Function-centered Engineering of Embedded Systems

Evaluating Industry Needs and Possible Solutions

Marian Daun

1

, Jens Höfflinger

2

and Thorsten Weyer

1

1

paluno- The Ruhr Institute for Software Technology, University of Duisburg-Essen, 45127 Essen, Germany

2

Robert Bosch GmbH, 70442 Stuttgart, Germany

Keywords: Automotive Engineering, Early Design, Embedded Systems, Functional Design, Function-centered

Engineering.

Abstract: Research in engineering disciplines has to keep track of current developments and challenges in industry to

provide adequate solutions. As function-centered engineering of embedded systems is commonly used in

industry to cope with several challenges (e.g., to deal with the increasing number of functions realized in

software rather than in hardware, to reduce redundancy among functions implemented, to reduce the num-

ber of cost-intensive electronic control units and sensors, or to foster re-use of developed functions in multi-

ple systems and environments), it is of importance for research to identify challenges and needs arising from

function-centered engineering and to provide fitting solution concepts. To identify these industry needs, we

recently conducted a study among German embedded industry. We used a combination of different investi-

gation techniques (i.e. questionnaires, workshops and expert interviews, and case studies) to identify, con-

cretize, and verify industry needs. Furthermore, possible solution ideas were developed and evaluated to (i)

check appropriateness of identified needs and to gain more insights, as well as to (ii) provide first solution

concepts suitable for industry. This paper discusses the evaluation method, the major results and the current

state of the solution approach.

1 INTRODUCTION

Embedded systems are highly integrated systems

consisting of hardware and software parts. The soft-

ware part of embedded systems is increasing and

more and more functionality is realized by software

(Broy. 2006). For example, the car’s engine temper-

ature is no longer measured using a specific sensor.

Nowadays, it is predicted using existing distant

sensors and algorithms. Within this evolution, func-

tionality is not only bound to single software func-

tions deployed on single control units. Functionality

is realized through the interplay of different func-

tions, even of different control units. For example,

passenger protection in crash situations is realized

by the interplay of: the door control unit (to unlock

the doors), the body control module (to use the turn

signals to indicate an accident), the engine control

unit (to stop the engine), and, of course, the airbags.

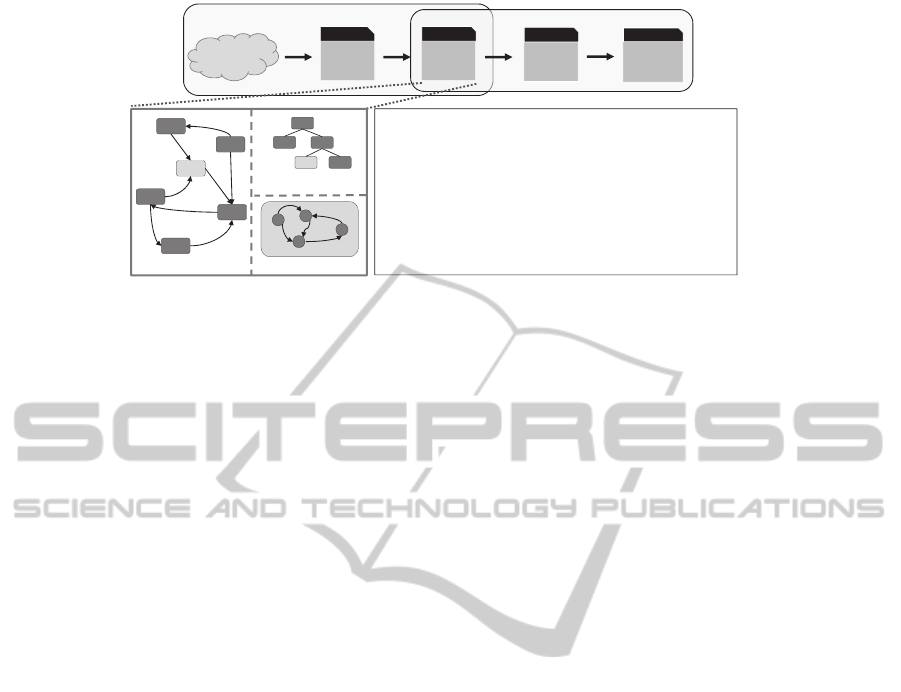

To design this functional interplay explicitly,

function-centered engineering (see e.g. (Pretschner

et al. 2007)) is commonly used. In function-centered

engineering, the system functions play a major role.

Therefore, a first functional design is created early in

the development process, right after the behavioral

requirements for the system have been specified (see

Figure 1). A functional design usually consists of

three types of artifacts: a function network which

defines the interactions and dependencies between

different functions, a function hierarchy which struc-

tures the system functions in terms of their sub-

functions, and diagrams defining the behavior of

each system function. The functional design then

serves as a basis for subsequent development activi-

ties like defining the electric and electronic architec-

ture or designing the deployment architecture.

To identify current industry needs and to meet

these needs by suitable solutions, we conducted a

study among German industry with regard to func-

tion-centered engineering of embedded systems. The

study was conducted in 2012/2013, participants stem

from large worldwide operating original equipment

manufacturers and suppliers. The study was qualita-

tive in nature with minor quantitative parts to gain

first insights. Therefore, we used questionnaires,

workshops and expert interviews, and case studies.

