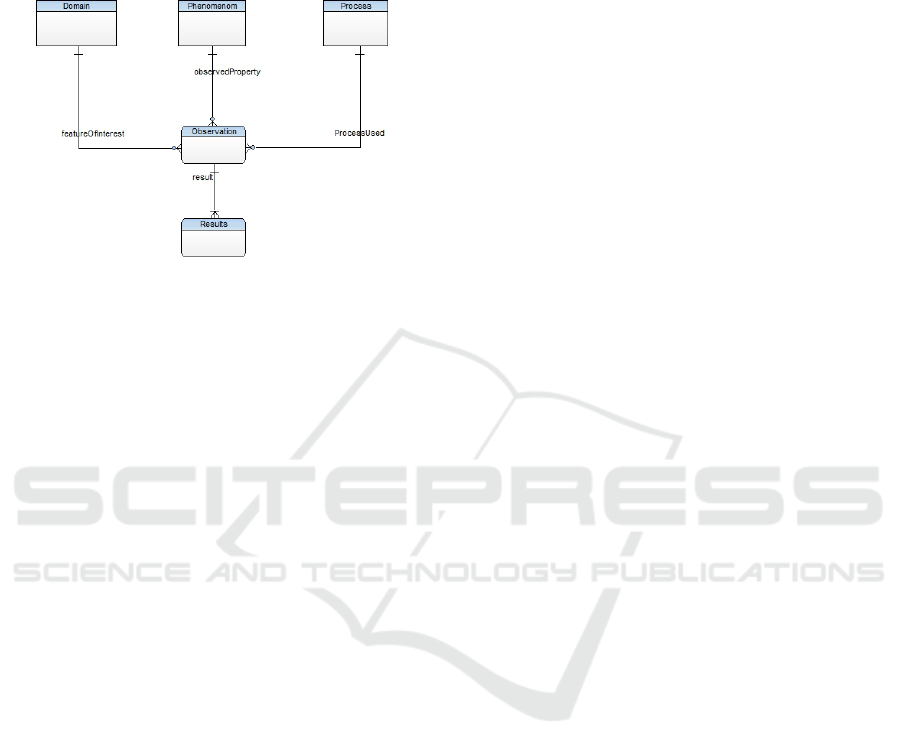

them to the respective steps of the measurement

process, an another standard of OGC has been

applied – Observations & Measurements (O&M). A

simplified conceptual diagram, designed to record

the results of measurements, is shown in Figure 5.

Figure 5: ERD diagram based on O&M.

Also in this case, individual entities and their

attributes essentially correspond to the classes and

attributes from the specifications O&M. The

relational model includes, among others, following

entities:

Domain – contains a list of objects from the real

world (featureOfInterest) which are investigated

by means of measurements (the list includes

values: atmosphere, air),

Phenomenon – contains a list of object properties

(observedProperty) which are investigated by

means of measurements (the list contains

humidity, temperature, pollution, dust),

Results – contains a list of measured values,

Process – contains a link to the measurement

process described by SensorML,

Observation – contains general data on the

elemental measurement which includes measured

values, among others, of various types of dust

and meteorological parameters.

4 CONCLUSIONS

Standards and specifications used to create

structures of relational databases are used to achieve

interoperability through data collection in an orderly

manner. Application of the standard SensorML and

guidelines from other standards of ISO and OGC, is

enabled by standardized description of the

measurement process. This is important when the

system consists of a number of measuring stations

and sensors. Building new, low-cost measuring

devices, that are designed to complement existing

measurement network, it was necessary to select

how to describe of devices, process, as well as

acquired data. In this context, the use of OGC

standards was quite natural, especially in the context

of the recently published OGC specification -

SensorThings API. Although, the currently operating

devices in Nowy Sacz are not directly available to

other users (and only the results of these

measurements), the use of OGC standards does not

close the possibility to this was available in the

future.

In the case of this system, there is a plan for

further development by adding more measuring

stations and sensors that measure other substances. It

is also possible to move existing measuring stations

to new places, so the above scheme will allow for

the storage of structured and standardized system

information. As a result, it is possible to build a

system whose elements will be fully interoperable.

