An Application of Goal Programming Technique

for Reconfiguration of Transfer Lines

Fatme Makssoud, Olga Battaïa and Alexandre Dolgui

Henri Fayol Institute, Department of Industrial Engineering,

Ecole des Mines de Saint Etienne, 158 Cours Fauriel, 42023, Saint Etienne Cedex 2, France

Keywords: Transfer Lines, Reconfiguration, Goal Programming, Multi-objective Optimization.

Abstract: In this paper, the reconfiguration problem of transfer machining lines is addressed. This problem appears

when an existing line has to be adapted for the production of a new or modified product. The objective is to

minimize the reconfiguration line cost. The compatibility constraints between old and new operations have

to be taken into account. Therefore, a compromise between introducing new equipment and reusing old one

is to be found. A goal programming model for this optimization problem is developed. This mathematical

model minimizes the reconfiguration cost of transfer line as the primary objective and maximizes the

reusability of old equipment as the second objective.

1 INTRODUCTION

Transfer machining lines are widely used in

mechanical industry for mass production (Dolgui et

al., 2006). This type of production line consists of a

sequence of stations such that, for each product item,

one subset of the required operations is executed on

the first station, then another subset on the second,

and so on until all the operations are executed. Each

station can be equipped with a number of multi-

spindle heads (Guschinskaya et al., 2008). These

heads will be called blocks. Each block performs a

set of operations. All blocks of the same station are

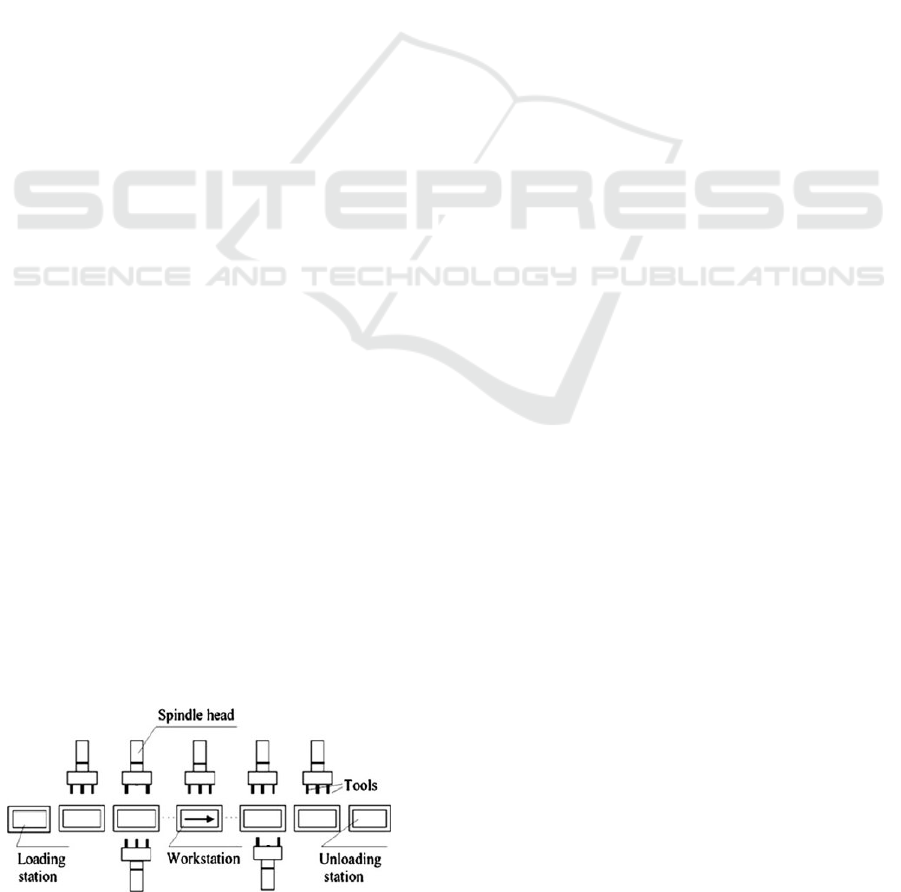

executed sequentially. An example of such a line is

presented in Figure 1.

Figure 1: An example of transfer line.

Transfer lines are designed for a long

exploitation time and need high investments.

However, currently, because of excessive production

capability and economic globalization it becomes

more and more important for companies to respond

to the changeable market demands faster and with

less cost. A wide variety of modifications may

require the reconfiguration of an existing transfer

line, for example:

changes in the product characteristics;

modifications of the cycle time due to changes

in market demand or sales; and

introducing new models or modification on

models (Gamberini et al., 2006; Boysen et al.,

2008).

