A Structuring Mechanism for Embedded Control Systems

using Co-modelling and Co-simulation

Xiaochen Zhang and Jan F. Broenink

Centre for Telematics and Information Technology, University of Twente, Enschede, The Netherlands

Keywords:

Model Structuring, Collaborative Modelling, Co-simulation, Embedded Control System.

Abstract:

In most embedded control system (ECS) designs, multiple engineering disciplines and various domain-specific

models are involved, such as embedded software models in discrete-event (DE) domain and dynamic plant

model in continuous-time (CT) domain. In this paper, we advocate collaborative modelling and co-simulation

to verify different aspects of the system as a whole before implementation. This paper proposes a development

approach and structuring mechanism for CT-intensive ECS designs using co-modelling and co-simulation

techniques. Based on this approach, an integrated co-model can be developed and refined using different

domain-specific languages and tools. Influences from one domain to the other can be simulated via co-

simulation and analysed in both perspectives. Our structuring and development process has been applied

to a mobile robot using this co-simulation technique. We have experienced that structuring the co-modelling

process allows us to produce co-models an co-simulations effectively. Future work is on checking for model

inconsistencies during collaboration, and provide approaches to deal with this.

1 INTRODUCTION

The nature of embedded control systems determines

that multiple engineering disciplines and various

domain-specific models are often involved. The con-

ventional way of modelling such system is to divide

the system into different engineering domains and as-

sign them to different domain experts.

However, there are some disadvantages to use this

modelling paradigm. Due to the differences between,

for instance, the software modelling tool Overture

(Overture Community, 2010) and the dynamic system

modelling tool 20-sim (Controllab Products, 2010),

distinct aspects of the system are modelled separately.

After both developments are finished and verified, the

system can be integrated and tested on the real setup

or using a prototype.

The late integration may cause fatal problems

since the impacts on each other are usually exposed

late when integration phase is reached. It will be very

costly and error-prone if engineers have to redesign

the system and change the actual device. In addition,

the lack of system-level support and communication

between domain experts may lead to entirely different

assumptions of the same system.

Hence, we advocate collaborative modelling and

co-simulation for complex embedded control syste-

ms, as being developed in the DESTECS project

(DESTECS, 2010). Integration can then be applied at

early stage of the development, and the system can be

verified as a whole before deploying to the real setup.

In our co-modelling and co-simulation terminology,

an embedded control system consists of a discrete-

event model (DE model) implementing the software

and a continuous-time model (CT model) implement-

ing the physics parts of the system, and the combina-

tion is called a co-model.

In order to construct a dependable and reusable

co-model, we propose a structuring mechanism and

design process to support the co-modelling and co-

simulation techniques.

In this paper, we restrict ourselves to dynamic-

intensive embedded control systems, in which the dy-

namic behaviour is more essential for the total be-

haviour than the software logic. The complementary

approach, in which the software logic is more essen-

tial is discussed in (Fitzgerald et al., 2012).

In this paper, Section 2 gives a brief introduction

to the technologies we used. Section 3 proposes the

structuring mechanism and design process to support

the development of a CT-intensive co-model. A case

study is followed and described in Section 4 to show

how to apply our approach in practice. Finally, Sec-

tion 5 gives the conclusion and a forward look.

131

Zhang X. and F. Broenink J..

A Structuring Mechanism for Embedded Control Systems using Co-modelling and Co-simulation.

DOI: 10.5220/0004059801310136

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 131-136

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

2 BACKGROUND

In order to achieve multidisciplinary modelling, the

CT/DE domains in our case, different modelling

paradigms and tools are required. This section intro-

duces the basic technologies and concepts we used in

our approach.

2.1 Bond Graphs and VDM

Bond graphs (Paynter, 1961) are labeled and directed

graphs, in which vertices represent submodels, and

edges, called bonds, represent an ideal energy con-

nection between the submodels. Different than block

diagrams, the bonds in bond graphs also represent a

bi-directional connection. For different physical do-

mains, such bi-directional connections are specified

as voltage and current, force and velocity, etc. Bond

graphs are domain independent which means that sys-

tems from different physical domains (e.g. electrical,

mechanical, hydraulic, etc.) can be modelled using

the same type of graphs.

