PRODUCT REPRESENTATION TO SUPPORT VALIDATION OF

SIMULATION MODELS IN COMPUTER AIDED ENGINEERING

Andreas Kain, Andreas Gaag and Udo Lindemann

Institute of Product Development, Technische Universitaet Muenchen, Boltzmannstr. 15, 85748 Garching, Germany

Keywords: Model validation, System modelling, Multiple domain matrix (MDM), Flexible multibody simulation.

Abstract: Computer aided engineering (CAE) provides proper means to support New Product Development (NPD) by

simulation tools. Simulation furthers early identification of product characteristics to reduce costs and time.

The applicability of simulation models in NPD strongly depends on their validity, thus validating a

simulation poses a major issue to provide correct experimentation results. The authors propose a matrix

based approach to combine solution neutral system representation, solution specific product representation,

and product behaviour in order to raise system comprehension to support validation of simulation models. A

case study exemplifies the suggested approach. This paper illustrates the matrix based product

representation at composing a flexible multibody simulation of a highly dynamic linear shafting machine

tool. The approach supports preprocessing and validation of a flexible multibody simulation model.

1 INTRODUCTION

New product development (NPD) nowadays grounds

on simulation tools provided by computer aided

engineering (CAE). It becomes reasonable to

evaluate engineering design in early stages before

starting physical prototyping and thus enables early

anticipation of product characteristics. Simulation

also assists further development of existing products

or establishing a line of products.

As summarized in (Musselman 1994; Robinson

and Bhatia 1995; Robertson and Perera 2002) a

simulation project comprises interpretive,

developmental, and analytical facets. Modelling

includes problem formulation, model

conceptualization, data collection, model building,

verification, validation, analysis, documentation and

implementation.

Validation requires that the model is an accurate

representation of the system being modelled taking

into account the modelling purpose (Robinson and

Bhatia 1995; Sargent 2004). The modelling purpose

includes requirements on the model itself. Reasoning

and derivation of conclusions by experimentation

with the model requires successfully model

credibility and thus completed validation. Thus

validating a simulation poses a major issue to

provide correct experimentation results. The authors

propose a matrix based system representation to

support validation of simulation models in CAE.

The paper contains in section 2 background

information. Section 3 introduces a matrix based

product representation to raise system

comprehension and thus to support system

validation in CAE. Section 4 illustrates a case study

of supporting a flexible multi body simulation in

further developing a machine tool. Section 5

discusses the application of the suggested approach

in the case study. Section 6 concludes the paper.

2 BACKGROUND

According to (Sargent 2004) analysis and modelling

derive a conceptual model based on the problem

entity which represents the system. The conceptual

model represents the system for a particular study.

Implementation of the conceptual model leads to a

computerized model. Validation of this

computerized model by operational validation

proves that the model’s output behaviour represents

sufficiently the problem entity for the model’s

intended purpose. VDI 3681 emphasises that

validation is the proof that a system satisfies the

requirements (VDI 2005). Bender narrows down the

term validation as “doing the right things” contrary

to the term specification that comprises “doing the

355

Kain A., Gaag A. and Lindemann U.

PRODUCT REPRESENTATION TO SUPPORT VALIDATION OF SIMULATION MODELS IN COMPUTER AIDED ENGINEERING.

DOI: 10.5220/0002249803550359

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2009), page

ISBN: 978-989-674-000-9

Copyright

c

2009 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

things properly” (Bender 2005). Sargent summarizes

and details several validation techniques (Sargent

2004): (1) Animation, (2) Comparison to other

models, (3) Degenerate Tests, (4) Event Validity, (5)

Extreme Condition test. (6) Face Validity, (7)

Historical data validation, (8) Internal Validity, (9)

Multistage Validation, (10) Operational Graphics,

(11) Parameter Variability – Sensitivity Analysis,

(12) Predictive Validation, (13) Traces, and (14)

Turing Tests. Either the developer, or the user or a

third party conduct one or more of these techniques

either concurrently with the development of the

simulation model or afterwards.

In product development concerned with not

merely mechanical products several types of

relations connect components systematically such as

function, structure, and behaviour (Pahl and Beitz

1995; Ariyo, Eckert et al. 2006). A physical form

with a specific structure characterizes design

artefacts and enables to carry out function. The

product structure comprises parts that interact

amongst other and cause behaviour.

Based on these various approaches of product

representation in NPS have been developed (e.g.

seePahl and Beitz 1995; Lindemann 2007). Solution

neutral and/ or solution specific system/product

representations exist. Solution neutral

representations support to lose fixation to specific

physical solutions to further generating new

conceptual ideas. E.g. functional modelling

describes a system abstractly without sticking to

specific solutions.

