ARTIFICIAL NEURAL NETWORK MODEL APPLIED

TO A PEM FUEL CELL

D. S. Falcão

1

, J. C. M. Pires

2

, C. Pinho

1

, A. M. F. R. Pinto

1

and F. G. Martins

2

1

CEFT - Centro de Estudos de Fenómenos de Transporte

2

LEPAE - Laboratório de Engenharia de Processos, Ambiente e Energia

Faculdade de Engenharia da Universidade do Porto, Rua Dr. Roberto Frias, s/n, 4200-465 Porto, Portugal

Keywords: Artificial neural networks (ANN), Proton Exchange Membrane Fuel Cell (PEMFC), Modelling.

Abstract: This study proposes the simulation of PEM fuel cell polarization curves using artificial neural networks

(ANN). Fuel cell performance can be affected by numerous parameters, namely, reactants pressure,

humidification temperature, stoichiometric flow ratios and fuel cell temperature. In this work, the influence

of relative humidity (RH) of the gases, as well as gases and fuel cell temperatures was studied. A

feedforward ANN with three layers was applied to predict the influence of those parameters, simulating the

voltage of a fuel cell of 25 cm

2

area. Different ANN models were tested, varying the number of neurons in

the hidden layer (1 to 6). The model performance was evaluated using the Pearson correlation coefficient

(R) and the index of agreement of the second order (d

2

). The results showed that feedforward ANN can be

used with success in order to obtain the optimal operating conditions to improve PEM fuel cell performance.

1 INTRODUCTION

Fuel cells are an innovative alternative to current

power sources with potential to achieve higher

conversion efficiencies thus reducing the

environmental impact. In particular, the proton-

exchange membrane (PEM) fuel cells are today in

the focus of interest as one of the most promising

developments in power generation with a wide range

of applications in transportation and in portable

electronics. Although prototypes of fuel cell vehicles

and residential fuel cell systems have already been

introduced, their cost must be reduced and their

efficiencies enhanced.

To achieve optimal fuel cell performance, it is

critical to have an adequate water balance to ensure

that the membrane remains hydrated for sufficient

proton conductivity, while cathode flooding and

anode dehydration are avoided (Baschuk and Li,

2000; Biyikoglu, 2005). Water content of the

membrane is determined by the balance between

water production and three water transport

processes: electro-osmotic drag of water (EOD),

associated with proton migration through the

membrane; back diffusion from the cathode; and

diffusion of water to/from the oxidant/fuel gas

streams. Understanding the water transport in the

PEM is a guide for materials optimization and

developments of new Membrane Electrode

Assemblies (MEA’s).

Mathematical modelling and simulation are

needed as tools for design optimization of fuel cells.

In this work, the effect of anode/cathode relative

humidity, reactants temperatures and fuel cell

temperature on the performance of a PEMFC with

multiserpentine flow channels is studied and the

results are compared to the predictions of an

artificial neural networks (ANN) based model. ANN

is a statistical model that is applied in different

fields, such as, process control, optimization,

medical diagnosis, decision making, signal and

speech processing (Gupta and Achenie, 2007; Nagy,

2007; Uncini, 2003). ANN models are characterized

by a set of processing neurons with an activation

function that are distributed in layers (input, hidden

and output layers). One of the problems of the

training step is the overfitting. A high number of

iterations lead to decrease the error in the training

set, but the achieved model presents a large error

when applied to a new set. A method often applied

to solve this problem is the early stopping (Nguyen

et al., 2005; Özesmi et al., 2006). Using this method,

the data should be divided into three sets (Chiang et

al., 2004): (i) the training set, used to determine the

435

Falcão D., Pires J., Pinho C., Pinto A. and Martins F. (2009).

ARTIFICIAL NEURAL NETWORK MODEL APPLIED TO A PEM FUEL CELL.

