MICROCOMPUTERIZED SYSTEM TO ASSESS THE

PERFORMANCE OF LUNG VENTILATORS

Daniel Marinho Silva

Biomedical Engineering Institute, Federal University of Santa Catarina, 88040 – 900, Florianópolis, SC, Brazil

Maurício Campelo Tavares

Biomedical Engineering Laboratory, Catholic University of Pelotas, campus I, 96010-000, Pelotas, RS, Brazil

Raimes Moraes

Electrical Engineering Department, Federal University of Santa Catarina, 88040 – 900, Florianópolis, SC, Brazil

Keywords: IEC 60601-2-12, NBR 13763, Bluetooth, Clinical engineering, Maintenance.

Abstract: Lung ventilators may harm patients if they are not properly calibrated. Therefore, they must be periodically

assessed to verify if the supplied volume and pressure match the ventilatory settings. This paper presents a

system based on a microcomputer to assess the performance of lung ventilators. The hardware of the

developed system contains three modules: transducer, conditioning and acquisition. The transducer module

converts, to electrical signals, the pressure and flow waveforms supplied to a lung simulator by a lung

ventilator. It also supplies digital measurements of temperature and relative humidity (RH). The

conditioning module amplifies and filters the pressure and flow signals. The acquisition module reads the

digital measurements (temperature and RH) and carries out the analog to digital conversion of the

conditioning module outputs, sending these data to the microcomputer via radio-frequency. Software

written in C++ shows the acquired waveforms on the PC screen and calculates the parameters required by

the IEC 60601-2-12. Data on the lung ventilator model, the sampled waveforms and the calculated

parameters are stored in a database, allowing the equipment follow-up. Comparative result of tests carried

out with the developed system and with commercial equipment is presented.

1 INTRODUCTION

Lung ventilators (LVs) supply air to patients that are

unable to breathe spontaneously, for instance, due to

chronic obstructive pulmonary disease, acute lung

injury, anesthesia or neurological disorder.

Therefore, they are widely used in intensive therapy

units (Pierce, 1995).

The LVs are built according to the IEC 60601-2-

12 that establishes the requirements needed to

minimize patients and operator risks (International

Electrotechnical Commission, 2001).

Since the LVs are used in critical clinical

situations, they must be periodically assessed to

verify if their performances were not degraded over

time, that is, if the supplied values match the

ventilatory settings on the LV. Besides, lungs may

be harmed by high airway pressure and high tidal

volume (Ricard et al., 2003; Wrigge et al., 2004;

Fernández-Pérez et al., 2006).

Therefore, it is very important to implement a

quality control program for LVs in order to avoid

patient injury.

Nevertheless, quality control programs in

developing countries are hampered by the high cost

of performance analyzers. Very often, heavy taxes

make the importation of these analyzers prohibitive,

preventing proper maintenance.

This work describes a lower cost LV analyzer

based on a PC microcomputer. It consists of an

electronic device to sample pressure, flow,

temperature and humidity. The sampled data are

sent, via radio-frequency, to a computer where the

waveforms are shown in real time. Parameters to

161

Marinho Silva D., Campelo Tavares M. and Moraes R. (2009).

MICROCOMPUTERIZED SYSTEM TO ASSESS THE PERFORMANCE OF LUNG VENTILATORS.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 161-166

DOI: 10.5220/0001432101610166

Copyright

c

SciTePress

evaluate the LV are calculated. All data are stored in

a database.