In our case, the 20-sim dynamic systema mod-

elling tool is used. It supports besides bond-graph

models also block-diagram models to cover the infor-

mation domain, which means that besides modelling

the CT part, it is also possible to model DE elements.

The Real-Time Vienna Development Method

(VDM-RT) (Bjorner and Jones, 1978) is an object-

oriented language and used for modelling and

analysing of real-time embedded systems from a

discrete-event point of view. It allows explicit mod-

elling of computation times on virtual networked pro-

cessors (Verhoef et al., 2006). Operations can be im-

plemented as periodic threads which run concurrently.

VDM-RT is supported by the Overture tool built on

top of the Eclipse platform and provides a textual en-

vironment to model the discrete-event aspect of em-

bedded control systems.

2.2 Co-simulation and Co-modelling

A precondition of co-modelling and co-simulation

CT/DE models is that two domain models must be

able to talk to each other and exchange information.

For a continuous-time simulation, the state of the sys-

tem changes continuously with respect to time. For

a discrete-event simulation, only the points in time

at which the discrete state of the system changes are

computed. The co-simulation engine supported by

the DESTECS tool is used to interact with the DE/CT

models to perform co-simulation. A synchronisation

scheme is the basis of the co-simulation engine, tak-

ing care of the simultaneous execution of DE and CT

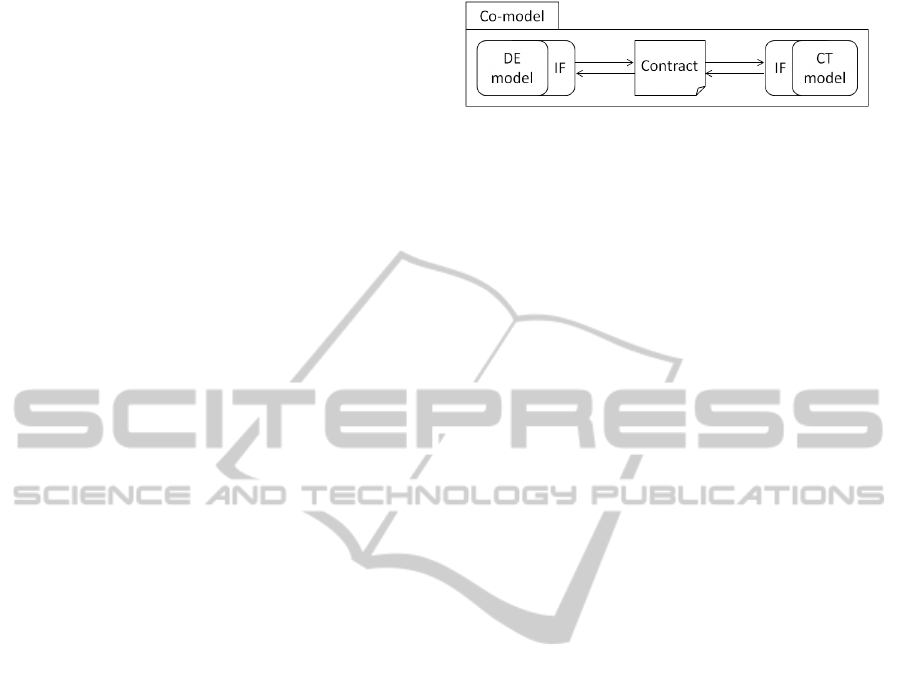

Figure 1: Conceptual view of a co-model.

models and keeping their local simulation time syn-

chronised (Fitzgerald et al., 2012).

Information sharing is achieved by defining

shared variables, parameters and events in the co-

simulation contract (see Figure 1). For example, a

discrete-event controller may control the continuous-

time velocity of an automobile by writing a steering

signal to an actuator. The steering signal can then be

considered as a shared variable which is defined in

the contract. Each domain model is connected to the

contract by attaching to a model interface (i.e. IF).

