Interaction of Simulation Tools with ERP Systems

Concept and Practical Implementation

Arne Koors

and Bernd Page

Department of Informatics, University of Hamburg, Vogt-Kölln-Str. 30, 22527 Hamburg, Germany

Keywords: Discrete Event Simulation, ERP Systems, ERP System Utilisation, System Interaction.

Abstract: The interaction approach introduced in this paper is aiming at coupling a full-fledged discrete event

simulator and an operational ERP system in a fully integrated manner. Here, the simulator is representing

the complete operative environment of the ERP system, substituting its daily business input. For this, the

company-specific utilisation of the ERP system has to be modelled in the simulator. In order to execute its

model and process concrete ERP functionality, the simulator is accessing the ERP system via software

interfaces, using it like a large subject-specific software library. Thus, the simulator is effectively carrying

out a complete remote control of the ERP system, in the sense of software automation. Amongst others, the

simulator is inducing arrival and booking events in the ERP system, is continuously triggering internal ERP

system processes and is processing the results of revised ERP planning by arranging future events in the

ERP system. Altogether, the simulator and the ERP system are interacting mutually with each other in a

cyclic process. In this paper, we introduce the core idea of the interaction approach and delineate its

potentials. We discuss arising challenges in practical application and describe the current state of

implementation.

1 INTRODUCTION AND

MOTIVATION

In this paper we report on a technology transfer

project between university and industry, combining

simulation technology with commercial ERP

systems.

We can on one hand define an ERP system as a

software supporting enterprise tasks, functions and

business processes in a holistic, cross-departmental

and integrative manner (Fink et al., 2005, pp. 207 et

seq.); (Jacob, 2008, pp. 1–2); (Gronau, 2010).

On the other hand we can understand simulation

as a method for executing experiments, employing a

model of dynamic processes in real or imaginary

systems, with the aim of gaining insights that are re-

transferable to the investigated original system.

Discrete event simulation is characterised by erratic

and punctual state transitions occurring at discrete

points in time (VDI, 1993); (Page and Kreutzer,

2005).

Discrete event simulation is applied in the

context of ERP systems mainly in three different

ways:

As ERP Simulation for the purpose of training

personnel or students (Schenk and Draijer,

2004); (Léger, 2006); (Hopkins and Foster,

2011); (Cronan and Douglas, 2012); (Nisula and

Pekkola, 2012);

As Online Simulation for operative

manufacturing support with short-term time

horizon (Wu and Wysk, 1989); (Davis, 1998);

(ElMaraghy et al., 1998); (Fowler and Rose,

2004); (Cardin and Castagna, 2011); (Noack,

2012);

As classic Offline Simulation studies for the

analysis of strategic or tactical design

alternatives (Kuhn, 1998); (Košturiak and

Gregor, 1999); (Bayer et al., 2003); (Page and

Kreutzer, 2005, chap. 15).

Each of the three approaches mentioned above has

its own focus; however none is completely

exploiting the full potential of combining a general

purpose, discrete event simulator with an actually

operational ERP system in an enterprise:

So-called ERP Simulation hardly employs

computer simulation in the narrower sense (cf. Page

and Kreutzer, 2005, pp. 9 et seq.). Here, we rather

229

Koors A. and Page B..

Interaction of Simulation Tools with ERP Systems - Concept and Practical Implementation.

DOI: 10.5220/0004595602290237

In Proceedings of the 3rd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2013),