As Browning states the design structure matrix

(DSM) is a well established method for handling

complex systems (Browning 2001).

Relations within one domain such as function or

structure fill the DSM in order to reveal

interdependencies between elements. Maurer

summarizes and details linking several DSMs by

applying domain mapping matrices (DMM), that

contain relations between elements of different

domains, to gain multiple domain matrices (MDM)

(Maurer 2007). Thus MDM methodology enables to

interconnect solution neutral representation, e.g. by

functional modelling, and solution specific

representation e.g. by component structure.

Interpretation and application of MDMs is a recent

research task, e.g. interpretation of the meaning of

specific patterns such as cycles (Biedermann and

Lindemann 2008).

Based on system representations methods such as

Failure Mode and Effects Analysis (e.g. ((VDA)

1999) or SAE J-1739) guide to reason about e.g. root

causes in a structured manner by pointing to

relations and evaluating these relations in NPD.

They support to document problem solving tasks and

application results in overall improvement of the

product itself.

Multibody simulations reveal the kinematic

behaviour of steep bodies. Schiehlen reviews the

history of multibody systems in detail (Schiehlen

1997). A multibody system comprises bodies, force

elements, and joints within a global reference frame

(Schwertassek, Wallrapp et al. 1999). Additionally

flexible multibody systems (fMBS) are capable to

handle constrained deformable bodies that undergo

large displacements, including large rotations

(Shabana 1997).

3 METHOD

The authors propose a matrix based product

representation to raise system comprehension and

thus to support system validation in CAE. Besides

the interconnection of the functional perspective on

the system and the component structure of a product

the suggested approach takes into account the

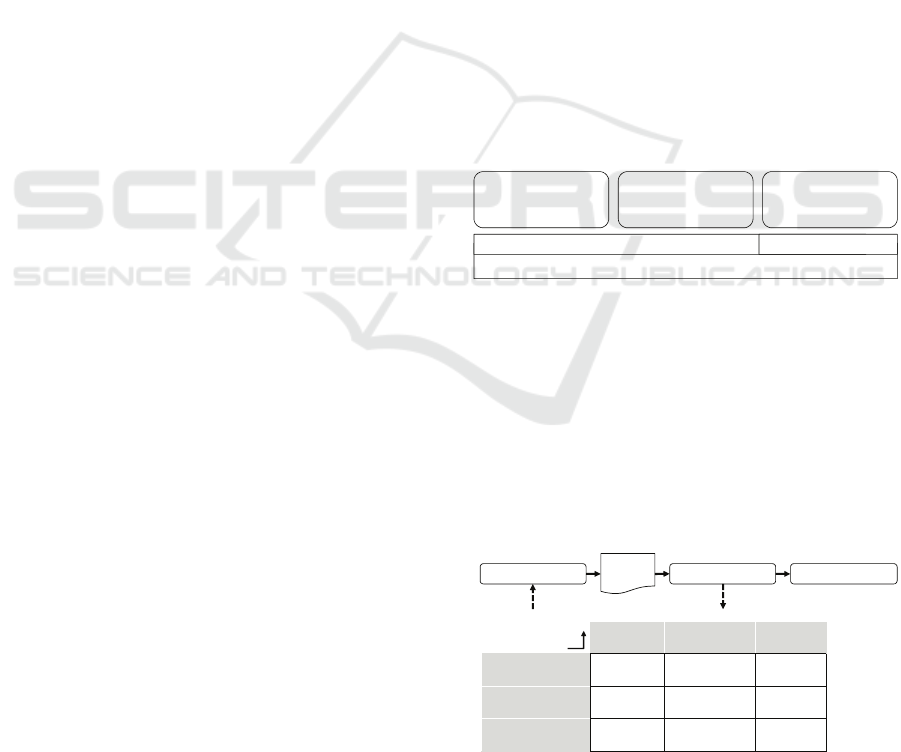

dynamic behavior of a product (see Fig.1).

system representation

solution neutral

description

product specific

description

behavioral

description

static dynamic

Figure 1: Components of the proposed system

representation.