A model interface defines the shared properties of the

model that can be accessed externally.

In order to support the co-simulation technique,

we propose a structuring mechanism for the devel-

opment of dynamic intensive embedded control sys-

tems. Our intention is to, besides promote collabora-

tive modelling and simulation, also streamlining the

co-model creation process and ensure cross-domain

model consistency when constructing a co-model.

3 MODEL STRUCTURING AND

DESIGN STEPS

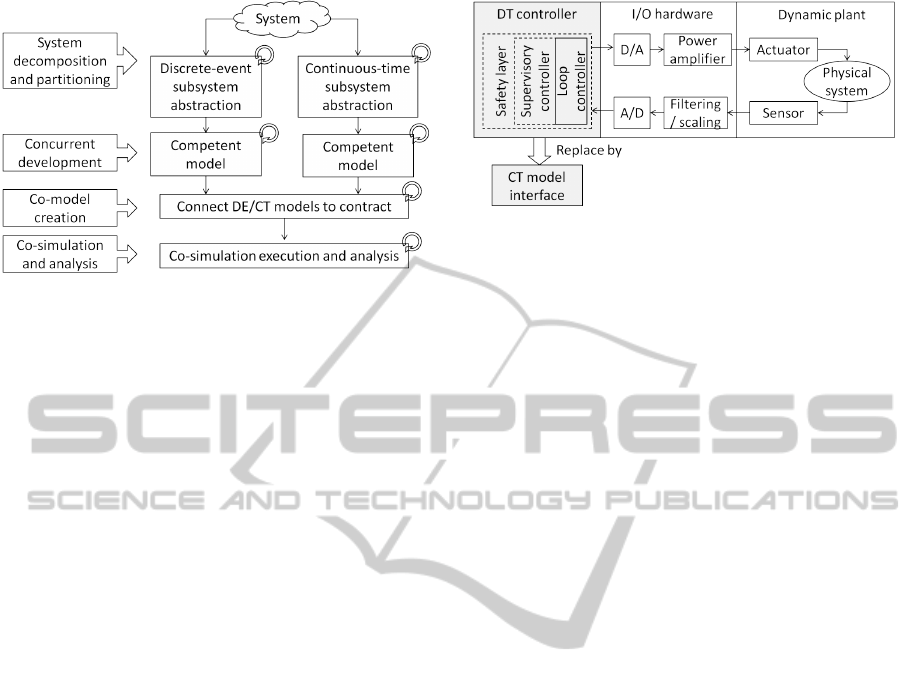

To support efficient development of a reliable co-

model using co-simulation technique is the ultimate

goal of our approach. The ideal way of applying co-

modelling and co-simulation is to: (1) partition the

DE/CT parts of a system and assign them to domain

experts; (2) concurrently develop the DE/CT models

based on the same abstraction and assumptions of the

system thus no need to worry about inconsistencies

between them; (3) both models are finished or reach a

certain level of maturity at the same time, such that the

co-model can be constructed and simulated using co-

simulation; and finally, (4) analyse the co-simulation

result and apply stepwise refinement or detailed engi-

neering (Broenink et al., 2007) if necessary, see Fig-

ure 2.

However, most embedded control systems in real-

ity do not always contain evenly distributed complex-

ity on two domains. One side may be more obvious or

easier to abstract than the other. Especially for motion

control systems, the dynamic behaviours and con-

trol algorithms are often more important and complex

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

132

Figure 2: Ideal development process using co-modelling

and co-simulation.

than the logic controller. Therefore, our approach is

to support the development of CT-intensive systems

and construct a co-model from this point of view. The

complementary DE-intensive development approach

using co-simulation can be found in (Fitzgerald et al.,

2012)

3.1 System Level Structuring

Coping with system-level complexity and decomposi-

tion is a major non-functional requirement behind all

embedded control system designs and developments.

A CT-intensive system-level structuring mechanism is

needed to help with these non-functional / informal

problems of a system. Figure 3 illustrates the system

level structure from a CT perspective in order to test

an initial co-model. This structure is adapted from the

embedded control system architecture in (Broenink

et al., 2010). It consists of three submodels, the DT

Controller, I/O hardware and the Dynamic plant, that

are modelled using CT formalism initially.

