Development of IR Single Mode Optical Fibers for DARWIN-nulling

Interferometry

Shahina M. C. Abdulla

1

, Lun-Kai Cheng

1

, Boudewijn v.d. Bosch

1

, Niels Dijkhuizen

1

,

Remco Nieuwland

1

, Wim Gielesen

1

, Jaques Lucas

2

, Catherine Boussard-Plédel

2

, Clément Conseil

2

,

Bruno Bureau

2

and João Pereira Do Carmo

3

1

TNO, Stieltjesweg 1, 2628 CK, Delft, The Netherlands

2

University of Rennes, Glass and Ceramic Laboratory, Campus of Beaulieu, 35042 Rennes, France

3

European Space Agency, P.O. Box 299, 2200 AG, Noordwijk ZH, The Netherlands

Keywords: Single Mode Fibers, Nulling Interferometry, DARWIN, Chalcogenide Glass, Infrared, Far Field Intensity,

Cross Core Scan, TeAsSe Fibers, TeGeGaI, Higher Order Mode Suppression.

Abstract: The DARWIN mission aims to detect weak infra-red emission lines from distant orbiting earth-like planets

using nulling interferometry. This requires filtering of wavefront errors using single mode waveguides

operating at a wavelength range of 6.5-20 µm. This article describes the optical design of the fibers, the

manufacturing protocol, the packaging for operating at cryogenic environment and various optical

characterisations performed. The latter includes investigation on the effect of gold and silver absorption

coatings, anti-reflection coating, fiber length on higher order mode suppression and attenuation of the fibers.

1 INTRODUCTION

The DARWIN mission by the European Space

Agency (ESA) (Woolf, 1998) is aimed to locate and

study earth like planets in other solar systems, in a

search for extra-terrestrial life (Kaltenegger, 2005)

.

DARWIN will consist of a nulling interferometer

(Bracewell, 1978); (Angel, 1978); (Spronck, 2012),

combining light from several telescopes that are

phase shifted from each other. This nulling

technique results in the light from a bright star being

cancelled out, leaving only light from the planets

around the star. Such a system, with capability for

imaging and spectroscopy, operating in the thermal

infrared spectral region, requires that wavefront

errors be reduced to a very high degree, in order to

achieve the required nulling quality (10

-4

to 10

-6

).

Such a high wavefront quality can only be achieved

with adequate wavefront filtering measures.

Modal filters like single mode fibers are the

preferred solution since they can filter both low and

high spatial frequencies (Bracewell, 1978); (Angel,

1978). Potential technologies for the development of

single mode fibers either using Step Index Fibers

(SIF’s) or Index Guiding Photonic Crystal Fibers

(IG-PCF’s) have been studied (Cheng, 2005)

(Zhukova, 2012) (Spronck, 2012). This article

describes the results on the development of Single

Mode Waveguides (SMW’s) based on SIF’s,

typically made of a solid material core and cladding

having slightly different refractive indices (n). For a

properly designed fiber, in the operational

wavelength range, the fundamental mode is only

guided by the core and the higher order modes

(HOMs) will experience a strong attenuation. After a

certain length of the fibre only the fundamental

mode remains. The wavelength limit for single mode

operation is mainly determined by the core diameter,

the symmetry of the core cross-section and the

difference in refractive index between core and

cladding which needs to be controlled very

accurately to achieve the required performance.

Table 1: Main requirements for the fibres to be used in

DARWIN mission.

Parameter Requirement

Operational wavelength range

6.5 to 20 m

Nr. of wavelength sub-bands ≤ 3

Total transmission > 57%

HOM suppression ratio < 10

-4

Operational temperature 40 K

Maximum SMW dimension 40 cm

Polarisation ≤ 2.5 mrad

11

M. C. Abdulla S., Cheng L., v.d. Bosch B., Dijkhuizen N., Nieuwland R., Gielesen W., Lucas J., Boussard-Plédel C., Conseil C., Bureau B. and Pereira

Do Carmo J..

Development of IR Single Mode Optical Fibers for DARWIN-nulling Interferometry.

DOI: 10.5220/0004674600110020

In Proceedings of 2nd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2014), pages 11-20

ISBN: 978-989-758-008-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

Since in reality the cladding diameter is finite,

HOMs will be guided by the cladding. Here

additional absorption coatings will be required to

suppress these cladding modes.

The main requirements for the fibres to be used

in DARWIN mission are summarized in the Table 1.

2 FIBER DESIGN

The focus of this research programme was to

develop manufacturing techniques for a reproducible

production of single mode SIF’s, aiming to result in

wavefront filters covering the complete DARWIN

wavelength range which can be directly used in

interferometric test set-ups operating in vacuum and

cryogenic environment. To this respect two major

types of chalcogenide glass materials, potentially

suitable for SIF manufacturing in the wavelength

range of interest for DARWIN, were identified and

investigated. The first one is TeAsSe (TAS) (Cheng,

2006); (Faber, 2006) glass for the short wavelength

(SW) range (6.5 μm–12 μm). Several manufacturing

techniques were explored resulting in the

manufacturing of several SIF samples from this

material and single mode behaviour was

demonstrated by Far Field Intensity (FFI)

distribution. The relation between the composition

and the refractive index of this type of fibers were

investigated. A proper selection of the composition

of the TAS glass will result in the desired refractive

index for the core and the cladding. The default

design parameters are:

- n-core: 2.9185

- Core radius: 17.5 μm

- n-cladding: 2.9157

- Cladding thickness: 250 μm

- Numerical Aperture (NA): 0.13

- Cut-off wavelength: 5.7 μm

- Absorption coating: Gallium (Ga)

- AR coating: BaF

2

/ZnSe/BaF

2

The second type of chalcogenide glass material is

Te-based glass for the long wavelength (LW) range

(12 μm – 20 μm) for which development was less

mature. It was demonstrated that Te-glasses are

potentially suitable for fiber manufacturing purposes

but still critical with respect to processing

parameters and risk of crystallization (Cheng, 2006).