In Proceedings of the International Joint Conference on Computational Intelligence, pages 435-439

DOI: 10.5220/0002317604350439

Copyright

c

SciTePress

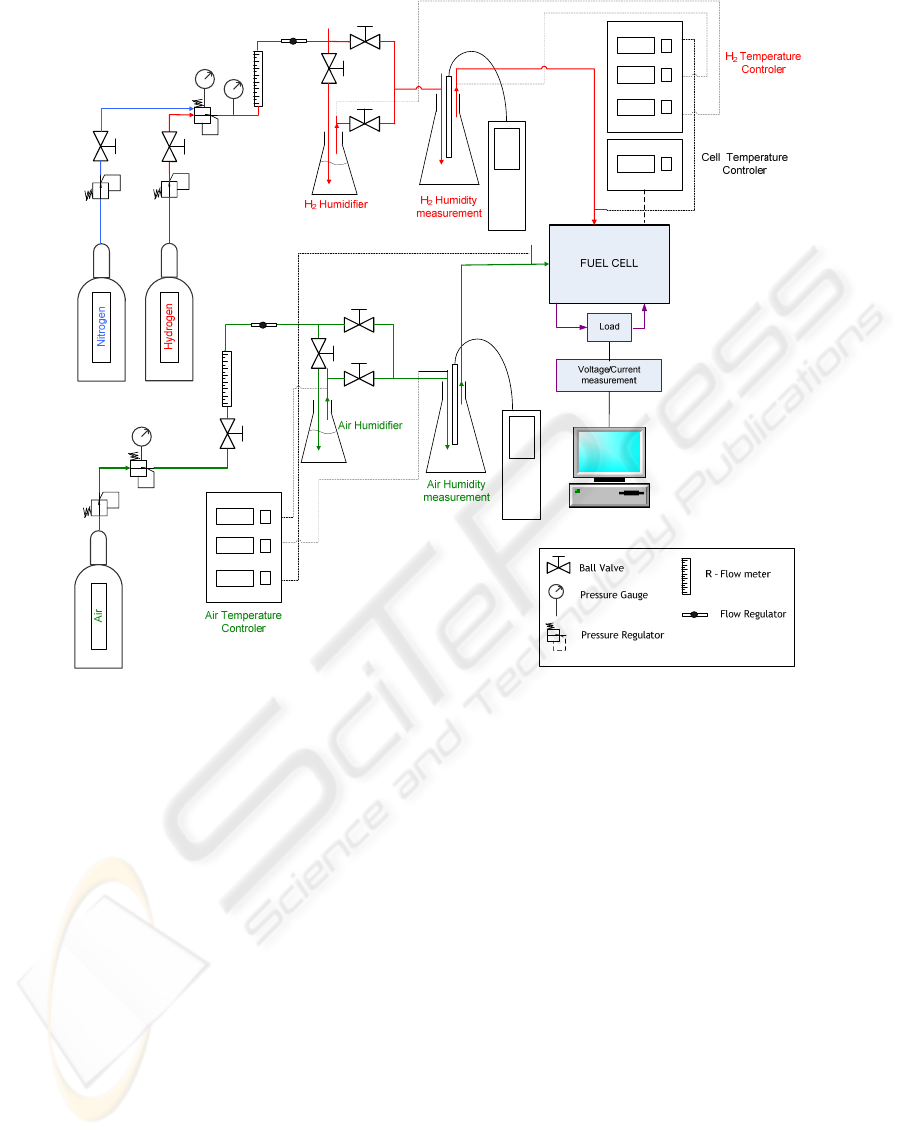

Figure 1: Schematic representation of the experimental set-up.

model parameters; (ii) the validation set, used to

evaluate the performance of ANN model during the

training step and to stop it when the validation error

starts to increase; and (iii) the test set, used to

evaluate the ANN performance when applied to a

new set. Some studies applying ANN models to fuel

cells can be found in recent literature (Ogaji et al.,

2006; Saengrung et al., 2007; Ou and Achenie,

2005). Ogaji et al. (2006) applied these models to

simulate the performance of solid oxide fuel cells

ANN presented great accuracy. Saengrung et al.

(2007) tried to predict the performance of a

commercial proton exchange membrane using two

ANN models. Both models presented successful

predictions of the stack voltage and current of the

fuel cell. Ou and Achenie (2005) compared the

performance of ANN and two hybrid models for

predicting the voltage of proton exchange membrane

fuel cells. The models presented similar

performance.

The scope of this work is the application of an

ANN model to predict fuel cells polarization curves

and verify the feasibility of this application.

