INTERACTIVE 3D PRODUCT ASSEMBLER FOR THE WWW

A Case Study of a 3D Furniture Store

Sophia M K Soo, Stephen C F Chan

Department of Computing, The Hong Kong Polytechnic University, Hong Kong

Ke

ywords: Assembling Mechanism, Parametric Object-Oriented Grouping Method, Assembly ML

Abstract: We describe a system that allows customers to interactively select, assemble, and modify 3D products over

the WWW, enhancing the usage of 3D techniques for e-business. It provides a framework for a web-based

3D assembling system that can significantly simplify the assembling process while retaining enough

flexibility to build an approximate model of real products. The assembled object is captured in a two-level

architecture. Components are first connected using simplified and automatic assembling mechanism; then a

bundle of connected components are grouped together by a parametric object-oriented grouping method.

This grouping method parameterize the components to build a group of descriptive, featured and related

object types - product, part and primitive within the assembling model. The system enhances the flexibility

and efficiency for the assembling process over the WWW. For archival and data transfer, we developed an

assembly-specific data format – Assembly ML. In the prototype implementation of our interactive 3D

assembler (I

3

DA), we integrated an intelligent decision helper to assist casual customers in selecting and

assembling their desired product.

1 INTRODUCTION

Using 3D visualization techniques in the web can

enhance consumer satisfaction through an

experience that comes closer to the “touch and feel”

of the brick-and-mortar environment, giving the

web-customer greater confidence in their purchase

decisions, and eventually help to promote

e-commerce for enterprises. There are many

commercial websites using 3D visualization

techniques to enhance their product presentation.

However, they are mainly limited to viewing the

models at different angles and distances. In this

paper, we describe an interactive 3D assembler

(I

3

DA) that is suitable for the web and e-commerce

websites.

The assembling task is rather complex and

challenging, involving many interactive, connective

and modification tasks. The general problems are:

1. Requirement of highly sophisticated geometric

and spatial skills in a 3D space :

At a first glance, assembling

components may seem to be intuitive and

straight forward, since human beings do that

all the time in real life. In reality, it requires

highly sophisticated skill to perform accurate

translations, rotations and scaling of the

geometries in a 3D space, particularly in the

environment of the common window-

keyboard-mouse computer interface. An

easy-to-use user interface must be developed

so that the assembling process can be

simplified for the average web user.

2. Need for a modifiable assembly structure :

A simple and intuitive way to create a

composite product is to create an assembly as

a bundle by attaching the components one by

one. However, when the assembly is modified

subsequently (e.g. enlarged), the model has to

be modified on a per-component basis -

because the changes required on each

component may be different. For models

which contain large numbers of components, it

can be quite tedious to change components

individually. An intelligent grouping

mechanism is necessary in the assembling

process to allow more efficient modifications.

Grouping is a popular mechanism in

many 3D authoring tools. When the user

changes the properties of the top component in

the group, the changes will be propagated to

all other components in the group. This is

useful, e.g., for the user to move a group of

components by moving the top level object.

However, this traditional grouping function

does not provide sufficient help in the

assembling process.

126

M K Soo S. and C F Chan S. (2004).

INTERACTIVE 3D PRODUCT ASSEMBLER FOR THE WWW - A Case Study of a 3D Furniture Store.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 126-133

DOI: 10.5220/0002616801260133

Copyright

c

SciTePress

The assembling process requires that

when properties of any group component

changes, all other group components will also

be changed relatively but generally differently.

An obvious example is the preservation of

shape, since this kind of adjustment is

frequently required. Using a drawer as an

example: if the user modifies the size of the

drawer’s bottom panel, all other components

need to be changed in size with different

values to preserve the overall shape. These

cannot be easily achieved using traditional

simple grouping methods. The parametric

object-oriented grouping method is designed

to deal with this type of problems. This

grouping method parameterizes all

components to build a more concrete and

representative object in the assembling model.

It makes it more intuitive for the user to

specify the modifications, and generally makes

the assembling process more efficient.

3. Incompatibility to well-established standards :

Some current techniques for Web 3D,

such as VRML (VRML 1997) and X3D (X3D

2003), only record the geometry of the 3D

model, but do not provide support for

assembly information on the model. Hence a

lot of assembling information will be lost

when data is exchanged with other

well-established standards in manufacturing.

In this project, an assembly ML data format is

introduced for the assembly-specific model.

