AN ADAPTABLE ARCHITECTURE FOR INTELLIGENT

CONVEYORS

Dennis Ommen, Jens Kamenik, Carsten Beth

OFFIS Institute for Information Technology, Escherweg 2, Oldenburg, Germany

Jan C. Busch, Alexander Kulas, Eckhard Cramer, Axel Hahn

Department of Computing Science, Carl von Ossietzky University, Ammerl

¨

ander Heerstrasse 114-118, Oldenburg, Germany

Keywords:

Intelligent Transportation System, Autonomous Agents, Automation Architectures, Networked Robotics.

Abstract:

To optimize the transportation processes inside transfer stations the degree of automation has to be increased

without the loose of flexibility. Therefore this paper proposes a detailed architecture for an intelligent material

flow system based on the technologies of Multi-Agent-Systems (MAS) and wireless sensor networks. Fur-

thermore, a novel framework is proposed that eases the integration process between the MAS and the physical

level of heterogeneous conveyors.

1 INTRODUCTION

Flexibility will be one of the most important drivers

for technological improvements in material flow sys-

tems in the future. A new flexible material flow sys-

tem has to be reconfigurable by design and in the

end there are no additional costs allowed (Windth,

2007). To circumvent this problem new systems

should be designed as autonomous decentralized co-

operating objects, e.g. goods and the transportation

system autonomously make decisions (Scholz-Reiter

et al., 2007b). The autonomous decisions can be made

in two ways (1) the good driven way(Scholz-Reiter

et al., 2007a) (Scholz-Reiter et al., 2006): An embed-

ded device attached to the package escorts the goods

to its destination. During the transportation process

the embedded device cooperates with the environ-

ment to achieve its goal. (2) The transportation sys-

tem driven way: The environment around the goods

makes the decisions. With the arrival and identifi-

cation of a good at the entry transfer point the in-

telligent environment autonomously creates a specific

transport order. From now on this virtual order es-

corts each intelligent transportation device that han-

dles these goods.

We assume that for material flows system that are spe-

cialized on movement of goods, it will not be feasible

to attach an intelligent device to each good, due to

cost reasons. Therefore we follow the approach of the

intelligent environment with its intelligent transporta-

tion devices. Thereby the intelligent conveyor is able

to plan and drive the appropriate route through the en-

vironment to reach the sink transfer point. These in-

telligent transportation devices can have very differ-

ent abilities and automation degrees and are therefore

suited for different transportation task and situations.

For example, automated guided vehicles (AGV) are

used for basic load while traditional fork lift trucks

(FLT) are used in peak load situation. The challenge

that will be addressed here is the coordination of het-

erogeneous conveyors inside a transfer station which

is based on Multi Agent Systems (MAS) and Wireless

Sensor Networks (WSN).

Paper Organization. The remainder of the paper is

organized as follows: Section 2 describes the transfer

station scenario with the heterogeneous transportation

devices within. Section 3 introduces the architecture

of the proposed MAS. Section 4 describes a frame-

work that eases the integration process between MAS

and the field level of the different conveyors. Section

5 describes the intelligent environment that is based

on WSN technology. Section 6 ends the paper with

concluding remarks.

2 SCENARIO

Traditionally, heterogeneous conveyor types are used

inside a transfer station. The transportation devices

249

Ommen D., Kamenik J., Beth C., C. Busch J., Kulas A., Cramer E. and Hahn A. (2010).

AN ADAPTABLE ARCHITECTURE FOR INTELLIGENT CONVEYORS.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 249-254

DOI: 10.5220/0002947102490254

Copyright

c

SciTePress

are operated and/or coordinated by human beings, to

transport goods from the entry transfer point to the

sink transfer point. Each kind of transportation device

has different abilities to cope with the current load sit-

uation of the transfer station, depending on its degree

of automation and flexibility. Each of these properties

make an optimal coordination of the heterogeneous

devices (regarding transportation cost, throughput or

optimal balance load of the conveyors) very difficult.

