AGENT-BASED MODELING AND SIMULATION OF RESOURCE

ALLOCATION IN ENGINEERING CHANGE MANAGEMENT

Bochao Wang and Young B. Moon

Departement of Mechanical and Aerospace Engineering, Syracuse University, Syracuse, NY 13244, U.S.A.

Keywords: Engineering Change Management, Agent-based Modeling and Simulation, Resource Allocation.

Abstract: An engineering change (EC) refers to a modification of products and components including purchased parts

or even supplies after product design is finished and released to the market. While any company involved in

product development would have to deal with engineering changes, the area of engineering change

management hasn't received much attention from the research community. It is partly because of its

complexity and lack of appropriate research tools. In this paper, we present preliminary research results of

modeling the engineering change management (ECM) process using an agent-based modeling and

simulation technique. The aim of the research reported in this paper is to study optimal strategies of

resource allocation for a company when it is dealing with two kinds of ECs: "necessary ECs" and

"initialized ECs." We discuss results from these simulation models to illustrate some insights of ECM, and

present several research directions from these results.

1 INTRODUCTION

Any company involved in product development

would have to deal with engineering changes. An

engineering change (EC) refers to a modification of

products and components including purchased parts

or even supplies after product design is finished and

released to the market (Lee 2006), (Clark &

Fujimoto, 1991), (Huang, Yee & Mak, 2003),

(Terwiesch & Loch, 1999), (Chen 2002, DEC et al.

1998). ECs may be initiated by customers, suppliers,

or the company itself.

While EC management is a complex task, the

increasing market competition forces the companies

to take a more pro-active role in handling the

engineering changes. In a sense, any engineering

change is a disruption to a normal operation. And it

may impact several functions across a company.

However, an effective and efficient management of

engineering changes can bring significant benefits to

company’s competitiveness (Rukta, 2006) by

satisfying its customers better and further improving

its products.

Despite of its importance, the area of engineering

change management hasn't received much attention

from the research community. Notable exceptions

are the works of Nadia (Nadia, 2006) and Terwisch

(Terwiesch, 1999). Nadia studied engineering

change orders (ECOs) thoroughly and even

identified key contributors to long ECO lead times

with improvement strategies advices. Terwiesch

compared the behavior of two methods of managing

an engineering change request (ECR) process.

The aim of the research reported in this paper is

to study optimal strategies of resource allocation for

a company when it is dealing with two kinds of ECs:

necessary ECs and initialized ECs. Necessary ECs

refer to those ECs dealing with must-to-do changes

to address problems such as technical problem,

manufacturing process or design fault. Initialized

ECs may arise from introducing new technology to

match competitors, to take the lead, to simplify or

improve manufacturing processes, or to

accommodate customers’ proposal. So the latter is

not mandatory but may bring potential benefits to

the company.

2 THE RESEARCH

METHODOLOGY

2.1 ABMS

ABMS (Agent-based Modeling and Simulation) is a

computational model for simulating the actions and

interactions of autonomous individuals in a network,

281

Moon Y. and Wang B. (2009).

AGENT-BASED MODELING AND SIMULATION OF RESOURCE ALLOCATION IN ENGINEERING CHANGE MANAGEMENT.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Artificial Intelligence and Decision Support Systems, pages

281-284

DOI: 10.5220/0001852302810284

Copyright

c

SciTePress

with a view to assessing their effects on the system

as a whole. It is a relatively new approach to

modeling complex systems (Macal, 2005) in order to

support decision-making (Nilsson, 2006) and obtain

deeper understanding of intrinsic regularity in a

system.

We adopted ABMS so that we can model ECM

activities (Garcia, 2005) affected by various factors

such as consumer bahavior, competitive or

cooperative relationship (Lam, 2007) among

companies, and different adaptive strategies by

manufacturers. These factors are quite difficult to be

modelled using other conventional simulation

modeling techniques.