2 EXPERIMENTAL SYSTEM

A schematic drawing of the experimental apparatus

used in this work is shown in Figure 1

Pure hydrogen (humidified or dry) as fuel and air

(humidified or dry) as oxidant are used. The pressure

of the gases is controlled by pressure regulators

(Air- Norgreen 11400, H

2

- Europneumaq mod. 44-

2262-241) and the flow rates are controlled by flow

meters (KDG – Mobrey).

The reactants humidity and temperatures are

monitored by adequate humidity and temperature

probes (Air – Testo, H

2

– Vaisala). The

humidification of air and hydrogen gases is

conducted in Erlenmeyer flasks by a simple

bubbling process. To control the humidification

temperature, each Erlenmeyer flask is thermally

isolated and surrounded by an electrical resistance

(50 W/m) activated by a Osaka OK 31 digital

IJCCI 2009 - International Joint Conference on Computational Intelligence

436

temperature controller. The same procedure is

applied along the connecting pipes from the

humidification point up to the entrance of the fuel

cells to guarantee the temperature stabilization of

each reacting gas flow, as well as to control the

operating temperature of the fuel cell. For the

measurement and control of the cell electrical

output, an electric load reference LD300 300W DC

Electronic Load from TTI is used. This device could

work with five different operating modes:

- Constant current – two possibilities were

available, 0 to 8 A (with 1 mA resolution) and 0 to

80 A (10 mA resolution), with a precision of ±0.2

%+20 mA;

- Constant voltage – two possibilities were

available, Vmin up to 8 V (1 mA resolution) and

Vmin up to 80 V (10 mA resolution (were V min is

10 mV for low power situation and 2 V for 80 A).

Precision is ±0.2 %+2 digits;

- Constant power – the available power range

goes from 0 till 320 W, with a precision of 0.5 %+2

W;

- Constant conductance - operating range from

0.01 up to 1 A/V (1 A/V resolution) and from 0.2 up

to 40 A/V (resolution of 0.01 A/V) with a precision

of 0.5 %+2 digits;

- Constant resistance – operating range from 0.04

up to 10 Ω (0.01 Ω resolution) and from 2 to 40 Ω

(with 0.1 Ω resolution) with a precision of 0.5 %+2

digits.

This load was connected to a data acquisition

system composed by Measurement Computing

boards installed in a desktop computer. The used

data acquisition software was DASYLab.

In the present work, all the components of the

PEMFC were “in house” designed, with exception

of the MEA. A Dupont Nafion 111 MEA with 25

cm

2

active surface area is used. The channels

configuration used for the anode and cathode flow

channels (multiserpentine design) is represented in

Figure 2. Channels depth is 0.6 mm for anode side

and 1.5 mm for cathode side.