2 MATERIALS AND METHODS

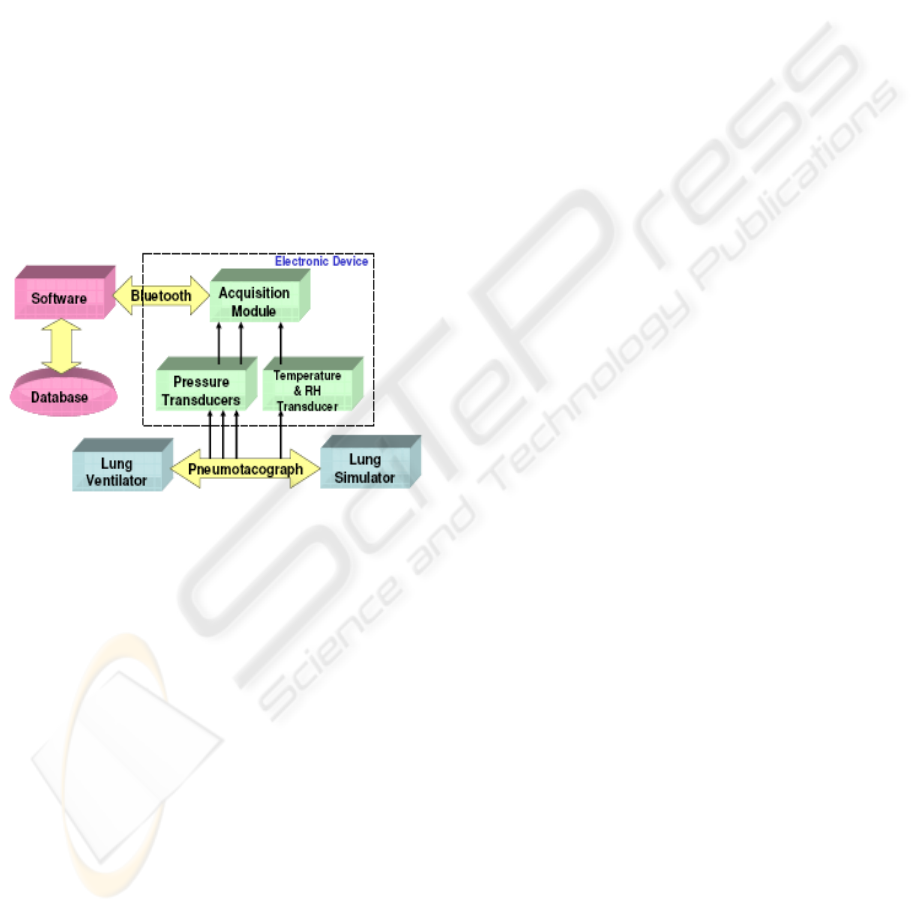

The Figure 1 depicts a block diagram of the

developed system and shows how it is connected to

the LV and lung simulator (LS). The LS acts as a

physiological load (resistance and compliance) for

the LV under assessment.

The developed system consists of an electronic

device that periodically measures the temperature

and relative humidity (RH) of the air inside the duct

that connects the LV to the LS as well as the flow

and the pressure waveforms generated by the LV.

The acquired data are sent to a PC microcomputer

via radio frequency (RF). The PC shows the sampled

data on the screen as well as parameters required by

the IEC 60601-2-12.

Figure 1: Block diagram of the system developed to assess

LV performance. It also shows how the system is

connected to the LV and LS.

The next sections describe each block of the

developed system.

2.1 Transducer Module

The transducer used to measure temperature and

relative humidity (RH) is the SHT75 (Sensirion Inc,

2007). It measures temperature from -40 to 123.8°C

(accuracy: ±0.5°C; resolution: 0.01°C) and RH from

0 to 100%RH (accuracy: ±1.8%RH; resolution:

0.03%RH). These transducers have a calibration

certificate issued by the manufacturer.

Due to its small size (0.42 x 4.88 x 2.5 mm), it is

possible to insert the transducer into the air duct that

connects the LV to the LS.

The SHT75 yields the measurements in digital

format (14 bits) via a 2-wire protocol. This is a

bidirectional protocol that allows the sensor to

receive data such as commands to carry out the

measurements.

Before connecting the LV to the LS, the sensor is

exposed to the environment, allowing the system to

register the local temperature and RH.