Creation and interpretation of the proposed

product representation result in a deep understanding

of the discussed product by raising awareness of

interrelations between the considered domains. In

CAE this understanding supports to define the

modelling purpose properly. Additionally extensive

collection of specifications enriches preprocessing of

the simulation model (see Fig. 2).

functional

modeling

component

structure

system

behavior

functional

modeling

DSM

relates to

DMM

implemented by

DMM

refers to

component

structure

DSM

connects

DMM

realizes

system

behavior

DSM

influences

preprocessing validation experimentation

model

Figure 2: Matrix based system representation supports

modelling.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

356

The matrix based system representation

identifies relevant elements within the integrated

domains and supports model conceptualization by

incorporating experience and knowledge gathered

along the product lifecycle. The product

representation finally assists validation of the

numerical simulation model applied in CAE.

According to the taxonomy of validation techniques

proposed by (Sargent 2004) the suggested approach

furthers historical data evaluation, whereas the data

proofs is the model behaves as the system does. The

following section summarizes a case study carried

out together with an industrial partner. This

technique may be applied by the developer assisted

by the user concurrently with the development of the

model.

4 CASE STUDY

In this case study a specific linear shaping machine

tool for fabricating crankshafts is modeled. The

authors apply the matrix based product

representation to support machine system simulation

as fMBS.

Measuring operation induced oscillations at the

machine tool itself confirmed the existence of

structural oscillations. The fMBS model is to

represent the structural bending induced by mass

forces that cause lower fabrication quality by

deflecting the tool from the manufacturing part. By

representing this problem entity the simulation

provides a means to finally evaluate design concepts

of sub assemblies to reduce the structural machine

misbehavior. Based on detailed product

comprehension the main purpose of applying the

suggested approach is to carry out system analysis to

support validation of the simulation model.

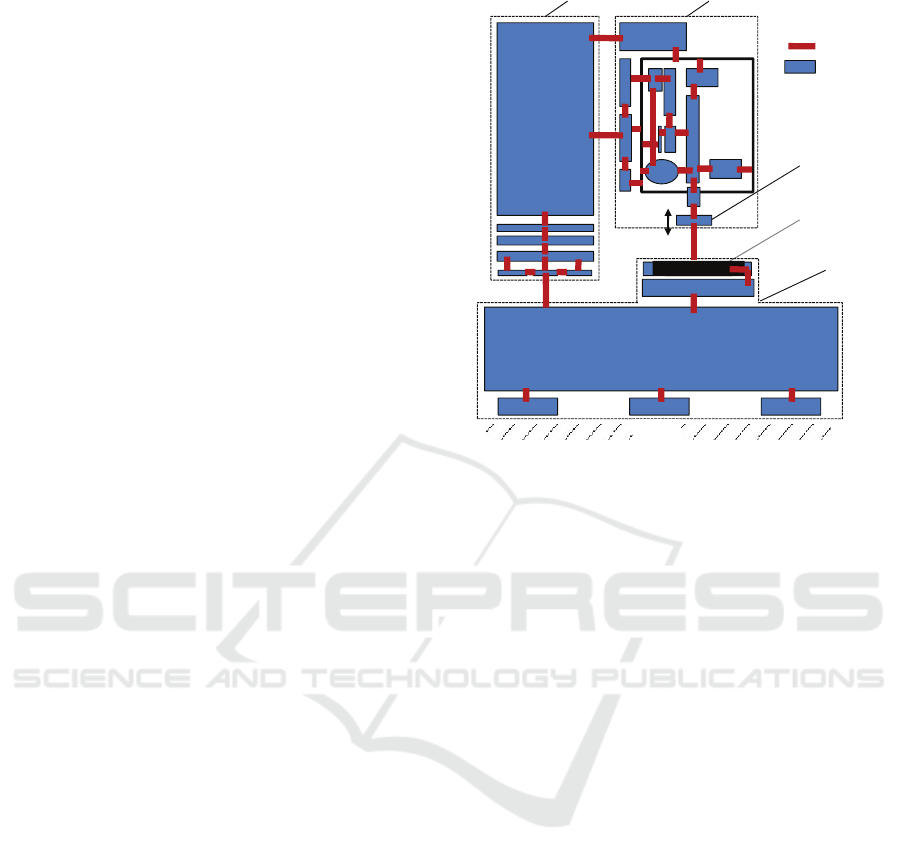

Figure 3 depicts a simplified component

structure of the shaping machine. It consists of (1)

machine bed on that the (2) machine column is

mounted. The (3) shaping head is connected to the

machine column and comprises the (4) tool that

moves highly dynamic up and down to machine the

(5) part that is fixed to the machine bed. Within the

shaping head the cutting tool moves up and down

along vertical-axis up to 700 times per minute with a

shifted weight of about 20 pounds and up to 20g.