2.2 Methodology

2.2.1 The Basic Model

The basic model was built to address a question:

what is the impact on customers' satisfaction level

when limited resources are allocated differently

between necessary EC and initialized EC. Some

simple properties and rules are given to agents, and

we expect aggregate macro-scale behaviours or

trends emerging from the self-adaptive and

interactions between agents.

2.2.2 Hypothesis

We came up with six hypotheses concerning EC

factors, then built models to see whether these can

be supported or not under certain circumstance. In

future, we plan to use real data to see its validation.

ECM Hypotheses

H1. The effectiveness of a company's ECM is

positively correlated with the firm's market share.

H2. The degree of co-operation between

manufacturers and suppliers is positively correlated

with the performance of the firm.

H3. Changing the ratio between initialized ECs

between necessary ECs may lead to a different result

in a short period time.

H4. Initialized ECs are not important in gaining

market share.

H5. The level of EC frequency is positively

correlated with customers' satisfaction.

H6. ECM results are different for different types of

industry.

3 MODEL DESCRIPTION

3.1 Agents and Behaviour Rules

Agents represent autonomous decision-making

entities that interact with each other and/or with their

environment based on a set of rules. In a reasonable

environment, every agent would get its necessary

information, make adjustments on its behaviour

following the rule through iterative learning, and

pursue a certain goal or objective. Specific agents

used in our models are described next.

3.1.1 Manufacturer Agent

Manufacturers make similar products in a same

industry. Besides arranging daily regular production,

they receive ECRs driven by customers as well as

themselves. Then they evaluate and make decisions

on whether an EC is a necessary EC or an initialized

EC. They implement and track ECs. Also they

obtain feedback from the market to adjust their

strategy.

Different types of manufacturers have different

rules to govern their behaviour. In our models, there

is one control manufacturer who keeps its strategy

constant. It depends only on feedback of market

share and adjusts the ratio of resources used for

necessary ECs vs. Initialized ECs in order to

determine how to get maximum profits. Another

type of manufacturer uses a feed forward strategy to

act. The third kind of manufacturer is an intelligent

manufacturer that memorizes prior decisions and

results and learns to perform best.

3.1.2 Consumer Agent

Consumers may propose ECRs, and consumer

satisfaction is based on price, other consumers’

opinions, product quality and the level of continuous

improvement in product. These rational consumers

take best offers with highest personal satisfaction

(Kano, 1984). The interactions between different

kinds of agents and among similar kinds agents lead

to an aggregate macro scale behaviours or emerging

trends.

3.1.3 Supplier Agent

Suppliers keep in close touch with a manufacturer,

and many ECs may need supplier’s help to reduce

EC cost and lead time, or improve efficiency.

However, these will cost extra communication and

research expenses. A manufacturer may choose to

cooperate with other suppliers or not, considering

ICEIS 2009 - International Conference on Enterprise Information Systems

282

their potential profits as in the prisoners’ dilemma

scenario.