Some Te-glass based materials are investigated. The

TeGeGaI (TGGI) glass is selected for the LW fiber

design. A typical transmission spectrum of a TGGI

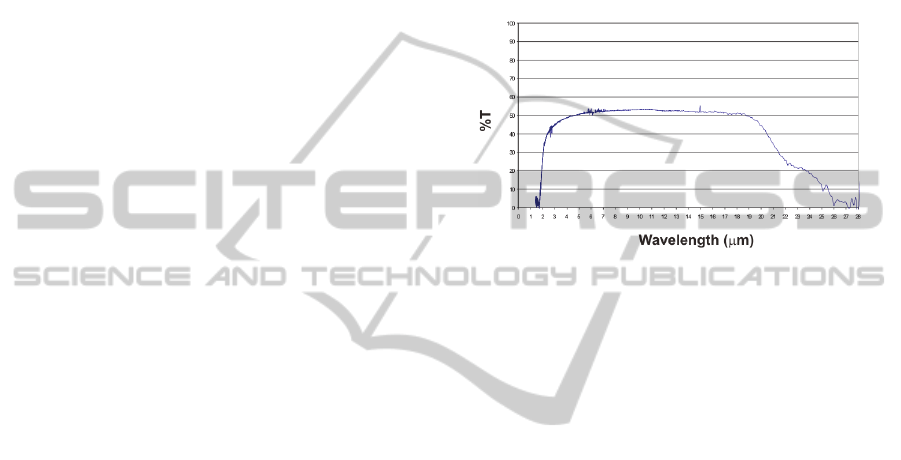

glass of about 2mm is shown in Figure 1.

For the TGGI based LW fiber only a provisional

default fiber design is defined:

- n-core: 3.350

- Core radius: 15 μm

- n-cladding: 3.338

- Cladding thickness: 250 μm

- NA: 0.29

- Cut-off wavelength: 11.3 μm

- Absorption coating: Gallium

- AR coating: Not defined.

Figure 1: Transmission spectrum of TGGI shows a

transmission window up to about 19 µm.

2.1 Development of Absorption

Coating

To ensure a sufficient nulling depth, the amount of

optical power in the higher order modes at the output

of the single mode fiber must be reduced. The HOM

suppression performance depends on the thickness

of the cladding and the imaginary part of the

refractive index (k) of the absorption coating

material applied. A material with a higher k is

expected to have a higher absorption than a material

with a lower k. Though Ga was successfully

demonstrated to be a suitable coating, it was difficult

to apply a homogeneous layer. Further handling was

critical due to the low melting point of Ga. Even at

room temperature Ga becomes soft and

mechanically unstable. To find a suitable alternative

material as absorption coating, with better

manufacturability, ease in handling and stability

(and if possible better absorption), Finite Element

Modelling of the SW TAS fiber was performed by

Optoelectronics Research Centre of University of

Southampton using a commercial software package

called COMSOL Multiphysics

TM

. The TAS SW

fiber with different coating materials including Cr

(k

Cr

≈ 15 at 10.6 μm) and Ga (k

Ga

≈ 30 at 10.6 μm)

are modelled and the effect on attenuation and HOM

are calculated (Cheng, 2009).

Modelling results confirm the expectation that

k

Ga

> k

Cr

requires a shorter fiber length (L) to

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

12

achieve a HOM suppression of 10

6

. The modelling

also yielded that the attenuation, the fiber NA and

cut-off wavelength are unaffected by the type of

coating applied. Hence it was concluded that the

absorption coatings can be developed separately

from fiber configuration. A survey of suitable

alternative coating materials is conducted with the

following criteria:

a k close to or higher than that of Ga (further

reduction of the required fiber length).

a thermal expansion, close to TAS (to survive

temperature range down to 40 K).

clean and easy deposition method (preferably

vacuum deposition)

Finally, gold and silver were selected as absorption

coatings for the final evaluation.

2.2 Development of AR Coating

For IR single mode fibers, having a n > 2, the loss

by Fresnel reflection will be more than 11% per

fiber interface. Suitable AR coatings therefore are

required to maintain sufficient transmission. Using

thin-film modelling, TNO investigated the

performance of various AR coating configurations.