To illustrate the functionalities of an I

3

DA, an

online office furniture store is used as a target

application. The store allows the user to tailor-made

his/her furniture online, and then makes a quotation

or order. It requires a number of functionalities that

can be easily generalized to other applications.

I

3

DA utilizes the Java Applet and Java3D

technologies (Java3D 2004

). This enables our

application to be run on any platform, and to be

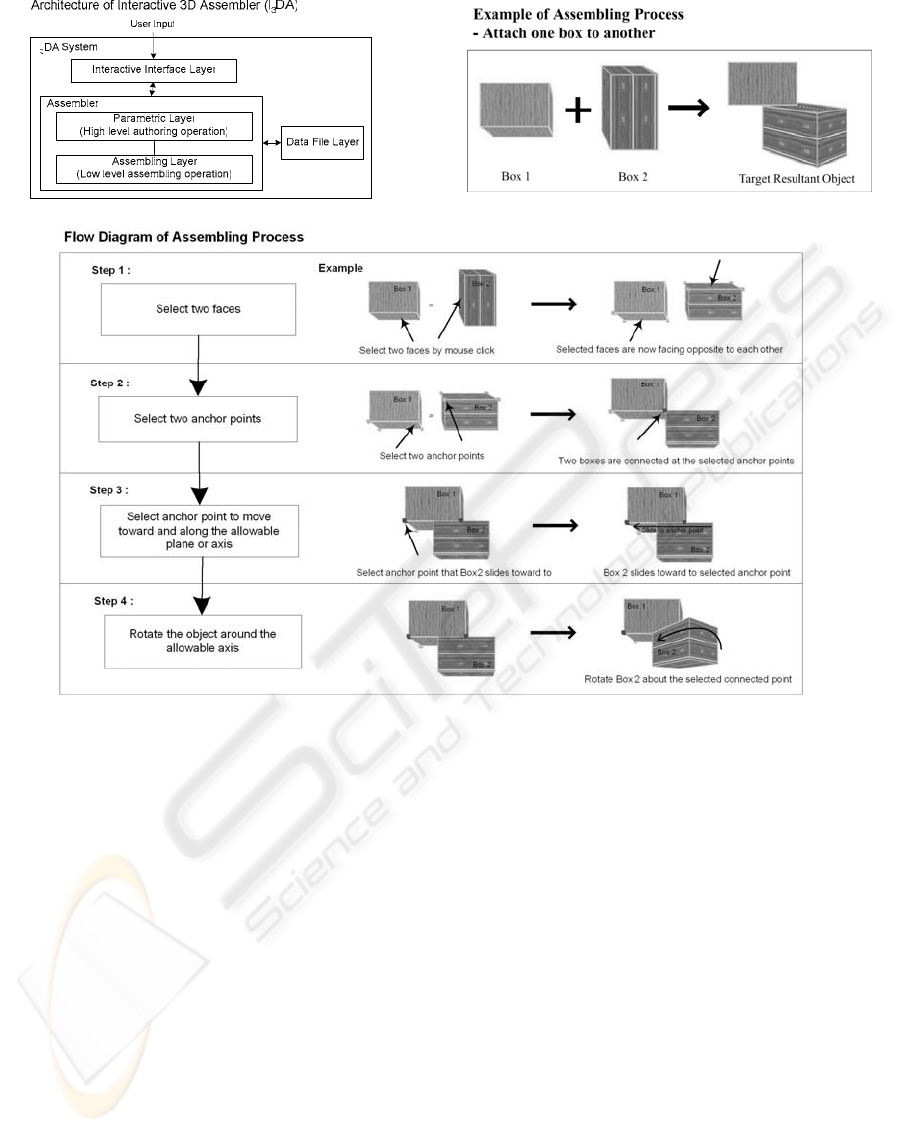

embedded in the web page. Figure 1 shows the

architecture of I

3

DA. It demonstrates the overall

design of our assembler.

2 PREVIOUS WORK

Much research have been conducted on the

integration of 3D technology to e-commerce and

manufacturing on the Internet.

Jayaram et al. (1997)

describes a virtual assembly environment for

manufacturing industry. It aims to enhance the

design and production process for the engineer and

designer. The system is not suitable for general web

users. Some researches such as

Varlamis et al. (2000)

and some web sites such as IKEA’s (IKEA 2003)

aim to support to virtual room construction. The

room assembling technique is not suitable for

product assembling as they have different design

processes and constraints. Some researches such as

Lescinsky et al. (2002), Blanchebarbe et al. (2001) aim

to support manipulation of 3D objects in display

scenes, but still fall short of actually changing and

assembling products in a design environment.

