MasDISPO xt

Process

Optimisation by Use of Integrated, Agentbased Manufacturing Execution

Systems Inside the Supply Chain of Steel Production

Sven Jacobi

Saarstahl AG, Hofstattstrasse 106, 66330 V

¨

olklingen, Germany

Christian Hahn, David Raber

German Research Center for Artificial Intelligence, Stuhlsatzenhausweg 3, 66123 Saarbr

¨

ucken, Germany

Keywords:

Intelligent Agents, Industrial Application of Artificial Intelligence, Decision Support Systems.

Abstract:

The production of steel normally constitutes the inception of many supply chains in different areas of industry.

Steel manufacturing companies are strongly affected by bull whip effects and other unpredictable influences

along their production chains. Improving their operational efficiency is required to keep a competitive position

on the market. Hence, flexible planning and scheduling systems are needed to support these processes, which

are based on considerable amounts of data, hardly processable manually anymore. MasDISPO

xt

is an agent-

based generic online planning and scheduling system for the observation on MES-level of the complete supply

chain of Saarstahl AG, a globally respected steel manufacturer. This paper concentrates on the horizontal and

vertical integration of influences of rough planning on detailed and the other way around. Based on model-

driven engineering business processes are modeled on CIM-level, a service oriented architecture is presented

for the interoperability of all components, legacy systems and others wrapped behind services. Finally, an

agent-based detailed planning and scheduling ensuring interoperability in horizontal and vertical direction is

approached effectively.

1 INTRODUCTION

The production chain of Saarstahl AG consists of a

multitude of specialised and complex metallurgical

manufacturing processes with a lot of dependencies

among them. First, a blast furnace factory produces

hot metal from iron ore, coke and limestone as raw

materials for the steel production. In fixed intervals

distributed over the day, a determined quantity of hot

metal is sent by rail to the steel works for the next pro-

duction step. Inside the melting shop, steel of differ-

ent quality grades is produced, according to concrete

customer orders and requirements. It is cast at contin-

uous casting plants into billets. Afterwards, these bil-

lets are delivered to the rolling mills. Here, steel bars

or wire rods of different shapes and formats are pro-

duced. In fixed, cyclic rolling campaigns of limited

capacities certain formats are produced. After rolling,

follow-up manufacturing steps concerning steel bars

are arrangement, pickling, annealing and saw cutting;

wire rods probably need a annealing and a pickling.

Finally, the products are delivered to the customers

– mostly suppliers of the automotive, shipbuilding or

aerospace sectors.

MasDISPO

xt

schedules the execution of each

concrete order along the production chain. It monitors

production on a rough—in weeks—and detailed—in

days and hours—level, and executes an online de-

tailed planning and scheduling for the different man-

ufacturing steps in each single factory. It has to detect

problems in the production and handle them in order

to return to normal production. The rough working

plan for each manufacturing level is calculated on de-

mand, before final order commitment.

The overall process chain is characterized by

changes in customer orders and it is affected by pro-

duction setbacks or problems. Therefore, steel manu-

facturing companies must be flexible and dynamic, by

adapting production plans fast in order to meet cus-

tomer requirements while still being cost-efficient.

These are requirements which need to be covered

in almost every industrial sector, hence, there are a lot

of commercial systems handling this. Existing solu-

tions are dominated by centralized decision making

347

Jacobi S., Hahn C. and Raber D. (2009).

MasDISPO_xt - Process Optimisation by Use of Integrated, Agentbased Manufacturing Execution Systems Inside the Supply Chain of Steel Production.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Artificial Intelligence and Decision Support Systems, pages

347-350

DOI: 10.5220/0001996503470350

Copyright

c

SciTePress

processes, mostly data driven and often not modeling

the business processes they should. ERP systems like

APO (Bartsch and Bickenbach, 2002) or APS (Ad-

vanced Planning and Scheduling) are suitable for a

rough planning, only. Big software companies have

adopted the strategy to provide integration mecha-

nisms for MES-level solutions (SAP, 2004) like the

presented solution.

MasDISPO xt, a decentralised agent based ap-

proach, is the proposed solution of this paper. In Mas-

DISPO xt, every order is modeled as an agent. The

agent calculates and observes its own schedule from

order entry, across rough and detailed planning, and

monitors the production up to the point of delivery.