The I/O (e.g. sensors and actuators) is treated sep-

arately in this structure because of its specific role in

the design trajectory. Inside the DT controller sub-

model, the Loop controller represents a controller that

directly communicates with the I/O and governs the

response of the plant model. For complex dynamic

systems, the control algorithms are usually complex

as well. So it makes sense to model the loop con-

troller together with the plant to verify the dynamic

behaviour, and deploy it on the virtual CPU at the DE

side for analysing the performance of the controller.

The supervisory controller and safety layer (i.e.

the dashed blocks in Figure 3) are more suitable to

model using DE formalism. A CT model interface

can then replace the entire DT controller submodel

and connect to the DE model through the contract to

construct a co-model.

We recommend this structure because it allows

Figure 3: CT-first system level structuring mechanism for

co-model integration.

different sensor, actuator and loop, sequence, super-

visory controller implementations. Continuous-time,

discrete-time or discrete-event controllers can easily

be replaced by a CT model interface to connect to

the co-simulation contract. Following this structuring

mechanism, three steps are required to accomplish the

co-model construction:

• Dynamic plant modelling and control law design.

• DT controller migration.

• Co-model integration.

Stepwise refinement is supported and design de-

cisions can be made at all stages of the development

processes listed above. This implies that modellers

can start with simple dynamic models and thus apply

simple control algorithms. Once the simulation result

fulfils the system requirements, more detailed infor-

mation can be added.

This structuring and development approach can

shorten the process of co-model integration. Both do-

main modellers are able to see the performance of the

system in their own perspective. Inconsistencies can

be examined and solved in early stages of the design

process. The following subsections describe each step

of development.

3.2 Modelling and Control Law Design

For many embedded control systems, various physical

domains are often involved, such as the electrical do-

main, the rotational/translational mechanical domain,

etc. that are interconnected to express different parts

of the system. So the structure of a dynamic model

can be further decomposed into submodels of differ-

ent mechanical parts, physical domains or functional

subsystems, and keep large-scale system organized.

Depending on different design requirements, ana-

logue (continuous in time) or digital (discrete in both

time and amplitude) loop controllers can be used in

the system. In most cases, if it is decided to use a

digital controller in the design, the control laws in the

AStructuringMechanismforEmbeddedControlSystemsusingCo-modellingandCo-simulation

133

Figure 4: An example of CT model interface for connecting

to the co-simulation contract.

CT model should be implemented in the discrete-time

domain instead of the continuous one, because the

control algorithms will be eventually moved and de-

ployed on a virtual digital computer in the DE model

supported by the DESTECS tool, or in an actual mi-

crocomputer in the real device.

A continuous-time value from the dynamic plant

model cannot be computed using the discrete-time

formalism. The analog-digital conversion can be done

by means of sensors/actuators or A/D converters, and

modeled in the I/O submodel.

When the control algorithm is ready, the plant

model can be connected to the DT controller via the

I/O submodel and simulated in the 20-sim tool to ver-

ify the performance of the system. At this stage, the

20-sim model is ready for the next step towards mi-

gration.

3.3 Migration and Replacement

A model interface in our terminology defines the part

of the model which can be accessed externally, i.e.

shared variables and design parameters. Shared infor-

mation can be exchanged between models through the

model interface by the DESTECS tool. An example

of the CT model interface is illustrated in Figure 4, in

which the actuator value and sensor value are

shared variables between DE and CT models and can

be accessed by DE model externally. The CT model

imports the steering value from the DE controller and

assigns it to the variable io pwm such that this signal

can pass across domains, vice versa.

The DT controller designed in the previous phase

can be replaced by the CT model interface without

changing anything in the I/O and plant submodels.

The model interface connects the I/O submodel from

the CT side to the co-simulation contract, assuming

the shared variables between the interface and the

contract have the same identity name, data type and

range. These will be checked by the tool in order to

keep two domain models consistent.

