MMI Fiber Optic Refractometer with Universal pH Indicator

Coating

Adolfo Rodríguez-Rodríguez

1

, René Domínguez-Cruz

2

, Daniel May-Arrioja

3

,

Ignacio Matías-Maestro

4

, Carlos Ruíz-Zamarreño

4

and Francisco Arregui

4

1

Department of Computer Systems Engineering, Autonomous University of Tamaulipas, Apdo. Postal 1460, Col. Arcoiris,

Reynosa, Tamaulipas, Mexico

2

Electrical and Electronics Department, Autonomous University of Tamaulipas, Apdo. Postal 1460, Col. Arcoiris, Reynosa,

Tamaulipas, Mexico

3

Centro de Investigaciones en Óptica, Unidad Aguascalientes, Prol. Constitución 607, Fracc. Reserva Loma Bonita,

Aguascalientes, Ags, Mexico

4

Departamento de Ingeniería Eléctrica y Electrónica, Universidad Pública de Navarra, Edif. Los Tejos,

Campus Arrosadía-31006, Pamplona, Spain

Keywords: Fiber Optic, Refractometer, Multimodal Effect, Universal pH Indicator.

Abstract: In this paper we show the preliminary results about fabrication of an optical fiber refractometer based on

multimode interference effects (MMI) provided with Universal pH Indicator coating. The layer, deposited

by coating dip-coating technique, allows increase the refractometer sensitivity which is around 344.5054

nm/RIU in a range of 1.333 to 1.4223. Highly repetitive and reversible refractometer have been achieved

using a simple fabrication process. The device shown offers the possibility to be used as instrument to

identify substances included aggressive liquids as gasoline.

1 INTRODUCTION

The refractometer is an interesting and useful tool to

analize the compounds and concentrations. This is

due to many applications as in biology, medical

science, environment control and process

engineering area. In this sense, optical fiber based in

refraction index (RI) sensors have been studied

broadly due to the advantages they offer such as

immunity to electromagnetic interference, compact

size, remote operation, high sensitivity and the

wavelength signals multiplexing. Some techniques

to implement RI sensing incorporate a fiber Bragg

gratings FBG (Han et al, 2010), long period gratings

LPG (Allsop et al, 2002), macro-bend single mode

fiber (Wang et al, 2009), surface plasmon resonance

(Liang et al, 2010), a Fabry-Perot interferometer

(Frazao et al 2009), or multi-D-shaped optical fiber

(Chen et al, 2010). However, an alternative,

attractive, low cost and simple technique for RI

measurements is based in multimodal interference

effects (MMI). MMI effect in optical fiber is

obtained by splicing a segment of Multimode Fiber

(MMF) between two segments of single mode Fiber

(SMF) as is showed in Figure 1. The MMI effect

relies on the fact that when the light field coming

from the input SMF enters the MMF, will excite

several modes, propagating along the MMF section,

thus causing interference between them. This means

that the optical power coupled to the output SMF

will depend on the amplitudes and relative phases of

the various modes at the exit end of the MMF. Also,

the MMI fiber structure can act as a bandpass filter

or edge filter depending on the length of the MMF

used. Thus, the operating principle of sensors based

on MMI structures relies in the interference between

excited modes that are propagating in MMF section,

which can be influenced by external perturbation

(Wang and Farell, 2006). Additionally, the MMI

devices has been proposed as sensors for micro-

displacement measurements (Antonio-Lopez et al,

2013), level sensor (Antonio-Lopez et al, 2011) and

temperature sensor (Ruiz-Perez et al, 2012).

Rodríguez-Rodríguez, A., Domínguez-Cruz, R., May-Arrioja, D., Matías-Maestro, I., Ruiz-Zamarreño, C. and Arregui, F.

MMI Fiber Optic Refractometer with Universal pH Indicator Coating.