It responds to changes during planning, scheduling

and production by dynamically adapting the sched-

ules. Also, each aggregate of any factory is also mod-

eled as an agent which also calculates its schedule au-

tonomously based on further local knowledge and re-

strictions.

The complete production chain is very complex

and could not be addressed with the appropriate de-

tail in the context of only one paper. Therefore, this

paper concentrates on the horizontal and vertical in-

tegration of solutions provided for detailed planning

into a global perspective regarding rough planning

and the other way round. As a presetting, rough plan-

ning influences detailed planning and vice versa a re-

arranged detailed planning might impact the rough

layer – probably on several manufacturing levels. Ex-

isting ERP solutions cannot provide such integrations

very suitable – the motivation for the presented ap-

proach.

2 PLANNING AT SAARSTAHL AG

Steel production in general is a very complex, dy-

namic and disassembling process. It starts inside the

blast furnace as hot metal and ends up in vast number

of products of different kinds. On each manufacturing

step, there are lots of restrictions regarding quality,

size, dimension and others which determine the cam-

paigns and batch units on each processing step. Of

course, time restrictions also have to be kept. Hence,

a delay on a certain step might have cascading effects

along different branches of further processing. As

mentioned, the average order backlog of Saarstahl is

about 17500 – each order composed of several order

position and each position with up to 50 processing

steps. Hence, it is a challenge to keep planning and

scheduling under control.

Competitive orientation concerning product con-

cepts, technology and others are discussed per annum

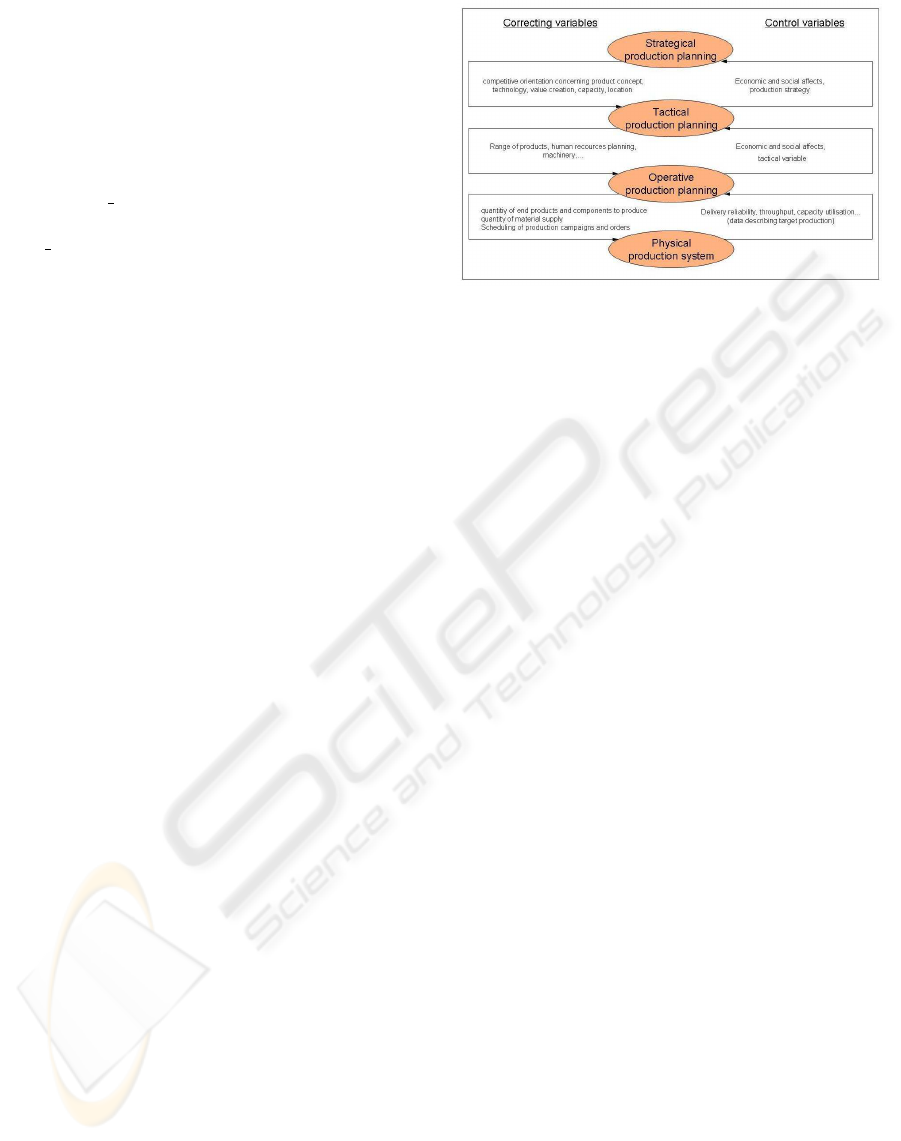

Figure 1: Control Cycle of planning influences and depen-

dencies.

