GATHERING PRODUCT DATA FROM SMART PRODUCTS

Jan Nyman, Kary Fr¨amling

Helsinki University of Technology, BIT research centre, P.O. Box 5500, FIN-02015 TKK, Finland

Vincent Michel

´

Ecole Nationale Sup´erieure des Mines de Saint-

´

Etienne 158, cours Fauriel F-42023 SAINT-

´

ETIENNE cedex 2, France

Keywords:

The Internet of Things, Distributed Systems, Smart Products.

Abstract:

The enabling of data produced by product embedded sensor devices for use in product development could

greatly benefit manufactures, while opening up new business opportunities. Currently products such as cars

already have embedded sensor devices, but the data is usually not available for analysis in real-time. We

propose that a world-wide, inter-organizational network for product data gathering should be created. The

network should be based on open standards so that it can be widely adopted. It is important that a common,

interoperable solution is accepted by all companies, big or small, to enable innovative new services to be

developed. In this paper, the concept of the Internet of Things (IoT) is described. The PROMISE project

is presented, and a distributed messaging system for product data gathering developed within the project is

introduced. Practical experiences related to the implementation of the messaging system in a real application

scenario are discussed.

1 INTRODUCTION

The emergence of technologies, such as Radio Fre-

quency Identification (RFID), enable consumer prod-

ucts to be identified individually, and makes it possi-

ble for productsto have some other information stored

on them as well. For example, a box of prescrip-

tion drug pills could have an embedded RFID tag,

which contains the identity of that specific box as

well as some metadata, for example an Internet URI.

The identity of the box and the metadata could then

be combined to fetch information about the specific

manufacturing batch the box originated from. The

increasing amount of product embedded information

devices (PEIDs), which provide functionality such as

self-diagnostics, could enable new services to be of-

fered to customers, if the data produced by the PEIDs

could be made available for real-time analysis.

To gain advantage from the possibilities of prod-

uct data, let it be simple location information for a

shipment, or more complicated information produced

by a product embedded information device, a global,

inter-organizational,open messaging network for data

gathering must be created. The Internet is the ideal

medium, as it is widely available. For the network to

become widely accepted, it must be built upon exist-

ing standards, and the communication interface defi-

nitions must be open, so that all implementations can

communicate with each other.

This paper has the following structure: First, the

concept of the Internet of Things is presented and

some requirements for different enabling technolo-

gies are outlined. Then work done in the PROMISE

project regarding product data messaging systems and

product embedded information devices is presented.

2 THE INTERNET OF THINGS

The Internet of Things (IoT) is a name for the phe-

nomenon of physical objects gaining a ”presence” on

the Internet (Gershenfeld et al., 2004). The objects

involved might be consumer products and industrial

machinery, but also simple sensors spread out in the

environment to form sensor networks. The ”tradi-

tional” Internet consists solely of computers provid-

ing services for human users without any explicit link

to things outside the electronic domain. When the

252

Nyman J., Främling K. and Michel V. (2008).

GATHERING PRODUCT DATA FROM SMART PRODUCTS.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - DISI, pages 252-257

DOI: 10.5220/0001700302520257

Copyright

c

SciTePress

Internet is augmented with the possibility of physi-

cal objects referencing services on the Internet, and

the ability for electronic services to track physical

objects, and access information stored on them, we

move towards a network that is no longer confined to

the electronic domain but deals instead with objects

and concepts that are present both in the electronic

and physical worlds.

The emergence of the IoT requires a network that

enables objects to reference electronic services on the

Internet, as well as technologies that enable entities

in the electronic domain to gain access to information

stored on individual product items. At the low end of

spectrum, ”things”, or physical objects participating

in the IoT just have some kind of identification, which

is machine readable in an automated fashion, such as

RFID or bar code tags. These objects are ”on-line”

only momentarily, perhaps just by an one-way link

that enables a tracker application to receive updates

on the new position of the object. Examples include

pallets with RFID tags in a logistics network. At the

high end of the spectrum, the objects are intelligent

themselves, they can gather statistical data about their

usage and have means of communicating that infor-

mation.

The IoT raises questions how the right to privacy

can be ensured. Privacy should be taken into account

already at the design phase of the product, by apply-

ing the principles of Notice, Consent, Anonymity, Lo-

cality, and Adequate security presented in (Langhein-

rich, 2001). The user should be made aware that data

is being recorded, and recording should not happen

without the user’s express approval. Collected data

should be anonymized, communicated using secure

means, and the user should have control on the data

also after it has been stored for analysis.