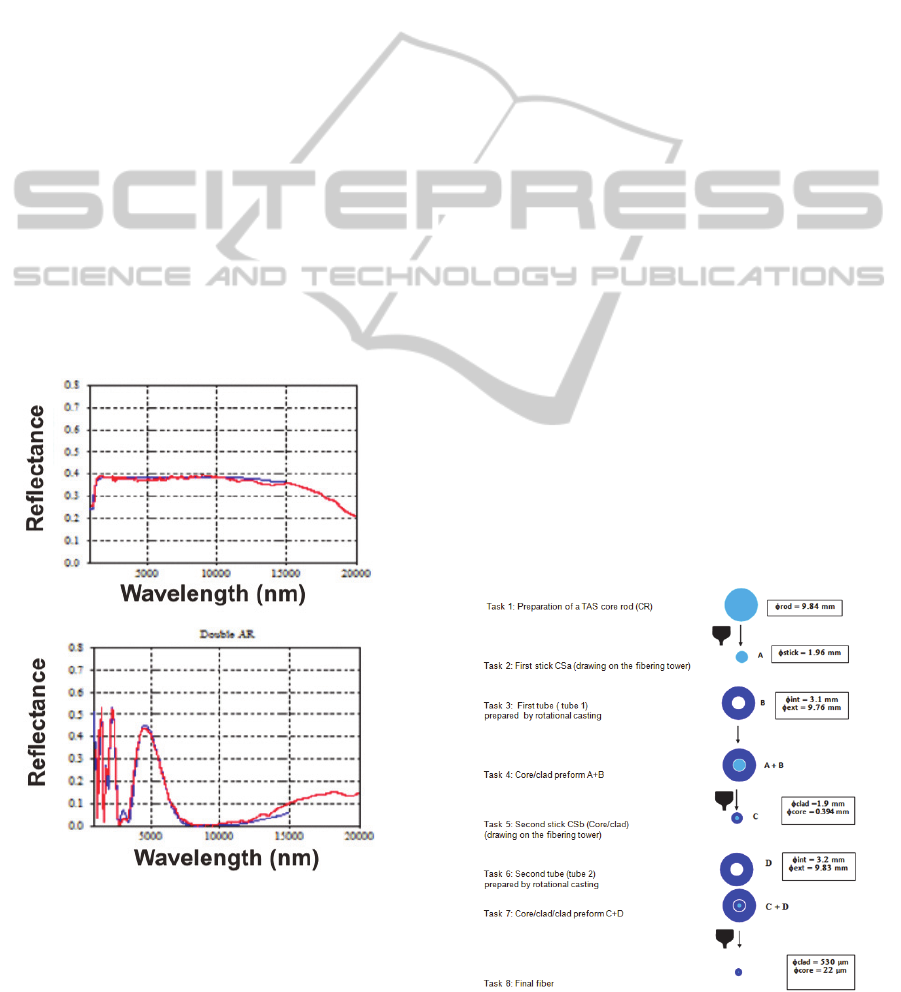

Figure 2: Demonstration of the effect of the designed AR

coating. Reflection of a bulk TAS sample (top). Reflection

of the same TAS sample with AR coating on both sides

(bottom).

A three-layer coating configuration of

BaF

2

/ZnSe/BaF

2

is considered to be a suitable

candidate for the chalcogenide TAS glass. This AR

coating design is further fine-tuned on TAS bulk

samples. Transmission and reflection of the final

configuration are measured. A TAS sample without

coating is also tested for reference. The results are

presented in Figure 2, showing a significant

reduction of the reflection of double AR coated TAS

compared to the uncoated TAS in the spectral region

6.5 – 12 m.

3 SW TAS FABRICATION

PROTOCOL

Manufacturing protocols for purification and

preparation of TAS glass and the fabrication of the

fiber are established. The right composition,

purification and temperature control are of vital

importance for quality of the parts and for the fiber

performance and hence have direct impact to the

performance of the fiber produced.

The control of the composition and hence the

refractive index of the TAS glasses is found to be

very critical. Relaxing the refractive index tolerance

is highly desirable to improve the manufacturing

yield. This results in a larger difference between the

refractive index of the core and the cladding. To

ensure single mode operation starting from 6.5 m,

the diameter of the core has also to be adapted. For

the final design, the core radius is reduced from 17.5

m to 11 m. The TAS SW fiber manufacturing

protocol using a special developed 2-steps rod-in-

tube technique is shown in Figure 3.

Figure 3: Manufacturing protocol of the TAS SW fiber.

DevelopmentofIRSingleModeOpticalFibersforDARWIN-nullingInterferometry

13

4 TAS FIBER MANUFACTURING

For the manufacturing of TAS cladding tubes,

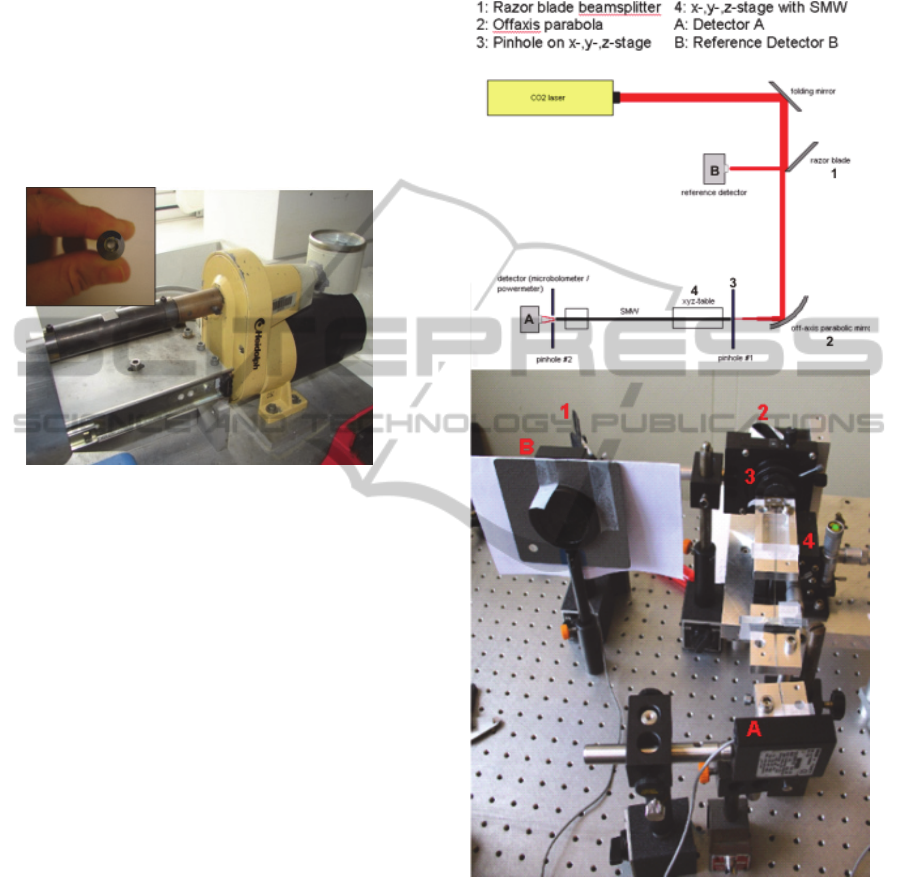

rotational casting is applied (Figure 4). The

dedicated set-up, manufacturing processes and

parameters have been calibrated and optimized as

the quality of the tube is highly influenced by the

proper levelling of the set-up, temperature during

rotational casting and rotation speed (Houizot,

2009). TAS tubes are manufactured with internal

diameter ranging from 2.8 mm – 3.2 mm.

Figure 4: Rotational casting machine and resulting TAS

tube (inset).