In the future, it is planned to expand the system

by, among others, adding a set of interactive

webservices (with interoperable interfaces like the

OGC Sensor Observation Service – SOS), which can

be easily integrated with existing SDI and

geographical information systems. This will make

possible to easily create extracts of data describing

system and combine them with data from other

sources, by which a full interoperability of the

system will be achieved.

REFERENCES

Bröring, A., 2012. Automated On-the-fly Integration of

Geosensors with the Sensor Web. Ph.D. Dissertation,

University of Twente, Enschede, The Netherlands.

Bröring, A.; Echterhoff, J.; Jirka, S.; Simonis, I., Everding,

T., Stasch, C., Liang, S.; Lemmens, R., 2011. New

generation sensor web enablement. Sensors, vol. 11,

pp. 2652–2699.

Chen, N., Hu, C., Chen, Y., Wang, C., Gong, J., 2012.

Using SensorML to construct a geoprocessing e-

Science workflow model under a sensor web

environment. Computers & Geosciences, vol. 47, pp.

119–129, doi: 10.1016/j.cageo.2011.11.027.

Chen, N., Wang, X., Yang, X., 2013. A direct registry

service method for sensors and algorithms based on

the process model. Computers & Geosciences, vol. 56,

pp. 45–55, http://dx.doi.org/10.1016/

j.cageo.2013.03.008.

Conover, H., Berthiau, G., Botts, M., Goodman, H.M., Li,

X., Lu, Y., Maskey, M., Regner, K., Zavodsky, B.,

2010. Using sensor web protocols for environmental

data acquisition and management, Ecological

Informatics, vol. 5, pp. 32–41, doi: 10.1016/

j.ecoinf.2009.08.009.

Dziadak, B., Makowski, L., Michalski, A., 2011.

Embedding wireless water monitoring system in

Application of SensorML in the Description of the Prototype Air Monitoring Network

313

Internet. Przegląd Elektrotechniczny, vol. 4, pp. 246–

248.

Fan, M., Fan, H., Chen, N., Chen, Z., 2013. Active on-

demand service method based on event-driven

architecture for geospatial data retrieval. Computers &

Geosciences, vol. 56, pp. 1–11.

Higuera, J., Polo, J., 2012. Autonomous and Interoperable

Smart Sensors for Environmental Monitoring

Applications, in: Mukhopadhyay, S.C. (Ed.), Smart

Sensing Technology for Agriculture and

Environmental Monitoring, Lecture Notes in

Electrical Engineering. Springer Berlin Heidelberg,

pp. 323–359, doi:10.1007/978-3-642-27638-5_16.

Hu, Ch., Li, J., Chen, N., Guan, Q. 2014. An Object

Model for Integrating Diverse Remote Sensing

Satellite Sensors: A Case Study of Union Operation.

Remote Sensing, vol. 6, pp. 677–699, doi:

10.3390/rs6010677.

Hu, L., Yue, P., Zhang, M., Gong, J., Jiang, L., Zhang, X.,

2015. Task-oriented Sensor Web data processing for

environmental monitoring. Earth Science Informatics,

vol. 8, pp. 511–525, doi: 10.1007/s12145-015-0235-1.

Huang, Ch., Wu, Ch., 2016. A Web Service Protocol

Realizing Interoperable Internet of Things Tasking

Capability. Sensors, vol. 16, doi: 10.3390/s16091395

(sensors-16-01395).

IEEE Standard, Institute of Electrical and Electronics

Engineers. IEEE Standard Computer Dictionary: A

Compilation of IEEE Standard Computer Glossaries.

p. 42, New York, 1990.

ISO/IEC, Technical Draft Report, Ref. No. JTC1 SC36

WG4 N0070. Information Technology – Learning,

education, and training – Management and delivery –

Specification and use extensions and profiles, 2003.

US SC36 Secretariat.

Jiménez, M., González, M., Amaro, A., Fernández-Renau,

A., 2014. Field Spectroscopy Metadata System Based

on ISO and OGC Standards. International Journal of

Geo-Information, vol. 3, pp. 1003–1022, doi:

10.3390/ijgi3031003.