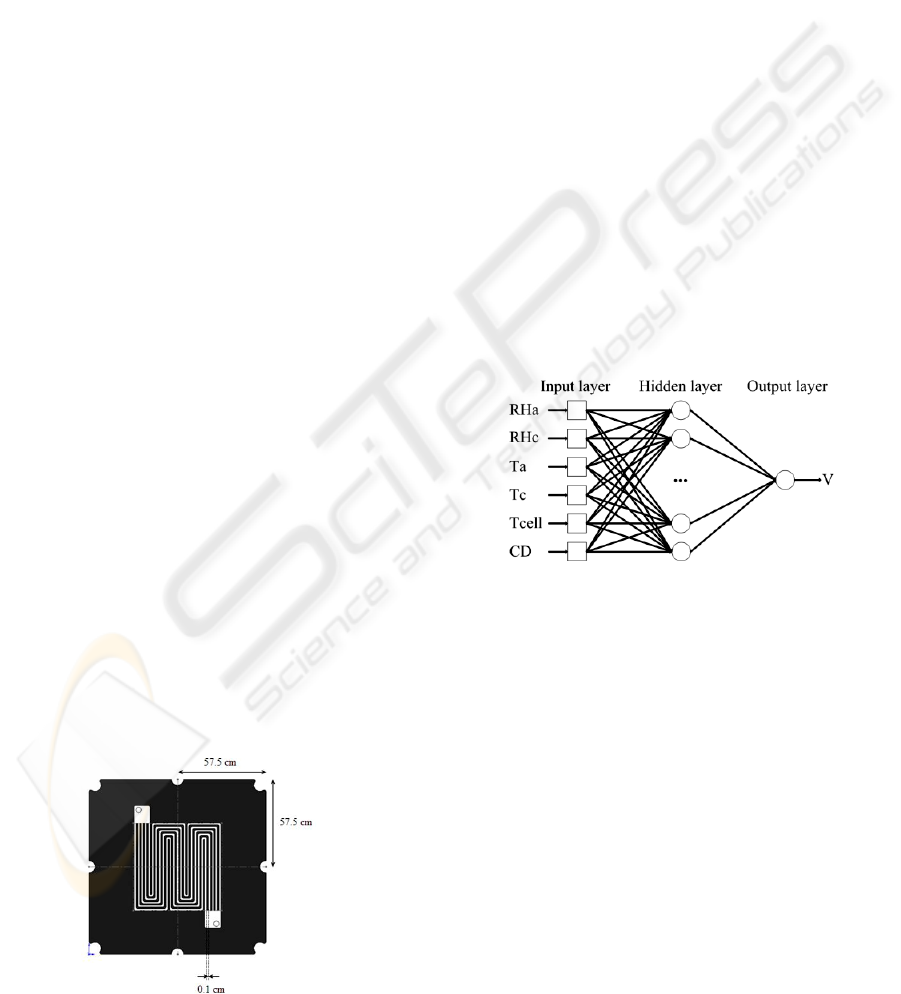

Figure 2: Flow channels configuration and dimensions.

3 ANN MODEL

In this study, a feedforward ANN with three layers

was applied to predict the voltage (V) of a PEM fuel

cell. The input variables (see Figure 3) were: Anode

Relative Humidity (RHa), Cathode Relative

Humidity (RHc), Anode flow rate Temperature (Ta),

Cathode flow rate Temperature (Tc), Cell

Temperature (Tcell) and Current Density (CD).

Hyperbolic tangent and linear functions were used as

activation functions in hidden and output neurons,

respectively. The objective function was the

minimization of the mean squared error of the

training data. The early stopping method was

applied and the data was divided into three sets

(training – 124 data points; validation – 25 data

points; and test – 38 data points). Different ANN

models were tested, varying the number of neurons

in the hidden layer (1 to 6). For each structure, 100

runs were performed. The best ANN model

corresponded to the minimum error in the training

and validation data. The model performance was

evaluated using the Pearson correlation coefficient

(R) and the index of agreement of the second order

(d

2

) (Sousa et al., 2007).

Figure 3: ANN structure for fuel cell electric voltage

modelling.