Based on TAS cladding glass composition and

known refractive index results, the TAS core glass

composition is defined. Purified core rods (CR)

having an external diameter of ~10 mm are

manufactured. The CR is drawn to a ø 2 mm core

stick having a length of about 60 cm (for core-clad

preform drawing) and several meters of ø 400 µm

mono-index fiber (used for fiber quality

verification).

5 CHARACTERISATION

Prior to the characterization, each SMW is visually

inspected for cracks or holes on the SMW surface

along its length. Both facets of the SMW are

carefully cleaved. The cleave which is not part of the

SMW, is further visually inspected under a

microscope to check the surface quality of the cross-

section as well as the angle of the cleave. The optical

measurements are performed using the set-up shown

in Figure 5. The source is a CO

2

laser at 10.6 µm

having a built-in Helium-Neon laser which is used

for alignment. A razor blade is used as a beam

splitter. The output power of the CO

2

laser fluctuates

about 20% (peak to peak) at 6% output power. It is

undesired to use higher power since it can damage

the fibre. Hence during the measurements, a

reference detector (with power P

ref

).is used in the

used range which is 3% - 7% of the output power.

Figure 5: Pulsed CO

2

laser set-up for fiber attenuation and

FFI characterization at 10.6 μm. They are numbered as 1-

Razor blade beamsplitter, 2- Off axis parabola, 3- Pinhole

on x,y,z stage, 4- xyz stage with SMW, A is detector A

and B is the reference detector B.

Several measurements are performed using this

set-up and detailed explanation of the results are

presented in the following sections.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

