Implementation of a Grating-type Spatial Optical Switch based on

Phase Change Material and its Static Measurement

Xiaomin Wang

1

, Masashi Kuwahara

1

, Hitoshi Kawashima

1

and Hiroyuki Tsuda

2

1

National Institute of Advanced Industrial Science and Technology (AIST), Tsukuba Central 4, Tsukuba, Japan

2

Graduate School of Science and Technology, Keio University, 3-14-1 Hiyoshi, Kohoku-ku, Yokohama-shi, Japan

Keywords: Spatial Optical Switch, Diffraction Grating, Phase Change Material.

Abstract: We have implemented a new grating-type spatial optical reflection switch based on phase change material

(PCM) for usage at optical communication wavelength. This grating device switches on/off the light or

steers the light propagation direction by switching the PCM grating between its amorphous and crystalline

states. Thus, the switching status is non-volatile and the device is promising for power saving optical

network. Based on the design by numerical computations, the prototype grating device was fabricated by

electron beam lithography and laser interference lithography techniques. The static switching characteristics

were measured by optical diffraction experiments for the two states of the grating.

1 INTRODUCTION

Since the proposal of chalcogenide-type phase

change material (PCM) memory and switching

devices by Dr. S. R. Ovshinsky in 1960s (Ovshinsky,

1968), PCM has achieved tremendous success in

rewritable optical disks such as CDs, DVDs and

Blue-ray Discs. Recently, this material has attracted

dramatically increasing interests in modern

semiconductor industry as a non-volatile phase

change random access memory (PRAM) (Burr et al.,

2010); (Raoux et al., 2010). Thanks to its fast-speed,

long cyclability and superior scalability, PRAM is

expected to replace the close-to-limit Flash Memory

and is even considered as a potential candidate for

the universal memory in new computer architecture.

Following exactly the same strategy, PCM has also

been proposed to be used in optical switches (Strand

et al., 2006); (Ikuma et al., 2008). Though the

expected speed of a PCM optical switch is on the

order of tens of nano-second, much slower than that

of a modern pico-second or femto-second optical

switch, the non-volatile characteristic makes it

attractive in fields such as optical path routers which

operate at moderate speed but require low power

consumption. In this genera, it is orders of

magnitude faster than the millisecond speed

achievable by micro electro mechanical system

(MEMS) switches, thermo-optic switches or liquid

crystal switches. Recently, a prototype waveguide-

type PCM optical switch has been demonstrated by

our group (Ikuma et al., 2010). We have also

proposed a spatial type PCM optical switch based on

diffraction grating (Wang et al., 2009).

In this paper, we review some aspects of the

proposed grating-type switch and describe its

fabrication process. Finally, its basic static

diffraction performance is measured and discussed.