4 RESULTS

In this work, the influences of gases relative

humidity and temperature and cell temperature were

studied. Additionally, several ANN models were

tested to predict the voltage using some

experimental conditions. The early stopping

methodology was applied to improve the

generalization of the ANN models obtained. The

data were divided into three sets: training, validation

and test. Training and validation sets were used to

determine the ANN model parameters. The test set

was used to evaluate the performance of ANN

model when applied to a new set (not influencing the

determination of the model parameters). The best

ARTIFICIAL NEURAL NETWORK MODEL APPLIED TO A PEM FUEL CELL

437

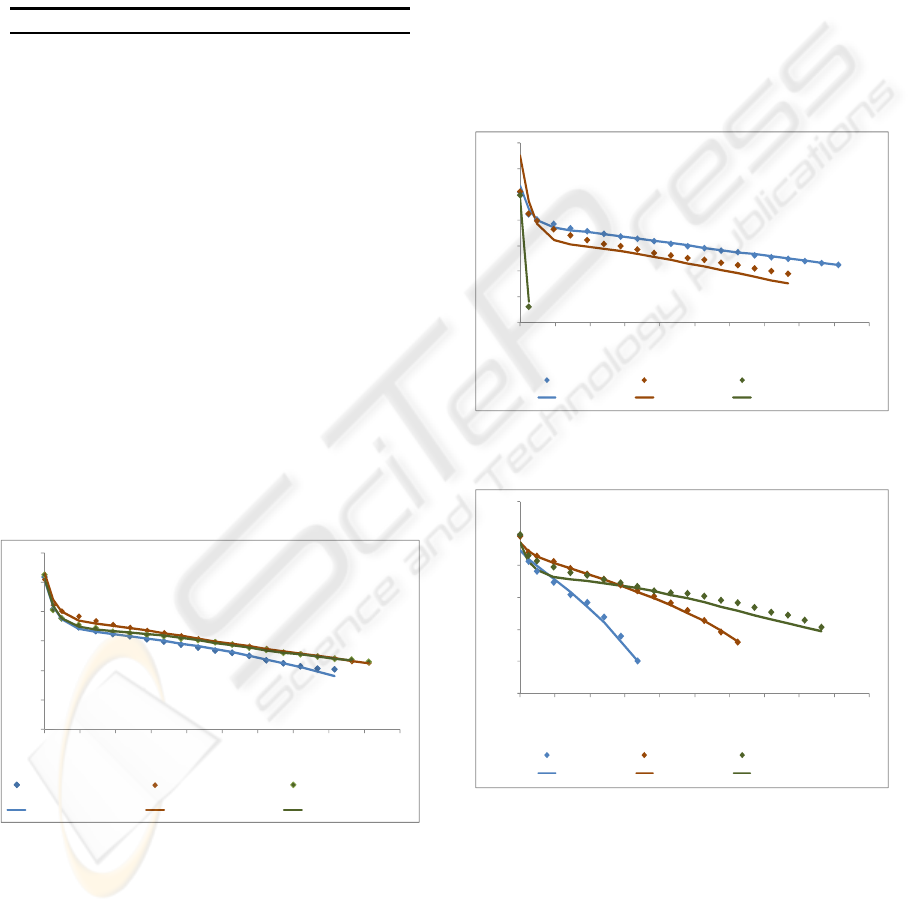

model, containing 6 hidden neurons, adjusts very

well experimental results, as can be seen in Figures

4 to 8. Accordingly, the performance indexes

obtained by this statistical model are presented in

Table 1. The values showed that the achieved ANN

model is good for predictive purposes.

Table 1: Performance indexes (R and d

2

) in training,

validation and test sets.

Set Training Validation Test

R

0.99 0.99 0.91

d

2

1.00 1.00 0.96

Figures 6 and 8 with a Tcell of 333 K and Figure 7

with a Tcell of 313 K show the performance of the

model in test set. The remaining figures show the

performance in the training and validation sets.

4.1 Influence of the Relative Humidity

of Reactants Gases

To study the influence of gases RH, three

experiments were done: two with only the anode or

cathode stream humidified and another with both

gases streams humidified. As can be seen in Fig. 4,

the best fuel cell performance was achieved when

both streams were humidified. Relatively to the

other two experiments, best results were obtained

when just the anode stream was humidified. In fact,

the water production occurs at the cathode side. So,

for these operating conditions, the cathode

humidification is dispensable.

Figure 4: Experimental and modelling data for dry anode

or cathode and for both gases humidified, for gases and

cell temperatures of 298 K.

4.2 Influence of Cell Temperature and

Reactant Gases Temperature

The influence of cell temperature was studied for

two gases humidification temperatures: 298 K and

333 K and the influence of gases temperature for

two cell temperatures: 298 K and 333 K. Fig. 5, 6, 7

and 8 show that the best performance was achieved

when the cell temperature is the same as the reactant

gases temperature. So, for all experiments, better

results were obtained for a cell temperature/gases

temperature of 298 K and 333 K. If the cell

temperature is higher than the gases temperature, the

membrane will dry and the proton conductivity is

severely affected. If the cell temperature is lower

than the gases temperature, the membrane will flood.

Excessive water amounts filling the pores inhibit the

access to active sites and block the transport of

gaseous reactants and products.

Figure 5: Experimental and modelling data for different

cell temperatures, for fully humidified gases at 298 K.

Figure 6: Experimental and modelling data for different

cell temperatures, for fully humidified gases at 333 K.