14

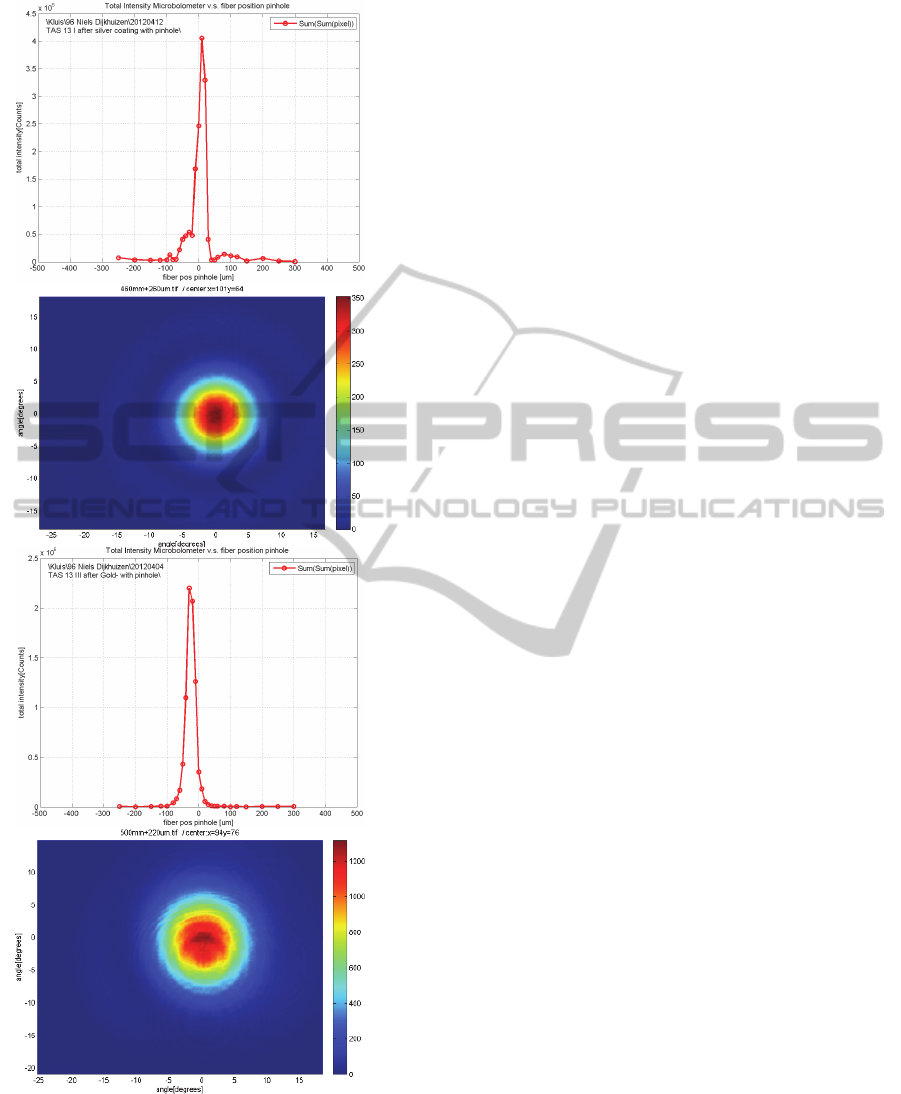

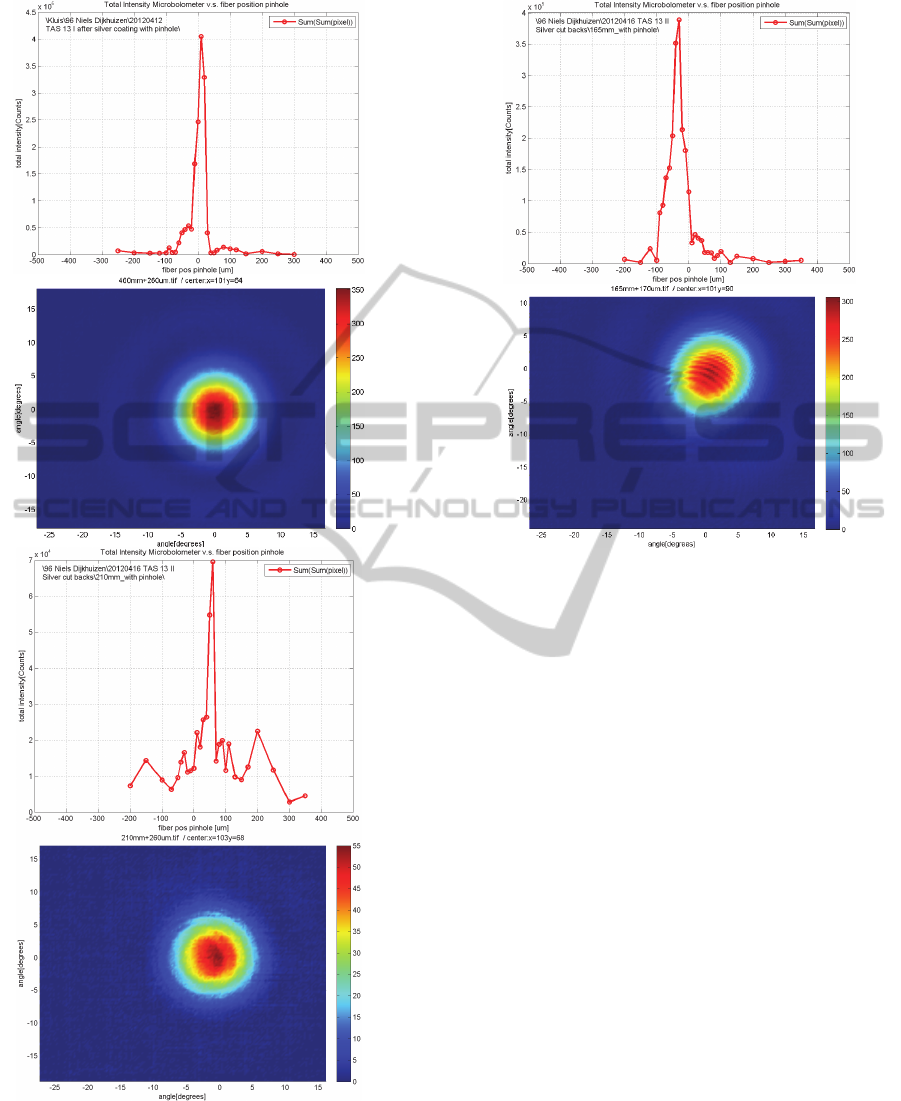

Figure 6: Cross-core and FFI performance of silver (top

two pictures, L=480mm) and gold (bottom two pictures,

L=495 mm) coated TAS fibers. The output pinhole

diameter is 100 µm and the P

ref

is 130mW in both cases.

5.1 Gold and Silver Absorption

Coatings on TAS

Due to its improved quality in manufacturability,

reproducibility, ease in handling and stability

compared to gallium, gold and silver are selected

as alternative absorption coatings for TAS fibers

in order to suppress the HOMs. Hence TAS fibers

are coated with gold and silver and are further

characterised with cross-core scan and FFI

distribution. The results of two samples (one

silver coated and the other gold coated) are shown

in Figure 6. All coated TAS samples show single

mode behaviour with an averaged NA of 0.22.

From performance point of view both gold and

silver demonstrate to be good alternatives but gold

is preferred for its durability (no oxidation) and

acceptance in space applications.

5.2 Effect of Fibre Length on Higher

Order Mode Suppression

Also the impact of reduction in fibre length to the

level of HOM suppression has been investigated.

For this, a silver coated and a gold coated sample

were selected and their lengths are reduced in

steps. Then cross-core scan and FFI distribution

were measured at each length. The silver coated

sample is reduced in 2 steps to a final length of

16.5 cm (still showing good performance with

output pinhole) and the gold coated sample is

reduced in 3 steps to a final length of 24 cm. The

results for the silver coated TAS sample at each

cut-back length are shown in Figure.

It was observed that, without pinhole, both

silver and gold coated fibers showed a decrease in

HOM suppression, with a shorter fiber length. By

using a 100 µm output pinhole, the change in

HOM suppression due to length reduction was not

observed. Apparently the output pinhole had more

effect than fiber length. The silver coated TAS

samples showed a deviation in NA for different

cutback lengths. This observation also drove to

finally select gold as preferred absorption coating

for further experiments. A consistency in NA was

observed for the gold coated TAS sample (NA =

0.20) for all cutback lengths, both “with” and

“without” pinhole.

DevelopmentofIRSingleModeOpticalFibersforDARWIN-nullingInterferometry

15

Figure 7: Cross-core and FFI results of silver coated

TAS sample at various cut-back lengths. The first and

second images are for L=480mm , the third and fourth

images are for L=210mm, fifth and sixth images are for

L=165mm. The output pinhole diameter is 100 µm. P

ref

is 130mW for L=480mm whereas P

ref

is 65mW for the

other two lengths.

Figure 7: Cross-core and FFI results of silver coated

TAS sample at various cut-back lengths. The first and

second images are for L=480mm , the third and fourth

images are for L=210mm, fifth and sixth images are for

L=165mm. The output pinhole diameter is 100 µm. P

ref

is 130mW for L=480mm whereas P

ref

is 65mW for the

other two lengths. (cont.)