To sample the flow and pressure produced by the

LV, two DC030NDC4 pressure transducers are used

(Honeywell Inc., 2008). The DC030NDC4 measures

the differential pressure applied to its inputs in a

range of ±76.2cmH

2

O. It has a sensitivity of

52.36mV/cmH

2

O, producing a voltage output of

2.25V ± 2.0V.

An acrylic apparatus containing an obstacle is

placed between the LV and LS to create resistance to

the gas flow (pneumotacograph - PT). The pressure

drop across the resistance, measured by one of the

transducers, is proportional to the flow velocity

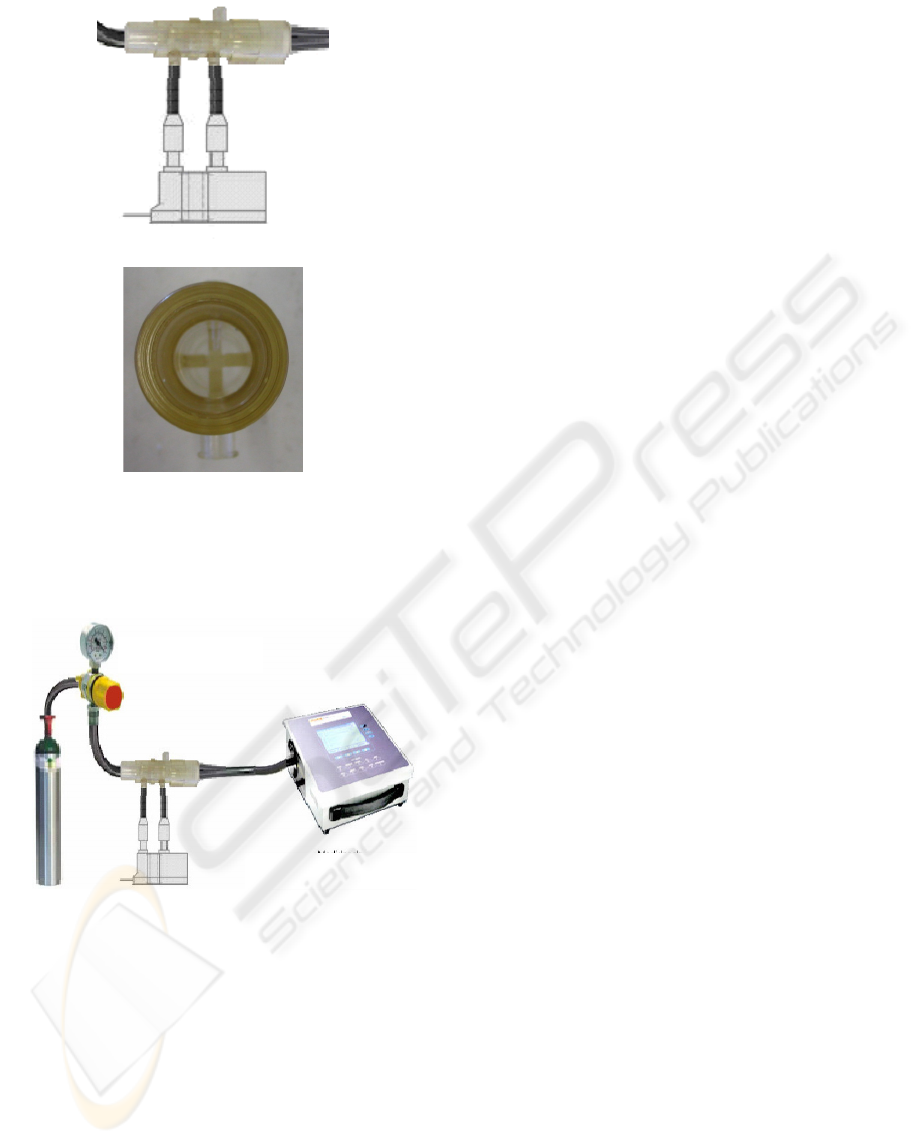

(Doeblin, 1990). The Figure 2 shows how the

transducer inputs are connected to the PT apertures

as well as a front view of the flow resistance. The

pressure drop is positive for inspiratory flow and

negative for expiratory flow.

