HIERARCHICAL PERFORMANCE-ORIENTED CONTROL OF

FLEXIBLE MANUFACTURING CELLS

Sherif Fahmy, Subramaniam Balakrishnan and Tarek ElMekkawy

Department of Mechanical and Manufacturing Engineering, University of Manitoba

75A Chancellors Circle, Winnipeg, Manitoba, R3T5V6, Canada

Keywords: Deadlock-free scheduling, Flexible manufacturing cells, Hierarchical control, Job shops, Marked graphs,

Petri nets.

Abstract: In a job shop, each product may have a different processing route through the system. Automated Flexible

Manufacturing Cells (FMC) that adopt this flow pattern are highly prone to deadlocks. A supervisor is a

controller that uses available data via feedback loops to characterize the current behavior of the cell, and

modify the equipment controllers to achieve the desired operational specifications in a deadlock-free

manner. This paper proposes a hierarchical control system divided into an upper level scheduler and a lower

level supervisor to control FMCs. The scheduler is responsible for determining a deadlock-free allocation of

the resources that optimizes some performance measure, based on the current production requirements, and

the supervisor guarantees that the flow plan (behavior) determined by the scheduler is realized on the shop

floor. For that purpose, a formal method that can transform a production schedule into a supervisor, in real

time, is also proposed. The supervisor is an augmented Marked Graph (MG) that captures all the events that

can take place in the cell. The proposed approach is validated by generating and simulating the supervisors

for two benchmark problems.

1 INTRODUCTION

Most automated manufacturing systems (AMSs)

feature three inherent operational properties; mutual

exclusion, no pre-emption, and the hold-while-wait

property. Because of these conditions and the

inherent flow complexities in job shop systems,

when they are automated they become highly prone

to deadlocks. A deadlock occurs in an automated

manufacturing system when a set of jobs enter a

circular wait, where each job continues holding

(blocking) a system resource indefinitely while

waiting for another resource to become available,

which is in turn held by another job in this same set.

Scheduling and control of manufacturing

systems have been widely researched and reported in

literature in the past decades. However, a wide gap

exists between the contributions found in the

scheduling literature and those pertaining to actual

implementation (supervision) on the shop floor (Sun

et al., 2006). A few attempts, however, have been

made to integrate deadlock-free scheduling and

supervision, but these either lacked a global view of

the system (Li & Jiang, 2006), or realized a poorer

performance when compared to pure deadlock-free

scheduling approaches.

In the previous literature, the Supervisory

Control Theory (SCT) (Ramadge & Wonham, 1987)

and Petri nets (PNs) have been the two most

frequently used and commonly accepted methods by

researchers for modeling and supervising AMSs.

Limitations of the SCT approaches have been

attributed to the large state space required to

represent even small systems, and the complexity of

analysis of the formal languages. On the other hand,

PN literature on Supervisory Control (SC) can be

classified into approaches that analyzed the

Reachability graph of the net (Viswanadham et al.,

1990, Hsieh & Chang, 1994) and approaches that

characterized the deadlock states using siphons

analysis (Ezpeleta et al., 1995, Chu & Xie, 1997).

While the former approaches suffered either from

the state explosion problem or the restrictiveness of

the PN model (Fanti & Zhou, 2004), the latter ones

suffered from the exponential complexity of

determining the siphons of the net.

Automata and PN SC approaches have usually

been combined with conventional scheduling

329

Fahmy S., Balakrishnan S. and ElMekkawy T.

HIERARCHICAL PERFORMANCE-ORIENTED CONTROL OF FLEXIBLE MANUFACTURING CELLS.

DOI: 10.5220/0002169103290332

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2009), page

ISBN: 978-989-8111-99-9

Copyright

c

2009 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

approaches to solve the deadlock-free scheduling

problem (Liljenvall, 1999, Golamakni et al., 2006,

Lee & DiCesare, 1994, Ben Abdallah et al., 2002).