The reconfiguration of manufacturing systems

was studied in several works (Abdi and Labib, 2003;

Merhabi et al., 2000; Merhabi et al., 2002; Koren et

al., 1999, Spiceret al., 2002; Youssef and

ElMaraghy, 2008). Reconfiguration allows adding,

removing, or modifying specific process capabilities,

controls, software, or machine structure to adjust

production capacity in response to changing market

demands.

Generally, manufacturing systems

reconfiguration activities are divided into two types:

hard and soft. Examples of hard reconfiguration

activities include adding or removing of machines,

machine modules and changing material handling

systems. Examples of soft reconfiguration activities

include re-programming of machines, re-planning,

539

Makssoud F., Battaïa O. and Dolgui A..

An Application of Goal Programming Technique for Reconfiguration of Transfer Lines.

DOI: 10.5220/0004046805390542

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 539-542

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

re-scheduling and increasing or decreasing of shifts

or number of workers.

Even if previously studied for different

manufacturing systems, the reconfiguration problem,

to the best of our knowledge, has not been

formulated for transfer lines yet. The objective of

this paper is to formulate this problem and then

apply one of the techniques of multiple-objective

programming (goal programming) to solve it.

In the formulation of goal programming, the

objectives are written in the form of goals

restrictions where each goal represents the value that

intends to be reached. Deviation variables are

introduced in each objective function, d

+

and d

-

,

indicating how much the objective was surpasses or

was lacked by that value, respectively. Goal

programming searches a form of reaching the goals

as close as possible; the objective of this technique is

to minimize the sum of the deviations for all the

objective functions.

This method has been already successfully applied

for solving optimisation problems appearing while

designing assembly lines, see for example (Deckro

and Rangachari, 1990; Gökçen and Erdal, 1997;

Gökçen and Agpak, 2006; Özcanand Toklu, 2009).

In the next section, the problem of the

reconfiguration of transfer lines is described in detail

and its mathematical model is presented.

2 PROBLEM FORMULATION

The reconfiguration problem appears when an existing

transfer line has to be chnaged in order to suit the new

manufacturing requirements. In order to reduce the

reconfiguration costs, the new equipment should be

reused as more as possible, but the investment in new

equipment has to be minimized as well.

2.1 Input Data

The following information about the product to be

manufactured and the characteristics of the line are

assumed to be known at the reconfiguration step.

Part characteristics:

N is the set of operations necessary for

machining the new part;

Pred(i) is the set of direct predecessors of i

∈

N;

t

i

operational time for operation i (i = 1,…,

|N|);

IS is a family of subsets of N representing the

inclusion constraints among operations: all

operations belonging to the same subset have

to be assigned to the same station;

ES is a family of subsets of N representing the

station exclusion constraints: all operations

belonging to the same subset cannot be

assigned to the same station together;

EB is a family of subsets of N representing the

block exclusion constraints: all operations

belonging to the same subset cannot be

assigned to the same block together;

Line characteristics:

N’ N set of ‘old’ operations in the initial

line;

n

0

maximum number of blocks on a station;

m

0

maximum number of stations;

T

0

objective line cycle time;

is an auxiliary time needed for activation

of a block (spindle head);

is an auxiliary time needed for

loading/unloading the part on a station;

C

1

is the cost of a station;

C

2

is the cost of a block;

C* is the cost of the initial line calculated as

C

1

m*+ C

2

n*, where m* is the number of

stations in the initial line and n* is the total

number of all blocks used at all stations of the

initial line.

2.2 Model Notations

The following notations are introduced in the

mathematical problem presented:

Indexes:

i, j for operations;

q for the blocks, q = (k-1)n

0

+1;

k for the stations, k = 1,…,m.

q

0

maximal possible value of q, q

0

= m

0

n

0

;

S(k) = {(k-1)n

0

+1,…, kn

0

} set of block indices

for station k;

Q(i) set of block indices on which i can be

processed;

K(i) set of station indices on which i can be

processed;

N

q

set of operations assigned to block q in the

initial line;

N

k

set of operations assigned to station k;

N

kl

set of operations assigned to block k of the

station l;

2.3 Decision Variables

{0,1}are binary decision variables

where = 1 if operation i is assigned to

block q in the new line configuration;

∈

b

τ

s

τ

iq

X

∈

iq

X

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

540

in

d

li

n

in

d

n

e

T

o

v

a

us

n

e

c

o

su

b

2.4

G

The obj

e

of the

p

given g

o

The

f

of the c

o

line, i.e.