DOI: 10.5220/0005821702730276

In Proceedings of the 4th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2016), pages 275-278

ISBN: 978-989-758-174-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

275

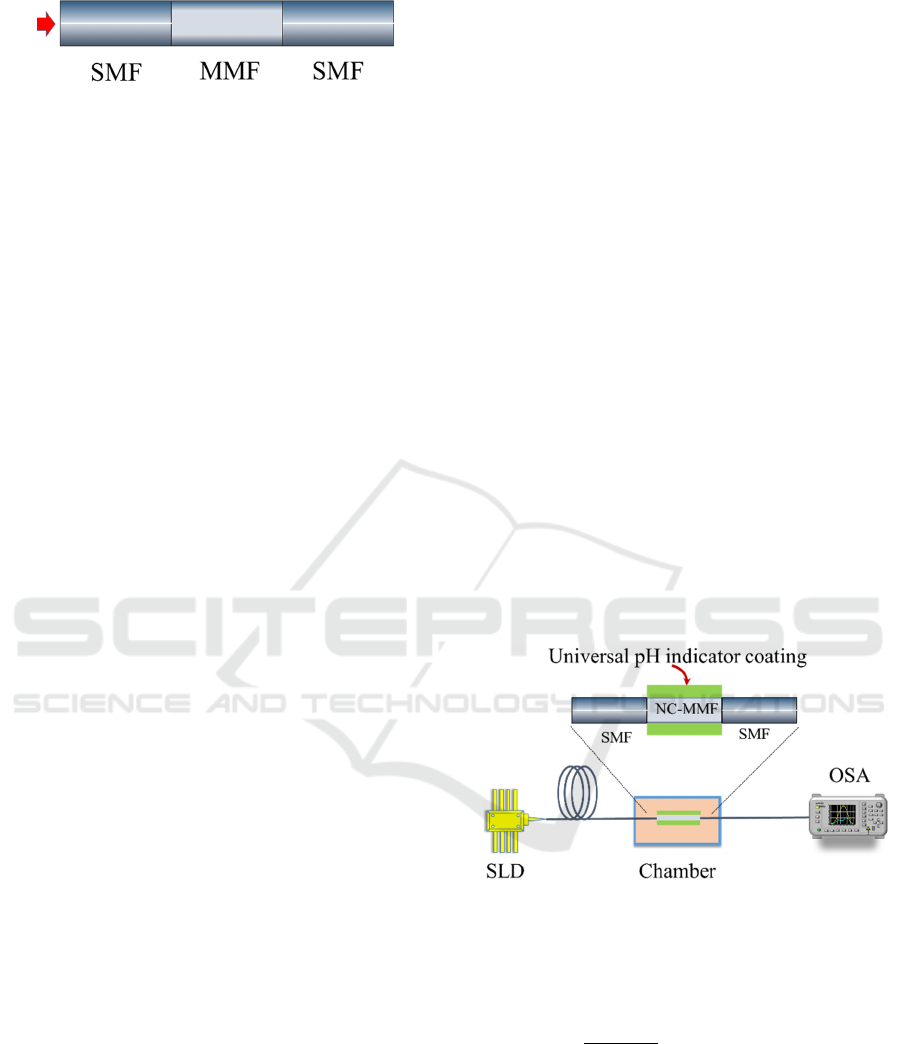

Figure 1: Structure of MMI element built in optical fiber.

(SMF, single mode fiber; MMF, multimode fiber).

In other hands, a universal indicator is

collectively a mixture of indicators which show a

colour change in a solution, which interprets how the

acidity or alkalinity of solutions is. Typically, a

universal indicator can be in paper form or present in

a form of a solution (Walker, 2007). Novel uses for

Universal pH Indicator have been proposed in

optical fiber sensors, such as ammonia detection

(Rodríguez et al, 2014) and in medicine field for

physiological processes in the patient’s body (Zajíc

et al, 2015). In this work we show a simple MMI

structure for RI measurements using No-core

Multimode fiber spliced between two Single Mode

fibers covered with a Universal pH Indicator coating

to increase the sensitivity. The MMI sensor is able to

detect different liquids such as water, ethanol

anhydrous and other liquid substances more

aggressive as gasoline.

2 EXPERIMENTAL SET-UP

2.1 MMI Refractometer Fabrication

To fabricate the refractometer based on the MMI

effect shown in this paper, we used two SMF

segments (with diameter of 8.2 µm for the core and

125 µm for coating) and No-core Multimode fiber

segment, NC-MMF (with diameter of 125 µm). For

a 58.13 mm segment of NC-MMF, their polymer

jacket was removed using acetone and it is spliced

between two SMF segments using a FSM Fujikura®

60S splicer. Lately, the NC-MMF section was

coated with the pH sensitive solution using a

standard dip-coating technique by deposition system

from Nadetech, Inc.® (Pamplona, Spain). The NC-

MMF fiber was inserted and pulled out of the

solution at a rate of 150 mm/min while the

temperature was maintained at 100 °C during the

whole process. The coated MMF element sensor was

kept at room temperature during 20 min, and then

placed into an oven for thermally curing at 85 °C for

15 min. To avoid losses for bending, we fixed the

MMI element on the surface of a chamber and we

perform all our measurement at room temperature.