3.4 Co-model Integration

This paper focuses on CT-intensive systems co-model

design, so hereby we assume that the DE model is

ready for co-simulation, and the DT controller devel-

oped in the CT model has been moved to the DE side

and implemented as a time-triggered loop controller.

The contract shall be specified at this stage of the de-

velopment.

An important issue of cross-disciplinary mod-

elling and co-model creation is that both domain mod-

els have to be developed based on the same assump-

tion of the system. For instance, when running the

co-simulation, the sampling time or discrete-time in-

terval in the CT simulator should be the same as set in

the DE model; assumptions on the size of a wheel

or the direction (e.g. positive-negative, clockwise-

counterclockwise) of a velocity between DE/CT mod-

els should be the same. Any syntactic or semantic in-

consistencies may cause wrong behaviours of the sys-

tem. So the DE/CT model interfaces and the contract

have to clearly indicate all shared information. Com-

munications are often required at this stage in case

requirement changes may cause cross-domain incon-

sistencies.

4 EXAMPLE: JIWYONWHEELS

Following the structuring mechanism and develop-

ment process, a case study is presented in this section

to show how to apply our approach in practice and its

advantages.

4.1 System-level Structure and

Dynamic System Modelling

The JiwyOnWheels robot (pronounce as “Jiwy [djee;

wai] on wheels”) is a mechatronic setup for carrying

and moving a camera around to take pictures. The

main goal is to design a stable and accurate robot con-

trol system with fast response time. The dynamic be-

haviour and control algorithms part of this design are

rather essential for the overall behaviour, so our CT-

intensive structuring approach is used here to achieve

co-simulation.

The development of this system can be decom-

posed into three subsystems similar as Figure 3, the

Controller, IO and Plant. A Joystick is implemented

inside the controller as a motion profile for the move-

ments. Using this structure, the system boundary and

subsystem functions can be easily indicated.

The dynamic behaviour of the robot can be fur-

ther decomposed into different physical domains. The

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

134

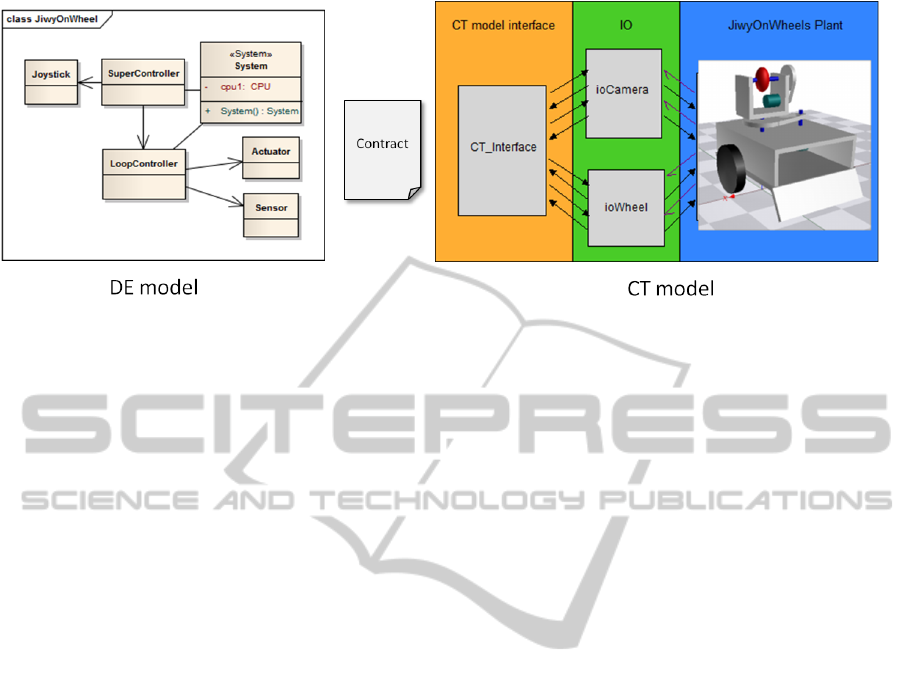

Figure 5: JiwyOnWheels from co-model perspective.

most dominant properties of the system are the move-

ment of the cart with two wheels and the rotation

of the camera mounted on top. All components are

connected to each other by electrical and/or mechan-

ical ports and this behaviour is modelled using bond

graphs. The corresponding control algorithms, e.g.

digital PID controllers in our case, can be designed.