:

Oth

e

initial li

n

assigne

d

remain

a

i.e. for

assigne

d

b

oth of

well as i

<

whe

r

the total

b

e assig

n

by

Wei

g

model

p

assigne

d

respecti

v

This ma

k

into acc

o

The

r

of devia

t

q

Y

k

Z

{0,1} is a

n

d

icates if blo

c

n

e configurati

o

{0,1}is

a

d

icates if sta

t

e

w line config

u

o

calculate bl

o

a

riables F

q

∈

[

0

ed.

and ar

e

gative devi

a

o

nsidered ar

u

bsection.

G

oals and

O

e

ctive functio

n

p

ositive and

o

als.

f

irst goal is t

o

o

sts of statio

n

:

e

r goals are to

n

e. If a bloc

k

d

together to t

h

a

ssigned to t

h

each pair o

f

d

to the sam

e

them are re

q

<

j and for ea

c

r

e g ranges fr

o

sum of num

b

n

ed to the sa

m

.

g

hted Goal

P

p

resented. Th

e

d

to the f

i

v

ely. These v

a

k

es the meth

o

o

unt the user’

s

r

efore, the ob

j

t

ions from th

e

q

∈

k

∈

n

auxiliary bi

n

c

k q exists (

o

n;

a

n auxiliar

y

t

ion k exists

u

ration.

o

ck processi

n

0

, T

0

–

τ

s

],

q

e defined as

a

tions of go

a

e presente

d

O

b

j

ective

F

n

minimizes

t

negative de

v

o

obtain the s

a

n

s and block

s

reuse all blo

c

k

is reused, t

h

h

e same bloc

k

h

e same bloc

k

f

i, j such t

h

e

block in th

q

uired for th

e

c

h

o

m 2 to G w

h

b

er of pairs o

f

m

e block mu

l

P

rogramming

e

weight fac

t

i

rst and se

c

a

lues can be

f

o

d subjective,

s

preferences.

j

ective is to

m

e

given goals,

Y

n

ary variable

= 1) in the

y

variable

( = 1) i

n

g times, auxi

l

q

=1, 2, …, q

0

the positive

a

l g. The

g

in the

F

unction

t

he weighted

v

iations from

a

me weighted

s

as in the i

n

c

ks created fo

r

h

en all opera

t

k

in the initial

k

in the new

h

at i and j

w

e initial line

e

new produ

c

:

h

ere G is equ

a

f

operations i

,

l

tiplied each

t

is used in

t

ors w

1

and

w

c

ond object

i

f

ixed by the

u

but allows ta

k

m

inimize the

i.e.:

q

Y

k

Z

that

new

that

n

the

l

iary

0

are

and

g

oals

next

sum

the

sum

n

itial

(1)

r

the

t

ions

line

line,

w

ere

and

c

t as

(2)

a

l to

,

j to

time

the

w

2

are

i

ves,

u

ser.

king

sum

(3)

2.

5

In

co

n

5

Model

C

addition to

n

straints have

All operat

i

exactly on

e

Precedenc

e

Station in

c

Block exc

l

ej

jq

X

∈

≤

∑

Station ex

c

The equat

i

value of

F

operation

t

(

qi

F

t

τ

≥+

The sum

o

assigned t

o

given valu

time const

r

()

q

qSk

F

T

∈

≤

∑

A block is

least one

o

q

y

X

≥

A station i

least one

b

k

Z

q

=

The bloc

k

station:

C

onstraint

s

constraints

(

t

o be taken in

t

i

ons from N

m

e

bloc

k

e

constraints:

c

lusion constr

a

l

usion constra

i

q

EBee ;∈;1

c

lusion constr

on (7) assure

s

F

q

cannot be s

t

imes of bloc

k

),

b

iq

Xi

N

τ

∈

o

f the process

i

o

the same s

t

e

T

0

–

τ

s

. Th

i

r

aint:

0

,

1

s

T

k

τ

−=

considered

a

peration assi

g

,,

iq

X

iNq∈

∈

s

considered

a

lock assigne

d

0

, 1,2,...,

(1) 1;

q

Yk

kn

≥=

=

−+

s are created

s

(

1)-(2), the

f

n

to account.

m

ust be assig

n

a

ints:

a

ints:

I

ej

jQ

q

∈

;)(∈

r

aints:

s

that for a bl

o

s

maller than

a

k

q

p

lus a con

s

,();

N

qQi∈

i

ng times of t

h

t

ation cannot

i

s is the so-ca

l

0

1

,2,..., ;m

a

s created, if

t

g

ned to it:

();Qi

∈

a

s created, if

t

d

to it:

0

,

,m

d

sequentially

f

ollowing

n

ed and to

(4)