However, these approaches have suffered from the

same complexities which their SC counterparts have

suffered from. To cope with these complexities,

some heuristic approaches have been introduced to

the literature to solve the problem. These included

the work proposed in Huan & Wu (2004), Mati et al.

(2001), and Fahmy et al. (2008). Others proposed

mathematical formulations that can be solved to

attain the optimal solutions for the problem

(Ramaswamy & Joshi, 1996).

Nevertheless, the literature still lacks a formal

approach that can transform a deadlock-free

schedule of a job shop system into an implementable

supervisor. The existence of such an approach would

guarantee the correct and performance-optimized

behavior of the system.

2 HIERARCHICAL CONTROL

The type of systems considered is Flexible

Manufacturing Cells (FMCs) that feature a job shop

flow pattern. Such cells usually comprise a number

of CNC machines that are served by a dedicated

material handler (like a robot manipulator). In

addition, they usually include some buffer capacity

that can be used to temporarily store a job to

preserve the continuity of flow or to resolve a

deadlock.

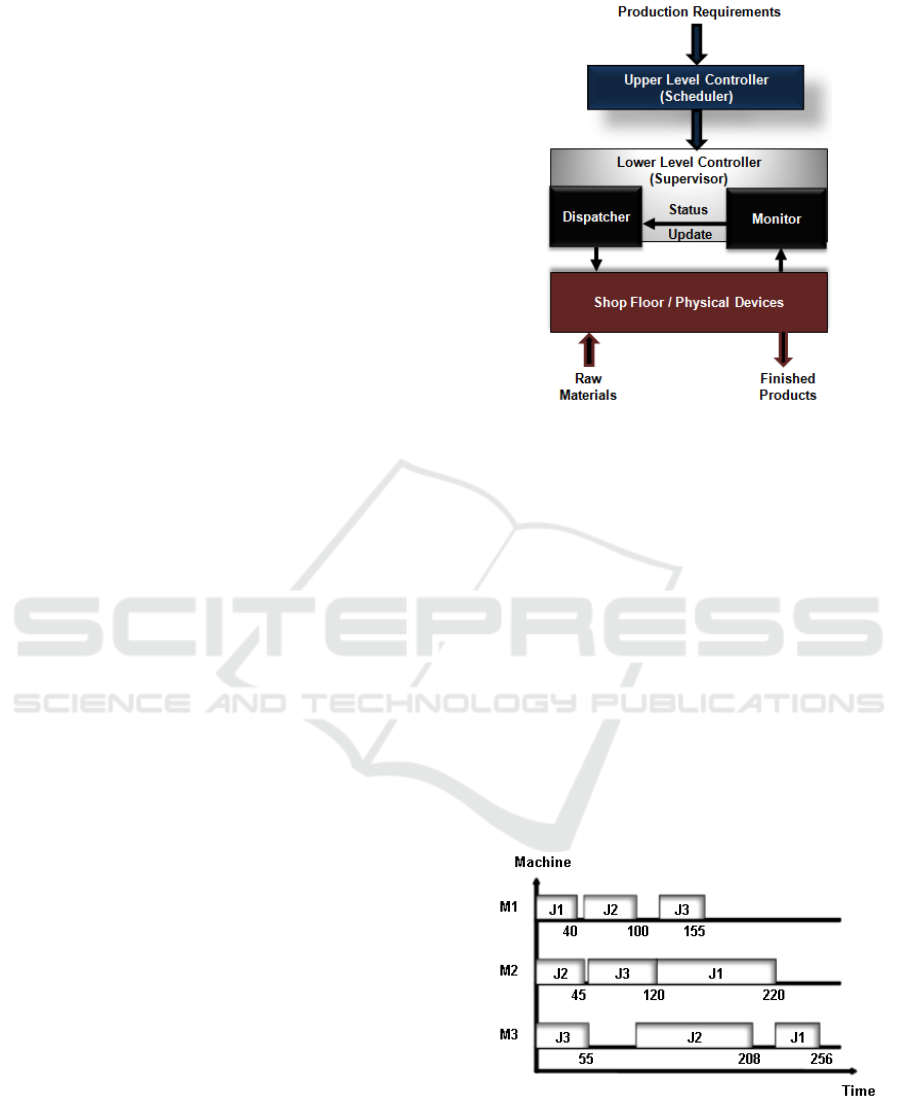

Ideally, the functions of a production control

system can be classified into three distinct functional

modules; a scheduler, a monitor, and a dispatcher.