In addition, solution approaches were developed to

226

Daun M., Höfflinger J. and Weyer T..

Function-centered Engineering of Embedded Systems - Evaluating Industry Needs and Possible Solutions.

DOI: 10.5220/0004967202260234

In Proceedings of the 9th International Conference on Evaluation of Novel Approaches to Software Engineering (ENASE-2014), pages 226-234

ISBN: 978-989-758-030-7

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

RequirementsEngineering

Architectural Design

Behavioral

Require‐

ments

Artifact

Functional

Design

Stakeholder

Intentions

Artifact

Electric&

Electronic

Design

Artifact

Deployment

Architecture

Artifact

Function Network

Function Behavior

Function Hierarchy

A

A

A

CreationoftheFunctionalDesign:Definitionofthesystemfunctions,their

interactions,theirdependenciesandeachfunction’sbehaviorsuchthatthe

interplayofthefunctionnetworkfulfillsthebehavioralrequirements.

DefinitionoftheElectric&ElectronicDesign.Designofhardwarecomponents

thatcanexecutethedefinedsystemfunctionssuchthatthe

system‘squality

requirements(notshown)arefulfilledaswell.

DesignoftheDeploymentArchitecture.Partitioningofsinglesystemfunctions

intologicalcomponentsanddeploymentofthesecomponentstohardware

controlunitstofulfillbehavioralrequirements,tomeetdesiredsystem

qualities,andtooptimizethesystem‘squality.

DefinitionofBehavioralRequirements:Specificationofthedesiredoverall

systembehaviorthatsatisfiesthestakeholderintentions

Figure 1: Function-Centered Engineering Process and its Main Artifacts.

verify revealed needs, to gain further insights, and to

ensure suitability and appropriateness for industrial

usage. The study design is described in detail in

Section 2.

Section 3 discusses our main findings and the

current state of the solution approach: Automated

techniques for correctness checking and co-

evolution of engineering artifacts are desired to

support function-centered engineering. Albeit auto-

mated techniques are strongly desired, fully auto-

mated approaches are often not applicable to indus-

try (e.g. because in the development of safety-

critical systems decisions cannot be made in fully

automated manner). As solution the use of dedicated

review models for correctness checking and model

evolution seems appropriate. These models can be

created and processed in fully automated manner to

support manual decision-making by the responsible

engineer. In addition, if desired, further automated

techniques can be applied to aid the manual review.

In the end Section 4 concludes this paper and

discusses the generalizability of the results.

2 STUDY DESIGN

The study was designed to gain qualitative insights

into the current state of practice and industry needs.

Therefore, several techniques like questionnaires,

workshops and case studies were used to address the

following research questions:

RQ-1 Determine the current state of practice.

RQ-2 Identify problems and room for improvement

within the current state of practice.

RQ-3 Determine how the industry needs can be

solved by the use of current techniques, and

which enhancements are necessary.

Section 2.1 first introduces the participating compa-

nies. Section 2.2 details the investigative method and

Section 2.3 presents the techniques used.

2.1 Participants

The study was conducted among companies in-

volved in the German SPES 2020 XTCore project.

The participating companies have their main focus

of interest within the development of automotive or

avionic systems, are internationally operating, and

can be considered as large original equipment manu-

facturers or suppliers. The participants were chosen

by the companies and stem from research and pro-

ductive units. Most participants are working for at

least 5 years within the specific unit of the company.

They take part in the development process as re-

quirements engineer, function designer, architect, or

department/project leader.

