A Non-lineal Mathematical Model for Annealing Stainless Steel Coils

Raquel González Corral, J. Bonelo Sánchez

Acerinox Europa S.A., Fabrica Campo de Gibraltar 11370 Los Barrios, Cadiz, Spain

Carlos G. Spinola, C. Galvez-Fernández, M. Martín-Vázquez

Dept of Electronics, University of Malaga, TCC S.L., Robinson Crusoe 5, 29006 Malaga, Spain

Keywords: Annealing, Self Organizing Map, Temperature, Heat, Stainless Steel, Furnace.

Abstract: Stainless steel manufacturing has experienced a high growth. Nowadays the stainless steel manufacturing is

an industry with many applications. Annealing process is an important process in the production of stainless

steel coils. The aim of this research is to obtain the classification of defective annealed coils. So a nonlinear

mathematical model has been developed for the annealing process. In this research the following techniques

have been used: SOM neural networks and classifications methods. For testing, temperature signals were

collected along the annealing furnace, also speed signal of the production line were collected. These signals

are correlated with each one of the manufactured coils.

1 INTRODUCTION

The conventional method to model the heating of a

furnace consist on solving simultaneously the

equations for radiation, convection and transmission.

This study proposes a new approach, using data

mining tools and neural networks to schedule and

control the annealing furnace line for stainless steel.

The following data are available: speed, temperature

and the parameters of the furnace. With these data

annealed coils can be classified in well annealed

coils and bad annealed coils. The following aims are

pursued: Reducing energy consumption, optimizing

output temperature, improving the surface quality

and optimizing the annealing time to increase

productivity.

2 ANNEALING PROCESS

The purpose of the annealing process is to remove

metal defects, to make it easier to work with. In cold

rolling, the thickness of a coil is reduced to the

desired thickness, but this process gives raise to

deformation in the crystalline structure of the metal,

that can be recovered by annealing. The annealing is

usually associated with other complementary

processes, such as superficial pickling. Resulting in

a production line type AP (Annealing and Pickling).

A coil circulates inside the annealing furnace

whose temperature must be maintained during the

time required on order that the annealing process to

occur. This time depends on the material thickness,

ranging from one to five minutes. The furnace is

divided into six zones, each one of which has its

burners and temperature control. The calculation of

temperature points determine the ideal amount of

heat to be transferred to the zone controllers,

according to optimum heat-up curve (Spinola,

2008).

Figure 1: Annealing furnace.

3 AIMS

The target of the investigation is to individually

analyze annealing of each coil, considering the

607

González Corral R., Bonelo Sánchez J., G. Spinola C., Galvez-Fernández C. and Martín-Vázquez M..

A Non-lineal Mathematical Model for Annealing Stainless Steel Coils.

DOI: 10.5220/0004112206070610

In Proceedings of the 4th International Joint Conference on Computational Intelligence (NCTA-2012), pages 607-610

ISBN: 978-989-8565-33-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

passage of the coil in each zone of the furnace

applying the model of heating of the annealing

furnace explained in Par. 4. Control of the heating

furnace is the calculation of heating points to be

permanently transferred to each area of the furnace,

with the aim of accomplishing the following: Attain

a decrease in temperature as close as possible to the

desired temperature, accommodation of operating

conditions according to the ratio variations on the

temperature of the furnace, minimize the

consumption of energy by optimizing heating

methods, classification of coils according to their

behaviour in the oven and prediction of the furnace

operating points based on initial conditions.

Data Mining tools and multivariate statistics are

useful when there is a significant historical volume

and good quality (Chapple, 2002). The thermal

energy received by each of the coil while in the

furnace can be calculated (Spinola, 2004). To do

this, the temperatures applied to each coil in each

area, top and bottom, are obtained from the data files

where they have been continuously registered. The

next step will be to rank the coils, depending on the

energy received as “bad annealed” or “well annealed

according to their characteristics, size and type of

steel. With all of this a model of annealing will be

made and a table of values of temperature and speed

set points will be obtained. Studying coil population

using ANN and classification to obtain an improved

model it is possible to reduce annealing transition

time between coils of different steel grades and

dimensions, optimizing the thermal transitions of the

different types of coils.

4 HOW TO OBTAIN THE

ANNEALING VALUE

In order to make easy the analysis and visualization

of the annealing of a complete coil, the process

consists in integrating the heat-up curve of all of the

points of the heated material along the furnace and

determines the temperature set points of the other

points of the heated coil. To summarize heating

information of each element we define the function

Ann1(d) as the integral in Eq 1.

(1)

Where d is the position of the coil element, t_in and

t_out are the time when the coil element enters and

exits the furnace and T(t,x(t)) is the temperature at

time t and position x(t) along the trajectory of the

element inside the furnace.

Let Tr be the annealing temperature. Function f1

is 0 below Tr and it is equal to T above it, as the

annealing is performed above this specific

temperature. If the temperature is below this value,

the coil is heated, but the grain structure is not

recrystallized and the contribution to the Ann1 value

is null. The physical dimension of Ann1(d) is

temperature by time (ºC* sec), and represents the

amount of effective thermal energy received by the

coil element d. But the function Ann1 depends

deeply on the critical value Tr. Although only high

temperatures recrystallize the stainless steel,

possibly there is not such a key value and

temperatures just below Tr also affect the metal. For

this reason an alternative function, Ann2, was

proposed.