To prepare pH sensitive solution, we use

Universal pH Indicator provided by the company

(PANREAC), which is made of a mixture of various

indicators such as methyl red (40 mg), p-

dimethylaminoazobenzene (60 mg), bromothymol

blue (80 mg), thymol blue (100 mg) and

phenolphthalein (20 mg) (Indicator Universal de pH,

2013). In order to immobilize the indicator on the

surface of the MMF fiber, the polymer is

incorporated into a thermoplastic host that allow

simple coating of the optical fiber. The pH sensitive

solution was prepared by mixing 120 mL of ethanol,

120 mL of pH universal indicator, and 4.32 g of

thermoplastic polyurethane (TPU), Tecoflex®

provided by the company Thermedics (Newton, NJ,

USA).

2.2 Experimental Array

Once upon fabricated the MMI refractometer and

fixed into a chamber, the ends of the SMF segments

are fused to single mode optical fiber provided with

FC/PC connectors. One of these connectors is

plugged to a Super-luminescent laser diode source

(SLD). The optical signal is propagating into the

MMI structure and is detected by an Optical

Spectrum Analyzer (OSA) ANRITSU MS9780. The

full experimental system is shown in Figure 2.

Figure 2: Experimental set-up.

To determine the operating parameters of the

MMI structure, we used the self-image distance L,

given as (Wang and Farell, 2006):

L= p ቈ

n

MMF

2

D

MMF

2

λ

o

; p=0, 1, 2, 3…

(1)

where D

MMF

= 125 µm and n

MMF

= 1.444 are the

diameter and refraction index of the NC-MMF

respectively, λ

o

is the wavelength in free space and p

is the number of the input field image that replicates

at the end of the MMF segment. However, due to the

nature of the MMI effect, the true images of the

input field are given at every fourth image (p=4).