To relate the A/D converter voltage input (that is,

the amplified and filtered differential pressure

transducer voltage output) to flow, 40 different flow

rates (20 positive and 20 negative) were applied to

the PT and to a calibrated flow meter (Fluke

Biomedical VT-Plus; uncertainty of ±1,1l/min for

the -70 to +70l/min range). They were connected in

series to allow the comparison of their

measurements. An illustration of the experimental

setup is shown in Figure 3. A polynomial of seventh

order was fitted to the experimental points (voltage

input versus flow rate measured by the calibrated

meter) to allow inferring measures for flow rates not

evaluated. Using the polynomial, the flow

measurements obtained with the developed system

have an uncertainty of ±4.4l/min.

The second transducer, connected to a third

aperture of the acrylic device, measures the

difference between the atmospheric pressure and the

one within the air duct.

To calibrate this transducer, 35 pressure values

(from 0 to 37.1cmH

2

O) were applied to the

transducer and, in parallel, to a calibrated meter

(Fluke Biomedical BP-Pump 2; uncertainty:

±0.2cmH

2

O for a range from 0 to 120cmH

2

O). The

conditioned voltage output of the transducer (as

supplied to an A/D input) and the pressure readings

obtained from the calibrated meter were annotated.

From these values, a first order polynomial

between voltage and pressure was obtained.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

162

(a)

(b)

Figure 2: Diagram that shows how the pressure transducer

is connected to sample the flow waveform (a). Below (b),

there is a front view of the air resistance that provides a

pressure drop proportional to the flow velocity.

Figure 3: Experimental setup to calibrate the flow

measurements obtained with the developed system.

2.2 Conditioning Module

The electrical outputs of the pressure transducers

require further processing before being sampled.

Both signals are applied to second order Butterworth

low pass filters that have cut-off frequencies of

40Hz. For the expected ranges (pressure: 0 to

40cmH

2

O; flow: −70 to +70l/min), the output

amplitudes are adjusted to the input range of the

acquisition module (0 to 2.5V). For that, they are

amplified and shifted to positive values. The

achieved resolution is 50.0mV·(cmH

2

O)

−1

for the

pressure and 17.9mV·(l/min)

−1

for the flow.

2.3 Acquisition Module

A microcontroller (ADuC841, Analog Devices,

2003) samples the flow, pressure, temperature and

RH. The ADuC841 is an optimized single-cycle 20

MHz 8052 core that has an 8-channel analog input

multiplexer that feeds a 420 kSPS 12-bit ADC.

In this development, the ADuC841 timer is

programmed to sample the flow and pressure

waveforms at 160SPS.

For each set of 480 flow and pressure samples

acquired (3s), the microcontroller gets

measurements of temperature and RH from the

SHT75.

Since cables could cause difficulties for the

equipment handling, the sampled data are sent to the

computer via RF. For that, Bluetooth protocol was

chosen since it operates on the ISM band and does

not produce interferences in medical equipment

(Jones and Conway, 2005; Wallin and Wajntraub,

2004). The Bluetooth module employed is the KC-

21 (KCwirefree, 2007), configured for a 115.2kbps

transmission rate. The ADuC841 communicates

with the KC-21 via its serial interface. A transceiver

(SN74LVC1T45, Texas Instruments) was used to

convert the ADuC841 TTL levels to the low voltage

logic (3.3V) used in the KC-21 bus.

2.4 PC Software

The software, developed in C++ for Windows®,

receives data from the electronic device described

above and calculates parameters that are stored in a

database.

The communication between the PC and the

device is established by means of another Bluetooth

module (KC-210) inserted into a USB port

(Kcwirefree, 2006).