2.2 Investigative Method

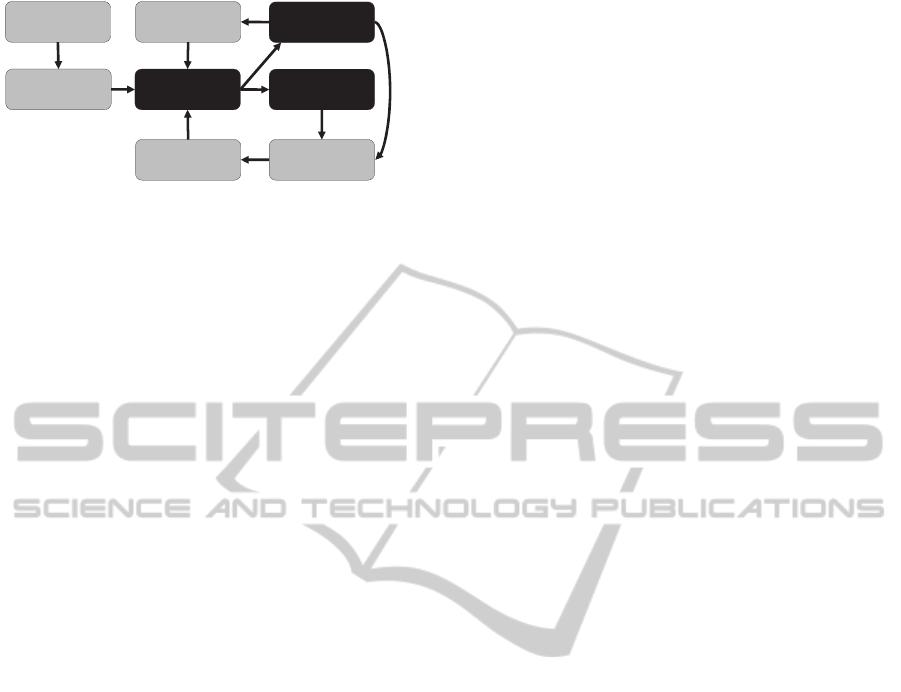

We performed our investigations in three steps (see

Figure 2). First, we developed an initial question-

naire to gain preliminary insights into the current

state of practice and into industry needs. Based on

the first results from the questionnaire, we conduct-

ed interviews with the participants as well as work-

shops to elaborate on the first results. Second, we

developed a solution approach to address the indus-

try needs that were revealed during the first step.

Third, we presented the solution approach to the

participants and conducted workshops and inter-

views again to gain more insights into their needs.

We used this newly gained knowledge to revise and

improve the solution approach. Besides, we also

applied our solution approach to industrial case

studies and presented them also to the participants.

Based on the feedback from the participants, we

once again concretized, revised, and enhanced our

knowledge about industry needs.

Function-centeredEngineeringofEmbeddedSystems-EvaluatingIndustryNeedsandPossibleSolutions

227

Figure 2: Used investigation techniques and results.

2.3 Used Elicitation Techniques

Questionnaire. The participants to the initial ques-

tionnaire were chosen and invited by their compa-

nies. The questionnaire itself was anonymous to

encourage real and unsugarcoated answers. This

prohibits drawing conclusions regarding a single

company. In total, 9 professionals participated in the

initial questionnaire.

The questionnaire was designed to get first in-

sights into current state of practice (RQ-1) and into

industry needs (RQ-2). Therefore, mostly half-open

questions were used to ensure all of participants’

answers could be sketched. Furthermore, 4-point or

6-point Likert scale items were used to elicit opin-

ions on industry needs and current state of practice.

This was chosen to force participants to make a

decision in terms of yes or no, good or bad, and not

allowing neutral answers. Also open questions were

used to give the participants the possibility to com-

ment on their answers and to discuss the understand-

ing of common used vocabulary. The questionnaire

itself was designed in iterative evolution by us, other

academic partners, and industry partners within the

SPES project. For final quality assurance, empirical

experts from the Fraunhofer Institute for Empirical

Software Engineering conducted a final review of

the questionnaire and provided suggestions.

Workshops and Expert Interviews. Experts partic-

ipating in interviews and workshops were also cho-

sen by the companies. Since questionnaires were

conducted anonymously, there is no knowledge

about the relationship between participants in the

questionnaire and participants in the interviews and

workshops. Most participants in the interviews or

discussion rounds were advanced engineers, with

knowledge gained by years of work within the com-

pany in different roles and projects. To reduce itera-

tion cycles between local workshops, regular tele-

phone conferences were held. This setting allowed

for fast feedback as well as fast rework of case stud-

ies and of the solution approach.

Workshops and expert interviews were conduct-

ed to validate and to detail the results taken from the

questionnaires. Furthermore, workshops were con-

ducted to evaluate possible solutions and the results

from the case studies. Thereby, the workshops ad-

dressed RQ-1, RQ-2, and also RQ-3.

Solution Approach. A solution approach was de-

veloped to support the identification of industry

needs (RQ-2) and to gain insights whether industry

needs may be solved by the current state of the art

(RQ-3). It revealed that the current state of the art

could not solve all industry needs. Therefore, we

developed our own initial solution approach based

on the state of the art. This initial solution approach

has been evaluated in workshops as appropriate and

will be enhanced in future work.

Case Studies. All case studies are typical represent-

atives of embedded systems of the automotive and

the avionic domain. The gained industry needs were

used to develop adequate case studies, for example,

of a lane keeping support, a parking assist system, or

a collision avoidance system. All case studies were

used to validate and concretize revealed industry

needs (RQ-2). Beside RQ-2, case studies also ad-

dressed RQ-3 by examining whether the developed

solution approach is appropriate.

Development of the case studies according to in-

dustry needs and the application of the solution

approach to the case studies were conducted in co-

operation between us, other academic partners, and

other industry partners.

3 RESULTS

During the study two major needs were identified:

(i) the need for continuous engineering (Section 3.1)

and (ii) the need to ensure correctness of the func-

tional design (Section 3.2). In addition, needs re-

garding the model usage in function-centered engi-

neering were unveiled (Section 3.3). These docu-

mentation formats result from the desire for continu-

ous engineering and correctness of the functional

design. They were also needed to develop a suitable

solution approach to meet industry needs. Section

3.4 presents the current state of the proposed solu-

tion approach.