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

276

The images formed at other positions are known as

pseudo-images, and although they resemble the

input field they exhibit higher losses. Thus, all our

experiments were operated at the fourth image of

MMI refractometer. To obtain tuning in 1560 nm in

air, the length of the NC-MMF must be L

π

=58.13

mm. A good approximation of the Equation (1) was

experimentally confirmed by the response of the

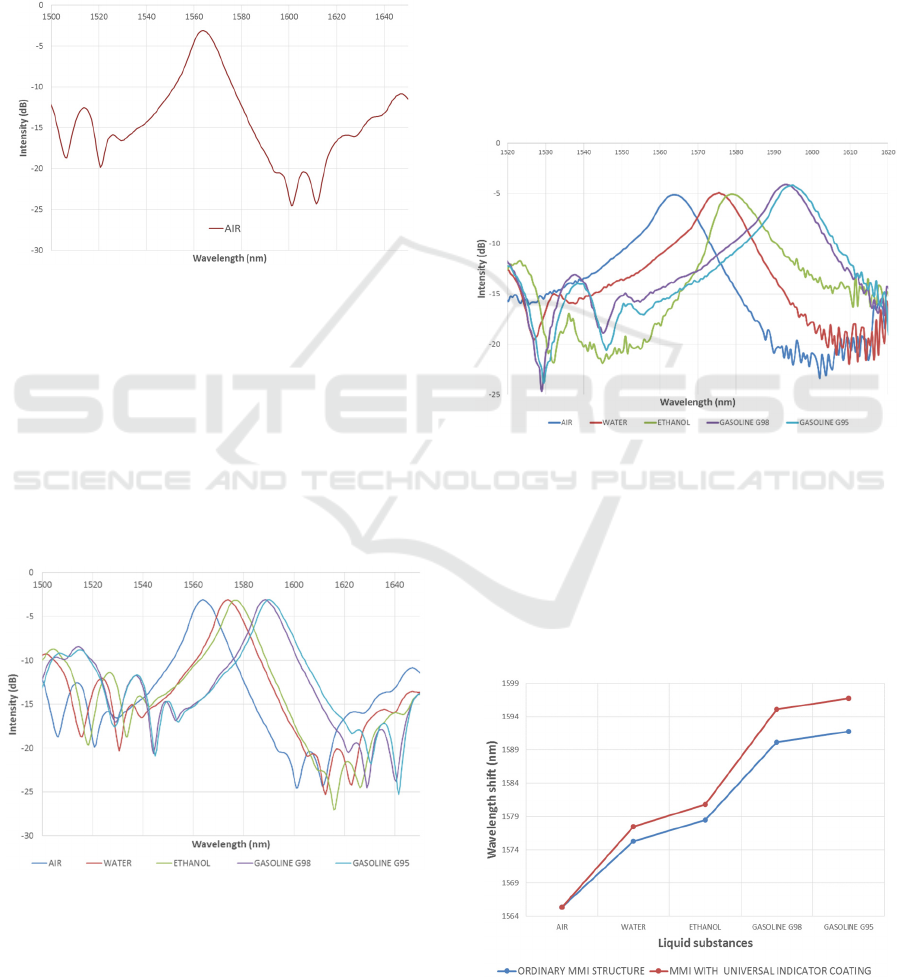

MMI structure shown in Figure 3.

Figure 3: Spectral response in air of MMI refractometer

without coating.

2.3 Results and Discussion

The MMI refractometer was initially characterized

without Indicator pH Universal coating with some

liquids such as water (n= 1.333), anhydrous ethanol

(n~1.3611), and commercial gasoline with 98

octanes and gasoline with 95 octanes (n ~ 1.4223).

The refractometer response to the different refractive

indexes is shown in Figure 4.

Figure 4: Spectral response of MMI refractometer without

coating for several liquid substances surrounding.

When we cover the NC-MMF segment with

water, anhydrous ethanol or gasoline, the condition

of self-image in the structure of MMI is modify and

we estimate a sensitivity around 290.1098 nm/RIU

(refractive index units).

The variation in humidity and temperature do not

significantly affect the behavior of MMI

refractometer when the measurements is performed.

Additionally, the recovery time of the device is less

than 15 seconds after a washing with acetone.

Due to the sensitivity of the MMI sensor is

directly related to the effective diameter (i.e. the

diameter of the NC-MMF and the surrounding

environment), we decided to fix on the NC- MMF a

coat of Universal pH Indicator coating thickness as

we explain in Section 2.1. The response of this new

refractometer shown in Figure 5. In this case, we can

estimate a sensitivity around 344.5054 nm/RIU.

Figure 5: Spectral response of MMI refractometer

provided with a Universal pH Indicator coating for several

liquid substances surrounding.

In Figure 6 we shows the shift of wavelength

peak for both MMI refractometers fabricated. In this

curve, we observe the increase in the sensitivity

when NC-MMF is provide with a Universal pH

Indicator coating. As consequence, this MMI device

offers a better resolution for the substances used.

Figure 6: Comparison of the wavelength shifts for

different MMI refractometers designed.

MMI Fiber Optic Refractometer with Universal pH Indicator Coating

277

As we explained before, a MMI structure is

fabricated by splicing a segment of MMF between

two SMF segments. In our device the MMI structure

is able to see the liquid surrounding the fiber

because the MMF does not have a cladding. A

simple way to enhance the sensitivity of the MMI

structure is to cover the MMF with a high RI thin

film. One aspect to consider is the control of the

coating thickness. If the film is too thick, it will start

guiding and all light from the MMF will be coupled

into the high RI film. When the MMI device with

high RI film is covered with a liquid, the effective

diameter of the fundamental mode is increased as

compared to a MMI structure without film under the

presence of the same liquid. As shown in Figure 6,

the MMI structure without film exhibits the typical

wavelength shift for the RI liquids (blue line).

Nevertheless, when the MMI structure is provided

with Universal Indicator coating, the MMI device

exhibit a larger wavelength shift and hence a higher

sensitivity (red line).

3 CONCLUSIONS

This paper we shown a fiber optic refractometer

based on the effect of multimodal interference

(MMI) provided with a Universal pH Indicator

coating on NC-MMF fiber and it was tested to detect

different liquids. The MMI device has a high

reproducibility and reversibility, no significant

interference against temperature or humidity.