pages 229-237

ISBN: 978-989-8565-69-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

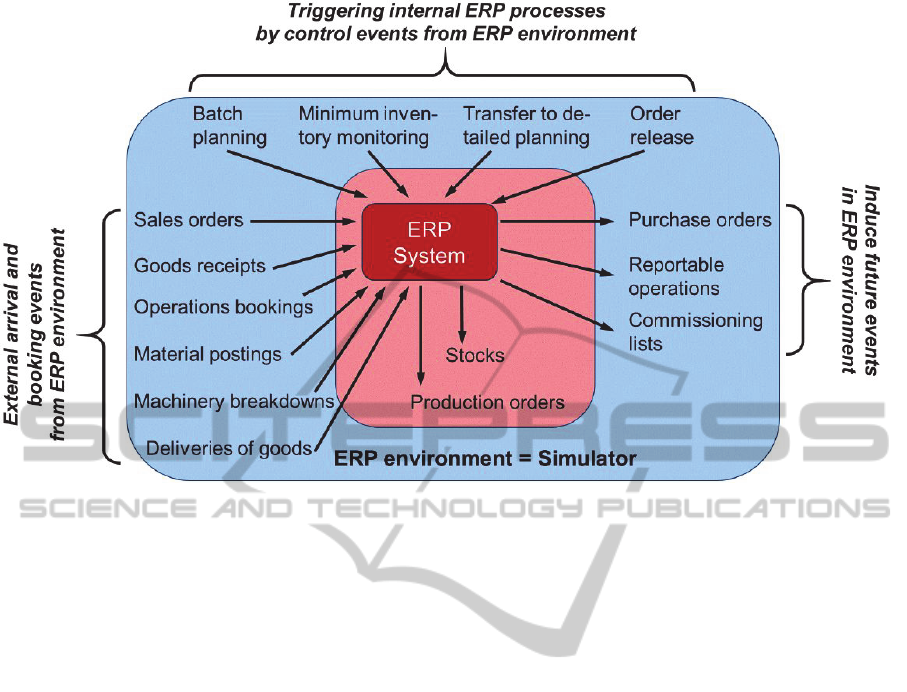

Figure 1: Structural relation between simulator and ERP system.

deal with turn-based strategy games utilising real

ERP systems with pre-initialised data bases.

Continual manual user intervention is desired and

also required.

Online Simulation is typically reacting only on a

small functional subset of ERP systems

(manufacturing, production control centre, possibly

medium-term scheduling) and does not necessarily

automatically affect the operational ERP system.

Often intervention remains reserved for the human

production supervisor.

In classic Offline Simulation studies only

important partial functionalities of the ERP system

are modelled as operational components. For effort

reasons, this is carried out mostly in an abstracted

and generalised form. This restricts transferability of

simulation results back into practice and limits the

validity of resulting conclusions.

This paper is structured as follows: Section 2

introduces the core idea of the interaction approach.

Sections 3 and 4 delineate the potentials and

challenges in practical application. Section 5

describes the current state of implementation and

Section 6 summarises and concludes the paper.

2 PROPOSED INTERACTION

APPROACH

In the following we introduce an Interaction

Approach between simulation and ERP systems,

reaching beyond the common three approaches

mentioned above for the following reasons:

Utilisation of a full discrete event simulator;

Coverage of all ERP functional areas;

Use of the original ERP system algorithms;

No data redundancy in simulator and ERP

system;

Free of manual interventions into simulation

process.

The core idea of the interaction approach is as

follows:

The concrete ERP system in use is copied to a

new simulation instance and initialised with a data

base snapshot of a given key date (e.g. today, last

inventory date or start of the financial year). The

simulator is simulating the complete ERP

environment against the ERP system, i.e. all

operationally relevant changes with impact on the

ERP system, like human input and third party

software interfaces (Figure 1).

This includes the arrival of new sales orders,

receipt of goods purchased, booking of operations,

posting of material, etc. Beyond that, the simulator is

periodically triggering internal batch processes in

the ERP system as it would happen in real daily

operation, such as batch planning, minimum

inventory monitoring, etc. Because of the modified

data situation caused by the simulator and its

triggering of ERP planning processes, the ERP

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

230

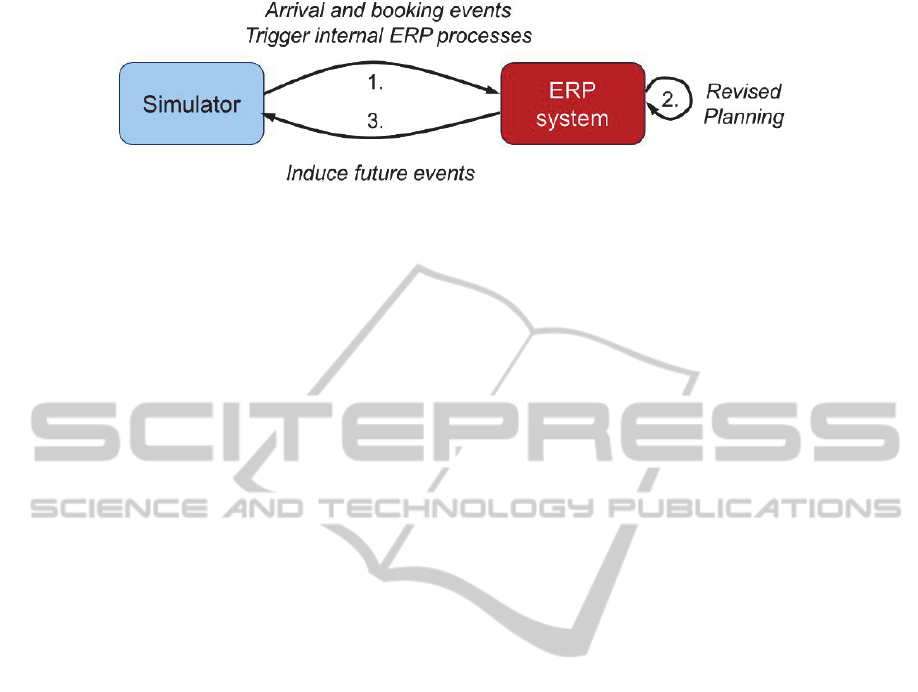

Figure 2: Flow of interaction between simulator and ERP system.