3.1 Continuous Development

We investigated industry needs regarding the devel-

opment process of function-centered engineering. In

a first step, we evaluated the current situation of

development processes used within the participants’

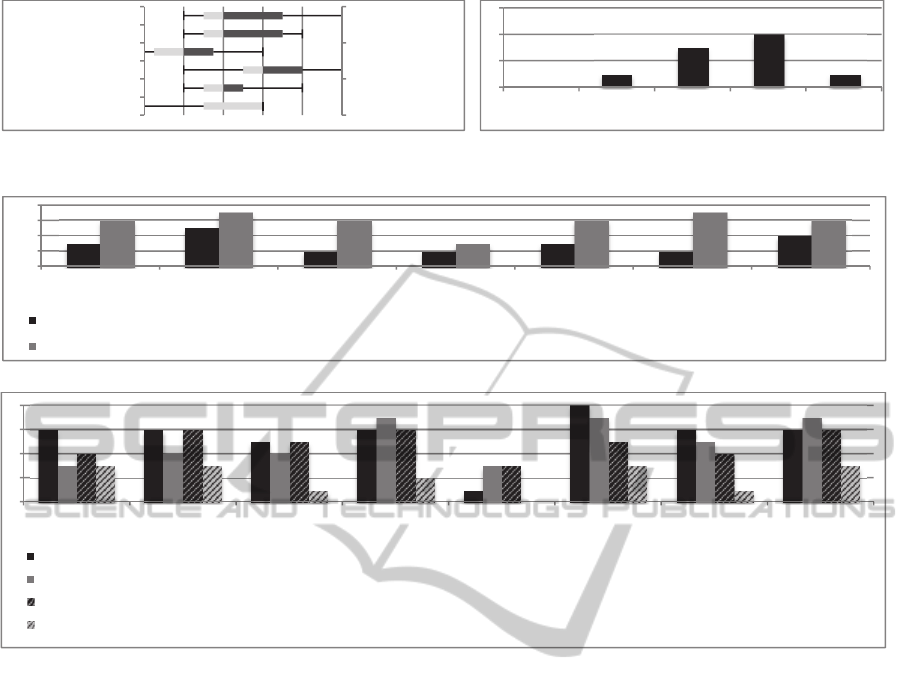

companies. As Figure 3 (a) depicts, in general the

Use Questionnaires to

gain first Insights

Validate Results by

the use of Workshops

and ExpertInterviews

Document and

UpdateKnowledge

about Industry Needs

Develop and

Concretize possible

SolutionApproaches

Develop realistic

industrial Case

Studies

Validate Solutionby

the use of Workshops

and ExpertInterviews

Validate Results by

the use of Workshops

and ExpertInterviews

Apply Solution

Approaches to the

CaseStudies

ENASE2014-9thInternationalConferenceonEvaluationofNovelSoftwareApproachestoSoftwareEngineering

228

(a) The current development process within our company is… (b) There is a need to develop an approach addressing the

continuous functional analysis of functional properties and

functional dependencies

(c) Consideration of function networks during development phases – current situation and needed situation

(d) Artifacts used and needed to document functional properties and functional dependencies

Figure 3: Results from the Questionnaires.

development process itself seems to be existent (i.e.

a systematic development process is applied and

pursued). It can also be recognized that model-based

development is used within the industry, as well as

explicit documentation seems to be rather common.

It becomes also clear, that most development pro-

cesses are rather uncontinuous. In addition, the re-

sults in Figure 3 (b) suggest that there is an intense

industry need to support continuous development

within function-centered engineering. This was

approved by the interviews and workshops.

To concretize the need regarding specific phases,

we asked the participants whether function networks

are considered during single development phases

within their companies and whether they think that

function networks should be considered in the single

phases. As the results depicted in Figure 3 (c) indi-

cate, function networks are currently mainly consid-

ered in basic design (i.e. the functional design is

built during basic design), and in configuration (i.e.

to derive single products from software product

lines). As shown, the most room for improvement is

seen regarding requirements engineering, detail

design (phase which develops the technical architec-

ture), safety engineering and testing.

In subsequent workshops and expert discussions

industry partners agreed on three major needs to

support the continuous development in function-

centered engineering:

Automated support for the evolution of the func-

tional design from behavioral requirements, and

for updating the functional design, due to chang-

es in the requirements specification.

Automated support for change propagation from

functional design back to the requirements. This

is due to the fact, that different responsible engi-

neers evolve the functional design and behavioral

requirements after their creation. These tasks are

often independent from each other and lead to

inconsistencies, which affect the correctness.

Automated support to develop artifacts in the

later phases. Since the functional design serves

as the major artifact of function-centered engi-

neering, all subsequent artifacts are based on the

functional design.

incomplete

not clearly arranged

not existent

uncontinuous

undocumented

not model-based

model-based

documented

continuous

existent

clearly arranged

complete

0

2

4

6

not agree tend to not

agree

tend to

agree

agree not

answered

0

2

4

6

8

Requirements

Engineering

Basic Design Detail Design Implementation Test Safety Engineering Configuration

Functionnetworks are considered during these development phases within our company

There is a need for consideration of function networks within these development phases

0

2

4

6

8

Textual Design Textual

Requirements

Scenario Models Logical/ Functional

Architecture

Technical

Architecture

Behavioral Models Contextual Models Informal Lines and

Boxes

These artifacts support modelling of functional properties

These artifacts support modelling of functional dependencies

These artifacts are used within our company

These artifacts are used for documentation of functional properties and dependencies within our company

Function-centeredEngineeringofEmbeddedSystems-EvaluatingIndustryNeedsandPossibleSolutions

229

Solution Idea. To support the continuous develop-

ment in early phases, common model transformation

techniques (e.g. (Milicev. 2002)) may be used.