To enable the product items to have individual

data and events associated with them, they must be

identifiable in some manner. This means that a global

registry of some sort must be created, with every

product item having its own Globally Unique Product

Identifier (GUPI) (Fr¨amling et al., 2007b). The identi-

fication is used to tie the physical object to some kind

of proxy service, or product agent (K¨arkkinen et al.,

2003) running on a host on the Internet. The proxy

acts as a representant providing information or ser-

vices on the behalf of the object.

There are several approaches to the identity-to-

proxy mapping. The address (as an Uniform Re-

source Locator, URL) of the proxy is either directly

or indirectly obtainable from the object, the so-called

direct or indirect sensing described in (Kindberget al.,

2002). In the direct sensing case, the object itself con-

tains the complete URL of the proxy service. In the

indirect sensing case the identity of the product is an

Uniform Resource Name (URN), which is used as a

search key to find the URLs of the proxies from a cen-

tral repository of identity-to-URL mappings, much in

the same way that the Domain Name System (DNS)

of the Internet works for converting Fully Qualified

Domain Names to Internet Protocol addresses.

The ID@URI naming scheme used in the Dialog

collaborativelogistics system (K¨arkkinen et al., 2003)

developed at the Helsinki University of Technology

represents the direct sensing approach. In the Dia-

log system, every item has an identity of the form

identity@URI

, where the URI part is the address

(URL) where the proxy service can be found, and the

identity part is used to identify that particular item to

the proxy. This scheme has the advantage of the in-

herent simplicity of the direct sensing approach, i.e.

no look-up service is required. On the other hand, if

the URL of the proxy service was to change at some

point, it would require a re-programming of every

item with the new address, a huge task. The ID@URI

scheme works well in a logistics network environ-

ment, where the existence of a particular item on the

network is temporally limited, but in an Internet of

Things environment, where the product is present on

the network for its entire lifetime, the static nature of

the URI could be problematic.

The EPCglobal network developed by the Auto-

ID consortium is using the indirect sensing approach

to map product identities to proxy services. In

this case, the GUPI is the Electronic Product Code

(EPC), which defines a way to encode existing prod-

uct numbering schemes for use in RFID tags and

inter-organizational data exchange. The EPCglobal

implementation of the identity-to-proxy mapping is

named the Object Naming Service (ONS), and is an

extension to the DNS system (Armenio et al., 2007).

This approach has the inherent advantage that the ad-

dress of the proxy can change freely. On the other

hand, this scheme requires an organization that con-

trols the allocation of id’s, because every id must be

unique. This could make the scheme less attractive to

manufacturers, because they are then dependent on an

external organization for obtaining the unique IDs.

The World Wide Article Information (WWAI)

system proposed by Trackway is a peer-to-peer net-

work for propagating requests related to product in-

formation. This approach represents the indirect sens-

ing approach, with the responsibility of maintaining

the mappings from GUPIs to product agent URLs dis-

tributed among the nodes of the network. The infor-

mation providers, manufacturers, form a network of

trusted nodes, which are identified by company num-

bers defined in existing product numbering schemes.

GATHERING PRODUCT DATA FROM SMART PRODUCTS

253

The manufacturer is free to assign product identi-

ties inside its own sub-space of WWAI object iden-

tifiers, the object GUPI being a concatenation of the

company prefix and node-specific suffix. Access to

the network of information providers is through any

node of the peer-to-peer network. The node prop-

agates the requests to other nodes on the network,

and gathers the results, (product agent URLs) and

presents them to the client that issued the request

(Fr¨amling et al., 2007b). The service provided by

the WWAI peer-to-peer network is the mapping of

WWAI identifiers, (keys) to proxy URLs, (values) in

a distributed data structure called Distributed Hash

Table, DHT. Finding the correct value (proxy URL)

for a key (GUPI) involves routing the request in the

peer-to-peer network to the node that contains the

relevant mapping. Similar routing overlay systems

for use as application-independent middlewares have

been implemented previously (see (Coulouris et al.,

2005), section 10.4 and 10.5). The peer-to-peer look-

up mechanism might provide better availability than

the DNS-based Object Naming Service in EPCglobal,

which is dependent on availability of the ONS root

server maintained by EPCglobal. Internet DNS root

servers have been subject to various denial-of-service

attacks in the past, and the ONS root servers might

also be targeted in the future.