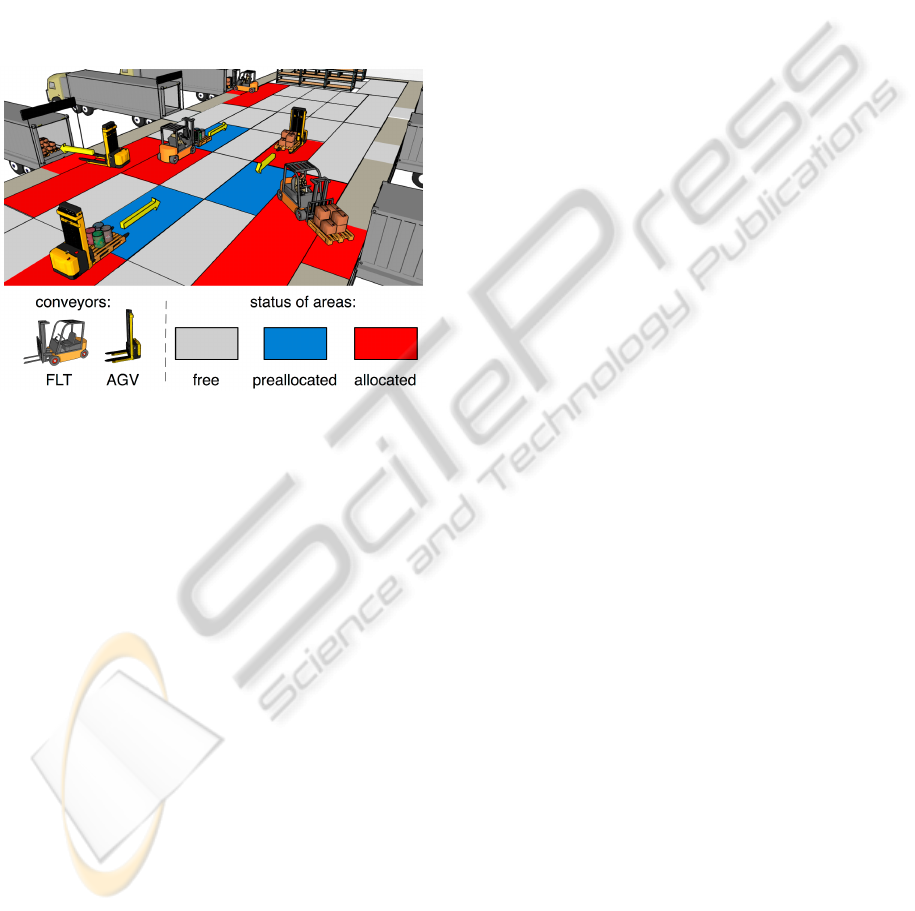

In the scenario depicted in figure 1, AGV and manu-

ally operated FLT work together to cope with the cur-

rent load situation.

Figure 1: Material flow with an intelligent environment.

To ease the coordination process for an optimal

throughput, all conveyors are intelligent transporta-

tion systems. This means each conveyor is able to

decide itself if he is willing to take a transport order

or not. But this freedom comes with duty. Each intel-

ligent transportation system has to offer its position to

an intelligent environment. The intelligent environ-

ment is virtually separated into areas that can either

be free or set to be (pre)allocated by the intelligent

conveyors. The different states of areas are needed

to avoid collisions between the heterogeneous intel-

ligent conveyors. Before an intelligent conveyor is

entering a new area, it will allocate this area (depicted

red) or will search for another route to reach his sink

transfer point. During the planning process of routes,

the conveyor will eventually be able to (pre)allocate

the areas it will need during its transport process (de-

picted blue). The intelligent environment is physi-

cally represented by a WSN. This WSN is able to lo-

cate the intelligent conveyors and also could act as a

database for the mentioned area status information.

3 CONTROL ARCHITECTURE

The scenario described in the previous section would

traditionally require a central control, incorporating

the state of every conveyor and the position of every

good into work directives given to every conveyor.