system updates and re-adjusts its plans, resulting in

modified dates and quantities of manufacturing,

adapted purchase order proposals, etc. Hereafter, the

simulator is reacting upon the adjusted ERP system

plans and is implementing them by utilising ERP

system functionality, e.g. by releasing new

manufacturing orders or generating new purchase

orders. Furthermore, the simulator schedules arising

future events like prospective operations and

material bookings for a later point in simulation

time. After advancing the simulation clock (and

simultaneously the synchronised ERP time), the

scheduled simulator events induce simulated

dynamics of the ERP system environment again. All

in all, the simulator and the ERP system are

interacting alternately and cyclically with each other

(see Figure 2).

From the ERP system point of view the simulator

is representing the operational environment where it

is receiving its input from. Moreover, the results of

re-adjusted ERP system plans influence the

simulation environment, as they would influence the

real operational environment in daily operation.

Conversely, the simulation model in the

simulator is describing the ERP system related

operational processes in a company. Here, only the

company-specific application is modelled (type,

order, points in time and duration of used ERP

system functions, as well as upstream extraction of

company specific data for parameterisation of the

simulation model). For the actual processing of ERP

functionalities, however, the simulation instance of

the ERP system is accessed by means of software

interfaces. From the simulator point of view, the

ERP system is “only” a large domain-specific

software library, whose functions it is calling and

whose successor states it is reading by appropriate

data interfaces. By executing a model, the simulator

is actually carrying out a software automation in the

sense of complete remote control of the ERP system.

A similar approach is suggested in Herrmann

(2007), however focus and implementation differ,

particularly in degree of interleaving between

simulator and ERP system. The work introduced

here has been developed independently, in the

context of industrial cooperation.

Our approach has a number of assets to offer:

It can be widely avoided to implement complex

ERP specific functionality in the simulator, e.g.

scheduling logic. Instead, the available ERP

system functionality is called 1:1, as on hand in a

program library. Thus effort and time of model

building are significantly reduced.

Likewise, calling original ERP system functions

avoids inaccurate mapping of ERP system

functionality into simulation models. Thus

simulation results guarantee a higher degree of

validity and significance as well as close

correspondence with the actual operational ERP

system, allowing easier transfer back into ERP

practice.

By employing the ERP system in its entirety,

questions relating to an enterprise as a whole,

from sales to purchasing departments, can be

analysed more adequately. Compared to common

isolated simulation of manufacturing, the

comprehensive view on the whole company

allows for a more substantial analysis of

department overlapping problems, stemming

from shortcomings in inter-departmental

cooperation or from the applied ERP system

itself, resp. from its parameterisation.

3 APPLICATION POTENTIAL

Beyond general simulation studies requiring detailed

modelling of the ERP system, our interaction

approach naturally is relevant for various issues

specifically dealing with ERP systems in operation,

their parameterisation or their company specific

utilisation. In more detail, the following application

options are at hand:

a) Variation of the simulated environment: Stress

factor testing as well as sensitivity analyses of

the company organisation can be carried out by

varying parameters of the simulation model

InteractionofSimulationToolswithERPSystems-ConceptandPracticalImplementation

231

while leaving the ERP system configuration

unchanged. For instance the impacts of an

extension or wider variance of material delivery

times or of an increase of machine failure

frequencies could be analysed. A variation of

sales order profiles or order arrival frequencies

allows for conclusions whether a company can

serve their clients in time, even in altering

market environment.

b) Variation of ERP parameters: By modification of

the ERP system parameters without changing the

simulation model itself, the behaviour and

parameter sensitivity of an ERP system can be

explored, eventually optimising ERP parameters.

Obvious examples for this option are variations

of lot size parameters, minimum stock levels,

machine group capacities or time horizons.

Beyond that, proposed modifications of the

production process (changed bills of material or

work plans) or the introduction of new products

and technologies can be investigated.

c) Variation of ERP utilisation: By altering the

business processes or called ERP functions in the

simulation model, modified handling of the real

ERP system can be studied, e.g. regarding

impacts of proposed business process

reorganisation.

d) Variation of ERP algorithms: Adaptations of

internal ERP program logic can automatically be

tested, driven by the simulation model and

without interference with productive ERP

operation. This allows assessing benefits and

side effects under defined environmental

conditions, on the side of the software producer

(e.g. new planning, scheduling or order release

algorithms) as well as of the users (e.g. company

specific adaptations).

By comparison of predefined key performance

indicators and analysis of relationships between

variation scenarios, additional insights into company

dynamics can be gained, in order to prepare or

support optimising measures.