Due to the moved mass mass-forces induce bending

of the whole machine structure that limits processing

quality.

(1) machine bed

(2) machine column (3) shaping head

(5) part

connection

components

base

(4) tool

Figure 3: Simplified component structure of the shaping

machine.

Physical components’ specification, the

assembly structure, and constraints between

components are input data for modeling. Detecting

tooth flank quality of the manufacturing part is an

indirect measure of structural bending and denotes

the machine tool behavior. Machine tool parameters

(hydraulic system pressure, lateral offset of the

column, …) as well as cutting parameters (feed,

speed, …) influence the machine behavior. Each

shaping application of particular crankshafts requires

specific cutting parameters, whereas machine

parameters are quite independent to select. fMBS is

considered a means to raise the awareness of the

actual structural bending during cutting conditions in

a new scale.

5 DISCUSSION

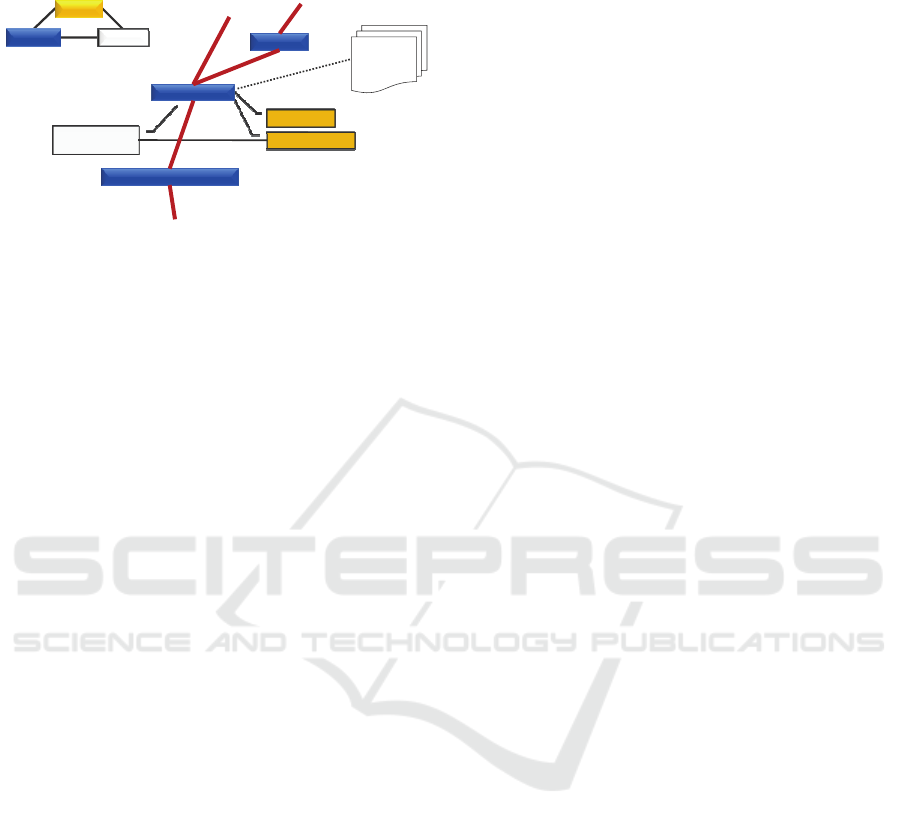

Figure 4 exemplifies information extracted from the

proposed matrix based product representation.

Aggregated information summarized vital aspects of

the system. It represents the domains component,

function, and behaviour. The mechanical parts are

connected by the flux of force (jack screw, machine

column, and guide rail of machine column) and are

interlinked to the functional modelling (perform

feed, vary part position) and the machine behaviour

(lateral offset of machine column). Additionally

PRODUCT REPRESENTATION TO SUPPORT VALIDATION OF SIMULATION MODELS IN COMPUTER AIDED

ENGINEERING

357

component specification such as stiffness, damping

and geometrics is attached.

lateral offset of

machine column

vary part position

perform feed

behaviorcomponet

function

stiffness

damping

geometry

machine column

guide rail of machine column

jack screw

Figure 4: Aggregated cluster of information.

This kind of data aggregation supports to set up

an enhanced fMBS simulation regarding important

modelling parameters and thus supports focusing the

modelling purpose and checking if the model’s

characteristic is as consistent to the system as

needed. The assembly shaping head is a rather

complex mechanical and functional structure and

needs to be discussed in detail regarding the

modeling purpose. Comprehension of interrelations

within this assembly is a key to become aware of the

system and thus vitally determines the preprocessing

of the fMBS. When modeling the system the

developers focus on representing the machine

complexity as far as needed, especially when

integrating machine parameters and flexible parts.