The design and implementation of a central control

system is a non-trivial and lengthy task, and “a key

cost driver” (Schmidt and Schulze, 2009) in the cal-

culation of transport costs.

De-centralized systems promise to alleviate this

costs by using self-organization of (semi-) au-

tonomous agents, allowing for rapid adaption of the

transport routes to new requirements. This paper pro-

poses a decentral organization for material flows, us-

ing a system of multiple autonomous agents work-

ing together (MAS). This distributed approach is also

the subject of other research projects, for example

(Ten Hompel et al., 2008) and (Leit 2009).

3.1 Agents

Our architecture consists of two types of agents –

transfer points and conveyors – interacting with each

other and an intelligent environment. While conveyor

agents expose a uniform set of properties and abilities

to the MAS, the underlying physical objects they rep-

resent can differ widely. In this regard, an agent is an

abstraction, providing a common way of interacting

with physical objects that perform the same function

(e.g. conveying goods), yet function in different ways.

Transfer Point. A transfer point represents a place

where goods are transferred from one part of the sys-

tem into another. The physical objects these agents

represent could be terminals stationed at transfer sta-

tions, used to enter transport jobs into the MAS. The

transfer point agents then communicate the job to all

conveyor agents.

A transport job consists of the start and end trans-

fer points, as well as a time constraint for finishing the

transport and relevant information about the good to

be conveyed, like weight and dimensions.

The conveyor agents, upon receiving a job, can bid

on the job in the manner of an auction, giving a cost

estimate for the transport. The transfer point agent

selects the conveyor with the least cost estimate, and

assigns the job to it.

Conveyor. A conveyor agent exposes the conveyors

functionality to the MAS, allowing the transport of

goods to be planned and executed. They receive job

announcements from the transfer point agents, and

bid on them with a cost estimate for the transport. The

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

250

estimate is calculated by finding a route through the

work area, querying the environment (see figure 2)

for the states of the areas along the planned route (see

section 2 and figure 1), and calculating the costs of a

transport along that route. The winner of the auction

then generates a job from the auction, and proceeds to

pick up and deliver the goods.

To do this, a series of operations needs to be gen-

erated which the physical agent has to execute. This

is done by breaking a transport job down into abstract

actions, which are then turned into a series of oper-

ations using a device dependent transformation. An

action is an abstract description of one step of the

transport process, such as ‘pick up good X’ or ‘trans-

port good to point A’, while an operation is an atomic

function that a physical conveyor can perform, such

as ‘drive forward’, ‘revolve belt’ or ‘locate good X

within environment’. Operations are sent via a mid-

dleware, which allows for device independent com-

munication. An overview of this process can be seen

in 2.

However, in case of a human operating the con-

veyor, actions are not broken down further but sent

directly, since it can be assumed that a human will un-

derstand the intention and act correctly, making fine

grained instructions pointless.

Figure 2: Control architecture of the conveyor.

3.2 Agent Requirements

To let an agent fulfill its tasks, it needs an intelli-

gent environment and a physical conveyor. An ad-

ditional middleware enables the agent to interact with

the physical objects, which can differ widely, and the

intelligent environment (see figure 2). For a detailed

description of the middleware, see section 4. The

intelligent environment consists of a WSN (see sec-

tion 5), where sensor nodes are placed throughout the

working area. It will be queried for information by

the conveyor agents, for example for their own posi-

tion in the environment, whether or not a certain area

is currently occupied by other conveyors, or how the

occupation of an area has been in the past.

In a pro-active scenario, the conveyors may ad-

ditionally exchange information about their predicted

usage of the environment, further improving the qual-

ity of the planned routes (preallocation, see section

2). However, since interactions with human beings

can not be fully predicted, information generated this

way is only of limited accuracy, possibly resulting in

a probabilistic planning strategy. It is currently not

determined how or where data about future usage of

areas can be saved and kept available to all agents.

Further research into this problem field is required.

4 MIDDLEWARE

The aforementioned MAS is one of the key compo-

nent to operate the described material flow scenario

with its heterogenous conveyors. But the MAS needs

always direct contact to the conveyor or its operator to

put the planned route into practice. Nevertheless the

communication between the MAS and the conveyer is

from the MAS point of view very abstract. Therefore

is a link between the MAS and the Conveyer needed.