and give a direction for human resource planning or

machinery on a tactical level. In planning levels re-

garding sales, the global production capacities for the

different production phases are booked. After that,

the planning process continues by planning at lower

levels. For each factory, the global planning level pro-

vides the lower level with a set of orders for a speci-

fied time horizon. These assigned orders are planned

in more detail while going down in planning levels

down to physical production systems. All these in-

fluences are correcting variables from ’above’ often

given just once.

On the other hand, physical production systems

might have any delays which has to adopted by

the planning system above. Delivery reliability or

throughput are measured constantly and influence the

next level above. These control variables go up to the

strategical planning on highest level. A cycle of inter-

dependencies as shown in figure 1 is created. Flexibil-

ity across these different layers is needed to guarantee

a flexible planning and production process.

The planning horizon on highest level is quite

rough, the closer it gets down to production the

shorter the horizon is. To realise this exchange of in-

formations, smooth interfaces between the acting sys-

tems are needed. On a higher level planning level,

usually normal ERP-systems are used. These systems

probably also support also provide a adavnced plan-

ning system (APS) for a rough planning. Beneath, a

so called MES is used for a detailed planning. The

last level is the automation level covered by ’SPS’

or ’SCADA’ (Supervisory Control and Data Acqui-

sition). A smooth vertical integration of these acting

systems is needed to guarantee a fast exchange of in-

formations which is especially needed in steel pro-

duction since materials are often molten between two

different processing steps and might not cool down.

Saarstahl is a historically grown company. Hence,

a lot of obsolete legacy systems are running. In-

ICEIS 2009 - International Conference on Enterprise Information Systems

348

tegrations as described above are especially regard-

ing dynamic aspects viable unsatisfying by exist-

ing, commercial approaches. Driven by this need

Saarstahl decided to develop own solutions and par-

ticipate in research projects like the European funded

project ’SHAPE’ (Semantically-enabled Heteroge-

neous Service Architecture and Platforms Engineer-

ing) (SHAPE, 2008) dealing with these problems.

2.1 Solution

The main idea in order to be in a position of handling

these problems is to model each single order posi-

tion as a software agent. Every single compolo agent

(comission - position - lot) calculates and observates

its own schedule from order entry until invoicing. In-

stead of handling a vast number of restrictions sub-

ject to the manufacturing step in general only a few

of which are relevant for a single order position are

handled by the entity autonomously. A decentralised

management of manufacturing control is received in-

stead of a centralised, data driven approach.

Definition 1. Having a finite set of factories F with

elements f

i

, where f

i

is the factory number i, aggre-

gates A with elements a

j

, where a

j

is the factory num-

ber j

F = { f

1

, . . . , f

n

} n ∈ N

A = {a

1

, . . . , a

m

} m ∈ N

O being the finite set of all orders to be planned, with

elements identified with the letter o,

O = {o

1

, . . . , o

q

} q ∈ N

L

i

being the ordered list of elements of A which are the

suitable aggretates for order o

i

in order of preference,

L

i

= {a

x

, . . . , a

y

}

where

| L

i

|≤ n; i = 1, . . . , q;

a

x

∈ L

i

∧ a

y

∈ L

i

∧

a

x

precedes a

y

in the list L

i

⇒

a

x

is preferable over a

y

for order o

i

L being the collection of preferences for all orders:

L = {L

1

, . . . , L

q

}

and the functions C, being the function which asso-

ciates an aggregte to its associated available capac-

ity for a given period, and c, the function which as-

sociates each order to its required capacity on an ag-

gregate,

C : M → N

c : O → N

the top level plannning problem for assinging aggre-

gates can be defined as the search for a set P that

associates each order in O to aggregates in A follow-

ing the preferences provided by L and making sure

that the sum of all sizes provided by c(x) of the orders

associated to a specific furnace do not exceed the fur-

nace’s specific maximal capacity C(a

j

):

P = O × A

where

∀a

j

∈ A :

∑

x∈{o|(o,a

j

)∈P }

c(x)

< C(a

j

) .