The matrix based machine tool representation

supported the determination of both the appropriated

system boundary and the level of detail in

preprocessing the fMBS. Besides it also supported

the identification of particular parameters, which

were primarily considered less important to

sufficiently represent the structural behavior of the

machine tool. The matrix based representation

provided the base for this information to become

worthy. Besides the matrix based representation also

measurements of operation induced structural

oscillations, and physical experiments supported the

validation of the fMBS. Concurrent model validation

enables to mature the fMBS simulation model

further. In order to provide a means to evaluate the

cause of tool deflection a properly validated fMBS is

needed. Currently the fMBS represents the

deflection of the tool identified by indirectly by

measuring crank shafts, but sensitivity analysis is

still been carried out. In modeling the iterative

approach is quite time consuming and it becomes

difficult to determine when the model is completely

validated. Validation of the model takes place quite

objectively by integrating the model developer and

the user systematically.

6 CONCLUSIONS

The exemplified case study has proven that the

suggested matrix based product representation could

successfully support preprocessing and validation of

a fMBS. Supported by the method specifications and

machine parameters are identified to be integrated in

the fMBS to represent structural bending induced by

moved mass. Applying the suggested approach of

matrix based product representation enables a

holistic view of the system regarding component

structure, functional modeling, and product behavior

to support both preprocessing and validation of the

simulation model. The significance of the suggested

matrix based product representation strongly

interrelates with the level of detail gained in each

domain.

The authors will detail the presented case study

further more to deeply illustrate the method and will

apply the suggested approach to different products to

enrich the application areas. Another task will be to

evaluate the transfer of the suggested matrix based

product representation to other simulation methods

in CAE.

REFERENCES

(VDA), V. d. A. e. V., Ed. (1999). Sicherung der Qualität

vor Serieneinsatz. Qualitätsmanagement in der

Automobilindustrie. Frankfurt am Main, Henrich

Druck+Medien.

Ariyo, O. O., C. M. Eckert, et al. (2006). On the use of

functions, behavior and structural relations as cues for

engineering change prediction. International Design

Conference - Design 2006. Dubrovnik, Croatia.

Bender, K., Ed. (2005). Embedded Systems -

qualitätsorientierte Entwicklung: Qualitätssicherung

bei Embedded Software. Berlin, Springer Verlag.

Biedermann, W. and U. Lindemann (2008). Cycles in the

Multiple-Domain Matrix – Interpretation and

Applications. 10th International DSM Conference,

Stockholm, Hansa.

Browning, T. R. (2001). Applying the Design Structure

Matrix to System Decomposition and Integration

Problems: A Review and New Directions. IEEE

Transactions on Engineering Management.

Lindemann, U. (2007). Methodische Entwicklung

technischer Produkte. Berlin, Spriger-Verlag.

Maurer, M. (2007). Structural Awareness in Complex

Product Design Munich, Dr. Hut.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

358

Musselman, K. J. (1994). Guidelines for simulation

project success. Simulation Conference Proceedings,

1994. Winter.

Pahl, G. and W. Beitz (1995). Engineering Design: A

Systematic Approach. London, Springer Verlag.

Robertson, N. and T. Perera (2002). "Automated data

collection for simulation?" Simulation Practice and

Theory 9(6-8): 349-364.

Robinson, S. and V. Bhatia (1995). Secrets of successful

simulation projects. Simulation Conference

Proceedings, 1995. Winter.

Sargent, R. G. (2004). Validation and verification of

simulation models. Simulation Conference, 2004.

Proceedings of the 2004 Winter.

Schiehlen, W. (1997). "Multibody System Dynamics:

Roots and Perspectives." Multibody System Dynamics

1(2): 149-188.

Schwertassek, R., O. Wallrapp, et al. (1999). "Flexible

Multibody Simulation and Choice of Shape

Functions." Nonlinear Dynamics 20(4): 361-380.

Shabana, A. A. (1997). "Flexible Multibody Dynamics:

Review of Past and Recent Developments." Multibody

System Dynamics 1(2): 189-222.

VDI, Ed. (2005). Classification and evaluation of

description methods in automation and control

technology, VDI/VDE 3681 Düsseldorf.

PRODUCT REPRESENTATION TO SUPPORT VALIDATION OF SIMULATION MODELS IN COMPUTER AIDED

ENGINEERING

359