This chapter presents a novel Integration Process for

Conveyor with a corresponding configurable Middle-

ware (MW). Thereby, the MW acts as mediator be-

tween the MAS and the Conveyers Sensor and Ac-

tors. Therefore we briefly discuss the requirements of

the such a MW and than propose the MW architecture

itself.

4.1 Middleware Requirements

Such a middleware should ease the integration pro-

cess between the MAS and the conveyer. Therefore

the MW should address the following aspects:

• adaptable to the unique conveyer specific query

set, that the MAS is presupposing

• adaptable to the heterogenous sensors and actors

the conveyer possesses. This means:

– eased integration of different communication

protocols, like CAN or ProfiBus, into the MW

– on-the-fly transformation of the exchanged bi-

nary messages between the MAS and convey-

ors. This is necessary due to the different mes-

sage content that the MAS and the Conveyors

imply.

AN ADAPTABLE ARCHITECTURE FOR INTELLIGENT CONVEYORS

251

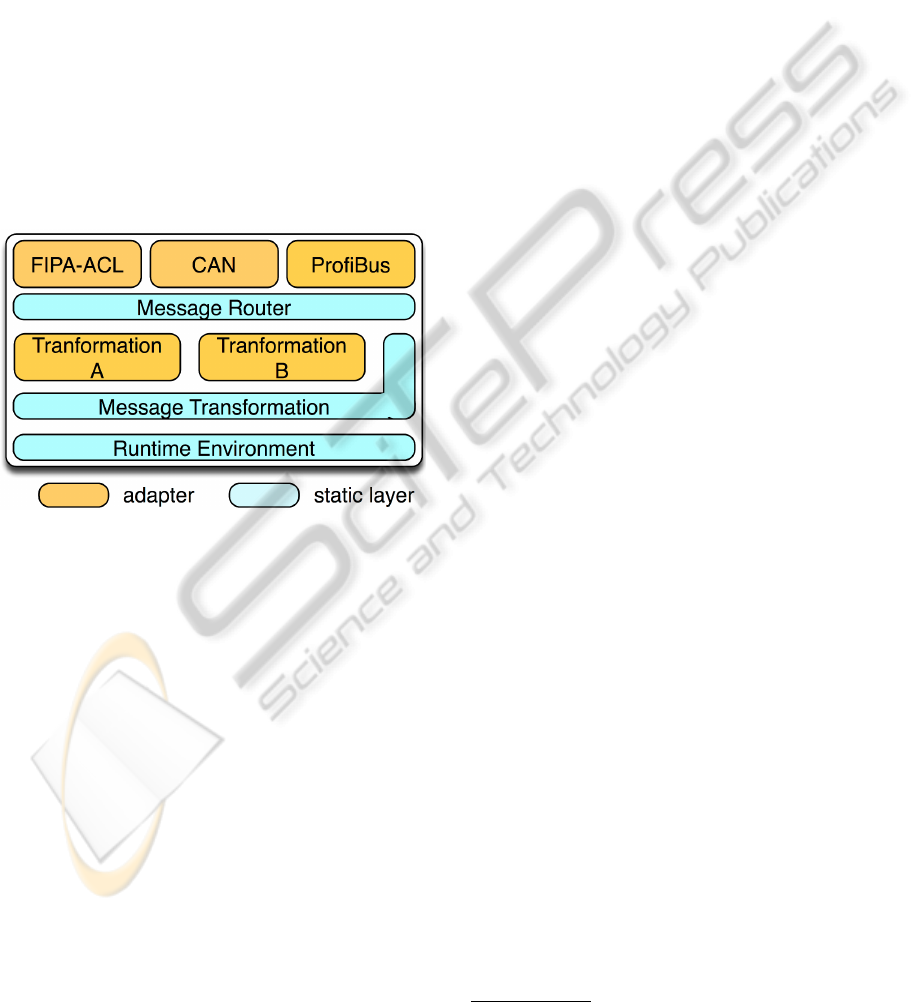

4.2 Architecture

To comply with the above stated requirements our ap-

proach is based on SOA Technology. Although we

don’t assume that XML based Automation-Protocols,

e.g. OPC UA, will achieve the major acceptance

in the domain due to real time constraint and over-

head, we propose to adapt the SOA idea of an En-

terprise Service Bus (ESB) to our needs. Histori-

cally ESB comes from the Enterprise Architecture In-

tegration where systems and protocols are tradition-

ally very heterogenous. Hence an ESB allows to inte-

grate different protocols extensions (called adapters)

to the middleware. To mediate now between the dif-

ferent semantic meaning of the messages a message

transformation is needed, which is traditionally XSLT

based. To overcome the realtime hurdles due to the

XSLT interpretation of the ESB our Middleware acts

as extendable Framework (see figure 3).

Figure 3: Middleware Architecture.

Each middleware layer (depicted in blue) will pro-

vide basic function that run the specific adapters (de-

picted in red). Such an Architecture will ease the

portation step to other programming languages and

other operating system so that this MW could even be

ported to an Embedded System.

5 WIRELESS SENSOR

NETWORK

In the cognitive environment of the proposed trans-

fer station scenario (Ommen et al., 2009) (Beth et al.,

2009) the routes are distributed and intelligent enti-

ties. They need to be networked to communicate with

the conveyors to enable the distributed localization

method. The routes have to provide the ability to lo-

calize the conveyor, to answer the occupation state of

the route and to give an average usage feedback of

the route (re-active approach). Furthermore the sen-