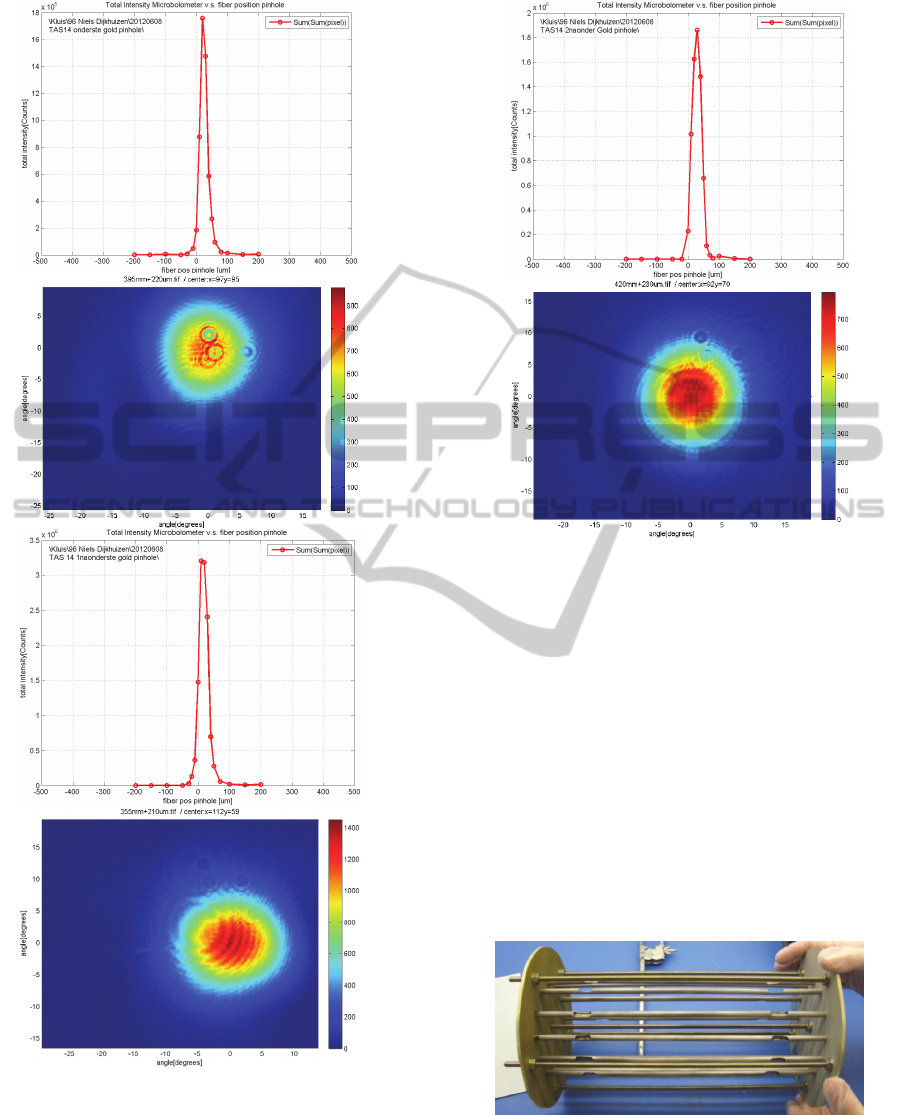

5.3 Manufacturing and Testing of

Final Single Mode TAS Fibers

From a new manufactured TAS fiber batch, final

five single mode TAS fibers are characterised and

delivered to ESA. Prior to final SMF preparation

and characterization, two fiber samples, randomly

selected out of the new batch, are coated with

Gallium and subjected to incoming inspection and

characterization, proving that the new TAS batch

is of sufficiently good quality to arrive at SMW’s

for delivery. To the remaining TAS fibers from

this new batch, a gold absorption coating is

applied by vacuum deposition techniques. These

gold-coated fibers show a good mode coupling

and HOM suppression, when measured with a 100

µm output pinhole a shown in Figure 8.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

16

Figure 8: Cross-core and FFI results of gold coated

TAS fibers, measured with a ø 100 µm output pinhole.

The first and second images are TAS 14-10(A) with a

L=400mm, third and fourth images are for TAS 14-

11(B) with a L=350mm,fifth and sixth images are for

TAS 14-12(C) with a L=420mm.

Figure 8: Cross-core and FFI results of gold coated

TAS fibers, measured with a ø 100 µm output pinhole.

The first and second images are TAS 14-10(A) with a

L=400mm, third and fourth images are for TAS 14-

11(B) with a L=350mm,fifth and sixth images are for

TAS 14-12(C) with a L=420mm. (cont.)

5.3.1 Anti Reflection Coating

As a next step, the three-layer BaF

2

-ZnSe-BaF

2

anti-reflection coating, initially developed by

TNO, is applied on all gold coated TAS fibers by

an external subcontracted coating facility. The

dedicated tooling for applying this coating is

shown in Figure 9. The coating uses a Ytrium

doped BaF

2

as first layer to improve bonding to

TAS.

Figure 9: Tooling used for AR coating.

Jointly with the external coating facility,

precautions were taken and arrangements were

made to optimize the fabrication process for the

DevelopmentofIRSingleModeOpticalFibersforDARWIN-nullingInterferometry

17

new special AR coating on both facets of the TAS

fibers. Due to the limited available time, the

fabrication process cannot be tested. For almost

all coated TAS fibres, the AR coating delaminated

from both fiber end facets and in some cases only

the thin first layer of Ytrium doped BaF

2

remained

on the fiber end.Figure Figure 10 shows

microscopic images of some of the fiber facets

showing delaminated AR coating.

Figure 10: Some examples of delaminated AR coating

on TAS end facets.

Cleaning of the fiber ends in an attempt to

remove the delaminating AR coating was only in

some cases successful. In most cases however the

cleaning appeared to be less effective. Hence it

was decided that cleaving of the TAS fiber end

facets is the best solution to remove the faulty AR

coatings. Thus the final single mode TAS fibers

were delivered to ESA without an AR coating.