When the user starts the program, a form is

launched to be filled up with data on the LV

(manufacturer, serial number, model and others).

This form also receives information on the

environment under which the test is being performed

(temperature, RH, atmospheric pressure, measured

power supply) as well as on the qualitative

assessment of the equipment (maintenance condition

of power cord, switches, alarms and others).

All inserted data is stored into an open source

relational database system (PostgreSQL -

http://www.postgresql.org/) that has native

programming interfaces for C++.

Pneumotachograp

Calibrated

Regulating Valve

Gas Source Pressure

MICROCOMPUTERIZED SYSTEM TO ASSESS THE PERFORMANCE OF LUNG VENTILATORS

163

The database implemented has two tables: one to

keep the information on the LV assessed and another

to store the test data.

Using two tables, different tests carried out with

the same LV can be stored on the database without

the need of reinserting data for each test performed.

By gathering the data on a same database, the

operator can promptly identify any performance

change since the previous results are available.

After registering the equipment in the database, it

is necessary to click on a button to proceed to the

next form page where the LV operating settings are

typed. This second form also requires information

on the range and resolution of the meters available in

the LV control panel.

Another button is shown that, when clicked on,

sends a command to the acquisition module to start

the data sampling.

The software was developed according to the test

procedure adopted by this laboratory (Tolotti, 2004).

The LV is switched on to work in volume cycled

mode during 40 minutes. After that, three set of

measurements carried out at intervals of 5 minutes

are recorded.

From the received flow waveform, the software

computes the volume supplied to the LS. Three

curves (pressure, flow and volume) are shown on the

screen in real time while temperature and RH

measurements are updated at 3s intervals. To

accomplish that, the software employs the graphic

library Graphics32 that provides fast operations with

pixels and graphic primitives

(http://www.graphics32.org/).

At the end of each respiratory cycle, the software

calculates the following indexes: breathing

frequency (BF), inspiratory time (IT), expiratory

time (ET), inspiratory/expiratory ratio (IER), peak

inspiratory pressure (PIP), positive end-expiratory

pressure

(PEEP), mean airway pressure (MAP), peak

inspiratory flow (PIF), peak expiratory flow (PEF),

tidal volume (Vt) and minute volume (Vm).

After 5 minutes, the software automatically

records the values of all these parameters into the

database and warns the operator by means of a pop-

up window. When this occurs, the operator has to

read the LV meters and type these measurements to

be stored. This procedure is repeated twice at 5

minute intervals.

All these parameters and the three curves (one

minute interval) are stored into the database.