2 PRINCIPLE

OF A GRATING-TYPE

OPTICAL SWITCH

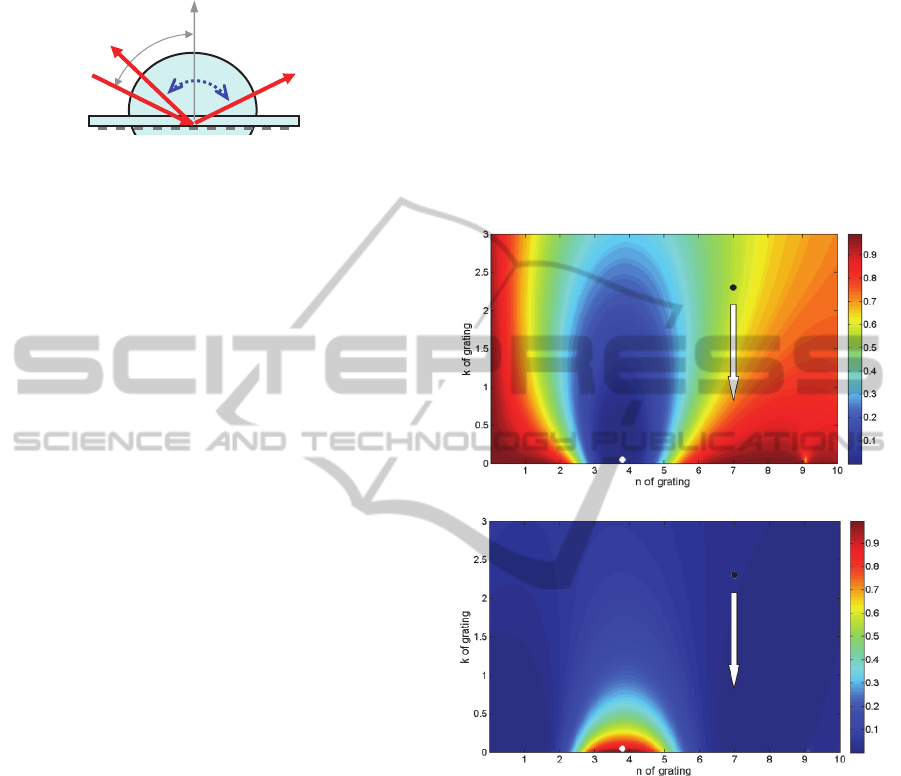

Figure 1 shows schematically the proposed grating-

based optical switch. It uses a Kretschmann

configuration with a semi-cylindrical prism on top of

the index-matched substrate to couple the light in

and out, and a PCM grating fabricated on the

opposite surface of the substrate to diffract the light.

This configuration has been carefully engineered so

that the number of diffracted orders by grating is

reduced to a minimum. First, the total-reflection

scheme suppresses all the transmitted diffraction

orders. Secondly, the period of grating is such

chosen that only the first order reflected diffraction

and the specular reflection are allowed to exist.

More details are provided in the reference (Wang et

al., 2009). As a result of the numerical simulations,

101

Wang X., Kuwahara M., Kawashima H. and Tsuda H..

Implementation of a Grating-type Spatial Optical Switch based on Phase Change Material and its Static Measurement.

DOI: 10.5220/0004338801010105

In Proceedings of the International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2013), pages 101-105

ISBN: 978-989-8565-44-0

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

the optimal grating structure is assumed to be of a

period of 600 nm and a duty-ratio of 50%.

Figure 1: Schematic of the proposed optical switch by

PCM grating. Light is coupled in and out by the top semi-

cylindrical prism. The incidence angle of input light is

indicated by

.

To show how the diffraction efficiency of the

grating depends on the refractive index, Figure 2

shows the simulated efficiencies of specular

reflection and first diffraction order as the contour

maps with regard to the grating’s refractive index n

+ i k. The simulation was carried out by the rigorous

coupled wave analysis (RCWA) method (Moharam

and Gaylord, 1982); (Li, 1997) for the optimal

grating with an incidence angle of 62° and an s-

polarization input. In the maps, the refractive indices

of a popular phase change material, Ge

2

Sb

2

Te

5

(GST), are represented by the white and black dots

for its two phase states. GST material was invented

by Yamada et al. (1987) and is an important PCM

because of its superior crystallization speed and

large refractive index contrast during phase change.

For the optical switch applications, this material is

also a good candidate because its amorphous state is

virtually transparent at 1.55 m wavelength (n + i k

= 3.8 + i0.05, as measured by our spectroscopic

ellipsometer), and its crystalline state has a moderate

absorption (n + i k = 7.0 + i 2.3).

According to Fig. 2, we can see that, when the

grating is in amorphous state (white dots), the

specular reflection efficiency is almost zero, while

the first diffraction has a very high efficiency of

92%. On the other hand, when the grating turns into

crystalline state (black dots), the efficiency of

specular reflection is about 60% but that of first

diffraction becomes negligible. All other orders of

diffraction are computed to be zero. Therefore, by

properly controlling the phase state of a grating

made of GST, we can turn on/off the specular

reflection light, or steer the inputted light to either

the specular reflection direction or the first

diffraction direction. Thus it can be used as an

optical path router. The first diffracted beam can

even be designed to couple back to the input

direction and diverted to other route by a circulator,

thus simplifying the optical coupling at input port.

The relatively poor reflection efficiency for the

crystalline state grating (black dot in Fig. 2(a)) is

due to the relatively larger absorption of crystalline

GST. As indicated by the arrows, if a PCM with

lower k becomes possible, a higher reflection

efficiency and lower first diffraction are achievable

for the crystalline state. In fact, Strand et al. (2006)

has tried and succeeded in tuning the absorption of

GST to a much lower value by adding some alloy

composition.

(a) Specular reflection

(b) First diffraction order

Figure 2: Contour maps showing the diffraction

efficiencies of specular reflection and first diffraction

order as functions of the refractive indices of PCM

grating. The white dots indicate the n + i k of the

amorphous GST material, and the black dots indicate that

of the crystalline GST. A lower absorption k for the

crystalline GST is desirable for better crystalline

performance. The incidence angle

is assumed to be 62°.