It integrates function f2. We chose an interval

Tm – Ta which should contain the critical value Tr.

The function slope above Ta is m2 which should be

0 or slightly above. This formula has a different

physical meaning. If we choose m2=0 and a coil

element is heated inside the furnace with a constant

temperature greater than Ta, Ann2(x) will be the

total time the element has been inside the furnace.

The time the element is exposed to a temperature

below Tm does not count at all, but the time the coil

is heated with a temperature from Tm to Ta is

proportionally counted. So, this function calculates

the annealing compensated time an element stays in

the furnace. If we choose m2>0, temperatures higher

than Ta overcompensate the annealing time, as the

annealing process speed and the temperature are

related. The parameter m2 reflects that fact (Spinola,

2004).

(2)

5 TOOLS AND METHODS

In order to classify the annealing of stainless steel

coils, a kind of neural network, self-Organizing

Maps (SOM) has been used. The software tools used

to implement the Classification program are Matlab

7.0 and The Self-Organizing Map Program Pakage

by Kohonen, that implements the techniques of

neural networks we need (Kangas, 1997). The SOM

consists of a two-dimensional lattice that contains a

number of neurons (Kohonen, 1992).

The Gaussian function has been chosen as the

neighbourhood function and the rectangular

structure as the topology of the map as we can see in

the figure 2. A prototype vector is associated with

IJCCI2012-InternationalJointConferenceonComputationalIntelligence

608

each neuron.

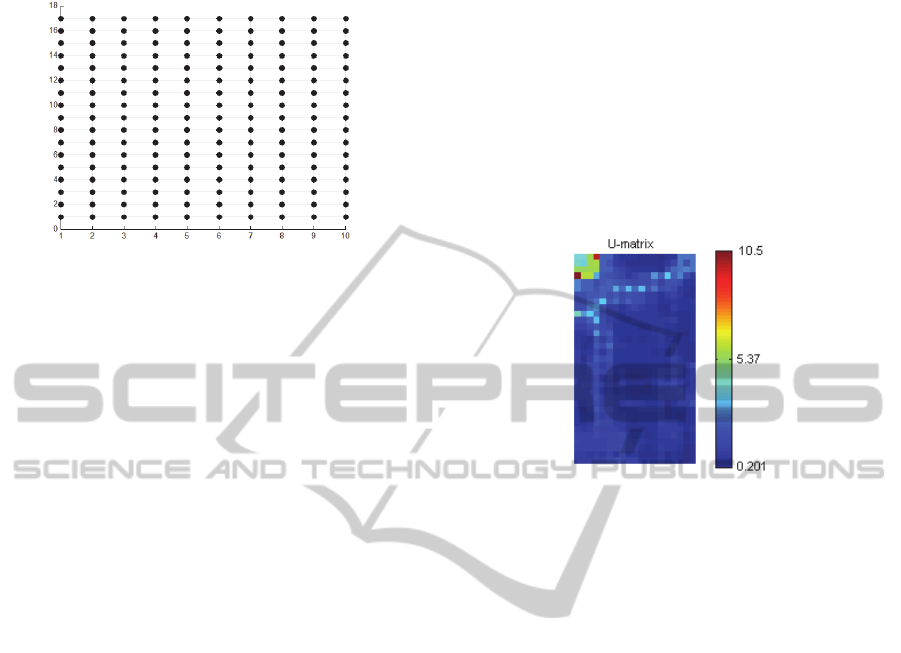

Figure 2: Training map.

For training and visualization purposes, the

sample vectors are assigned to the most similar

prototype vector, or best-matching unit (BMU),

which means that input vectors which are relatively

close in the input space should be mapped to units

that are relatively close on the lattice. Once the map

has been trained, it is ready for post-processing and

evaluation.

In this study we have calculated the values of

annealing temperatures and speeds of the coil points

located every 10 meters and the average of these

values for each coil.

The input vector has the main variables that take

part in that annealing process. They are: annealing

calculated with Rec 1 equation, annealing calculated

with Rec2 equation, heating, top and bottom

temperatures of six zones, steel band speed, length,

wide and thickness. In that way, the vector is such as

[Stainless_steel_type Rec1Sup Rec1Inf Rec2Sup

Rec2Inf CalorSup CalorInf Output_temperature

Speed thickness Wide Length Z1Sup Z1Inf Z2Sup

Z2Inf Z3Sup Z3Inf Z4Sup Z4Inf Z5Sup Z5Inf

Z6Sup Z6Inf]. Due to the number and variety of data

for each type of steel coils we have decided to use a

few of them for training and the others for

validation.

Scaling of variables is of special importance in

the Toolbox. Typically, one would want the

variables to be equally important.