sor network should acts as a communication relay for

the conveyors and other sensor nodes.

5.1 Limited Resources

Resources are a critical point in designing a sensor

network. For the deployment of the sensor network in

the logistic in-door scenario the following points have

to be considered.

1. One point to consider is the critical bandwidth and

range of the sensor network.

2. For the deployment of a large number of nodes

in industrial environments – with high flexibility

and mobility requirements – the installation of a

static electric power supply for all nodes is too

expensive and not feasible. Therefore there are

always nodes that can not be supplied with static

electric power and the limited energy of the sensor

nodes has to be considered.

3. A third point is the limited storage space of a sen-

sor node, e.g. a typical sensor node like the MicaZ

1

has only 4KB RAM and 512 KB of flash mem-

ory on board.

4. A last point is the inaccurate RSSI-based localiza-

tion of standard sensor nodes.

5.2 Approaches

In the proposed scenario the sensor network uses

multi-hop communication to circumvent the limited

propagation of radio waves in logistic in-door facili-

ties and to extend the range of the sensor nodes and

the conveyors.

Localization Procedure. The conveyors need to

know their own position. The distributed fixed sen-

sors nodes have an area to observe. This area is sur-

rounded by at least three - in our model - four sen-

sor nodes. A special node of the group is the home

node, it is a sensor node responsible for fault toler-

antly storing the data of one or more routes in the area.

For the localization a trilateration method based on

IEEE 802.15.4b compatible (Nanotron Technologies,

2007) ranging data will be used. In (R

¨

ohrig, 2009)

this localization method, combined with appropriate

Kalman filtering, provided an accuracy of 0,5m. The

conveyor node has to initiate the localization proce-

dure with the nodes of the localization group. A lo-

calization group is formed by issuing a broadcast call

1

www.xbow.com

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

252

for all neighborhood nodes able to localize the con-

veyor node. The localization procedure comprises the

gathering of the distances from the mobile conveyor

node to all nodes in the localization group and the

necessary algorithms

2

to calculate the position. Af-

terwards, the conveyor node sends the position back

to the home node. The home node of the route has to

store the arrival time of the query, the ID of the con-

veyor and the estimated occupation time of the route.

The estimated occupation time is a worst case time

consisting of the average passing time for the route

and an additional time for loading or unloading goods

on the route.