The fabricated devices provide a simple and

inexpensive solution (based in a segment of NC-

MMF with specified length spliced between two

segments of SMF). The sensitivity of the structure is

increased when a layer of Universal pH indicator is

deposited on NC-MMF, which is 344.5054 nm/RIU.

The device can be a tool in the detection or

identification of substances included aggressive

liquids as gasoline, where the measured variable

depends of refractive index.

ACKNOWLEDGEMENTS

A.R.R. and R.D.C. thank the UAT for the support to

achieve this work. This paper was also supported by

the Spanish Economy and Competitivity Ministry-

TEC2013-43679-R.

REFERENCES

Han, M., Guo F., W., Lu, Y.(2010). Optical fiber

refractometer based on cladding-mode Bragg grating.

Opt. Lett, vol. 35, No. 3, pp. 399-401.

Allsop, T., Reeves, R., Webb, D. J., Bennion, I., Neal, R.

(2002). A high sensitivity refractometer based upon a

long period grating Mach-Zehnder interferometer.

Review of Scientific Instruments, vol. 73, no. 4, pp.

1702-1705, 2002.

Wang, P., Semenova, Y., Wu, Q., Farrell, G., Ti, Y.,

Zheng, J. (2009). Macrobending single-mode fiber-

based refractometer. Applied Optics, vol. 48, no. 31,

pp. 6044-6049.

Liang, H. M., Miranto, H., Granqvist, N., Sadowski, J. W.,

T. Viitala, Wang, B. C., Yliperttula, M. (2010).

Surface plasmon resonance instrument as a

refractometer for liquids and ultrathin films. Sensors

and Actuators B Chemical. Vol. 149, no. 1, pp. 212-

220,

Frazao, O., Caldas, P., Santos, J. L., Marques, P. V. S.,

Turck, C., Lougnot, D. J., Soppera, O. (2009). Fabry-

Perot refractometer based on an end-of-fiber polymer

tip. Optics Letters, vol. 34, no. 16, pp. 2474-2476.

Chen, C. H., Tsao, T. C., Tang, J. L. and Wu, W. T.,

(2010). A multi-D-shaped optical fiber for refractive

index sensing. Sensors, vol. 10, no. 5, pp. 4794-4804,

Wang, Q. and Farrell G. (2006). All fiber multimode

interference based refractometer sensor: proposal and

design. Optics Letters, vol. 31, no. 3, pp. 317-319.

Antonio-Lopez, J. E., LiKamWa, P., Sanchez-Mondragon,

J. J., and May-Arrioja, D. A. (2013). All-fiber

multimode interference micro-displacement sensor.

Measurement Science and Technology, vol. 24,

055104.

Antonio-Lopez J. E., May-Arrioja D. A. and LiKamWa P.

(2011). Fiber Optic Liquid Level Sensor. Photonics

Technology Letters, vol. 23, no. 23, pp. 1826-1828.

Ruiz-Perez V. I., Lopez-Cortes D., Sanchez-Mondragon J.

J. and May-Arrioja D. A. (2012). MMI Fiber Optic

Temperature Sensor. Procc. Latin American Optics

and Photonics Conference LAOP 2012, Paper LS3B.4.

Walker, D. (2007). Acids and Alkalis (1st Ed.). London:

Evans. p. 13. ISBN 0-237-53002-3. Retrieved 4 June

2015.

Rodríguez, A. J., Zamarreño, C., Matías-Maestro, I.,

Arregui, F. May-Arrioja, D.A. Domínguez-Cruz, R.F.

(2014), A Fiber Optic Ammonia Sensor Using a

Universal pH Indicator, Sensors, vol. 14, no. 3, pp.

4060-4073.

Zajíc, J., Traplová,L., Matjjec, V., Pospíšilová,M. and

Barto, I. (2015). Optical pH Detection with U-Shaped

Fiber-Optic Probes and Absorption Transducers.

Conference Papers in Science. Meeting on Materials

and Their Applications for Devices and Sensors.

Volume 2015, Article ID 513621.

PANREAC. Indicador Universal de pH. Available on:

<http://www.patacake.net/panreac/spanish/catalogo/fic

hastec/281370ES.HTM> [Accessed on 09 November

2015].

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

278