Agent look-up services to replace or supplement

the ONS have been proposed, such as the Extensible

Supply-chain Discovery Service (ESDS) by Afilias

(Young, 2007). The ESDS system also specifies an

event mechanism for passing information about the

current life cycle of a tracked object.

The solutions discussed previously are all solu-

tions that act on the application layer. The problem

of GUPIs could also be addressed on the network

layer, which is the level on which the Internet Proto-

col works. Ordinary Internet Protocol (IP) addresses

as such cannot be treated as GUPIs, even though the

address space in IPv6 is sufficiently large, because an

IP address uniquely determines the host’s location on

the network, and tells how to route datagrams to the

host. An IP address is confined to a particular net-

work, even if the underlying data link layer technol-

ogy would allow geographical movement of the host.

On the other hand, using the Mobile IP approach, the

identity (GUPI) of the product item would be the IP

address of its product agent, or home agent in Mo-

bile IP terminology, which must be a permanent ad-

dress that is always reachable. The agent keeps track

of the current IP address where the product can be

reached by receiving a notification from the product

every time the address changes.

Combined with the auto-configuration features

and larger address space of IPv6, and a standard ap-

plication layer interface for delivering messages, such

as the interface described in the next section, Mo-

bile IP could provide a neat solution for data gather-

ing. The drawback would be that every product item

would have to have its own product agent (or home

agent) with a distinct IP address, and it probably does

not make sense to allocate an IP to every conceivable

product item because of the associated administrative

overhead.

A challenge for the design of the messaging sys-

tem is how to create a single solution that spans

the entire spectrum of products, from intermittently

connected products with a simple smart tag that can

store an ID and a limited amount of information, to

products that have a powerful embedded computer.

The messaging system must have some standard data

model for sensor readings and events, in other words

there must be a standard way for presenting infor-

mation created by the products. There must also be

mechanisms for gaining information about what kind

of information a particular device provides.

Physical products in the physical world constitute

hierarchies. For example, a car is made from several

different sub-assemblies, which can be seen as sepa-

rate products that sum up to make the car. To properly

support hierarchies, the underlying messaging system

must be able to constitute things of a higher-order

from lower-order ”building blocks”. Consider for ex-

ample the box of pills with a RFID tag. The box can

be thought as an independent object in the network.

But when a shipping pallet is filled with these boxes

of pills, it does not make sense that every one of them

is reported separately, but rather they should appear

as sub-objects of the shipping pallet. These product

hierarchies can be modeled by applying the Compos-

ite design pattern (Fr¨amling et al., 2007a).

The messaging system to enable IoT must be able

to convey product life cycle events, such as the prod-

uct becoming a sub-product of an other product, or

the end-of-life of a product, in addition to the gath-

ering of product data such as sensor readings for the

needs of product monitoring systems. The data model

associated with the EPCglobal network, the EPC In-

formation Services, has support for product events

that are needed in inter-organizational logistics appli-

cations and inventory management. A generic event

model for product life cycle monitoring is not part of

the standard, nor is any mechanism for data gathering

from product instances (Armenio et al., 2007).

In the following section we shall take a look at a

proposed system for product data gathering that aims

also to address the needs of distributing product life

cycle events.

ICEIS 2008 - International Conference on Enterprise Information Systems

254

3 THE PROMISE PROJECT

The PROMISE project is financed by the Euro-

pean Union sixth framework programme, in which

research is being conducted in to ways of gathering

and processing of product data created by product em-

bedded sensors and information systems. The aim

is to create a framework of solutions that would en-

hance the usability of product data at various product

life-cycle phases and to create sufficiently generic in-

terfaces for data transfer, so that the solutions could

be applicable in any product, let it be mass-produced

household appliances or custom-built complex pieces

of machinery. The PROMISE project is focusing on

specifying interfaces between components and how

data is stored and processed, in contrast to EPCglobal,

which defines a GUPI and agent look-up infrastruc-

ture, and specifies data exchange and event interfaces

focusing on consumer product logistics.