Nousch et al. (1999) describes a specialized

web-based program for user to modify the closet

design by direct interaction with the visualized 3D

model. It also provides knowledge-based system to

ensure that the design is obey the relevant design

rules. And finally a shopping list of all needed parts

and customized multimedia assembly manual are

generated for user. Its idea is similar to our approach

that creates a virtual environment for user to design

and modify their 3D products. However,

Nousch et al.

(1999)

discusses only on the special construction of

closet but not general products. It only solves the

assembling problems specific for closet. Also it does

not provide a general 3D assembling system. Our

research provides a framework for a web-based 3D

assembling system that can significantly simplify the

assembling process while retaining enough

flexibility to build an approximate model of real

products for average web users.

3 ASSEMBLING LAYER

3.1 Object Definition

This layer defines the basic operations of the

assembling mechanism, which is to connect the

basic components (smallest pre-defined units), in

order to make up the model.

3.2 Design of the Assembling

Mechanism

The operations (the user interface provided)

supported by our assembling mechanism parallels

the procedures with which human beings assemble

real objects. A processor (of the interface) then

performs automatically most of the complex 3D

assembling operations. This simplifies the usage of

the mechanism, while maintaining the simulation of

reality for the customer. To visualize the operations

of our mechanism, one can imagine the many ways

in which two boxes (Box1 and Box2) can be

attached to each other (see Figure 2). The flow

diagram and description of the assembling process

are shown in Figure 3.