(5)

(6)

(7)

(8)

o

ck q, the

a

ny of the

s

tant

τ

b

:

(9)

h

e blocks

exceed a

l

led cycle

(10)

t

here is at

(11)

t

here is at

(12)

within a

AnApplicationofGoalProgrammingTechniqueforReconfigurationofTransferLines

541

1

00

0, ( ) \

{( 1) 1}, 1,2,..., ;

qq

YY qbk

kn k m

−

−≥ ∈

−+ =

(13)

The stations are created sequentially as well:

10

0, 2,3,..., ;

kk

Z

Zk m

−

−≥ =

(14)

where j∈N, i∈P(i), q=1,2,…,m

0

n

0

, k=1,…,m

0

.

3 CONCLUSIONS

In this paper, a goal programming model for the

reconfiguration of transfer lines was suggested. This

problem appears when an existing transfer line has

to be modified due to the changes of the product

being manufactured of the market demand. The new

line configuration must take into account

compatibility constraints between new operations

and old equipment. The objective is to minimize the

cost of line reconfiguration and to reuse as more as

possible the existing equipment.

A goal programming formulation was used in

order to deal with the multi-objective character of

this optimisation problem. An experimental study is

in progress in order to evaluate the performance of

the proposed method on the datasets of industrial

problems. The future research will concern the

formulation of the same problem with the

Lexicographic Goal Programming (LGP) approach

and a comparison between WGP and LGP will be

necessary.

REFERENCES

Abdi, M., Labib,A., 2003. A design strategy for

reconfigurable manufacturing systems (RMSs) using

analytical hierarchical process (AHP): a case study,

International Journal of Production Research 41 (10),

pp. 2273–2299.

Boysen, N., Fliedner, M. and Scholl, A., 2008. Assembly

line balancing: which model to use when? ,

International Journal of Production Economics,

111(2), pp. 509-28.

Deckro, R. F, Rangachari, S., 1990. A goal approach to

assembly line balancing, Computers and Operations

Research 17, pp. 509-521.

Delorme, X., Dolgui, A., Essafi, M., Linx, L., Poyard, D.,

2009. Machining lines automation, In: Nof S, editor.

Springer handbook of automation, pp. 599-618.

Dolgui A, Finel B, Guschinsky N, Levin G, Vernadat F.,

2006. MIP approach to balancing transfer lines with

blocks of parallel operations. IIE Transactions 38, pp.

869–882.

Gamberini, R., Grassi, A., and Rimini, B., 2006. A new

multi-objective heuristic algorithm for solving the

stochastic assembly line re-balancing

problem,International Journal of Production

Economics, 102, pp. 226-43.

Gökçen, H., Erdal, E., 1997. A goal programming to

mixed-model assembly line balancing problem,

International Journal of Production Economics 48,

pp. 177-185.

Gökçen, H., Agpak, K., 2006. A goal programming

approach to simple U-line balancing problem,

European Journal of Operational Research.

Guschinskaya O, Dolgui A, Guschinsky N, Levin G.,

2008. A heuristic multi-start decomposition approach

for optimal design of serial machining lines.European

Journal of Operations Research 189(3), pp. 902-913.

Koren, Y., Heisel, U., Jovane, F., Moriwaki, T., Pritchow,

G., Brussel, H. V., Ulsoy, A., 1999. Reconfigurable

manufacturing systems, CIRP Annals - Manufacturing

Technology 48 (2), pp. 527–598.

Mehrabi, M., Ulsoy, A., Koren, Y., 2000. Reconfigurable

manufacturing systems: Key to futur manufacturing,

Journal of Intelligent Manufacturing 11, pp. 403–419.

Mehrabi, M., Ulsoy, A., Koren, Y., Heytler, P., 2002.

Trends and perspectives in flexible and reconfigurable

manufacturing systems, Journal of Intelligent

Manufacturing 13, pp. 135–146.

Özcan, U., Toklu, B., 2009. Multiple-criteria decision-

making in two-sided assembly line balancing: A goal

programming and a fuzzy goal programming models,

Computers & operations Research.

Spicer, P., Koren, Y., Sphitalni, M., Yip-Hoi, D., 2002.

Design principles for machining system

configurations, CIRP Annals-Manufacturing

Technology, 51, pp. 275-80.

Urban, T. L, 1998.Note: Optimal balancing of U-shaped

assembly lines, Management Science, 44 (5), pp. 738-

741.

Youssef A., H. ElMaraghy, 2008. Availability

consideration in the optimal selection of multiple-

aspect RMS configurations, International Journal of

Production Research 46 (21), pp. 5849–5882.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

542