4 CHALLENGES

In order to achieve the expected benefits from the

interaction approach, the following aspects have to

be taken into consideration:

Necessity of modelling: By copying the

productive ERP system, simulation modelling of

ERP functionalities becomes redundant.

Company specific settings and adaptations in the

ERP system are copied as well. By importing a

current or historical snapshot of the ERP data

base, no further initialisation on the ERP system

side is needed. Nevertheless, the simulation

model has to be adjusted to the way the concrete

modelled company handles its ERP system; i.e.

the business processes of ERP utilisation have to

be documented and represented in the simulation

model. This is an individual process for each

company, requiring corresponding individual

analyses and manual work in implementation,

comparable to a classic simulation study.

Our interaction approach cannot provide an

adequate simulation environment ‚out of the box‘

that is suitable for each company without

modification.

Experiment duration: A simulation experiment

covering for instance one financial year of a

company is requiring in principal at least the

same computing time as the sum of all called

ERP system functions would consume in daily

operation during the simulated time, assuming

simulation is performed on the same hardware.

Additional overhead for processing the

simulation model itself has to be added, and a

certain experimentation factor has to be taken

into account; i.e. ERP functions run partially

concurrently on network clients in real company

operation, whereas in simulation experiments

these functions may be called sequentially only

on one client or server, unless the simulation

model itself is implemented in a true concurrent

manner.

Very significant factors are time-consuming ERP

batch runs like daily batch planning. With a

realistic batch planning time requirement of 1

hour per day, the simulation of one financial year

(260 working days) will result in a time

consumption of at least 260 hours per

experiment, corresponding to 11 calendar days

per experiment. In addition, experiment

replications with varying starting values of

random number generators are indispensable for

statistical reasons. For efficiency considerations,

this suggests parallel execution of simulation

experiments (Illner, 2013) and therefore parallel

operation of multiple ERP system copies for

simulation purposes.

The general value of each simulation study is highly

dependent on data quality. This is also true for our

interaction approach. Thus, the following aspects

have to be taken into account:

The underlying ERP system data may be

incomplete, because not all ERP relevant

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

232

business processes are handled via the ERP

system. The degree of ERP system

implementation in daily operation may depend

on how long the ERP system is in practical use,

likewise on the expected utility of using or not

using certain ERP system functions. For

instance, purchase orders of auxiliary materials

and consumables could still be handled outside

the ERP system, or messages on machine

malfunction could be waived. Accordingly, the

statistical data basis for simulation could be

incomplete.

A related problem arises if the ERP system is not

utilised continuously or not in a consistent

manner, i.e. users may use the ERP system only

partially or carry out different ERP system

operations for the same task. If business

processes with identical content are treated in

different ways in the ERP system, semantically

equivalent data may be fragmented in the data

base. These aspects can lead to seemingly

missing or inconsistent data and wrong

conclusions about utilisation frequency. For

instance, inconsistent or mingled use of stock

correction bookings and inventory postings will

communicate a wrong image of the real

inventory process. In such cases the statistical

data basis for simulation would be incomplete or

distorted and therefore invalid.

Possible shifts of model structure in timeframes

used for statistical data extraction may be an

issue in every simulation study; however here

they have to be examined with special care,

because companies indeed are subject to

permanent change and continuously aiming at

optimisation. Business processes and thus ERP

system utilisation have a high potential for

alteration during the time interval used for

statistical data extraction: For instance

introduction of new market segments, opening or

closing down of production sites, commissioning

of new production technologies or other internal

process reorganisation may lead to certain

additional, different or missing data in the ERP

system data base. Such structural discontinuities

have to be accounted for, as the data generating

process has changed during the analysis period

and we cannot act on the assumption of

identically distributed data anymore. Thus,

ignoring existent development of a company will

lead to statistical problems, e.g. due to mistaken

multimodal distributions.

Beyond the statistical data basis issue, we have to

model the individual company utilisation pattern of

the ERP system. In this context the following

aspects have to be considered:

When modelling ERP utilisation for simulation,

it is essential to systematically investigate those

ERP relevant functions which are deliberately

handled outside the ERP system or which are in

principle not covered by the given ERP system

functionality. These business processes have to

be reproduced in the simulation model by

complementing the model with a formal

representation of the original human handling

process. This might be very labour-intensive,

especially if the reason for non-utilisation of the

ERP system arose from the complexity of a task

whereas the ERP system producer was unable to

provide an adequate solution. Examples could be

scheduling and order release priorities or short

notice re-scheduling of orders due to external

events or unexpected instructions from higher

management. If necessary, additional automation

interfaces to indispensable third-party IT-systems

have to be implemented in case expertise has

been outsourced, e.g. to APS or MES.