INTERACTIVE 3D PRODUCT ASSEMBLER FOR THE WWW - A CASE STUDY OF A 3D FURNITURE STORE

127

Figure 1

Figure 2

Figure 3

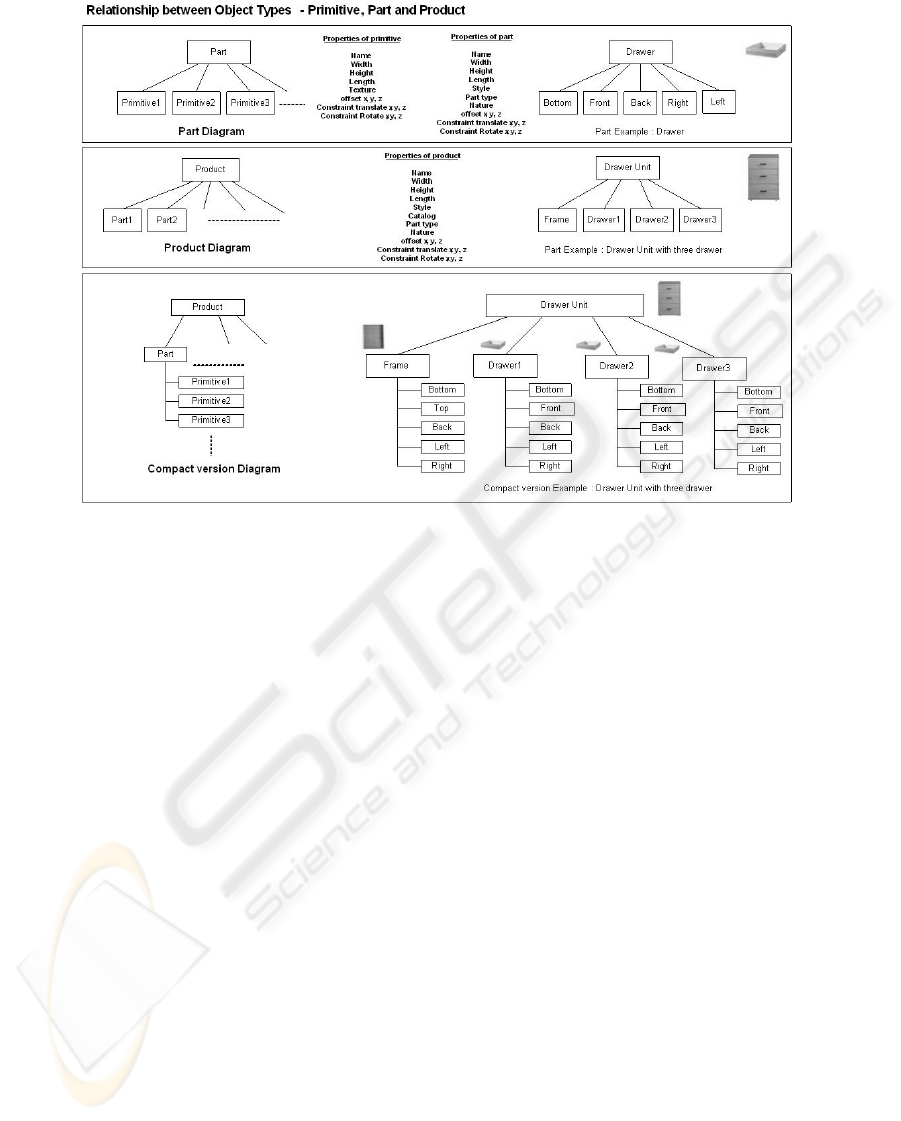

4 PARAMETRIC LAYER

4.1 Object Definition

In the assembling layer, the assembling model is

controlled on a per-component basis. This layer has

no intuitive parameter for the user to control the

model. In the real world, the model is always made

up of some parts, and the parts are made up of

smaller components. In this layer, to simulate the

model in the real world, a new grouping method –

parametric object-oriented grouping method, is

introduced to better control the assembling model.

This grouping method is to parameterize the

connected components to become a group of

descriptive, featured and related objects with type of

product, part and primitive (smallest component).

Parameterized objects have their own properties.

The new grouping method enhances the model

control from per-component basis to per-object basis.

In this grouping method, components or group of

components can be defined as primitive, part or

product. Figure 4 demonstrates the definition and

relationship of the three object types within the

model.

In Figure 4, the part diagram illustrates that

primitives make up the part; the product diagram

shows that parts make up the product; and the

compact version diagram shows the relationships

between the product, parts and primitives. The

properties of primitive, part and product are also

listed in the centre of the figure. To the right of the

figure are examples for each type of diagram. A

drawer unit contains a frame and three drawers; the

drawer unit is a product; frame and drawer are parts;

bottom, top, back, left and right are primitives. In

our model, each component will be a primitive of a

part, a group of components will be a part of a

product.

ICEIS 2004 - HUMAN-COMPUTER INTERACTION

128

Figure 4

This object definition is more product-oriented,

and more intuitive for the user to specify the design

and modification. For a complex model with

hundreds of components, the user can request a

modification with only a few parameters, letting the

parametric relationships between the product and

parts and primitives to effect the eventual

modifications, instead of specifying hundreds of

component modifications. This layer improves the

flexibility and efficiency of adjustments of the

model with minimal user interaction. This

enhancement is demonstrated in next section 4.2.