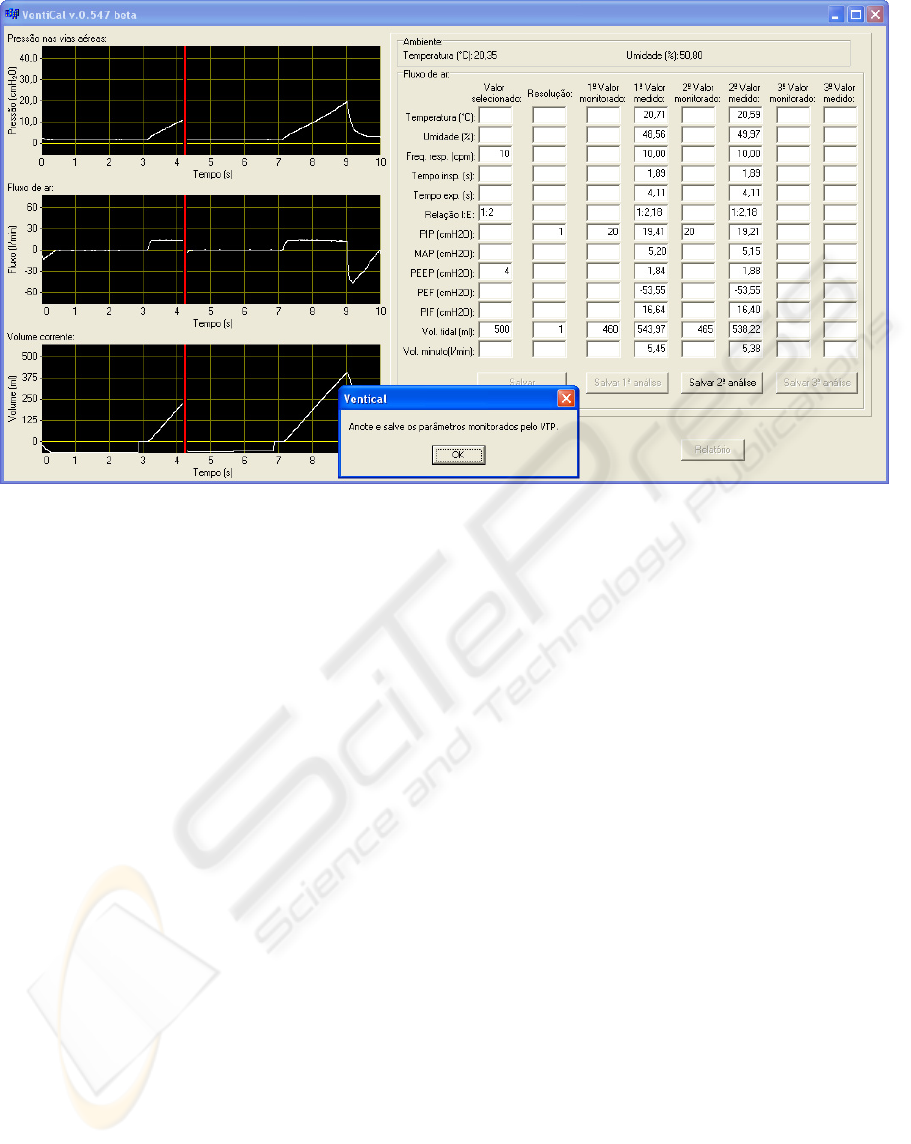

The Figure 4 gives an example of the waveforms

plotted on the screen as well as the fields filled up

with the data on the LV and indexes calculated by

the software.

A LV belonging to a public hospital was tested

using the developed system and a calibrated

commercial analyzer.

The test was carried out according to the

procedure proposed by Tolotti (2004). The LV was

working in volume-cycled mode (10 breaths/minute;

IER: 1:2; PEEP: 4cmH

2

O; Vt: 500ml).