In order to promote an initial trust into the

constructed simulation model it makes sense to

initialise the simulation copy of the ERP system

with a historical data base snapshot (e.g.

beginning of the previous calendar year) and to

afterwards run the simulation to a second past

point in time (e.g. beginning of the current

calendar year). An impression on the model

quality and its dynamics can be gained by

comparison of the final simulation state with an

independent ERP data base snapshot of the

second point in time, where the simulation

ended. However, dynamic deviation of real ERP

system utilisation, as contrasted with static use

patterns modelled for simulation, might turn out

problematic, but may be more likely here than in

many other domains. In this instance, model

validation based on historical data might fail and

following simulation results can be questioned.

For validation purposes, any rapid or subtle

changes in ERP utilisation patterns over the

course of time have to be detected and replicated

in the model, which may require considerable

effort. At worst, comprehensive modelling of

dynamics might become impossible, if altering

ERP system utilisation is not documented, not

specifiable or simply unaware in the modelled

company.

InteractionofSimulationToolswithERPSystems-ConceptandPracticalImplementation

233

5 IMPLEMENTATION

Our interaction approach described above has been

implemented in graduate thesis and master projects

at the University of Hamburg (Kühnlenz, 2011);

(Schäfer, 2011); (Reichelt, 2012), using the open

source simulation framework DESMO-J developed

at the University of Hamburg (Page, 2013) as well

as the commercial ERP system ERP COM of Infor

GmbH (Infor, 2013). For practical substantiation and

review of the concepts introduced, we established a

cooperation with two German medium-sized

manufacturing companies, which have been using

ERP COM operationally for many years.

The choice of Infor’s ERP COM system was

motivated by easy academic accessibility, very

suitable student training material, a broad customer

base for potential cooperation and already existing

program know-how. In contrast and corresponding

to DESMO-J’s free availability, interaction with an

open source ERP system could have been an

appropriate alternative, establishing an affordable

combination of tools for innovative small and

medium size enterprises. However, currently open

source ERP systems have a rather low market

penetration in Germany and often lack reliable

support (Borgmann, 2010). In order not to

complicate the project more than necessary, it was

decided to interact with an established ERP system.

First, we turned our attention to development of

a technical interface to the ERP system data base.

The interface permits to read actual arrival and

booking events of the ERP system within a selected

concrete historical interval of time. Using the

empirical data collected, parameters for diverse

random distribution type candidates are estimated by

an R script. Subsequently, the final distribution types

are identified, making use of the Kolmogorov-

Smirnov and Anderson-Darling goodness-of-fit

tests.

In this way, 8 distributions with their parameters

are estimated from concrete ERP system data, e.g.

for sales orders, operation durations and purchase

order delivery times (Schäfer, 2011). A further tool

allows visualisation of these distributions directly

from the utilised ERP system. Here, the derived

stochastic distributions are presented superimposed

by the actual ERP system data. This validation step

serves as visual check as well as for transparency

and confidence building for model users, concerning

the quality of simulation model input. The tool

provides further added value by facilitating

adjustment of independent ERP system parameters

w.r.t. actually observed data in ERP system

application, e.g. comparison of operation duration

master data vs. practically observed operation

duration (Reichelt, 2012).

As a second step, a reference simulation model

has been implemented in DESMO-J, reproducing the

standard business processes of using ERP COM in

practice, as advised by its producer Infor (Infor,

2012). Here, all standard business activities from

sales to planning, manufacturing, warehousing and

purchasing have been included. Altogether 15

functional interaction points have been identified,

where the simulator is calling ERP system

functionalities, e.g. creation of sales orders,

triggering of planning, release of manufacturing

orders, generation of purchase orders, booking of

goods receipt or manufacturing operations, etc. The

simulation model is accessing the ERP system via

abstracted technical interfaces in order to create

business objects like sales orders or call ERP

functions on existing business objects, just in the

same way a human operator would do in the

modelled company. In this context the simulation

model is controlled by the 8 extracted statistical

distributions described above. Additional 9 model

control parameters can be specified by XML-files or

are directly read out of the ERP system’s data base.

Beyond that, we provide a replay mode,

accessing original object sequences from the

analysed ERP system data base instead of artificial

random numbers. Thus, historical sales orders along

with their empirically observed inter-arrival times

can be re-used in a 1:1 manner in simulation

experiments, as an alternative to stochastic

distributions. This is in particular useful for both

simulation model validation by means of output

comparisons and later model parameter calibration.

The comprehensive reference simulation model

has been extensively documented in textual form as

well as with BPMN 2.0 diagrams (Kühnlenz, 2011).