It should be noted that the above behaviour does

not apply to a p-polarization light because of the

inherent anisotropy in the grating structure. The p-

polarized light always comes out as specular

reflection. From another point of view, the PCM

grating may also be used as a switchable

polarization splitter where the s-polarization can be

Specular

reflection

Prism

Quartz

substrate

PCM grating

Input light

1

st

diffraction

PHOTOPTICS2013-InternationalConferenceonPhotonics,OpticsandLaserTechnology

102

selectively separated from the specular reflection

port.

3 FABRICATION OF THE PHASE

CHANGE MATERIAL

GRATING

According to numerical simulations, the optimized

grating structure is a GST grating of 50 nm thickness

and a 300 nm line-and-space. We had used electron-

beam (EB) lithography to fabricate this sub-

micrometer PCM grating on a silica substrate. For

easy optical alignment, a large grating area of 22

mm

2

is preferable. It turned out that this large area of

electron beam writing is quite challenging because

of the charging-up effect on a silica substrate. We

had to choose a lower electron acceleration voltage

and carefully coat the resist film with a conducting

polymer layer (Epacer 300). After hours’ EB writing

a rather uniform grating structure was obtained.

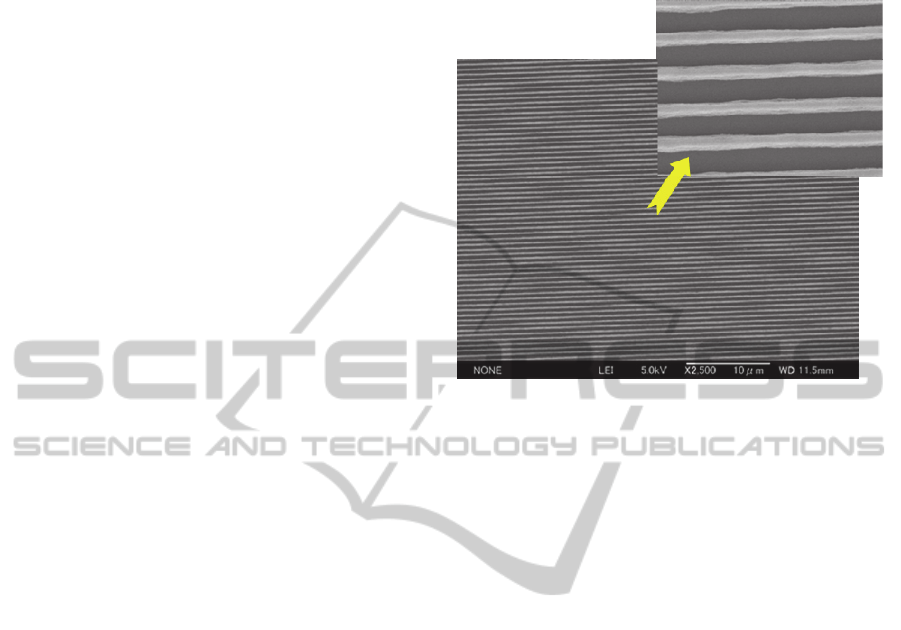

To make the fabrication process simpler and

cheaper, later we shifted our process to the laser

interference lithography where a Lloyd’s mirror

interferometer (Fucetola et al., 2009) was built up. A

He-Cd laser of 441.6 nm wavelength was used as the

optical source. The sample holder was located at

about 70 cm far away from the spatial filter, and the

holder angle α is set as 68.4° in order for the grating

period to be 600 nm (as period = /2cosα). The

diluted photo-resist OFPR800 was found to be

sufficiently sensitive at the wavelength of 441.6 nm

and have adequate resolution to produce the 300 nm

line and space pattern. By carefully tuning the

exposure time and develop time to the optimal

condition, a large area (13 cm

2

elliptic shape) of

uniform grating could be developed in very short

time. An example of such made grating pattern is

shown in Fig. 3. Because of the existence of small

residual fluctuation in wavefront of our interference

system, the grating lines also show some

fluctuations when observed under a scanning

electron microscope (SEM), and are less uniform

than those fabricated by EB lithography.

Nevertheless, it is expected that the fluctuation will

not affect much when conducting the optical

experiment.

Then, a GST PCM layer was deposited on the

resist pattern with a reactive RF-magnetron

sputtering system (CFS-4ES by Shibaura Co.) in an

Ar gas atmosphere. The pressure of the Ar gas was

set to 0.5 Pa and the RF power was set to 100 W to

keep the sample cool enough. After lifting-off in

acetone, a GST grating of designed period was

obtained.