The number of units in each map is calculated

using a heuristic formula determined by the SOM

method. It is based on Map_units=5* dlen ^0.54321

* k where dlen represents the number of vectors

used in the training and k = 4 because a ‘big’ map

has been chosen. After the number of map units has

been determined, in this map 168, the map size is

fixed [17, 10]. Then the SOM is initialized by a

linear initialization along two greatest eigenvectors

tried. After initialization, the SOM is trained in two

phases: first rough training and then fine-tuning.

6 ANALYSIS OF RESULTS

We have built and trained a SOM neural network,

using real data coil measured in a production line in

the Acerinox factory in Algeciras.

The U-matrix displays distances between

neighboring map units, and shows the structure of a

cluster map: high values of the U-matrix indicate a

cluster border, uniform areas of low values indicate

clusters themselves. Each component plane shows

the values of one variable in each map unit.

Figure 3: U-matrix.

The result of training is shown in Figure 4. This

figure shows the matrix distances and projections of

each variables of the input space. This type of

network elements, called neurons, are arranged in a

two-dimensional network, each of these elements

will be calculated in the learning process of the

network. They are representatives of different states

of annealing, such as: excess, lack or correct

annealing. The objective of this type of network is to

determine relationships inherent in data according to

their relationships. So, our objective is to visually

determine relationships between the different

variables of interest in our study.

In figure 4, we can see the homogeneity of the

variables representing the temperature of the

annealing furnace. The left top colour blue

represents highest temperatures and corresponds to

highest values of annealing and the thickness of the

steel band. On the other hand, we also note that the

width and length have no real connection to the

others variables. Finally, the velocity tends to be

higher in cases of lower annealing and lower in

cases of higher annealing.

Two of the properties most of the measures of

SOM Quality try to evaluate are vector projection,

which is sometimes referred to as “topology

preservation”, and vector quantization. Technically,

there is a trade off between these two, increasing

projection quality usually decreases the projection

properties. The Quantization Error (QE) is computed

ANon-linealMathematicalModelforAnnealingStainlessSteelCoils

609

by determining the average distance of the sample

vectors to the cluster prototype vectors by which

they are represented. We have obtained a

quantization error of 0,985 and a topographic error

of 0,026. All entries area presented to SOM network

are assigned to a cluster. The Clustering process

groups those areas or clusters where the Euclidean

distance between adjacent vectors is lesser

(Kohonen, 1997). To measure how an entry point

belongs to the cluster it has been assigned to, the

quantization error can be used. This error is

calculated as the Euclidean distance between the

inlets to the vector of the neuron is activated.

Figure 4: Projections of each variable of the input space.

Figure 5: Clusters.

Finally, the structure is chosen optimal using the

Davies-Bouldin index considering both the distance

between clusters as internal distance of each cluster.

The red zone represents the coils that have less

heating than required, the yellow zone the well

annealing coils and the blue zone represents the coils

with excess of heating ant the dark blue the rest.

7 CONCLUSIONS

An alternative and successful approach has been

introduced based on neural networks for

classification of data series and it has been applied to

the classification of annealing data acquired in a

stainless steel production line. The main results

obtained in this investigation are: An improved

clustering algorithm that generates clusters including

all the annealing neurons. The creation of SOM has

been improved by means of a better quality of the

training data and so a successful classification of

annealing stainless steel has been got.

At the moment we have centred on the global

classification of coils but we can’t characterize what

kind of abnormality it is affected for. Additional

work is necessary to do in this field and a supervised

neural network is proposed to use it in future

investigations. This study will be continued in a

thesis with a more detailed analysis and we will

contrasted SOM method with other techniques that

could also be employed in this scenario.

REFERENCES

Chapple Mike, “Data Mining: An Introduction”, 2002.

http://databases.about.com/library/weekly/aa100700a.

htm

J. Kangas, T. Kohonen, (1997). Developments and

applications of the self organizing map (SOM) and

related algorithms. Mathematics and Computers in

simulation, 41 (1-2); 3-12.

Khan S. H., Ali F., Nusair Khan A., Iqbal M. A., (2008).

Eddy current detection of changes in stainless steel

after cold reduction. Computational Materials Science,

vol.43, no.4, 2008, pp. 623-8.

T. Kohonen (1997) The Self Organizinf Map. Springer. 2ª

Ed.

T. Kohonen, J. Hunniyen, J. Kangas, J. Laaksonen, (1992-

1997). The Self Organizing Map program package”.

Helsinki University of Technology, Finland.

Reed, R. J., (2003). North American Combustion

Handbook. North American Manufacturing Company.

Cleveland.

C. Spinola, J. Bonelo, J. Vizoso et al., (2008). Supervision

model for the annealing process in a stainless steel

production line. IEEE International Conference on

Industrial Technology. Pages 1-4.

C. Spinola, J. Bonelo, J. Vizoso et al., (2004). An

approach to the analysis of thickness deviations in

stainless steel coils based on self-organising map

neural networks. Springer London. Pages 309-315.

DOI: 10.1007/s00521-004-0426-z.

Ben Young, (2008). Experimental and numerical

investigation of high strength stainless steel structures.

Journal of Constructional Steel Research, vol.64,

no.11, 2008, pp. 1225-30.

IJCCI2012-InternationalJointConferenceonComputationalIntelligence

610