These approaches are adapted to fit the transfor-

mation from behavioral requirements to functional

design. Albeit, this seems to be an appropriate sup-

port to develop an initial consistent functional de-

sign, it does not support the continuous development

in later phases (when the behavioral requirements

and the functional design are already existent). Par-

ticipants claimed that a fully automated approach

(e.g. by use of model synchronization techniques

like (Giese and Wagner. 2006) or (Hermann et al.,

2013)) is desired, but not applicable. This is due to

parallel development: it is common in industry that

different specifications are reworked at the same

time. This means that changes may be applied to the

behavioral requirements, while at the same time

other changes are applied to the functional design.

Automated techniques cannot resolve inconsisten-

cies in this case, since it is not decidable, which

elements are correct. To address this issue the use of

dedicated review models seems appropriate. These

models are generated by automated model transfor-

mations and reviewed and revised by the responsible

engineer. Note that, these revisions may lead to

necessary changes to the source model as well.

These changes once again are propagated by the use

of another review model.

To support the development of artifacts of the

later phases, such as the electric and electronic archi-

tecture or the deployment architecture, existing au-

tomated techniques can be adopted. Therefore, graph

analysis techniques (e.g. (Cox et al., 2001)), or pat-

tern matching techniques (e.g. (Beyer et al., 2005),

or (Gross and Yu, 2001)) seem appropriate.

3.2 Correctness of the Functional

Design

Discussions regarding the need for continuous de-

velopment and its possible solution pointed out that

the functional design is the central engineering arti-

fact and is connected to nearly all other artifacts

such as the behavioral requirements, the electric and

electronic design and the deployment architecture.

Therefore, industry professionals stressed the need

to ensure the correctness of the functional design.

In particular automated support for detection and

correction of deficiencies is needed. Following cir-

cumstances were described as major sources of an

incorrect functional design:

Changes to the behavioral requirements.

Changed stakeholder intentions, which have not

been documented within the behavioral require-

ments. These typically arise during the evolution

of the functional design and concretizations dis-

cussed with the stakeholders.

Unspecified behavior resulting from functional

interplay, which arises from the combination of

multiple functions. The single functions behav-

iors create new, unspecified behavior in their in-

terplay, much akin to feature interactions.

Solution Idea. Like supporting the continuous de-

velopment, the problem of decidability whether the

behavioral requirements or the functional design is

correct, prohibits the use of automated correctness-

checking techniques like (Clarke et al., 2009) or

(Holzmann, 1997). In addition, stakeholder inten-

tions may change due to realization decisions and

thereby both artifacts (the functional design and the

behavioral requirements) may become outdated.

Another reason, why current correctness-checking

techniques are not applicable is that they provide

only one single counterexample that is not related to

the original models. According to the participants,

this is also inadequate for industrial use. This finding

is consistent with shortcomings of model checking

described by (Borges et al., 2010).

In contrast manual review approaches seem to be

very effective in many studies (e.g. (Boehm and

Basili. 2001); (Gilb and Graham. 1993)). Especially

perspective-based reviews seem to be promising (cf.

e.g. (Shull et al. 2002)). In discussions, the partici-

pants also stated that they think perspective-based

reviews could be helpful to check the correctness of

the functional design. By application of this tech-

nique to the case studies, some deficiencies were

unveiled: e.g. manual reviews of both artifacts (be-

havioral requirements and functional design) did not

necessarily ensure consistency between them, and

architects reviewing the requirements and require-

ments engineers reviewing the functional design

were not familiar with the documentation languages

in which the respective artifacts were documented.

To this end it was agreed, that a dedicated review

model supports the correctness checking of the func-

tional design best. The review model can be derived

by automated model transformations from behavior-

al requirements and functional design. Thereafter,

manual and automated reviews can be performed to

ensure the correctness of the review model. By fully

automated back transformations of the review model

changes can be propagated and the correctness be

ensured. As the use of a review model is also sug-

gested to address continuous function-centered engi-

neering, this is convenient to increase acceptability,

since model evolution and correctness checking can

ENASE2014-9thInternationalConferenceonEvaluationofNovelSoftwareApproachestoSoftwareEngineering

230

be conducted within one step.

3.3 Model Usage

As the functional design is the central development

artifact and the correctness of the functional design

is related to the documented behavioral require-

ments, requirements regarding both artifacts were

elicited. To determine which model types are neces-

sary to document requirements and the functional

design, we questioned the possible benefit of model

types to support the documentation of functional

properties and functional dependencies. We also

asked about the current overall usage of these arti-

fact types within the interviewees’ companies and

their current usage to support documentation of

functional properties and functional dependencies.

The results are depicted in Figure 3 (d). By further

interviews, these results have been concretized.

Behavioral Requirements. Currently, textual re-

quirements, scenario models, behavior models and

context models are mainly used for specifying em-

bedded software requirements in practice. All of

them seem to be appropriate to support the docu-

mentation of functional properties and functional

dependencies. But, neither of them is used to support

the documentation of functional properties and de-

pendencies in practice. By further discussions with

domain experts we gained the insight that this is

once due to the use of partial models in different

languages and once due to the fact that many func-

tional dependencies result from design decisions not

taken during requirements engineering.