Distributed Queries. Occupation and Average

Queries from the conveyor nodes can be executed

from every point in the scenario area and are answered

by the home nodes of the localization groups. On Oc-

cupation Queries the conveyor asks for the occupa-

tion state of a route with a certain ID and at the time

of the query. To answer this query, a message with

the route ID and the occupation query type has to be

sent to the home node of the route. If the route is

occupied, the home node answers the query by send-

ing back the occupation time to the inquirer ID. On

Average Queries The conveyor asks for the average

occupation state of a route in the past. This allows the

conveyor to derive a usage estimation and to choose

an alternative route in case of a possible jam situation.

To answer this query, a message with the route ID and

the estimation query type has to be sent to the home

node of the route. The home node has to gather the

past occupation times of the route belonging to the

queried ID and averages them. Afterwards, it sends

the averaged time back to the inquirer.

The data scheme for the localization of the nodes

needs the attribute of the identity of the conveyors,

the entry time of the conveyors and the (estimated)

occupation time of the route:

RouteOccupation : { [ID: char, entrytime: float,

occtime: float] }

The data scheme for the averaged values of the nodes

needs the attribute of the identity of the route and the

average occupation time t

occtime

in time period t

average

:

RouteAvg: { [RouteID: char,occtime: float] }

Storage Strategy and Energy Consumption.

(Diao et al., 2007) stated that the storage of sen-

sor data is energetically (Pottie and Kaiser, 2000)

more efficient instead to transmit the data via the

rf-channel. As a side-effect the bandwidth usage of

2

Solving a linear equation

the sensor network is reduced too. Furthermore, a

consideration of the storage place of the sensor data

necessary. The variables that have to be considered

are the query rate, the event rate and the storage

place. There are three approaches to choose the

storage place in a distributed sensor network. The

central data storage to an external server. This is

optimal for applications where the query rate to

the server is larger than the event rate (Tilak et al.,

2006). For applications with a higher event rate than

query rate the local storage is more energy efficient.

For large scale sensor networks, e.g greater than

10000 sensor nodes, with a slightly higher event

rate than query rate - the data centric storage (DCS)

(Ratnasamy et al., 2002) is suitable. Here the place

for data storage is chosen based on the attributes of

the sensor data. For the scenario in this paper the

local storage is suitable. The data is stored at the

same place where the query takes place and therefore

no additionally communication is necessary. The

limited storage space on the sensor nodes has to be

considered too. Assumed that the typical workload

for an 100m x 100m sized cross-docking area is

750000 goods a year, the workload per hour would

be 129

3

goods. If the localization group is squared

and has a side length x

loc

of 25m , e.g. the typical

working range for a nanotron localization system, the

memory used per hour M

hour

would be 9288 Bytes (8

localizations x 9 bytes per localization x 129 goods).

A simple approach is to store every localization event

occurred in one single home node responsible for the

whole scenario. The (MicaZ) RAM would last for

1/2 hour and using the (MicaZ) flash storage would

last for 56 hours. The intelligent approach is to store

the localization events only for the occupation time

of the conveyors and afterwards the time is used to

build the average occupation time. If only the average

value per hour is stored - the RAM is sufficient for

4 days (4kb / 5 bytes/ 8 localizations) and the flash

storage would last for 546 days.

5.3 Wireless Sensor Network -

Conclusion

The main problems for a wireless sensor network

in a decentral logistic scenario are reliable localiza-

tion and the limited resources of the nodes. It was

discussed that the localization with IEEE 802.15.4b

based ranging is suitable for the scenario. Further-

more, with an appropriate storage strategy the limited

storage space and energy resources are sufficient for

the scenario.