Figure 3: SEM image of the grating pattern fabricated by

laser interference lithography.

4 STATIC DIFFRACTION

MEASUREMENTS

To validate the switching behaviour given by

Section 2, we measured the static optical diffraction

of the GST grating when it is in the amorphous or

crystalline state. All the measurements were

performed on a modified spectroscopic ellipsometer

(VASE by J. A. Woollam Co., Inc). We used the

ellipsometer simply as an optical platform, to take

advantages of its convenient optical coupling system

as well as the precise goniometric mechanism. The

equipment’s standard sample holder and stage were

replaced by a handmade stage together with other

optical gadgets in order to implement the

Kretschmann configuration. In addition, the

hardware control setting has been customized to

allow the angles of input and output arms to be set

independently. In this way, for a fixed incident

beam, we can measure its diffraction at any

direction.

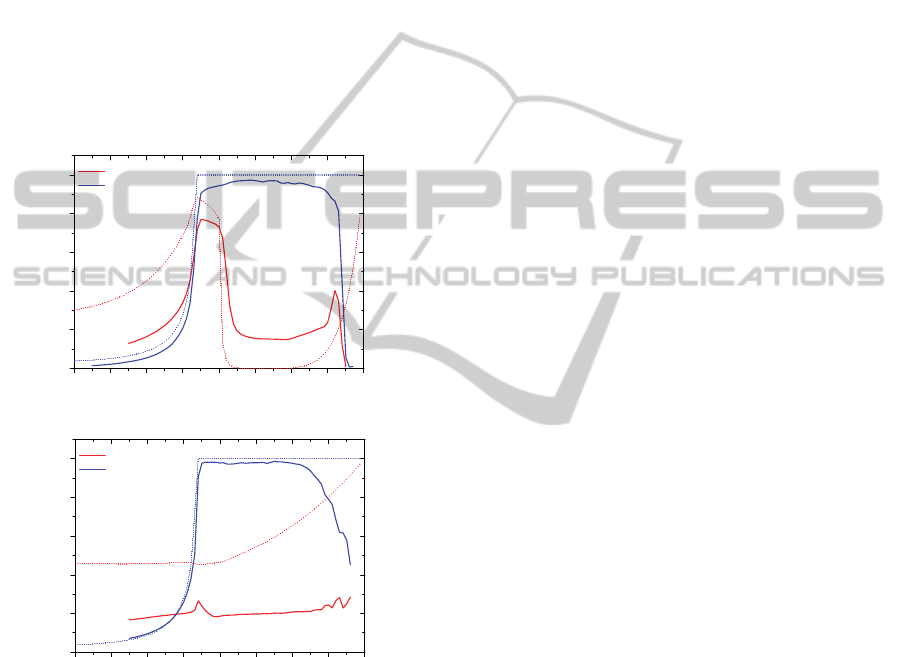

In Figure 4(a), the specular reflection efficiency

of s-polarized light for an amorphous GST grating

was measured for different incident angle

. The

reflection of the no-grating area was also measured

and plotted in the same figure as a reference. Indeed

as the incidence angle

goes beyond the total

reflection angle, the specular reflection drops

quickly because of the diffraction by the grating.

This behaviour agrees well with the light scattering

ImplementationofaGrating-typeSpatialOpticalSwitchbasedonPhaseChangeMaterialanditsStaticMeasurement

103

predicted by simulation which is also plotted in the

same figure with dotted line. However, the residual

specular reflection at incidence angles larger than

55° does not go to zero. The reason is considered to

be due to imperfection of the PCM grating.

Next, to conduct the measurement for a

crystalline GST grating, the as-deposited amorphous

GST grating sample was annealed at 200°C for 5

minutes to convert into the crystalline state. The

measured results are shown in Fig. 4(b). As

expected, the specular reflection does not show a

fast drop. However, the overall amplitude is quite

lower than simulation which might also be due to

fabrication error and large absorption in crystalline

GST. Especially the thickness of GST was suspected

to be thicker than designed.

10 20 30 40 50 60 70 80 90

0.0

0.2

0.4

0.6

0.8

1.0

Specular reflectivity [a.u.]

Incidence angle [

o

]

grating area

no grating area

(a) Amorphous GST grating

10 20 30 40 50 60 70 80 90

0.0

0.2

0.4

0.6

0.8

1.0

Specular reflectivity [a.u.]