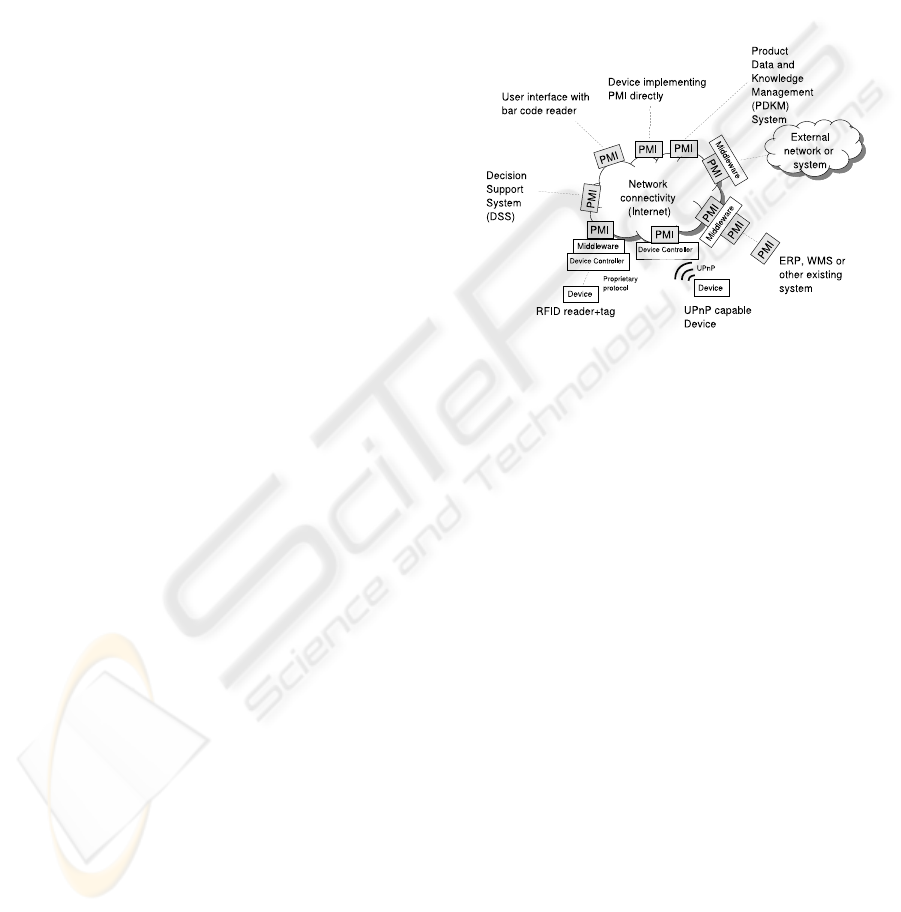

In the PROMISE world (Fig. 1), the messaging

between the participants, e.g. products and the Prod-

uct Data Knowledge Management systems, is done by

passing messages between nodes over a messaging in-

frastructure defined by the PROMISE Messaging In-

terface, PMI. PMI uses the SOAP remote procedure

call system, which uses the HTTP protocol as trans-

port medium. The choice of SOAP over other RPC

mechanisms is above all dictated by the presence of

network firewalls, which typically block many types

of traffic other than requests to port 80. For the mes-

saging system to become widely adopted, it cannot

require changes to network firewalls, which are usu-

ally tightly controlled by the network security staff.

A defining characteristic of PMI is that nodes do not

have predefined roles, as it follows the ”peer-to-peer”

approach to communications. A ”full” PMI node ca-

pable of sending as well as receiving requests does

have to include both HTTP client and server function-

ality, but a more limited node can just have the HTTP

client functionality, if it is assumed that it will only

send messages to other nodes. An example of such

”limited” nodes are ones associated with RFID tag

readers, or generally, nodes that are unreachable from

the outside because of a firewall, which periodically

send product data to a product monitoring system ac-

cording to a ”subscription” that is specified when the

product is installed.

The current incarnation of the PMI is a collec-

tion of methods that can be called over the SOAP re-

mote procedure call mechanism. The methods repre-

sent different operations such as a read or write of the

value of a particular info item. The info items repre-

sent actual values such as sensor readings of a device.

Methods also exist for querying metadata, such as the

list of info items that a device provides. A PMI node

is a communications end-point in a PMI network, and

manages communications for one or several devices.