3.2 EC comparison

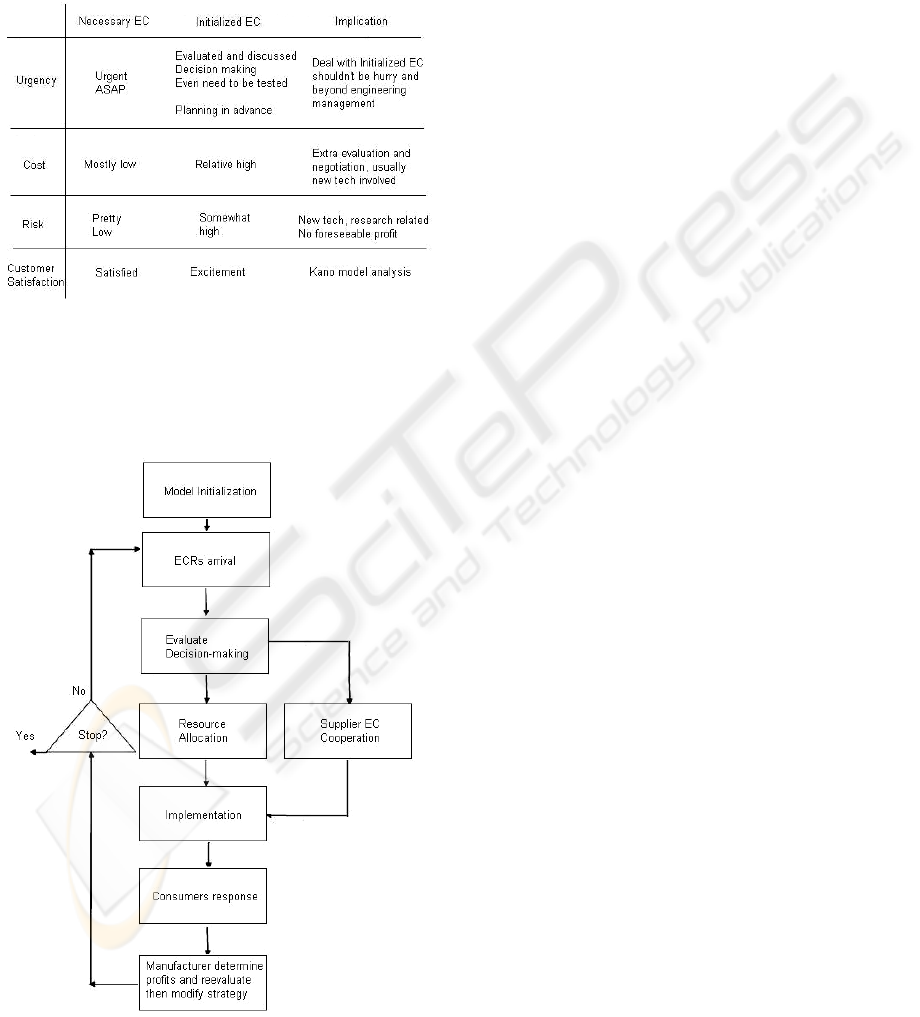

A summary of characteristics of two kinds of EC

(necessary EC and initialized EC) is given in Fig. 1.

Figure 1: Comparison of two kinds of ECs used in models.

3.3 Model Procedure

Figure 2 shows a general procedure used in the

models.

Figure 2: General model procedure.

First, we initialize the population of manufacturers

and consumers. Also, we determine the

manufacturers’ initial resource allocation value with

adaptiveness that limits the range of allocation

adjustment.

Every consumer has some probability to buy a

certain kind of product regardless of its vendor, and

the probability varies depending on people and

products. We also inject some influencing

consumers whose opinions have more weights on

other consumers.

An initial risk is determined based on different

industries’ attributes, but it can be changed during

simulation.

We take ECM tool quality and components

standardization into consideration in ECM attributes.

There exists one variable called "competition

degree" that means how fast potential manufacturers

may grow and enter into this market for competition,

and of course along with potential bankruptcy.

Output displays show the status of manufacturer

resource allocation of initialized ECs, market share

ratio comparison, profit comparison, number of

consumers who prefer initialized ECs. An agent map

shows consumer inclination switch by color change.

4 RESULTS

4.1 Preliminary Observations

The model results show that the initial ratio of

allocation plays a significant role. If one

manufacturer cannot obtain accurate information of

consumers’ preference or inclination unlike its

competitor, the performance in terms of market

share is very poor. Early bird catches the worm.

However, if other conditions are similar or the

same, a manufacturer a backward strategy may catch

up with others and even dominate the market. A feed

forward strategy works to some extent, but the

efficiency rely on initial difference between

forecasted data with real data. Intelligent agent

always performs best, since it obtains the advantage

of the pervious two strategies, makes distinctive

approach from learning experience. The strategy to

stay unchanged usually results in the worst

performance.