The digital/analog conversion is modelled as A/D

converters with necessary scaling in the IO submodel.

4.2 Migration

When the CT model is competent enough to be used

to construct a co-model, the step of migrating the DT

controller can start. The controller submodel can be

replaced by the CT model interface directly without

changing the IO and plant submodels, see Figure 5.

Signals shared between the DT controller and the IO

submodel are now shared between the CT model in-

terface and IO submodel.

In order to test the performance of the digital con-

troller on different hardware platforms, the DT con-

troller has to be moved from the CT model to DE

model to be deployed on different architectures sup-

ported by the DESTECS tool.

The migration requires converting the DT con-

troller to a time-triggered DE controller using the

VDM formalism. It is implemented as a peri-

odic thread that reads the signals from the sen-

sors and writes to the actuators, shown as the

LoopController class on the left side of Fig-

ure 5. The SampleTime defined in the time-triggered

LoopController has to be the same as set in the CT

simulator to ensure both models are executed at the

same co-simulation time.

In order to describe real-time behaviour in the DE

model, the System class is constructed to handle the

creation of a virtual CPU and the deployment of the

SuperController and LoopController.

In this case study, the DE model is simply de-

signed as an event-triggered supervisory controller, a

time-triggered loop controller and a joystick that gives

steering signals to the robot. More complex DE mod-

els, such as distributed CPU’s running different con-

trollers and connected through a BUS, can be studied

and developed in depth when required.

4.3 Co-model Integration and Result

Finally, the co-model (see Figure 5) is created by

defining the contract in the DESTECS tool and ex-

ecuted using the co-simulation engine. All shared

information between the DE/CT models of JiwyOn-

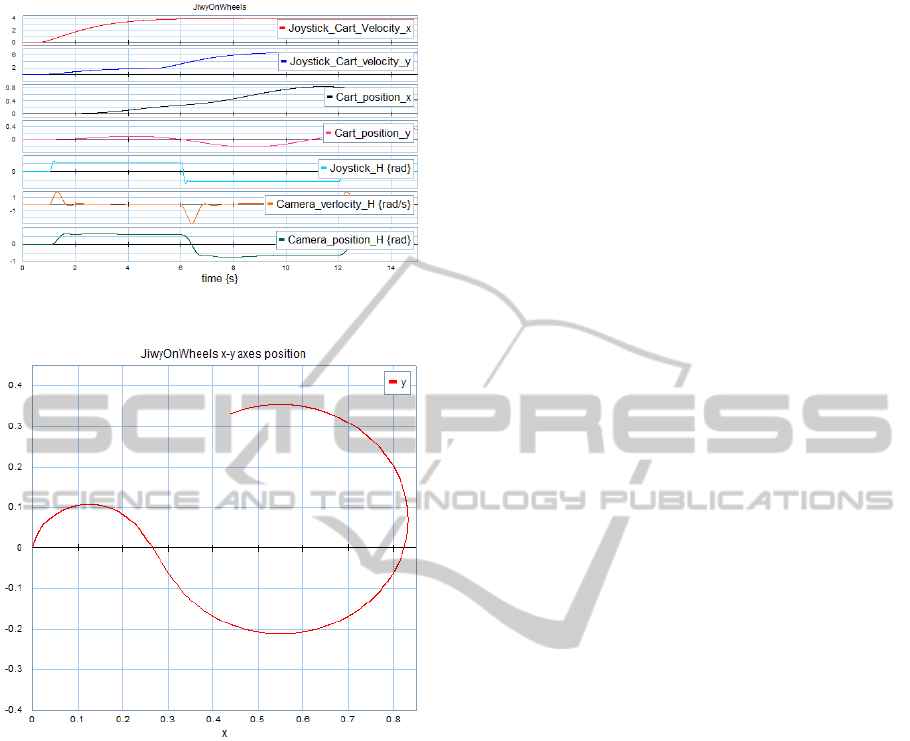

Wheels is defined in the contract. Figure 6 illustrates

the final co-simulation results in the CT simulator, in

which the steering signals are generated from the DE

model as user inputs from the joystick. The rotation

of the camera and the movement of the cart are con-

trolled by the time-triggered DE controller through

co-simulation. Figure 6(b) shows the trajectory of the

robot movement.