Accordingly, a hierarchical control system divided

into an upper level scheduler, and a lower level

supervisor that monitors and dispatches commands

to the shop floor (Figure 1) is proposed. According

to the current product mix, the scheduler allocates

processing slots for the jobs on the available

machines while optimizing an objective criterion.

The schedule further ensures that the resulting job

flow cannot cause any deadlock situations. The

assigned processing slots, and hence the underlying

flow plan of the schedule is transformed into a

supervisor. The supervisor will guarantee that the

flow plan (behavior) determined by the scheduler is

realized on the shop floor. The supervisor then

interacts with shop floor devices by receiving

feedback signals and accordingly issuing action

commands directly from/to the shop floor.

Figure 1: Proposed hierarchical control system.

3 SUPERVISOR REALIZATION

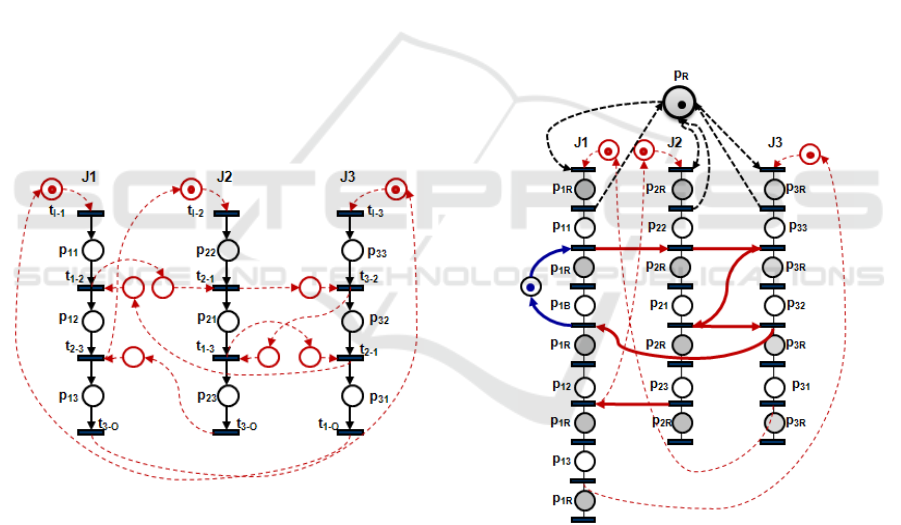

PN supervisors embedding a Marked Graph (MG)

structure can be easily verified for liveness and

reversibility. A MG is an ordinary PN in which each

place has exactly one input transition and one output

transition. A MG is live (deadlock-free) if the net

structure obtained by deleting all the places marked

by the initial marking contains no circuits, and a live

MG is also reversible (Campos et al., 1992).

Accordingly, the proposed approach initially

transforms a given deadlock-free schedule into a live

and reversible MG.

Consider the schedule of three jobs on three

machines shown in Figure 2.

Figure 2: Schedule of illustrative example.

The first step to transform such schedule into a MG

is to represent the processing route of each job by a

production Petri net (PPN) (Banaszak & Krogh,

1990). This PPN provides the sequence of places

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

330

and transitions that describe the flow of the job;

places represent the processing operations, and

transitions model the release and/or acquisition of

the corresponding machine(s). A token in these

places (flow places) indicates that a job is currently

holding the corresponding machine, either while

begin processed or while waiting for the next

machine in its route. To represent the sequence of

jobs visiting each machine as indicated by the

schedule, each transition representing the release of

a machine is connected to an additional place

(scheduling place) by an input arc. This place is then

connected by an output arc to the transition

representing the acquisition of the same machine by

the next visiting job. Accordingly, this machine will

not be assigned to the next job until it is released by

the current job (hold-while-wait condition). In order

to ensure the initiation and repetition of the

schedule, a token-occupied place is added between

the transition that releases the machine from the last

job in the visiting sequence, and the transition that

acquires the machine for the first job in the sequence

(Figure 3). Note that the resulting net is still a MG

and will henceforth be referred to as a scheduling

marked graph (SMG).