The parameters for the method calls are XML strings

whose structure is defined by an XML schema. The

XML string conveys additional request information,

such as the involved device, information item, sub-

type of request, etc. As PMI messages are in essence

XML documents transmitted over the HTTP protocol,

all the technologies for making HTTP traffic secure

can be applied.

Figure 1: The PROMISE world featuring some possible

participants. All participants can send messages to each

other by using the Promise Messaging Interface (PMI).

In addition to ordinary ”synchronous” reads and

writes, the PMI also provides a callback method for

asynchronous communications. Examples of asyn-

chronous communications include a ”subscription”

read, a call to the read method with parameters that

specify that the target node should not respond di-

rectly with a value, but rather send multiple responses

at a specified interval. The callback method interface

also provides a mechanism for nodes to send events

to each other (with or without a prior subscription,

subject to the particular node implementation). In-

deed, the callback method is an embodiment of the

Observer pattern in (Fr¨amling et al., 2007a).

The PMI implementation created at the Helsinki

University of Technology, called PMI-Dialog, is

based on earlier work done in the Dialog project, in

which a messaging infrastructure for logistics was

created. Dialog is licensed under the GNU Lesser

General Public License. The Dialog architecture

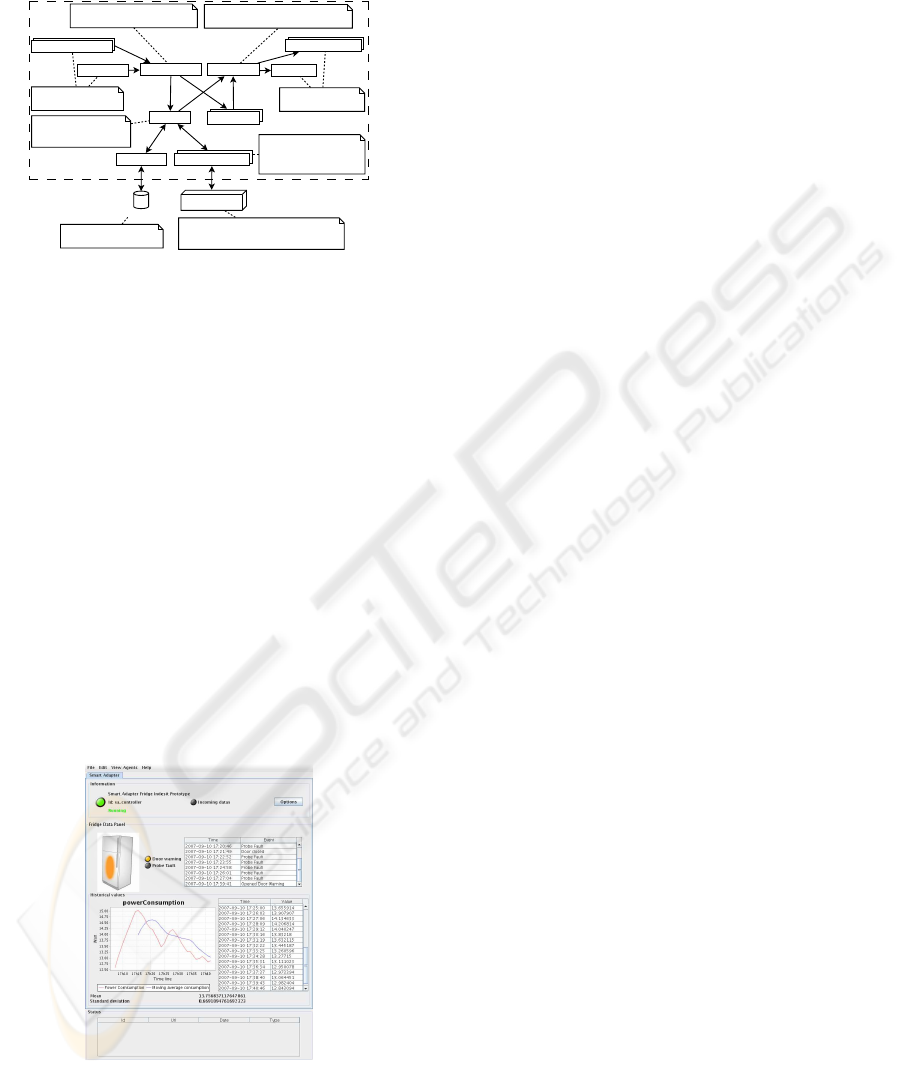

(Fig. 2) is centered around agents, which commu-

nicate with remote agents by sending and receiv-

ing messages. Different send and receive mecha-

nisms are supported, one of which is the SOAP pro-

tocol. The software is implemented in Java, using

the Apache Axis SOAP implementation running un-

der the Apache Tomcat servlet container. To support

GATHERING PRODUCT DATA FROM SMART PRODUCTS

255

PMI, a Dialog agent has been created for handling

PMI messages.