4.2 Relationship between Parametric

Layer and Assembling Layer

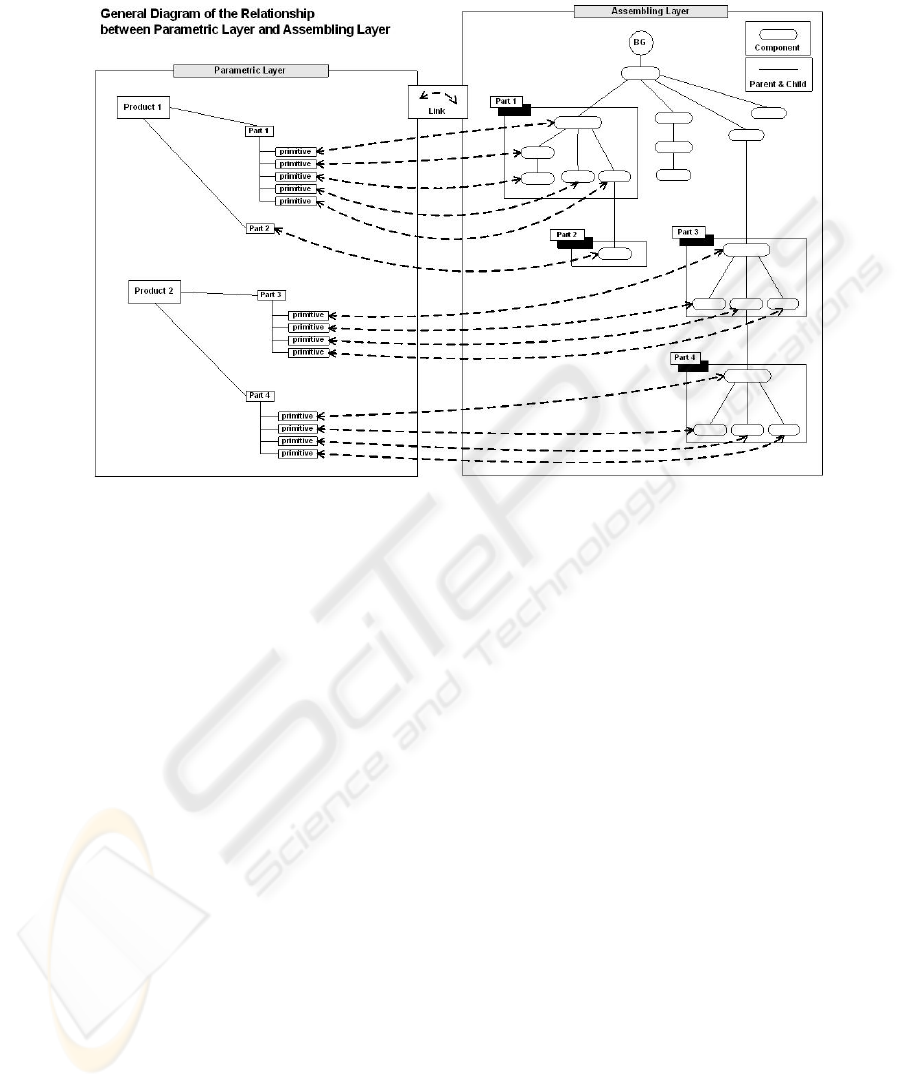

In the assembling layer, the components are

attached/connected. As Java3D technology is used to

implement our graphical assembler tool, a

hierarchical scene graph concept is used to represent

the spatial hierarchy of the connected components.

In this case, the parametric layer is added upon the

scene graph hierarchy. The relationship between the

parametric layer and the assembling layer is

illustrated in Figure 5. Each component of the model

has a parameterization that defines its object-

belonging relationship with other components within

the model. When the parameterized model is altered,

modifications are propagated to the components

based upon its belonging relationship.

In Figure 5, product 1 has two parts – Part1

and Part2. Part1 is composed of five primitives. The

primitives in the parametric layer are linked to the

correspondent components in the assembling layer.

If one component is selected in the assembling layer,

its primitive, part and product information can be

obtained by link searching from the assembling layer

to the parametric layer. Then, the selection and

modification process can be per-primitive based,

per-part based and per-product based. This approach

makes the model design and modification more

flexible and efficient. With a few objects relative to

the number of individual components, complex

models comprised of hundreds of components can

be designed and modified efficiently, with very little

user-interaction.

5 DATA FILE LAYER

The data format definition of the assembly model

must contain all the properties and relationship of

the objects in the model, allowing the model to be

restored from the encoded string. A data format

based on XML is defined for this purpose. It aims to

provide a general data file format to represent any

type of assembling models. Apart from capturing all

the useful information, reusability and network

loading are also considered in the design of the data

file.