3

365 days a year and 16 hours a day

AN ADAPTABLE ARCHITECTURE FOR INTELLIGENT CONVEYORS

253

6 CONCLUSIONS AND FUTURE

WORK

In this paper several approaches for optimization of

the transportation processes inside a transfer stations

have been showed. The proposed architecture for in-

telligent material flow systems includes Multi-Agent-

Systems and wireless sensor networks that are coop-

erating in a pro-active or re-active manner. Further

research has to be done to decide the best cooperating

manner. The main problems for a wireless sensor net-

work in a intelligent material flow system have been

figured out and it was discussed that with an appro-

priate storage strategy the limited storage space and

energy resources are sufficient for an intelligent ma-

terial flow systems. Furthermore, a novel framework

was proposed that eases the integration process be-

tween the control level and the physical level of het-

erogeneous conveyors. In the future the architecture

and the framework have to be tested for real logistic

setups and the lessons learned will be demonstrated

in successive publications.

ACKNOWLEDGEMENTS

This contribution was supported by the German fed-

eral state of Lower Saxony with funds of the Euro-

pean Regional Development Fund (ERDF) within the

scope of the research project ”Cognitive Logistic Net-

works” (CogniLog).

REFERENCES

Beth, C., Kamenik, J., Ommen, D., and Hahn, A. (2009).

Design aspects of cognitive logistic systems. In Int.

Conf. on Dynamics and Logistics (LDIC), Bremen.

Diao, Y., Ganesan, D., Mathur, G., and Shenoy, P. J. (2007).

Rethinking data management for storage-centric sen-

sor networks. In CIDR, pages 22–31.

Leit ao, P. (2009). Agent-based distributed manufacturing

control: A state-of-the-art survey. Eng. Appl. Artif.

Intell., 22(7):979–991.

Nanotron Technologies, G. (2007). Real time location sys-

tems, version 1.02, document-id: Na-06-0148-0391-

1.02.

Ommen, D., Beth, C., Kamenik, J., and Hahn, A. (2009). A

system-architecture for robotic movements of goods -

approaches towards a cognitive material flow system.

In Filipe, J., Andrade-Cetto, J., and Ferrier, J.-L., edi-

tors, ICINCO-RA, pages 342–347. INSTICC Press.

Pottie, G. J. and Kaiser, W. J. (2000). Wireless integrated

network sensors. Commun. ACM, 43(5):51–58.

Ratnasamy, S., Karp, B., Yin, L., Yu, F., Estrin, D., Govin-

dan, R., and Shenker, S. (2002). Ght: A geographic

hash table for data-centric storage in sensornets. In

citeseer.ist.psu.edu/ratnasamy02ght.html, editor, Pro-

ceedings of the First ACM International Workshop on

Wireless Sensor Networks and Applications (WSNA).

ACM.

R

¨

ohrig, C. (2009). Lokalisierungsverfahren f

¨

ur drahtlose

Sensornetzwerke. In Sieck, J. and Herzog M.H.,

editors, Wireless Communication and Information

– Radio Engineering and Multimedia Applications,

pages 81–97. Verlag Werner Hlsbusch, Boizenburg,

Deutschland.

Schmidt, T. and Schulze, F. (2009). Future approaches to

meet complexity requirements in material handling

systems. In FME Transactions, volume 37, pages

159–166.

Scholz-Reiter, B., Jagalski, T., and Bendul, J. (2007a). Selb-

ststeuerung logistischer prozesse in produktionsnet-

zen. Industrie Management, 23:7–10.

Scholz-Reiter, B., Jagalski, T., and de Beer, C. (2007b).

Selbststeuerung logistischer prozesse in produktion-

snetzen. Industrie Management, pages 19–22.

Scholz-Reiter, B., Rekersbrink, H., and Freitag, M. (2006).

Kooperierende routingprotokolle zur selbststeuerung

von transportprozessen. Industrie Management,

22:19–22.

Ten Hompel, M., Follert, G., and Roidl, M. (2008). Kuen-

stliche intelligenz im internet der dinge: Die zukunft

der materialflusssteuerung mit autonomen agenten.

Tilak, S., Abu-Ghazaleh, N. B., and Heinzelman, W. (2006).

Storage Management in Wireless Sensor Networks,

pages 257–281. John Wiley & Sons, Inc.

Windth, K. (2007). Selbststeuerung intelligenter objekte in

der logistik. Selbstorganisation - Ein Denksystem fr

Natur und Gesellschaft, pages 19–22.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

254