Use of interviews and applications to the case

studies gave rise to the comprehension that the most

valued requirements for embedded systems are be-

havioral requirements. To be more precise, especial-

ly interaction-based behavioral requirements models

(e.g. sequence diagrams) have been proven useful in

the context of embedded systems. This is due to

their capabilities in discussing stakeholder intentions

(which are well known from scenario-based re-

quirements engineering) and due to their ability to

focus on the externally visible behavior by means of

interactions. The latter is of special interest to agree

on the interfaces of the embedded software and to

separate the software under development from its

context.

As Figure 3 (d) shows, textual requirements are

used and seem to be able to support the documenta-

tion of functional properties and dependencies. By

further discussions it was revealed that textual re-

quirements are mostly used due to contractual needs

between supplier and integrator or supplier and sub-

supplier. From application of the case studies and

further investigations, it was agreed that textual

requirements as well as textual design documents do

not support function-centered engineering adequate-

ly: textual requirements and design artifacts lack

formalism, which is needed to support industry

needs regarding automated support for continuous

development and formal proof of correctness.

Solution Idea. As discussed, behavioral require-

ments are defined to distinguish between the system

and its context, to briefly sketch the system’s inter-

faces in terms of message exchanges and to describe

the intended system behavior in terms of inputs and

outputs. To document such behavioral requirements,

interaction-based models are appropriate. In the

engineering of embedded software, message se-

quence charts (ITU. 2011) are commonly used for

this purpose (Weber and Weisbrod, 2002). There-

fore, the participants of our study agreed on using

message sequence charts for documenting behavior-

al requirements. Their formal semantics (see (ITU,

2011), (Mauw and Reniers, 1999), and (Hélouёt and

Maigat, 2001)) adequately support the usage of

automated techniques.

Functional Design. As Figure 3 (d) depicts, behav-

ioral models, logical/structural models and context

aspects seem to be of specific importance to the

function-centered engineering process. Since the

functional design is the central artifact of function-

centered engineering, it is important to keep the

functional design self-contained. Workshops, inter-

views and applications to the case studies revealed

following requirements for the desired documenta-

tion format of the functional design.

Specify the behavior of system functions. Fur-

thermore, not only the behavior of single system

functions has to be defined, there is a specific

need to reckon the functional behavior resulting

from the interplay of different system functions.

Document the structure of functional dependen-

cies. For example, these dependencies are needed

to analyze the functional design, to detect defi-

ciencies or to support the partitioning of func-

tions for the electric and electronic design.

Separate between system functions and context

functions. Context functions are functions in the

context of the software under development. They

belong to other software parts of the system, can

be used, but not changed.

Solution Idea. To address all requirements, a model

for the functional design, consisting of three diagram

types, was developed. As it is common to use com-

plementary diagrams to describe function behavior

Function-centeredEngineeringofEmbeddedSystems-EvaluatingIndustryNeedsandPossibleSolutions

231

(e.g. (Klein et al., 2004)), we suggested the use of

interface automata (cf. (Alfaro and Henzinger,

2001)) to describe the functional behavior of single

functions. Interface automata can be composed to

describe the overall system behavior. To document

the functional hierarchy, we suggested the use of

feature trees (cf. (Kang et al., 1998)). On the one

hand, these diagrams are common in industry and,

on the other hand, they provide the opportunity to

describe variability which is of specific relevance to

the automotive industry. In addition, to document

functional dependencies, we suggested the use of

function network diagrams. Current notations lack

the necessary formalization to address industry

needs regarding automation (cf. (Brinkkemper and

Pachidi, 2010)). Therefore, a formalized diagram

type was defined, that is compatible to the informal

diagrams currently used in industry (e.g. (Jantsch

and Sander. 2000), (Grönniger et al., 2008), or

(Beeck, 2007)).

3.4 Solution Approach

As explained in Section 2, a solution approach was

developed (i) to address the revealed industry needs

and thereby improve current function-centered engi-

neering processes, and (ii) to validate and concretize

the revealed industry needs themselves. While sev-

eral solution ideas approved by industry profession-

als were discussed within Sections 3.1, 3.2, and 3.3,

this section summarizes the current state of the over-

all approach and discusses necessary future en-

hancements. A more detailed view on several parts

of the solution can be found in (Daun et al., 2014).