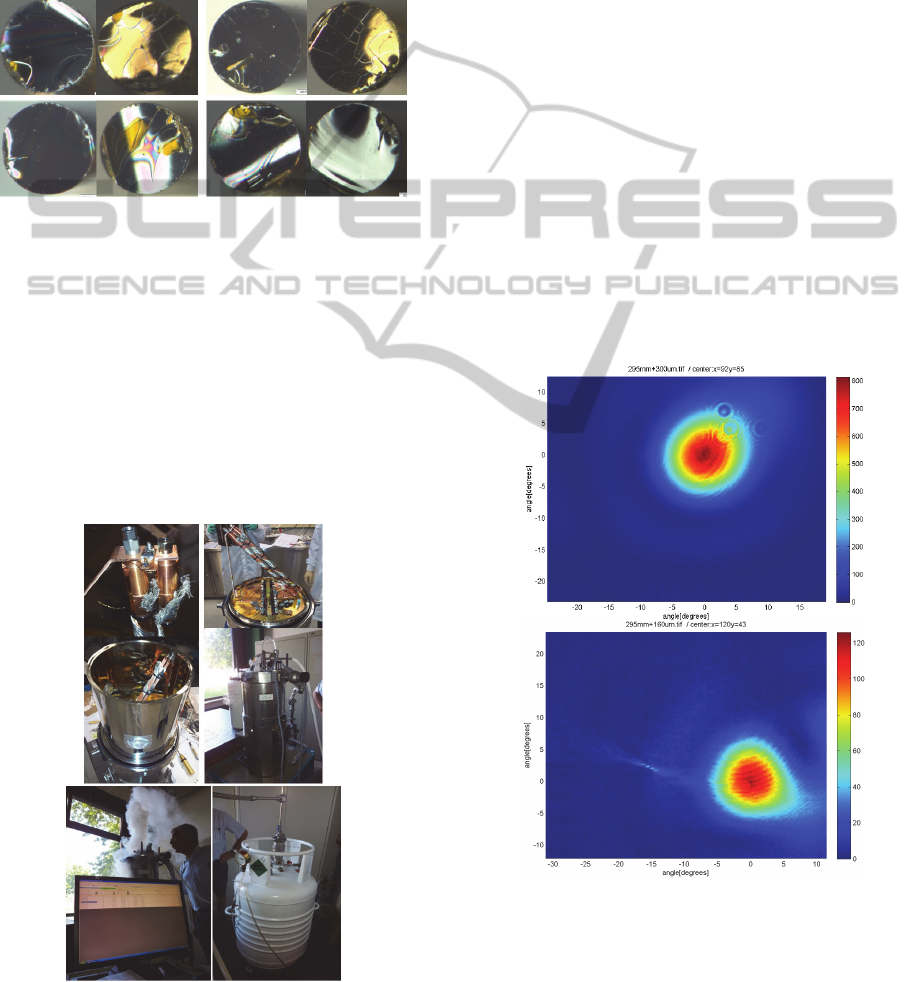

5.3.2 Cryo Testing

Figure 11: Photographs of cryogenic test set-up and

Helium facility (SRON) for controlled 40K cycle tests.

Two gold coated TAS fibers were mounted in the

special designed cryogenic copper SMW holder

and were subjected to a controlled cryo-test (1

cycle for more than 2 hours at 40K), using a

Helium cryostat facility of Netherlands Institute

for Space research (SRON) as shown in Figure

11.

Following the cryo-cycle test, visual

inspection did not show any significant change of

the copper holders nor any failure/degradation of

the TAS fibers after de-mounting from the holder.

Microscopic inspections proved that the quality of

the fiber end facets and gold coated surfaces did

not degrade due to the 40K exposure. Also the FFI

performance remained still good after cryo-tests.

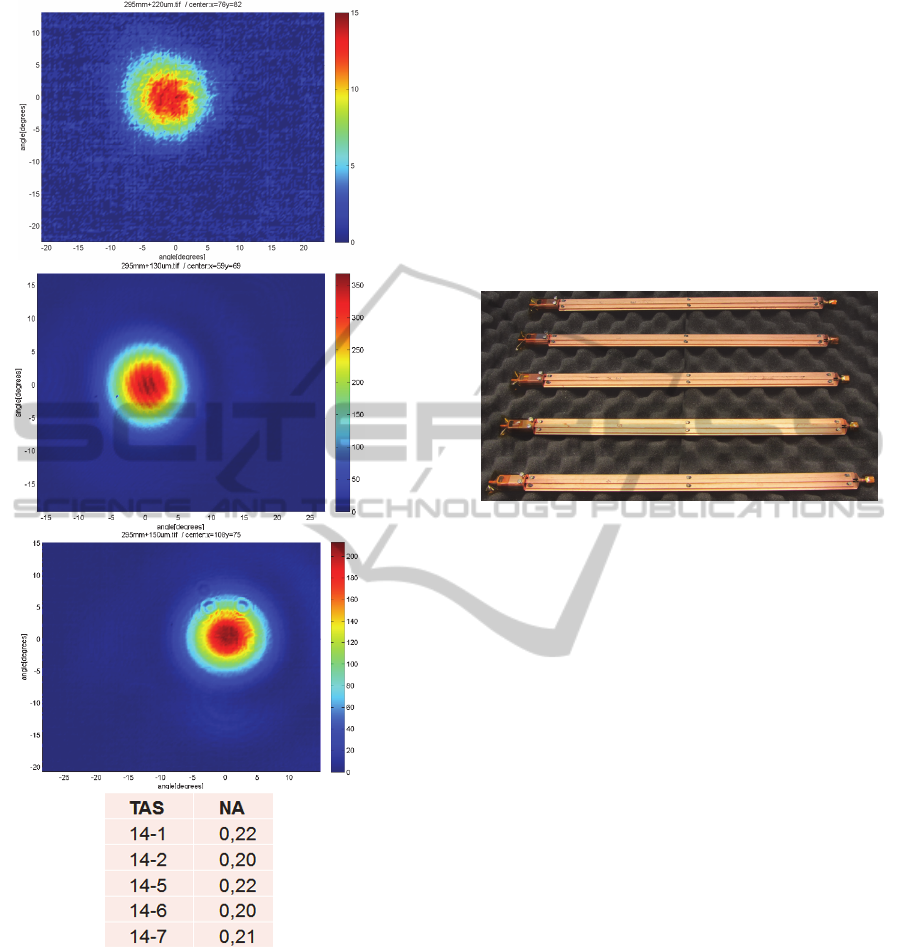

5.3.3 Copper Mounting

For delivery to ESA, five gold coated TAS fibers,

having no AR coating are selected and mounted in

the special designed cryogenic copper SMW

holders. The mounted fibers are delivered without

SMA connector interface but with the fiber end

facets protruding outside the holder for a few

millimetres at both sides of the mount.