3 RESULTS

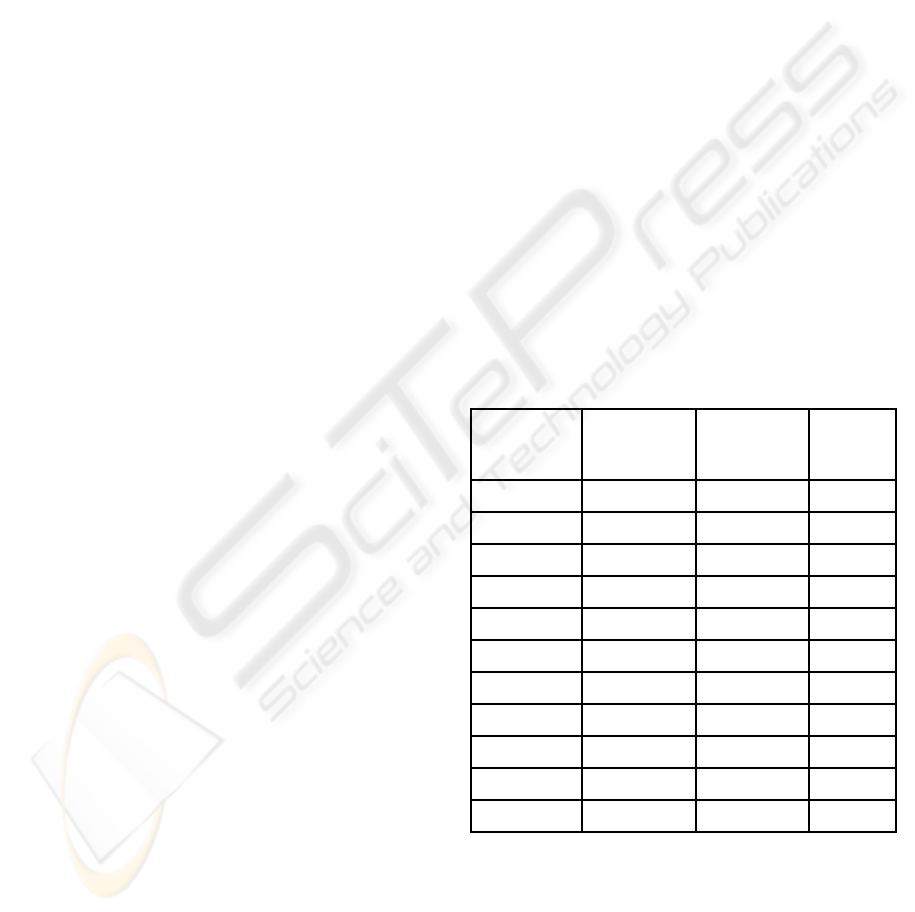

Table 1 shows the average of three sets of

measurements obtained with developed system (DS)

and with a calibrated commercial analyzer (CA).

The relative error was calculated using the CA

values as reference. Since the flow resistance may

affect the results, it was not acceptable to connect

the two equipments in series to the LV and LS.

Therefore, the measurements were separately carried

out with each analyzer.

Table 1: Average of three set of measurements obtained

with the developed system (DS) and the commercial

analyzer (CA). For the other acronyms, refer to the text.

Indexes

Averaged

Measurements

(CA)

Averaged

Measurements

(DS)

Relative

Error

BF(min

-1

) 10 10 0.00%

IT(s) 2.023 2.05 1.33%

ET(s) 3.963 3.953 −0.25%

IER 1:1.953 1:1.93 1.19%

PPI (cmH

2

O) 27.2 26.957 −0.89%

MAP(cmH

2

O) 8.8 8.843 0.50%

PEEP(cmH

2

O) 4.03 3.94 −2.23%

PEF(l/min) 48.34 54.89 13.54%

PIF(l/min) 20.61 20.63 0.10%

Vt(ml) 552.53 551.33 −0.22%

Vm(l/min) 5.537 5.517 −0.36%

Figure 4 exemplifies how the measurements and

sampled waveforms are obtained.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

164

Figure 4: Screen presented by the developed software after performing a second set of measurements. A pop-up window

asks to insert the LV meters readings. In the first column, the operator has to inform the LV settings and, in the second one,

the resolution of the available LV meters. The fourth, sixth and eighth columns will be automatically filled up by the

measured and calculated indexes. Each one is obtained 5 minutes apart from each other. The third, fifth and seventh are

filled by the operator with the readings from the available LV meters. The indexes, from the first to last row, are:

Temperature, RH, BR(min

-1

), IE, IT, ET, IER, PIP, MAP, PEEP, PEF, PIF, Vt, Vm. The presented curves from top to

bottom are: pressure, flow and volume. The red line is a cursor that shows where the previously acquired waveforms are

being overwritten by the new samples.

4 DISCUSSION

Table 1 points out that, except for the PEF value, the

developed system has a good performance.

The error for the PEF can be explained by the

differences between the mechanical resistances of

both systems. During the expiratory phase, the LV

just opens a valve to empty the LS without

controlling the flow. Therefore, if the analyzers have

different flow resistances, they will produce

different PEF measurements. It should be mentioned

that the IEC 60601-2-12 does not establish a flow

resistance value for the analyzers. Therefore, to

analyze the LV performance over the time based on

this index, a same analyzer model shall be used.