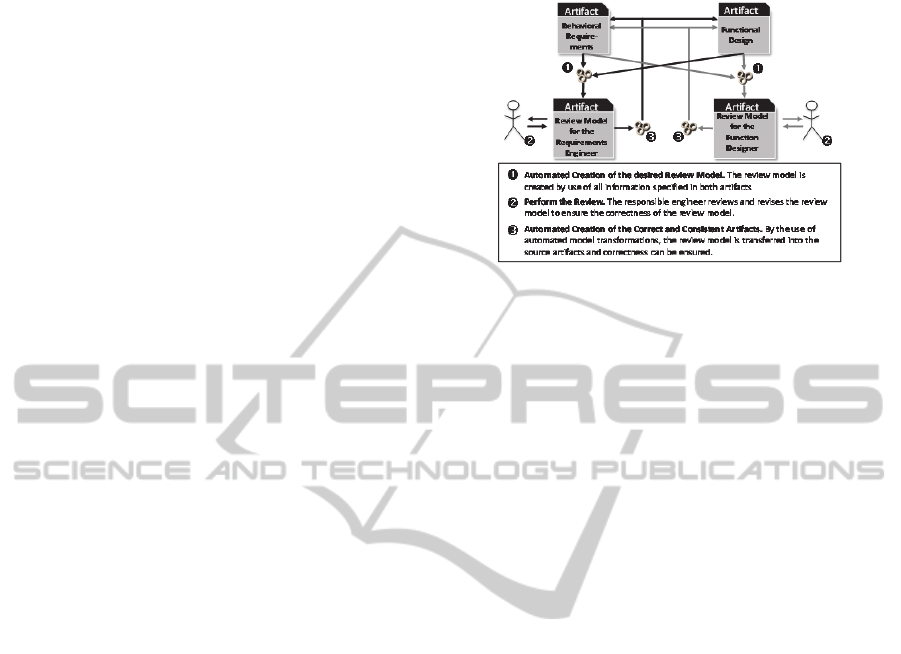

The main idea is based on the use of dedicated

review models to support continuous model evolu-

tion between behavioral requirements and functional

design, and to support correctness checking of the

functional design. The solution approach mainly

uses adaptations and enhancements of existing tech-

niques to address the automated creation of the re-

view model and its back transformation. Therefore,

model synthesis and transformation were designed

to address behavioral requirements (described by use

of message sequence charts) and a functional design

(described by function network diagrams, function

behavior diagrams, and function hierarchy dia-

grams). The process steps for creation and pro-

cessing of the review models are sketched in Figure

4. To review and evolve the functional design, the

requirements engineer is provided with a behavioral

requirements like description of the functional de-

sign, the functional architect is provided with a func-

tional design like description of the behavioral re

quirements.

Figure 4: Proposed solution concept.

As discussed, future work will have to deal with

the automated analysis of the functional design to

support the creation of subsequent artifacts like the

deployment architecture. Promising techniques to

foster this issue were identified, but were not applied

to the case studies, yet. Such automated techniques

are also desired to support the review itself, for ex-

ample to determine, which parts of the review model

are probably incorrect and what solutions could be

like. In addition, the current solution revealed the

desire for more concrete diagrams within the review

models. For example, to detect functional interplay

and to decide, whether this interplay is desired or not

specific diagrams, detailing only the interplay could

support the engineers. Therefore, current approaches

to detect implied scenarios (e.g. (Letier et al., 2005),

or (Alur et al. 2000)) and approaches dealing with

the feature interaction problem e.g. ((Felty and Nam-

joshi, 2003), or (Shiri et al., 2007)) seem promising.

4 DISCUSSION & CONCLUSION

We presented a study conducted to gain insights into

industry needs regarding the function-centered engi-

neering of embedded systems. The study design, the

major industry needs revealed and ideas for suitable

solutions to the industry needs were discussed in

more detail. It revealed that industry desires auto-

mated method support to foster continuous engineer-

ing and model evolution as well as correctness

checking of the functional design, which is the main

artifact in function-centered engineering. As fully

automated techniques were evaluated as not applica-

ble in every situation, the presented preliminary

solution approach is widely based on dedicated re-

view models. These models can be created in auto-

mated manner and the review results can be pro-

ENASE2014-9thInternationalConferenceonEvaluationofNovelSoftwareApproachestoSoftwareEngineering

232

cessed fully automated as well, but the review itself

is mainly based on manual investigations.

As the study was conducted among German in-

dustry and the number of participants was small it

must be discussed, whether the results are general-

izable or not. The participating companies were

asked to send only professionals that are representa-

tive for the company. Furthermore, the questionnaire

was not used to determine industry needs presented

within this paper. The questionnaire was used to

gain first insights into potential industry needs.

Therefore, the results of the questionnaires were

qualified by interviews. Afterwards, they were con-

cretized and confirmed by the use of workshops and

by the use of industrial case studies. By the combi-

nation of these techniques, we assume that the re-

sults are representative for at least large European

companies in the automotive and avionics domain.

Participants stem from worldwide operating compa-

nies with branches in other countries, especially

throughout Europe, which indicates, that our find-

ings are not bound to national borders. Beside of

this, we assume that our findings are probably not

valid for all parts of the embedded systems domain:

Since the usage of model-based engineering and the

desire for consistency and correctness within speci-

fications is related to the development of safety-

critical systems.

ACKNOWLEDGEMENTS

The research serving as basis for this paper has has

been funded in part by the German Federal Ministry

of Education and Research (support code:

01IS12005C+M). We thank Carsten Albers (with

Inchron), Arnaud Boyer (with Airbus) and Matthias

Büker (with the offis institute) for their fruitful sup-

port in designing the questionnaire and conducting

the study. We thank Nelufar Ulfat-Bunyadi (with

paluno) for the inspiring discussions about the paper.

REFERENCES

Alfaro, L. & Henzinger, T. (2001), Interface Automata.