In parallel 15 entry points for functional

interaction have been created in the ERP system,

allowing for automation of the ERP system by the

simulator. A newly constructed control process in

the ERP system is receiving simulator Remote

Procedure Calls, including parameters, via a TCP/IP

socket interface. According to the received message

content, the control process branches into ERP

functionalities by calling and processing standard

business logic of the ERP system. Meanwhile, the

simulator waits until the called ERP functionality is

processed completely. Hereupon the ERP control

process communicates possible return values or

status messages back to the simulator, again via

TCP/IP sockets (Schäfer, 2011). In addition, the

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

234

simulator can access the ERP system data base via

an abstracted interface in read-only mode, in order to

access new or modified business objects of the ERP

system effected by preceding ERP remote calls.

The simulator permanently is synchronizing the

local time of the ERP system by setting the

computer’s resp. virtual machine’s wall clock time

to its own internal simulation clock. After execution

of ERP functionality by remote procedure calls, the

simulation clock is not adjusted to the current wall

clock time, because events already scheduled on the

simulator’s event list could be skipped, especially in

cases of long ERP batch runs. By this means,

execution of ERP functionality does not consume

simulation model time and appears atomic. This

deviates from reality, because race conditions and

transaction collisions will not be observed in

simulation experiments. A refined implementation

could delegate every ERP function call to an own

processor thread and synchronise the simulation

clock with wall clock time as long as ERP function

calls are executed, resulting in true realistic

concurrency with respect to the ERP system.

However, it is questionable if this effort would be

justified in the presence of a generally stochastic

simulation. In summary, the ERP system is jumping

from time point to time point along with the

simulator in a synchronous manner, reaching

processing speed as fast as possible by employing

the next-event simulation approach (Kühnlenz,

2011).

The simulation model has been implemented in

an event-oriented fashion, mainly for two practical

reasons: First, we aimed at keeping the run-time

overhead attributable to model execution down, as

experiment duration is a non neglectable issue.

Second, we envisage enhancing experiment handling

by deploying an extension of DESMO-J that permits

saving, loading and resuming event-oriented

experiments at any simulation run time instant (Janz,

2010). When taking and restoring ERP data base

snapshots simultaneously, interesting intermediate

states of ERP simulation experiments can be

preserved. By duplicating saved intermediate states

and varying their parameters upon restart, alternative

scenarios can be studied. In these cases, considerable

time for re-obtaining intermediate states of interest

can be saved, since experiment execution ab initio is

avoidable. Due to restrictions of the Java standard

VM, this technique is not feasible for the process-

oriented paradigm, which is implemented in

DESMO-J on basis of Java threads.

Modelling a company in an event-oriented style,

from a bird’s-eye view, seems natural in many cases,

as often self-contained impersonal events like order

arrival, operation booking or triggering of batch

processes occur. However, it can be argued that

human utilisation patterns of ERP systems may

alternatively suggest process-oriented modelling, as

far as company business processes are concerned

and modelling is performed on a departmental level.

Even one step further, agent-based simulation, as

provided e.g. by DESMO-J’s extension FAMOS

(Knaak, 2002) could be considered, if individual

roles in the company organisation are in focus and

fine-grained data and detailed description of role

behaviour is available at an acceptable effort.

However, in this first approach we remain with

event-oriented modelling, for the reasons given

above.

At the end of a simulation experiment,

DESMO-J can create a trace file during the

simulation run, recording the course of simulated

business processes. This is an important basis for

model validation. Additionally, first statistical

results are accessible in the standard simulation

report, e.g. for queues used in the simulation model.

For comparison and evaluation of simulation results,

further 9 company key performance indicators (KPI)

have been defined and partially implemented, e.g.

adherence to delivery dates and average delay of

purchase orders. Here, data from simulation runs are

combined with the ERP system’s data base. The

aggregated KPI are output in textual form in a report

file and are also visually presented in a graphical

tool (Reichelt, 2012).

Apart from minor open work concerning material

posting, the cyclic interaction of simulator and ERP

system is completely implemented.

6 SUMMARY AND

CONCLUSIONS

In contrast to conventional approaches of linking

ERP systems with discrete event simulators, our

interaction approach introduced in this paper aims at

coupling a full-fledged discrete event simulator and

a copy of an ERP system in full productive

operation, fully integrating comprehensive ERP

functionality as used in real, daily practice and

without human manual intervention. Here, the

simulator is representing the complete operative

environment of the ERP system, substituting its

daily business input. For this, the company-specific

utilisation of the ERP system (not the ERP

functionality itself) is modelled in the simulator. In

InteractionofSimulationToolswithERPSystems-ConceptandPracticalImplementation

235

order to execute its model and process concrete ERP

functionality, the simulator accesses the ERP system

via software interfaces, using it like a large subject-

specific software library. Thus, the simulator is

effectively carrying out a complete remote control of

the ERP system, in the sense of software

automation.

The simulator causes arrival and booking events

in the ERP system, is triggering internal ERP

processes on a regular basis and is processing results

like revised planning and adjusted orders by

scheduling future events, according to stochastic

distributions extracted from the ERP system

beforehand. Altogether simulator and ERP system

are interacting mutually with each other in a cyclic

process.