Incidence angle [

o

]

grating area

no grating area

(b) Crystalline GST grating

Figure 4: Measured specular reflection efficiency of

s-polarized light for a GST grating. The optical

wavelength is set as 1.55 μm. The specular reflection of

no-grating area is also measured as a reference. In

addition, the simulation results are plotted in dotted lines.

5 CONCLUSIONS

To verify the concept of a spatial grating-type PCM

optical switch, we have fabricated the designed

grating structure using electron-beam lithography

and laser interference lithography techniques. The

laser interference lithography is especially useful to

generate large area periodical pattern. The static

switching characteristic of the grating was verified

by optical diffraction measurements for both the

amorphous and crystalline states, and they agree

roughly with the theoretical expectations. We

believe that further precise control in fabrication will

improve the experimental results. In the future,

dynamic phase change by laser pulse will be

necessary to testify the switching actions. The

optical switch can be driven by a more absorptive

visible wavelength to switch between its two phase

states, just as what have been done in an optical disk

system. In addition, PCM with a lower absorption at

1.55 m is greatly desirable in order to improve the

switching efficiency of the crystalline state switch.

ACKNOWLEDGEMENTS

This study was supported by a grant from the

Industrial Technology Research Program, 2011, of

the New Energy and Industrial Technology

Development Organization (NEDO), Japan. A part

of the fabrication work was conducted at AIST

Nano-Processing Facility, supported by

“Nanotechnology Network Japan” of the Ministry of

Education, Culture, Sports, Science and Technology

(MEXT), Japan.

REFERENCES

Burr, G. W. et al., 2010. Phase change memory

technology. Journal of Vacuum Science & Technology

B: Microelectronics and Nanometer Structures, 28(2),

pp.223–262. doi:10.1116/1.3301579.

Fucetola, C. P., Korre, H. & Berggren, K.K., 2009. Low-

cost interference lithography. Journal of Vacuum

Science & Technology B: Microelectronics and

Nanometer Structures, 27(6), p.2958. doi:10.1116/

1.3245990.

Ikuma, Y., Saiki, T. & Tsuda, H., 2008. Proposal of a

small self-holding 2×2 optical switch using phase-

change material. IEICE Electronics Express, 5(12),

pp.442–445. doi:10.1587/elex.5.442.

Ikuma, Y. et al., 2010. Small-sized optical gate switch

using Ge

2

Sb

2

Te

5

phase-change material integrated

with silicon waveguide. Electronics Letters, 46(5),

pp.368–369. doi:10.1049/el.2010.3588.

Li, L., 1997. New formulation of the Fourier modal

method for crossed surface-relief gratings. Journal of

the Optical Society of America A, 14(10), pp.2758–

2767. doi:10.1364/JOSAA.14.002758.

Moharam, M. G. & Gaylord, T. K., 1981. Rigorous

coupled-wave analysis of planar-grating diffraction.

PHOTOPTICS2013-InternationalConferenceonPhotonics,OpticsandLaserTechnology

104

Journal of the Optical Society of America, 71(7),

pp.811–818. doi:10.1364/JOSA.71.000811.

Ovshinsky, S. R., 1968. Reversible Electrical Switching

Phenomena in Disordered Structures. Physical Review

Letters, 21 (20), pp. 1450–1453. doi: 10.1103/

PhysRevLett.21.1450.

Raoux, S., Wojciech Wełnic & Ielmini, D., 2010. Phase

Change Materials and Their Application to

Nonvolatile Memories. Chemical Reviews, 110(1),

pp.240–267. doi:10.1021/cr900040x.

Strand, D. et al., 2006. Optical routers based on ovonic

phase change materials. In Proceedings of European

Phase Change and Ovonic Symposium (Grenoble,

France, 2006). http://www.epcos.org/library/

Library2006.htm.

Wang, X. et al., 2009. Proposal of a grating-based optical

reflection switch using phase changematerials. Optics

Express, 17 (19), pp. 16947–16956. doi: 10.1364/

OE.17.016947.

Yamada, N. et al., 1987. High Speed Overwritable Phase

Change Optical Disk Material. Japanese Journal of

Applied Physics, 26S4(Supplement 26-4), pp.61–66.

doi:10.1143/JJAPS.26S4.61.

ImplementationofaGrating-typeSpatialOpticalSwitchbasedonPhaseChangeMaterialanditsStaticMeasurement

105