Proc. of the ESEC/FSE, pp. 109-120.

Alur, R., Etessami, K., & Yannakakis, M. (2000), Infer-

ence of Message Sequence Charts. TSE, pp. 623-633.

Beeck, M. (2007), Development of logical and technical

architectures for automotive systems. Software Sys-

tems Modeling, pp. 204-219.

Beyer, D., Noack, A. & Lewerentz, C. (2005), Efficient

Relational Calculation for Software Analysis. TSE, pp.

137-149.

Boehm, B. & Basili, v. (2001), Software Defect Reduction

Top 10 List. IEEE Computer, pp. 135-137.

Borges, R., Garcez, A. & Lamb, L. (2010), Integrating

Model Verification and Self-Adaptation. Proc. of the

ASE, pp. 317-320.

Brinkkemper, S. & Pachidi, S. (2010), Functional Archi-

tecture Modeling for the Software Product Industry.

Proc. of the ECSA, pp. 198-213.

Broy, M. (2006),Challenges in automotive software engi-

neering. Proc. of the ICSE, pp. 33-42.

Clarke, E., Emerson, E. & Sifakis, J. (2009), Model check-

ing: algorthmic verification and debugging. Commun.

ACM, pp. 74-84.

Cox, L., Delugach, H. & Skipper, D. (2001), Dependency

Analysis Using Conceptual Graphs. Proc. of the ICCS,

pp. 117-130.

Daun, M., Weyer, T. & Pohl, K. (2014), Validating the

Functional Design of Embedded Systems against

Stakeholder Intentions. Proc. of the MODELSWARD,

pp. 333-339.

Felty, A. & Namjoshi, K. (2003), Feature Specification

and Automated Conflict Detection. TOSEM, pp. 3-27.

Giese, H. & Wagner, R. (2006), Incremental Model Syn-

chronization with Triple Graph Grammars. Proc. of

the MoDELS, pp. 543-557.

Gilb, T. & Graham, D. (1993), Software Inspection. Addi-

son-Wesley.

Grönninger, H., Hartmann, J., Krahn, H., Kriebel, S.,

Rothhardt, L. & Rumpe, B. (2008), View-Centric

Modeling of Automotive Logical Architectures. Proc.

of MBEES, pp. 3-12.

Gross, D. & Yu, E. (2001), From Non-Functional Re-

quirements to Design through Patterns. Requirements

Engineering Journal, pp. 18-36.

Hélouët, L., & Maigat, P. (2001), Decomposition of Mes-

sage Sequence Charts. SDL Forum, pp. 348-364.

Hermann, H., Ehrig, F., Orejas, K., Czarnecki, Z., Xiong,

Y., Gottmann, S. & Engel, T. (2013), Model Synchro-

nization based on triple graph grammars: correctness,

completeness, invertibility. Journal on Software Sys-

tems Modeling, pp. 348-364.

Holzmann, G. (1997), The Model Checker SPIN. TSE, pp.

279-295.

ITU. (2011), Recommendation Z.120.

Jantsch, A., & Sander, I. (2000), On the Roles of Func-

tions and Objects in System Specification. Proc. of the

8

th

Intl. Workshop on HW/SW Codesign, pp. 8-12.

Kang, K., Kim, S., Lee, J., Kim, K., Kim, G., & Shin, E.

(1998), FORM: A feature-oriented reuse method with

domain specific reference architectures. Annals of

Softw. Eng., pp. 143-168.

Klein, T., Conrad, M., Fey, I. & Grochtmann, M. (2004),

Modellbasierte Entwicklung eingebetteter

Fahrzeugsoftware bei DaimlerChrysler. Proc. of Mod-

ellierung, pp. 31-41.

Letier, E., Kramer, J., Magee, J., & Uchitel, S. (2005),

Function-centeredEngineeringofEmbeddedSystems-EvaluatingIndustryNeedsandPossibleSolutions

233

Monitoring and Control in Scenario-Based Require-

Requirements Analysis. Proc. of the ICSE, pp. 382-

391.

Mauw, S., & Reniers, M. (1999), Operational Semantics

for MSC'96. Journal of Computer Networks, pp.

1785–1799.

Milicev, D. (2002), Automatic Model Transformations

Using Extended UML Object Diagrams in Modeling

Environments. TSE, pp. 413-431.

Pretschner, A., Broy, M., Kruger, I. & Stauner, T. (2007),

Software Engineering for Automotive Systems: A

Roadmap. Proc. of FOSE, pp. 55-71.

Shiri, M., Hassine, J., & Rilling, J. (2007), Feature Interac-

tion Analysis: A Maintenance Perspective. Proc. of the

ASE, pp. 437-440.

Shull, F., Basili, V., Zelkowitz, M., Boehm, B., Brown,

A., Port, D., Rus, I. & Tesoreiro, R. (2002), What we

have learned about fighting defects. Proc. of the Intl.

Conf. on SW Metrics, pp. 133-154.

Weber, M. & Weisbrod, J. (2002), Requirements Engi-

neering in Automotive Development - Experiences

and Challenges. Proc. of the RE, pp. 313-340.

ENASE2014-9thInternationalConferenceonEvaluationofNovelSoftwareApproachestoSoftwareEngineering

234