Interfaces for receiving

messages

Interfaces for sending

messages

Arriving messages are examined and

forwarded to the correct agent

Departing messages are examined and sent

using the correct protocol

Database

Device data can be saved

to a DB for later retrieval

Device controller acts as

a "device driver", presents

device data to the PMIAgent

as item/value pairs

Smart Device(s)

Smart Device (RFID reader, home appliance...)

connected to the PMI-Dialog node using a

wired or wireless connection

PMI Agent

PMIAgent receives PMI

messages, interprets them

and creates replies

PMI Sender

PMI Receiver

Send HandlerReceive Handler

DB Interface

Other Sender Types

Other Sender Types

Other Receiver Types

Other Receiver Types

Other Agents

Other Agents

Device Controller(s)

Device Controller(s)

Figure 2: The Dialog architecture. The dashed line shows

the node boundary. The Dialog architecture can support

many different interfaces for receiving and delivering mes-

sages.

We have been involved the development one of the

PROMISE technology demonstrators, in which sup-

port for data gathering from an intelligent refrigera-

tor’s statistical data collection unit was integrated to

the PMI-Dialog messaging system. The refrigerator

prototype was provided by Indesit, a major European

domestic appliance manufacturer, and has functional-

ity similar to what can be expected of smart household

appliances available in the near future. By integrat-

ing to the refrigerator a device capable of collecting,

storing and communicating statistical data obtained

from the various embedded sensors, the manufacturer

plans to enhance final product testing performance at

the manufacturing plant, as well as the possibility of

offering a preventive maintenance service contract to

customers. This latter business scenario is the most

interesting from a distributed systems point of view.

Figure 3: Information gathered from the refrigerator-

embedded information device displayed on a product

agent’s user interface.

The refrigerator-embedded information device was

interfaced to the Dialog software using a purpose-

built device controller agent, and for gathering data

from the product embedded information device, a

product agent was created. The agent’s graphical user

interface can be seen in Fig. 3.

It is assumed that in the future, product embed-

ded devices such as the one presented here, will be

using some wireless technology (eg. WLAN), and

a communications software stack capable of auto-

configuration, (eg. Universal Plug-and-Play, (UPnP).

To support UPnP, the PMI-Dialog implementation

will just have to be changed at the device controller

level, by adding a UPnP-aware device controller

agent.

When the first drafts of the promise messaging in-

terface were created, the Web Services/SOAP tech-

nology was chosen as the RPC mechanism. It was

thought that the interface should include a multitude

of methods to represent different operations, with

atomic parameters. But as the project evolved, it was

discovered that with a complex multi-method, multi-

parameter interface it is hard to keep the interface in

synch between the nodes during deployment, because

if the interface changes (eg. number of parameters

for a method change), different implementations are

no longer compatible. As a solution to this problem

the decision was made to keep the multi-method inter-

face, butchange the parameter format to XML strings,

with the format governed by an XML schema. This

way, even if different participants would use differ-

ent schema versions, some level of compatibility (ie.

”understanding” of the transmitted messages) would

be preserved. This enables nodes implementing an

older PMI version to continue operating with nodes

implementing a newer version without the need for

the newer PMI versions to include a ”legacy inter-

face” for compatibility. But a multi-method interface

with ”rich” XML parameters led to the evolution of

the interface to the point where it was no longer use-

ful to have several methods, but instead express dif-

ferent operations purely by XML requests defined by

the PMI XML schema. In practice the multiple meth-

ods just caused more complex code than a single-

method interface. Also, if the meaning of a mes-

sage can be deduced from the message contents itself,

without a need to know to which method the mes-

sage was posted to, it makes adapting PMI to work on

some other RPC mechanism easier, which is good for

a generic message interface specification.