Figure 3: SMG of illustrative example.

The schedule shown in Figure 2 features a circular

wait that would eventually result in a deadlock

(Figure 3 contains three empty circuits). This

circular wait can be resolved by placing J

1

in the

buffer after completion on machine M

1

, and hence

expanding t

1-2

into a flow place p

1B

in-between two

new transitions, t

1-B

and t

B-2

. A token in p

1B

represents J

1

while residing in the buffer. Firing t

1-B

releases M

1

and places J

1

in the buffer, while firing

t

B-2

acquires M

2

and moves J

1

from the buffer.

Using a hybrid approach earlier proposed in

literature (DiCesare et al., 1993), through a series of

top-down and bottom-up steps, the obtained SMG

can then be augmented to represent the material

handling (robot) operations while preserving the

liveness and reversibility of the original SMG. Top-

down decomposition first divides each flow place

into two places with a transition in-between. The

first place models the robot while handling the job

and the second preserves the function of the original

flow place. In order to ensure that the robot is not

acquired simultaneously by more than one job, the

bottom-up aggregation step adds a robot place p

R

with one token to the SMG. This place is connected

with output arcs to transitions that model the

acquisition of the robot, and input arcs from

transitions that model its release. After applying

both steps, the augmented SMG (ASMG) can be

obtained as shown in Figure 4. In this figure, arcs

that connect p

R

to its associated transitions are

partially omitted and scheduling places along with

their corresponding arcs are represented by bold arcs

for the sake of clarity.

Figure 4: ASMG of illustrative example.

4 APPROACH VALIDATION

In order to validate the proposed approach, the

supervisors for two benchmark problems are

generated and simulated. Simulation entails

executing the corresponding ASMGs of the

problems to simulate the production process. The

selected problems are the ‘4 jobs x 3 machines’

problem introduced in Ramaswamy & Joshi (1996),

HIERARCHICAL PERFORMANCE-ORIENTED CONTROL OF FLEXIBLE MANUFACTURING CELLS

331

and a ‘6 jobs x 6 machines’ problem that can be

found in the OR library under the name ft06. The

instance selected for problem ‘4J x 3M’ features a

unit buffer capacity, and for problem ft06, no buffer

space is available in the system. The times required

to obtain the deadlock-free schedule using the

heuristic proposed in Fahmy et al. (2008) and

generate the corresponding ASMG for the 4Jx3M

and ft06 problems were 0.19 and 0.8 seconds,

respectively. In order to test the reversibility of the

supervisors, they were run for lot sizes of five parts

for each job type. The two ASMGs were executed,

and all the parts for all the job types for the two

problems were completed successfully. The two

ASMGs can now be implemented through a

computer, which can be connected to cell devices to

complete the required product mixes.

5 CONCLUSIONS

This paper has proposed an efficient hierarchical

scheduling and control architecture for FMCs. The

inputs to the proposed architecture are simply the

available resources in the system and the production

routes of the jobs to be produced. The output is a

readily implementable supervisor, capable of driving

the system to autonomously produce the required

products in a deadlock-free manner, according to the

best production schedule. The supervisor can further

be updated in real time to accommodate any changes

in the product mix, while preserving the optimized

performance of the system. The output of this work

can to some extent narrow the gap that exists

between scheduling and control literature of AMSs.

REFERENCES

Banaszak, Z. A., Krogh, B. H., 1990. Deadlock avoidance

in flexible manufacturing systems with concurrently

competing process flows. IEEE Transactions on

Robotics and Automation, vol. 6, no. 6, pp. 724-734.