Jirka, S., Bröring, A., Kjeld, P., Maidens, J., Wytzisk, A.,

2012. A Lightweight Approach for the Sensor

Observation Service to Share Environmental Data

across Europe. Transactions in GIS, vol. 16: pp. 293–

312, doi: 10.1111/j.1467-9671.2012.01324.x.

Kim, J.-D., Kim, J.-J., Park, S.-D., Hong, C.-H., Byun, H.-

G., Lee, S.-G., 2011. A Smart Web-Sensor Based on

IEEE 1451 and Web-Service Using a Gas Sensor, in:

Computers,Networks, Systems, and Industrial

Engineering. Springer, Berlin, Heidelberg, pp. 219–

235, doi: 10.1007/978-3-642-21375-5_19.

Kotsev, A., Peeters, O., Smits, P., Grothe, M., 2015.

Building bridges: experiences and lessons learned

from the implementation of INSPIRE an e-reporting of

air quality data in Europe. Earth Science Informatics.

vol. 8, pp. 353–365, doi: 10.1007/s12145-014-0160-8.

Kotsev, A., Schade, S., Craglia, M., Gerboles, M., Spinelle

L., Signorini, M., 2016. Enriching Authoritative

Environmental Observations: Findings from

AirSensEUR. GSW 2016 - Geospatial Sensor Webs

Conference, Münster, Germany.

Kularatna, N., Sudantha, B.H., 2008. An Environmental

Air Pollution Monitoring System Based on the IEEE

1451 Standard for Low Cost Requirements. IEEE

Sensors Journal, vol. 8, pp. 415–422,

doi:10.1109/JSEN.2008.917477.

Lee, K., 2007. Sensor standards harmonization-path to

achieving sensor interoperability, in: IEEE

Autotestcon. IEEE, pp. 381–388.

Liang, S., Croitoru, A., Tao, C., 2005. A distributed

geospatial infrastructure for Sensor Web. Computers

& Geosciences, vol. 31, pp. 221–231, doi:

10.1016/j.cageo.2004.06.014.

Postolache, O., Girão, P.S., Pereira, J.M.D., 2011. Water

Quality Assessment through Smart Sensing and

Computational Intelligence, in: Mukhopadhyay, S.C.,

Lay-Ekuakille, A., Fuchs, A. (Eds.), New

Developments and Applications in Sensing

Technology, Lecture Notes in Electrical Engineering.

Springer Berlin Heidelberg, pp. 191–206, doi:

10.1007/978-3-642-17943-3_10.

Pu, F., Wang, Z., Du, C., Zhang, W., Chen, N., 2016.

Semantic integration of wireless sensor networks into

open geospatial consortium sensor observation service

to access and share environmental monitoring systems.

IET Software, vol. 10, pp. 45–53, doi: 10.1049/iet-

sen.2014.0141.

Rogulski, M., Rossa, M., 2015. The applicability of SWE

in Polish spatial data infrastructures - the example of

the SensorML language. Foundations of Computing

and Decision Sciences, vol. 40, pp. 187–201, doi:

10.1515/fcds-2015-0012.

Sánchez López, T., 2011. RFID and sensor integration

standards: State and future prospects. Computer

Standards & Interfaces, vol. 33, pp. 207–213, doi:

10.1016/j.csi.2010.09.002.

Saponara, S., Fanucci, L., Neri, B., 2011. IEEE 1451

Sensor Interfacing and Data Fusion in Embedded

Systems, in: Conti, M., Orcioni, S., Madrid, N.M.,

Seepold, R.E.D. (Eds.), Solutions on Embedded

Systems, Lecture Notes in Electrical Engineering.

Springer Netherlands, pp. 59–73, doi: 10.1007/978-94-

007-0638-5_5.

Tang, S.-M., Yeh, F.-L., Wang, Y.-L., 2001. An efficient

algorithm for solving the homogeneous set sandwich

problem. Information Processing Letters, vol. 77, pp.

17–22.

GISTAM 2017 - 3rd International Conference on Geographical Information Systems Theory, Applications and Management

314