A solution P is produced by searching for each

order o

i

∈ O (sorted by arrival date) a factory f

i

∈ F

and an aggregate a

j

∈ A with available capacity, fol-

lowing the list L

i

. Furthermore, S

o

q

is the finite set

of processing steps with elements s

k

, where s

k

is the

step number k necessary to meet customer require-

ments according o

q

. H is the function assigning the

number of different factories along the process chain

of each single order position.

S = {s

1

, . . . , a

l

} l ∈ N

H : S

o

q

× S

o

q

→ N,

h(s

k

, s

k+1

) 7→

½

0 : f (a

s

k

) = f (a

s

k+1

)

1 : f (a

s

k

) 6= f (a

s

k+1

)

;

f (a

s

k

) maps step s

k

on aggregate a

s

k

to factory i

min

∑

S

o

q

∑

k

h(s

s

k

,s

k+1

)

By minimizing this function transportation costs will

be optimised. Of course, this is not the single ob-

jective. Along the complete process chain, there are

several and also conflicting goals. But this is not ad-

dressed in this paper.

This general definition is valid across the complete

supply chain for every single order position in each

local subsystem. Additional restrictions and others

are takeninto account while going down on more de-

tailed level. The degree of detailedness also define the

framework for information exchange. The goal is to

exchange the least data as possible but at least what is

necessary to guarantee transparency as demanded.