Figure 12: Cross-core and FFI characterization of the

five packaged TAS fibers. First image is TAS 14-1 in

(Cu holder 1), second image is TAS 14-2 in (Cu holder

2), third image is TAS 14-5 in (Cu holder 3), fourth

image is TAS 14-6 in (Cu holder 5), and the fifth image

is TAS 14-7 in (Cu holder 4). The output pinhole

diameter is 100 µm and P

ref

is 100mW.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

18

Figure 12: Cross-core and FFI characterization of the

five packaged TAS fibers. First image is TAS 14-1 in

(Cu holder 1), second image is TAS 14-2 in (Cu holder

2), third image is TAS 14-5 in (Cu holder 3), fourth

image is TAS 14-6 in (Cu holder 5), and the fifth image

is TAS 14-7 in (Cu holder 4). The output pinhole

diameter is 100 µm and P

ref

is 100mW. (cont.)

The length of these fibers range from 288 mm

to 292 mm. After packaging, the cross-core scan

and FFI distribution of each fiber was measured

and the results of it are shown in Figure 12. All

five fibers show a clear single mode behaviour.

With a 100 µm output pinhole they showed a

strong circular FFI distribution. The NA of these

fibers range from 0.20 to 0.22.

For safe transport, storage and handling (when

not in use) of the fibers, which are mounted in the

copper holder, the packages were provided with

removable protection caps at both ends of the

mount. This will protect the TAS fiber end facets

protruding from the mount. Figure3 shows these

five fibers packaged inside five copper holders

including protection caps in the final

configuration delivered to ESA.

Figure 13: Five TAS fibers fully packaged as delivered

to ESA.

6 CONCLUSIONS

A number of conclusions were drawn from the

characterisations performed on single mode

waveguides. Modelling of the impact of Ga

coating on HOM suppression of a short

wavelength TAS fiber shows that the NA and cut-

off wavelength are not affected by the type of

absorption coating applied. According to

simulation, Ga with a higher k than Cr requires a

shorter fiber length to achieve the desired HOM

suppression. Further accurate measurement of

refractive index is of vital importance for fiber

design optimization. The quality and purity of the

base materials determine largely the final SMF

results and performance. Effectiveness of vacuum

deposited silver and gold as absorption coating is

comparable to that of the Gallium coating.

However, gold coating is more stable and can be

applied and handled more easily. Therefore the

gold coating is selected for the final deliverable

fibers. The suppression of cladding modes on an

absorption coated fiber increases with its length.

However, even for a length of about 500mm, the

presence of cladding modes can still be observed

in the FFI measurement. The application of an

output pinhole of 100 µm diameter improves this

suppression significantly. AR coating design is

DevelopmentofIRSingleModeOpticalFibersforDARWIN-nullingInterferometry

19

optimized and the performance of this coating on

bulk TAS sample is demonstrated successfully.

Proper design of a copper fiber holder for

cryogenic temperature application is investigated

and realized. Cryogenic test with gold coated TAS

fibers mounted in this holder has proven that the

TAS fibers successfully survives cool down to 40

K without visible degradation or failure. Five

short wavelength TAS single mode waveguides

with gold absorption coating but without AR

coating are integrated in the fiber holder and

characterised by cross core scan and FFI.

ACKNOWLEDGEMENTS

This project was funded by the European space

Agency under the contract No. 20914/07/NL/CP.

The authors would like to thank the

Optoelectronics Research Centre of University of

Southampton for the modelling of the cladding

mode suppression and Netherlands Institute for

Space research (SRON) for providing their

Cryogenic facility.

REFERENCES

Woolf, N., and Angel, J., 1998 “Astronomical searches

for earth-like planets and signs of life,”

Astron.Astrophys.36, pp. 507-537.

Kaltenegger, L., Fridlund, M., 2005, “The Darwin

mission: Search for extra-solar planets”, Advances

in Space Research 36, pp 1114-1122.

Bracewell, R. N., 1978 “Detecting nonsolar planets by

spinning infra-red interferometer”, Nature 274, pp

780-781.

Angel, J. R. P., Cheng, A. Y. S., and Woolf, N. J., 1978

“A space telescope for infra-red spectroscopy of

earth like planets”, Nature 322, pp 341-434.

Cheng, L. K., Faber, A. J., Gielesen, W., Boussard-

Pledel, C., Houizot, P., Lucas, J., and Pereira Do

Carmo, J., 2005 “Test results of the infrared single-

mode fiber for the DARWIN mission,” Proceedings

of SPIE 5905, 59051F.

Cheng, L. K., Faber, A. J., Gielesen, W., Lucas, J.,

Boussard-Plédel, C., Houizot,P., and Pereira do

Carmo, J., 2006 “Development of broadband

infrared single-mode fibers for the DARWIN

mission,” Proceedings of SPIE 6268, 62682F.

Faber, A. J., Cheng, L. K., Gielesen, W. L. M.,

Boussard-Plédel, C., Houizot, P., Danto,S., Lucas,

J., and Pereira Do Carmo, J., 2006, “Single Mode

Chalcogenide Glass Fiber as Wavefront Filter for

the Darwin Planet Finding Mission,” Proceedings

of ‘6th International. Conference. on Space Optics’

ESTEC, pp. 27-30.

Cheng, L. K. et al., 2009, “Development of infrared

single-mode fibers for 2 wavelength bands of the

Darwin mission: Test results of prototypes”,

Proceedings of SPIE 7420.

Houizot, P., Boussard-Plédel, C., Faber, A. J., Cheng,

L. K., Bureau, B., Van Nijnatten, P. A., Gielesen,

W. L. M., Pereira do Carmo, J., and Lucas, J., 2007,

“Infrared single mode chalcogenide glass fiber for

space, Optics Express 15 (19), pp 12529-12538.

Zhukova, L., Korsakov, A., Chazov, A., Vrublevsky, D.

and Zhukov, V., 2012, “Photonic crystalline IR

fibers for the spectral range of 2–40 μm”, Applied

Optics 51, pp. 2414-2418.

Spronck, J. F. P., Fischer, D. A. and Kaplan, Z A.,

2012, "Use and limitations of single-and multi-

mode optical fibers for exoplanet detection."

Optical Fibers/Book 3.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

20