Ben Abdallah, I., ElMaraghy, H. A., ElMekkawy, T.,

2002. Deadlock-free scheduling in flexible

manufacturing systems using Petri nets. International

Journal of Production Research, vol. 40, no. 12, pp.

2733-2756.

Campos, J., Chiola, G., Colom, J. M., Silva, M., 1992.

Properties and performance bounds of timed marked

graphs. IEEE Transactions on Circuits and Systems,

vol. 39, no.5, pp. 386-401.

Chu, F., Xie, X.-L., 1997. Deadlock analysis of Petri nets

using siphons and mathematical programming. IEEE

Transactions on Robotics and Automation, vol. 13, no.

6, pp. 793-804.

DiCesare, F., Harhalakis, G., Proth, G. M., Silva, M.,

Vernadat, F. B., 1993. Practice of Petri nets in

manufacturing. Chapman & Hall, London.

Ezpeleta, J., Colom, J. M., Martinez, J., 1995. A Petri net

based deadlock prevention policy for flexible

manufacturing systems. IEEE Transactions on

Robotics and Automation, vol. 11, no. 2, pp. 173-184.

Fahmy, S. A., ElMekkawy, T. Y., Balakrishnan, 2008.

Deadlock-free scheduling of flexible job shops with

limited capacity buffers. European Journal of

Industrial Engineering, vol. 2, no. 3, pp. 231 – 252.

Fanti, M. P., Zhou, M., 2004. Deadlock control methods in

automated manufacturing systems. IEEE Transactions

on Systems, Man, and Cybernetics, vol. 34, no.1, pp.

5-32.

Golmakani, H. R., Mills, J. K., Benhabib, B., 2006.

Deadlock-free scheduling and control of flexible

manufacturing cells using automata theory. IEEE

Transactions on Systems, Man, and Cybernetics, vol.

36, no.2, pp. 327-337.

Hsieh, F.-S., Chang, S.-C., 1994. Dispatching-driven

deadlock avoidance controller synthesis for flexible

manufacturing systems. IEEE Transactions on

Robotics and Automation, vol.10, no. 2, pp. 196-209.

Lee, D. L., DiCesare, F., 1994. Scheduling flexible

manufacturing systems using Petri nets and heuristic

search. IEEE Transactions on Robotics and

Automation, vol.10, no. 2, pp. 123-132.

Li, L., Jiang, Z., 2006. Formal design and analysis of a

hybrid supervisory control structure for virtual

production systems. International Journal of

production Research, vol. 44, no.13, pp. 2479-2497.

Liljenvall, T., 1999. Scheduling for production systems

with limited buffers. Proceedings of the IEEE

International Conference on Systems, Man, and

Cybernetics, vol. 6, pp. 469-474.

Mati, Y., Rezg, N., Xie, X., 2001. Geometric approach

and Taboo search for scheduling flexible

manufacturing systems. IEEE Transactions on

Robotics and Automation, vol. 17, no. 6, pp. 805-818.

Ramadge, P. J., Wonham, W. M., 1987. Supervisory

control of a class of discrete event processes. Siam J.

Control and Optimization, vol. 25, no. 1, pp. 206-230.

Ramaswamy, S. E., Joshi, S. B., 1996. Deadlock-free

schedules for automated manufacturing workstations.

IEEE Transactions on Robotics and Automation, vol.

12, no.3, pp. 391-399.

Sun, R.-L., Li, H.-X., Xiong, Y., 2006. Performance-

oriented integrated control of production scheduling.

IEEE Transactions on Systems, Man, and Cybernetics,

vol. 36, no. 4, pp.554-562.

Viswanadham, N., Narahari, Y., Johnson, T. L., 1990.

Deadlock prevention and deadlock avoidance in

flexible manufacturing systems using Petri net models.

IEEE Transactions on Robotics and Automation,

vol.6, no. 6, pp. 713-723.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

332