ECM tool and standardization play important

roles in EC process. A higher implementation level

of these can help to increase profits and market share

of the manufacturer. However, the model results

show that the significance of such ECM tool and

AGENT-BASED MODELING AND SIMULATION OF RESOURCE ALLOCATION IN ENGINEERING CHANGE

MANAGEMENT

283

standardization are not so great. Since an initial

strategy determines whether a manufacturer receives

the right information of trend from consumers, the

adaptability (Weiss, 1996) is the key for catching up

with a market leader and for keeping its market

share as well as its loyal consumers.

Other influencing factors such as advertisement,

consumers’ forum, etc., seem to make the

manufacturer easier to dominate the market if their

products attract most of the consumers in the

beginning. However, it does not mean that this

situation cannot be altered, even though the change

seems to be pretty hard. The difficulty for one

manufacturer to snatch the dominator position is

positively correlated with the value of influence-

probability.

Competition become much more fierce when

potential manufacturers' market shares grow at a

faster speed and are aggressive such as certain

suppliers who want to expand to become a

manufacturer. Eliminating manufacturers who

occupy very limited market share with low profit

through competition happens easily.

4.2 Conclusions on the Hypotheses

In this Section, the six hypotheses that we posed in

Section 2 are assessed based on the simulation

results.

H1. An effective ECM brings low cost and high

efficiency to a company, which leads to higher

profits and market share.

H2. Our model focused on the relationship

between supplier & manufacturer using the game

theory of prisoner’s dilemma to see the consequence.

A higher level of cooperation helps both of them,

but especially the manufacturer.

H3. The ratio between initialized ECs and

necessary ECs tells what a manufacturer emphasizes.

However, the impact is observable only after some

time.

H4. Initiated EC may or may not be a major

contributor toward gaining market share, depending

on the circumstances such lead time. If a lead time

for EC implementation is relatively short, the

initialized EC makes little impact. However, if

competition is intense enough, the pressure from the

market and competitors may force manufacturer to

make initialized ECs more frequently, thus giving

consumers more satisfaction.

H5. Up to a certain point, increasing EC

frequency helps to attract more loyal consumers.

However, very frequent ECs introduce more

disruptions to the manufacturing system leading to

worse performance in market share gain.

H6. We considered EC risk, EC lead time and

EC complexity to differentiate different industries. A

high risk causes two extreme phenomena.

Manufacturers may gamble to pursue profits even

though they are sometimes temporary profit. Or they

may stay with a conservative strategy to keep

foreseeable market share. While at low EC risk, the

competition is being encouraged.

5 CONCLUSIONS

The model results confirm that it is useful to classify

ECs into initialized ECs and necessary ECs. Also,

the competitive nature of a market influences how a

firm should emphasize necessary EC vs. initialized

EC. The greater the competitions are, the greater the

need to emphasize initialized ECs exists. The

situation will necesseciate the adoption of new

technologies that promote customer satisfaction to

excitement rather than just satisfaction.

Another interesting result is that intelligent

manufacturer who combines forecasting and

feedback strategy and learns from past experience

performs best in most cases. Still, adaptive feed

forward and feedback strategy works even better in

some cases. A possible explanation for this

phenomenon is that even though intelligent

manufacturer learns from past, some changes happen

without any foreseeable notices. As a result, the

adaptive ones outplay intelligent ones since they

simply rely on difference between expectation and

reality.

REFERENCES

Garcia R., 2005. Uses of Agent-Based Modeling in

Innovation/New Product Development. Journal of

Product Innovation Management, 2005, Vol 22, 380-

398.

Macal C., North M., 2005. Tutorial on agent-based

modeling and simulation, Proceedings of the 2005

Winter Simulation Conference, 2005, 2-15.

Moon, Y.B., 2007. Enterprise Resource Planning (ERP): a

review of the literature, International Journal of

Management and Enterprise Development, Vol. 4, No.

3, 2007, pp. 235-264.

Nadia B., Gregory G., Vince T., 2006.Engineering change

request management in a new product development

process, European Journal of Innovation Management

Vol. 9 No. 1, 2006, 5-19.

ICEIS 2009 - International Conference on Enterprise Information Systems

284