5 CONCLUSIONS

In this paper, we have proposed a structuring mecha-

nism and design process to support the development

of continuous-time intensive ECSs using collabora-

tive modelling and co-simulation techniques. Based

on this approach, complex embedded control systems

can be decomposed into continuous-time (CT) mod-

els and discrete-event (DE) models and further devel-

oped using their own domain-specific languages and

tools. Co-simulation can then be achieved by con-

necting these two models through the co-simulation

contract and DE/CT model interfaces.

Another key feature of our approach is that it al-

lows modellers to design the digital loop controllers

AStructuringMechanismforEmbeddedControlSystemsusingCo-modellingandCo-simulation

135

(a) Co-simulation results: the velocity / position of cart

movement; the velocity / position of camera rotation.

(b) JiwyOnWheels simulated position, x versus y.

Figure 6: JiwyOnWheels co-simulation results.

in the CT model, and then migrate them to the DE

model using the time-triggered (TT) DE formalism.

Doing so, the dynamics of the controller can be de-

signed and tuned in the CT domain, and in turn, the

performance of the controller on different hardware

architectures can be tested in the DE domain. In addi-

tion, the same controller/plant models can be reused

easily. We also have described a CT-intensive case

study which demonstrates how to apply this structur-

ing approach and the co-model creation process.

When using collaborative modelling and co-

simulation techniques, many challenges may en-

counter, such as the inconsistency issues caused by

different modelling knowledge across domains or

lack of communications between domain experts.

Our future work will focus on addressing and solving

these challenges and prevent inconsistencies between

domain models while using co-simulation.

ACKNOWLEDGEMENTS

The research leading to these results has received

funding from the European Community’s Seventh

Framework Programme (FP7/2007-2013) under grant

agreement no. 248134 (project DESTECS).

REFERENCES

Bjorner, D. and Jones, C. (1978). The vienna development

method: The meta-language. Lecture Notes in Com-

puter Science.

Broenink, J. F., Groothuis, M. A., Visser, P., and Bezemer,

M. M. (2010). Model-driven robot-software design

using template-based target descriptions. In Kubus,

D., Nilsson, K., and Johansson, R., editors, ICRA

2010 workshop on Innovative Robot Control Architec-

tures for Demanding (Research) Applications, pages

73 – 77. IEEE.

Broenink, J. F., Groothuis, M. A., Visser, P., and Orlic,

B. (2007). A model-driven approach to embedded

control system implementation. In Anderson, J. and

Huntsinger, R., editors, Proceedings of the 2007 West-

ern Multiconference on Computer Simulation WMC

2007, San Diego, pages 137–144, San Diego. SCS,

San Diego.

Controllab Products (2010). The 20-sim dynamic modelling

tool website. http://www.20sim.com.

DESTECS (2010). The DESTECS project website.

http://www.destecs.org.

Fitzgerald, J. S., Larsen, P. G., Pierce, K. G., and Ver-

hoef, M. (2012). A formal approach to collabora-

tive modelling and co-simulation for embedded sys-

tems. Mathematical Structures in Computer Science,

vol(no):1–25. To be published.

Overture Community (2010). The Overture Tool project

website. http://www.overturetool.org.

Paynter, H. (1961). Analysis and design of engineering sys-

tems. MIT Press, Cambridge, MA.

Verhoef, M., Larsen, P., and Hooman, J. (2006). Model-

ing and validating distributed embedded real-time sys-

tems with vdm++. FM2006: Formal Methods.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

136