By using this concept, only very few ERP

functionality has to be represented in the simulation

model, allowing for a faster and more precise model

construction with less effort. Simulation results are

more trustworthy and easier to re-transfer into ERP

practice.

Our approach represents a comprehensive and

integrated simulation of business processes and is in

particular predestinated for issues where concrete

ERP systems in real company operations play a

significant role. Application potential is on one hand

arising from variation of the simulated environment,

e.g. for company sensitivity analyses or load tests of

manufacturing. On the other hand, variation of ERP

parameters allows exploring the behaviour and

sensitivity of the ERP system, in order to eventually

optimise ERP parameters. Furthermore, the

simulation of altered utilisation of the ERP system

can help analyse alternative business processes,

whereas variations of ERP algorithms allow for

examination of modified program logic in a safe,

controlled and dynamically reproducible

experimental environment

In order to assess the utility of the interaction

approach, the length of simulation experiments has

to be regarded. Comparable to a classic simulation

study, individual modelling of ERP utilisation is

necessary, even if a copy of the real ERP system

with extensive ERP functionality is at hand. It has to

be stressed that trustworthy simulation results can

only be expected if the ERP data basis and the

modelled ERP utilisation processes are complete,

consistent, valid and representative. Ensuring this

may require considerable effort.

The interaction approach has been implemented

using the open source simulation framework

DESMO-J developed at the University of Hamburg

in conjunction with the commercial ERP system

ERP COM of Infor GmbH. Implementation was

carried out in cooperation with two medium-sized

manufacturing companies, in the context of graduate

thesis and master student projects.

At the current status of our project, company

specific ERP model parameters are extracted

automatically from the ERP data base and control a

comprehensive, well documented event-oriented

simulation model under DESMO-J. The simulation

model is automating the ERP system via newly

generated technical interfaces. The results of

triggered ERP processes affect the simulation model

which in turn is reacting with new external impulses.

In addition, tools for measurement and visualisation

of company KPI have been implemented.

The interaction cycle as presented in this paper is

basically operational. As a next step, some fine

tuning and software additions are required as

prerequisite for real-world simulation experiments in

the ERP environments of the two cooperation

companies.

Once the technical basis is established, it

carefully has to be dealt with methodical challenges

regarding data quality, model accuracy and run time.

Further validation is needed before concrete ERP

related operative and tactical investigations like ERP

parameter tuning, load tests and analysis of

alternative ERP utilisation can be addressed.

ACKNOWLEDGEMENTS

The authors would like to thank the company Infor

GmbH, the Infor User Forum, the two industrial

cooperation partners, the PML Section of

Department 4 at the FH Düsseldorf as well as the

Computing Center of Hamburg University for their

support, software, ideas and contacts. We also want

to express our recognition of the strong working

contributions of our graduate students Claas-Michael

Kühnlenz and Fabian Schäfer.

We appreciate the comments of two anonymous

referees of this conference, whose advice has been

incorporated into the body text.

REFERENCES

Bayer, J., Collisi, T. and Wenzel, S. (2003), Simulation in

der Automobilproduktion, Springer, Berlin.

Borgmann, S. (2010), “Open-Source-ERP-Systeme im

praktischen Einsatz in kleinen und mittleren

Unternehmen (KMU)”, Master's Thesis, Carl von

Ossietzky Universität Oldenburg, Oldenburg, 2010.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

236

Cardin, O. and Castagna, P. (2011), “Proactive production

activity control by online simulation”, International

Journal of Simulation and Process Modelling, Vol. 6

No. 3, p. 177.

Cronan, P. and Douglas, D. (2012), “A Student ERP

Simulation Game: A Longitudinal Study”, Journal of

Computer Information Systems, Vol. 53 No. 1, pp. 3–

13.

Davis, W.J. (1998), “On-Line Simulation: Need and

Evolving Research Requirements”, in Banks, J. (Ed.),

Handbook of Simulation, John Wiley & Sons, Inc,

Hoboken, NJ, USA, pp. 465–516.

ElMaraghy, H.A., Abdallah, I.B. and ElMaraghy, W.H.

(1998), “On-Line Simulation and Control in

Manufacturing Systems”, CIRP Annals -

Manufacturing Technology, Vol. 47 No. 1, pp. 401–

404.

Fink, A., Schneidereit, G. and Voss, S. (2005),

Grundlagen der Wirtschaftsinformatik: Mit 16

Tabellen, Physica-Lehrbuch, 2nd ed., Physica-Verl.,

Heidelberg.

Fowler, J.W. and Rose, O. (2004), “Grand Challenges in

Modeling and Simulation of Complex Manufacturing

Systems”, SIMULATION, Vol. 80 No. 9, pp. 469–476.