When we end up with a SOAP interface with just

one method accepting an XML string as a parameter

(and returns XML too), the question arises, that what

is the point of having the SOAP layer between the

web server and the application. Our current under-

standing is that it is useless overhead, and the alter-

ICEIS 2008 - International Conference on Enterprise Information Systems

256

native solution would be to just send operations ex-

pressed in XML using the POST method offered by

the HTTP protocol.

The real performance ”acid-test” would be to sim-

ulate an environment where the node must process

messages arriving continuously from a very large

group of nodes. That would represent a situation

where a service company has a preventive mainte-

nance contract with a large group of customers, or

when an appliance manufacturer wishes to monitor

their products for the purpose of product develop-

ment. In any case, the performance of PMI implemen-

tations in general should not differ from other pro-

grams using SOAP as RPC mechanism. When PMI

implementations from other PROMISE partners be-

come available, measurements should be carried out

to obtain information about the relative performance

of our implementation. Measurements against other

messaging systems is not relevant, as messaging sys-

tems with a similar scope do not exist.

4 CONCLUSIONS

In this paper the concept of the Internet of things was

explained, and various approaches to product identity

management were presented. Generic requirements

for a messaging system to support the IoT were out-

lined. A messaging system interface specification, the

PMI, created within the PROMISE project was pre-

sented, and experiences related to the implementation

of a messaging system implementing the PMI were

discussed. In addition to a messaging interface for

exchanging data between entities in the IoT, a look-

up mechanism for obtaining the address of the soft-

ware agent is required. It was argued that the look-up

system should be globally distributed for reasons of

availability, and that a peer-to-peer architecture seems

most suited for such a system.

It was also argued that dependence on a particular

RPC mechanism, in this case SOAP, is not good for a

generic messaging interface, and the interfaces should

be defined so that any communicationsprotocol could

be used.

ACKNOWLEDGEMENTS

The PROMISE project is funded by the European

Union sixth framework (IST). The PMI has been cre-

ated as joint effort between the PROMISE partners.

REFERENCES

Armenio, F., Barthel, H., Burstein, L., Dietrich, P.,

Duker, J., Garrett, J., Hogan, B., Ryaboy, O.,

Sarma, S., Schmidt, J., Suen, K., Traub, K.,

and Williams, J. (2007). The EPCglobal Ar-

chitecture Framework, EPCglobal Final Version

1.2 Approved 10 September 2007. Available at

http://www.epcglobalinc.org/standards/architecture/

architecture 1 2-framework-20070910.pdf, refer-

enced on September 17, 2007.

Coulouris, G., Dollimore, J., and Kindberg, T. (2005). Dis-

tributed Systems, Concepts and Design. Addison-

Wesley, fourth edition. ISBN 0-321-26354-5.

Fr¨amling, K., Ala-Risku, T., K¨arkk¨ainen, M., and Holm-

str¨om, J. (2007a). Design patterns for managing prod-

uct life cycle information. Commun. ACM, 50(6):75–

79.

Fr¨amling, K., Harrison, M., Brusey, J., and Petrow, J.

(2007b). Requirements on unique identifiers for man-

aging product lifecycle information: comparision of

alternative approaches. International Journal of Com-

puter Integrated Manufacturing, 20(7).

Gershenfeld, N., Krikorian, R., and Cohen, D. (2004). The

internet of things. Scientific American, 291(4):76–81.

K¨arkk¨ainen, M., Ala-Risku, T., and Fr¨amling, K. (2003).

The product centric approach: a solution to supply

network information management problems? Com-

puters in industry, 52(2):147–159.

Kindberg, T., Barton, J., Morgan, J., Becker, G., Caswell,

D., Debaty, P., Gopal, G., Frid, M., Krishnan, V., Mor-

ris, H., Schettino, J., Serra, B., and Spasojevic, M.

(2002). People, places, things: web presence for the

real world. Mob. Netw. Appl., 7(5):365–376.

Langheinrich, M. (2001). Priacy by design - principles of

privacy-aware ubiquitous systems. LNCS 2201, pp.

273-291.

Young, M. (2007). Extensible Supply-chain Discovery

Service Concepts (Internet Draft). Available at

http://www.ietf.org/internet-drafts/draft-young-esds-

concepts-00.txt.

GATHERING PRODUCT DATA FROM SMART PRODUCTS

257