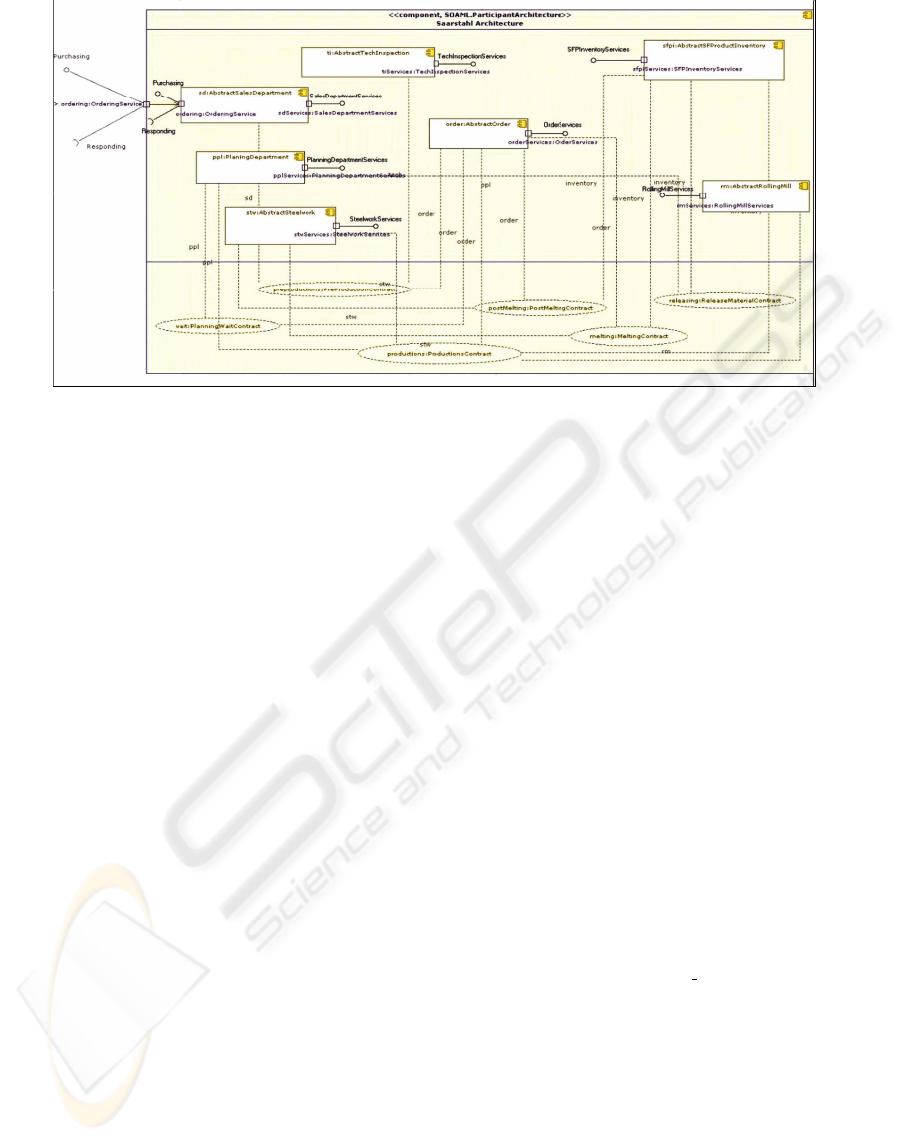

How are existing legacy systems be integrated into

workflow and how are interactions realised? This

is solved by use of a Service Oriented Architecture

(SOA). An extract of the complete process chain is

choosen to explain the approach in more detail. The

extract concentrates on the phase of production report

of the steelwork until preparation of rolling. In this

phase, all compolo agents release semi finished prod-

ucts of the steelwork in order to find potential better

assignments especially concerning time and quality.

MasDISPO_xt - Process Optimisation by Use of Integrated, Agentbased Manufacturing Execution Systems Inside the

Supply Chain of Steel Production

349

Figure 2: Service Oriented Architecture of Saarstahl AG.

The planning process is formalized via busi-

ness process modeling notation (BPMN) using ARIS

(IDS Scheer AG , 2008) on computation-independent

model (CIM level). A model transformation to PIM

level (platform-independent model) is done using

SOAML (OMG, 2008). Another model transforma-

tion is done on PIM level to PIM4Agents (Hahn et al.,

2007). The metamodel of agent aspect is centered

on the concept of an agent, the autonomous entity

capable of acting in a specified environment. The

last transformation is going down to platform specific

model (PSM). On this layer, a detailed planning as

described in (Jacobi et al., 2007) is fulfilled.

Since there are a lot of legacy systems running, in-

formation exchange between these systems has to be

arranged. On each level certain services are already

specified. A service oriented approach is straightfor-

ward. Legacy systems are wrapped behind services.

Figure 2 depicts an extract of the generated service

oriented architecture for the described phase.

3 CONCLUSIONS

A need for flexible integrated planning systems with a

clear workflow and a fast information exchange is un-

deniable. By use of a SOA, vertical integration but

also horizontal integration of information exchange

is eased. Response times are reduced by use of ser-

vices provided by orders or aggregates both modeled

as agents. Informations are exchanged without de-

tours anymore. No informations are lost, because ser-

vices are embedded in specified protocols which en-

sure completeness.

The described examples of this paper state a sub-

set of the different problems which need to be solved

along production inside the supply chain. An auto-

matic and responsive planning system is needed. The

decentralised approach with multiagent systems make

the system easier to handle, really models the de-

manded business processes and is able to manage the

huge data amount along production – requests which

are not always met by the existing centralised ap-

proaches. By use of SOA, a more flexible environ-

ment easily to extent is received.

REFERENCES

Bartsch, H. and Bickenbach, P. (2002). Supply Chain Man-

agement mit SAP APO. SAP Press, 2nd ed.

Hahn, C., Madrigal-Mora, C., and Fischer, K. (2007). Inter-

operability through a platform-independent model for

agents. Proc. 3rd Inter. Conference on Interoperabil-

ity for Enterprise Software and Applications (I-ESA

2007).

IDS Scheer AG (2008). Aris. http://www.ids-

scheer.com/en/ARIS/ARIS Software/3730.html.

Jacobi, S., Leon-Soto, E., Madrigal-Mora, C., and Fischer,

K. (2007). Masdispo: A multiagent decision support

system for steel production and control. AAAI Inno-

vative Applications of Artificial Intelligence.

OMG (2008). Service oriented architecture modeling

language (soaml) - specification for the uml pro-

file and metamodel for services (upms). http://

www.omg.org/docs/ad/08-08-04.pdf.

SAP (2004). Integration von mes-systemen in sap for mill

products.

SHAPE (2008). Semantically-enabled heterogeneous ser-

vice architecture and platforms engineering. http://

www.shape-project.eu.

ICEIS 2009 - International Conference on Enterprise Information Systems

350