Curiously, in Figures 6 and 7, for lower current

densities, better results are obtained for Tcell/gases

temperature of 313 K. For lower current densities,

the water production in the cathode is lower and, so,

the introduction of more water improves the cell

performance.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

Volt a ge [V]

Current Density [A/cm

2

]

RHa=5%, RHc=95% Exp RHa=95%, RHc=95% Exp RHa=95%, RHc=5% Exp

RHa=5%, RHc=95% Model RHa=95%, RHc=95% Model RHa=95%, RHc=5% Model

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

Volt age [V ]

Current Density [A/cm

2

]

Tcell=298 K Exp Tcell=313 K Exp Tcell=333 K Exp

Tcell=298 K Model Tcell=313 K Model Tcell=333 K Model

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

Vo lt age [V ]

Current Density [A/cm

2

]

Tcell=298 K Exp Tcell=313 K Exp Tcell=333 K Exp

Tcell=298 K Model Tcell=313 K Model Tcell=333 K Model

IJCCI 2009 - International Joint Conference on Computational Intelligence

438

Figure 7: Experimental and modelling data for different

gases temperatures (fully humidified), for a cell

temperature of 298 K.

Figure 8: Experimental and modelling data for different

gases temperatures (fully humidified), for a cell

temperature of 333 K.

5 CONCLUSIONS

The effect of the relative humidity of the gases, and

of the temperature of the reactant gases and cell on

fuel cell performance was studied. It was concluded

that the fuel cell works better with both anode and

cathode humidified and that the temperature of the

gases and of the fuel cell should be the same. The

model developed in this work predicts very well the

experimental results. This kind of models could be

used with success for quick predictions of fuel cell

behaviour.

ACKNOWLEDGEMENTS

The partial support of “Fundação para a Ciência e

Tecnologia - Portugal” through project POCI/

EME/55497/2004 and scholarships SFRH/

BD/28166/2006 and SFRH/BD/23302/2005 is

gratefully acknowledged.

REFERENCES

Baschuk, J..J. and Li, X., 2000, Modeling of polymer

electrolyte membrane fuel cells with variable degrees

of water flooding, J. of Power Sources, Vol. 86, pp.

181-195.

Biyikoglu, A., 2005, Review of proton exchange fuel cell

models, International Journal of Hydrogen Energy,

Vol. 30, pp. 1185-1212.

Chiang, Y.M., Chang, L.C., Chang, F.J.,2004.

Comparison of static-feedforward and dynamic-

feedback neural networks for rainfall–runoff

modelling. Journal of Hydrology 290 (3-4), 297-311.

Gupta, R.R., Achenie, L.E.K., 2007. A network model for

gene regulation. Computers & Chemical Engineering

31 (8), 950-961.

Nagy, Z.K., 2007. Model based control of a yeast

fermentation bioreactor using optimally designed

artificial neural networks. Chemical Engineering

Journal 127 (1-3), 95-109.

Nguyen, M.H., Abbass, H.A., McKay, R.I., 2005.

Stopping criteria for ensemble of evolutionary

artificial neural networks. Applied Soft Computing 6

(1), 100-107.

Ogaji, S.O.T., Singh, R., Pilidis, P., Diacakis, M., 2006.

Modelling fuel cell performance using artificial

intelligence. Journal of Power Sources 154 (1), 192-

197.

Ou, S., Achenie, L.E.K., 2005. A hybrid neural network

model for PEM fuel cells. Journal of Power Sources

140 (2), 319-330.

Özesmi, S.L., Tan, C.O., Özesmi, U., 2006.

Methodological issues in building, training, and

testing artificial neural networks in ecological

applications. Ecological Modelling 195 (1-2), 83-93.

Saengrung, A., Abtahi, A., Zilouchian, A., 2007. Neural

network model for a commercial PEM fuel cell system.

Journal of Power Sources 172(2), 749-759.

Sousa, S.I.V., Martins, F.G., Alvim-Ferraz, M.C.M.,

Pereira, M.C., 2007. Multiple linear regression and

artificial neural networks based on principal

components to predict ozone concentrations.

Environmental Modelling & Software 22 (1), 97-103.

Uncini, A., 2003. Audio signal processing by neural

networks. Neurocomputing 55 (3-4), 593-625.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

Vo lt age [V ]

Current Density [A/cm

2

]

Tgases=298 K Exp Tgases=313 K Exp Tgases=333 K Exp

Tgases=298 K Model Tgases=313 K Model Tgases=333 K Model

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

Vo lt age [V ]

Current Density [A/cm

2

]

Tgases=298 K Exp Tgases=313 K Exp Tgases=333 K Exp

Tgases=298 K Model Tgases=313 K Model Tgases=333 K Model

ARTIFICIAL NEURAL NETWORK MODEL APPLIED TO A PEM FUEL CELL

439