5 CONCLUSIONS

A micro-computerized system to analyze the

performance of lung ventilators was successfully

implemented.

It has some better characteristics when compared

to commercial equipments.

A database is integrated to the analysis software.

For each test carried out, it is possible to store the

date, sampled waveforms and measurements under

the same equipment record. Therefore, it is easy to

follow up the LV performance along the time.

Besides, the database can provide information on the

life expectancy and the average number of repairs

for a given LV model, assisting the purchase of new

equipments.

RF communication between the acquisition

module and microcomputer provides comfort to the

operator. The computer can be placed by the LV

control panel to facilitate the registration of its meter

readings as required by the adopted procedure.

As the equipment interface and indexes

calculation are provided by the microcomputer

(usually available to the clinical engineering staff),

the hardware module has lower design complexity

when compared to similar analyzers and, therefore,

lower cost.

MICROCOMPUTERIZED SYSTEM TO ASSESS THE PERFORMANCE OF LUNG VENTILATORS

165

ACKNOWLEDGEMENTS

The authors thank CNPq (507363/2004-3) and

FAPESC (CON14598/2005-0) for financial support.

REFERENCES

Analog Devices 2003, ADuC841/ADuC842/ADuC843

microcConverter 12-Bit ADCs and DACs with

embedded high speed 62-kB Flash MCU datasheet.

USA.

Doeblin, E. O., 1990. Measurement Systems: application

and design. Chapter 7, McGraw-Hill, Singapore.

Fernández-Pérez, E. R., Keegan, M. T., Brown, D. R.;

Hubmayr, R. D., Ognjen G. 2006. Intraoperative Tidal

Volume as a Risk Factor for Respiratory Failure after

PneumonectomyAnesthesiology, 105: 14-18.

Honeywell Inc., 2008. DC030NDC datasheet.

http://sensing.honeywell.com/index.cfm?ci_id=14030

1&la_id=1&pr_id=82004

International Electrotechnical Commission, 2001. IEC

60601-2-12: Medical electrical equipment – Part 2-12:

Particular requirements for the safety of lung

ventilators – Critical care ventilators. Switzerland.

Jones, R. P., Conway D. H, 2005. The effect of

electromagnetic interference from mobile

communication on the performance of intensive care

ventilator, European Journal of Anaesthesiology; 22:

578–583.

Kcwirefree, 2006. KC-210 embedded bluetooth USB

serial adapter datasheet. USA.

Kcwirefree, 2007. KC-21 OEM bluetooth module

datasheet. USA.

Pierce, L. N. B., 1995. Guide to Mechanical Ventilation

and Intensive Respiratory Care, W. B. Saunders

Company, USA.

Ricard, J. D., Dreyfuss, D., Saumon, G., 2003. Ventilator-

induced lung injury, Eur Respir J, 22: Suppl. 42, 2s–

9s.

Sensirion, 2007. SHT1x / SHT7x humidity & temperature

sensor datasheet v3.01, Switzerland.

Tolotti, A. A., 2004. Desenvolvimento de procedimento

para realização de ensaio de desempenho em

ventiladores pulmonares, Monograph, Clinical

Engineering Graduate Course, Federal University of

Santa Catarina, Florianópolis, Brazil.

Wallin, M. K. E. B., Wajntraub S., 2004. Evaluation of

Bluetooth as a Replacement for Cables in intensive

Care and Surgery, Anesth Analg; 98:763–767.

Wrigge, H., Uhlig, U., Zinserling, J. , Behrends-Callsen,

E., Ottersbach, G., Fischer, M., Uhlig, S., Putensen,

C., 2004. The Effects of Different Ventilatory Settings

on Pulmonary and Systemic Inflammatory Responses

During Major Surgery, Anesthesia & Analgesia, 98:

775-781.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

166