Gronau, N. (2010), Enterprise Resource Planning:

Architektur, Funktionen und Management von ERP-

Systemen, 2nd ed., Oldenbourg, München.

Herrmann, F. (2007), “SIM-R/3: Softwaresystem zur

Simulation der Regelung produktionslogistischer

Prozesse durch das R/3-System der SAP AG”,

WIRTSCHAFTSINFORMATIK, Vol. 49 No. 2, pp.

127–133.

Hopkins, J.L. and Foster, S. (2011), “Supply Chain ERP

Simulation: A unique learning experience”, paper

presented at AMCIS, 4-8 August, Detroit, Michigan,

USA.

Illner, M. (2013), “Konzeption und Implementation einer

Batch-Verarbeitung von Experimentreihen in

DESMO-J”, Bachelor’s thesis, University of

Hamburg, Hamburg, 2013.

Infor (Deutschland) GmbH (2012), Training material on

ERP COM 7.1.

Infor (Deutschland) GmbH (2013), ERP COM 7.1: ERP-

System. http://www.infor.de/produkt-spotlight/erp/erp-

com.

Jacob, O. (2008), ERP Value: Signifikante Vorteile mit

ERP-Systemen, Xpert.press, Springer, Berlin,

Heidelberg.

Janz, T. (2010), “Prototypische Implementierung einer

Verwaltung von Momentaufnahmen im

Simulationsframework Desmo-J”, Bachelor's Thesis,

University of Hamburg, Hamburg, 2010.

Knaak, N. (2002), “Konzepte der agentenbasierten

Simulation und ihre Umsetzung im Rahmen des

Simulationsframeworks DESMO-J”, Master's Thesis,

University of Hamburg, Hamburg, 2002.

Košturiak, J. and Gregor, M. (1999), “Simulation in

production system life cycle”, Computers in Industry,

Vol. 38 No. 2, pp. 159–172.

Kuhn, A. (1998), Simulation in Produktion und Logistik:

Fallbeispielsammlung, Springer, Berlin.

Kühnlenz, C.-M. (2011), “Interaktion von

Simulationswerkzeugen mit ERP-Systemen -

Konzeption und Realisierung von

Interaktionsworkflows am Beispiel von DESMO-J und

Infor ERP COM”, Master’s thesis, University of

Hamburg, Hamburg, 2011.

Léger, P.-M. (2006), “Using a Simulation Game Approach

to Teach Enterprise Resource Planning Concepts”,

Journal of Information Systems Education, Vol. 17

No. 4, pp. 441–448.

Nisula, K. and Pekkola, S. (2012), “ERP-based simulation

as a learning environment for SME business”, The

International Journal of Management Education, Vol.

10 No. 1, pp. 39–49.

Noack, D. (2012), “Online Simulation in Semiconductor

Manufacturing”, PhD thesis, Fakultät für Informatik,

Universität der Bundeswehr München, Munich, 2012.

Page, B. (2013), DESMO-J: Simulation framework.

http://www.desmo-j.de, Universität Hamburg,

Fachbereich Informatik, Modellbildung und

Simulation.

Page, B. and Kreutzer, W. (2005), The Java simulation

handbook: Simulating discrete event systems with

UML and Java, Shaker, Aachen.

Reichelt, D.G. (2012), “Interaktion von

Simulationswerkzeugen mit ERP-Systemen - Konzept

und Umsetzung zur Erweiterung und

Vervollständigung der bestehenden ERP-Simulation”,

Report on Master's project, University of Hamburg,

Hamburg, 2012.

Schäfer, F. (2011), “Interaktion von

Simulationswerkzeugen mit ERP-Systemen -

Konzeption und Realisierung von Datenanalysen

sowie technischen Schnittstellen am Beispiel von

DESMO-J und Infor ERP COM”, Master’s thesis,

University of Hamburg, Hamburg, 2011.

Schenk, D.J. and Draijer, C. (2004), “Best Practices of

Business Simulation with SAP R/3”, Journal of

Information Systems Education, Vol. 15 No. 3, pp.

261–265.

VDI Verein Deutscher Ingenieure and Gesellschaft

Fördertechnik, Materialfluss und Logistik (1993),

Simulation von Logistik-, Materialfluß- und

Produktionssystemen: Simulation of systems in

materials handling, logistics and production, VDI-

Richtlinien No. 3633, VDI-Verlag, Düsseldorf.

Wu, S.-Y.D. and Wysk, R.A. (1989), “An application of

discrete-event simulation to on-line control and

scheduling in flexible manufacturing”, International

Journal of Production Research, Vol. 27 No. 9, pp.

1603–1623.

InteractionofSimulationToolswithERPSystems-ConceptandPracticalImplementation

237