INTERACTIVE 3D PRODUCT ASSEMBLER FOR THE WWW - A CASE STUDY OF A 3D FURNITURE STORE

129

Figure 5

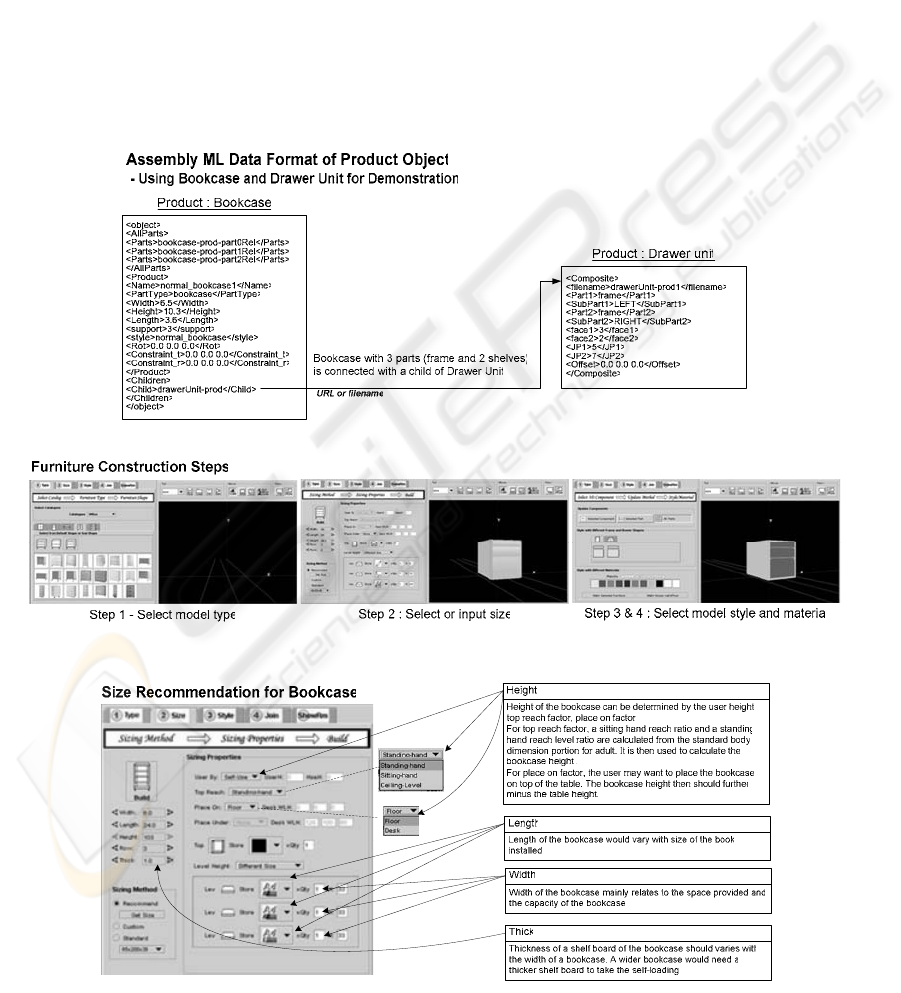

5.1 Assembly ML

The data format – Assembly ML is based on XML. It

is illustrated by an example of a bookcase which has

a child of a drawer unit (see Figure 6). The data file

needs to capture all the parent-child relationships.

Product object “Bookcase” is a “base object”.

It has a “Drawer unit” as its child. Each child will

have connection attributes such as “part attached to”

(part1), “part attached at” (part2), “primitive

attached to” (subPart1), “primitive attached at”

(subPart2), “face to” (face1), “face at” (face2),

“anchor point attached to” (JP1), “anchor point

attached at” (JP2) and offset to represent their

connection. In this example, “Left” of “frame” of

“Bookcase” joins with “Right” of “frame” of

“Drawer unit”.

A child is represented by a URL or filename

that contains the encoded string instead of having a

nested structure in the parent encoded string. This

makes the encoded string of the composite objects

reusable and sharable. Also, when the assembly

model is modified, only those data files containing

modified components need be altered. Therefore, the

number of file transfers and data volumes can be

greatly reduced, helping to reduce the network load

on the Internet.

6 INTERACTIVE INTERFACE

LAYER

The design of our I

3

DA aims to provide high level

methods for building different kinds of product

assemblies. However, there is generally a gap

between the customers’ desires and the capabilities

of the underlying geometric model. Our 3D

assembler layer still requires an intelligent and

user-oriented interface layer on top of it, to allow

casual users to select and assemble products

efficiently.

6.1 User-friendly and easy-to-use

The construction procedure should be clear, intuitive

and “life-like”. Figure 7 demonstrates the user

constructing a custom furniture in four easy and

straightforward steps.

6.2 Fitness Recommendations

Customers do not always know the exact dimensions

of the desired furniture. In such cases,

recommendations can be provided to make his/her

most comfortable, fitting furniture - fitting to the

customer’s size, installed objects, or home space.

ICEIS 2004 - HUMAN-COMPUTER INTERACTION

130

6.2.1 Size Recommendations

The customer may need to fit the furniture to his

space or his height. An intelligent module in the user

interface can calculate the appropriate size of the

furniture based on the following factors: human

body dimensions, objects installed on/into the

furniture, number of users of the furniture, house

dimensions and other furniture dimensions. The

factors considered by the recommendation module

for the bookcase are shown in Figure 8.

6.2.2 Style & Material Recommendations

Some customers may like the design, but

cannot figure out the type of materials. In this case, a

tool can choose appropriate materials which match

the other furniture in the designated room.

6.3 Fitness Demonstration

The assembler should provide some environments

for the user to validate that the tailor-made model is

fitting in terms of size, style and materials, etc. A 3D

man (Figure 9) in the user’s height and a virtual

show room (Figure 10) are developed to provide a

more realistic environment for examination by the

user.

Figure 6

Figure 7

Figure 8

INTERACTIVE 3D PRODUCT ASSEMBLER FOR THE WWW - A CASE STUDY OF A 3D FURNITURE STORE

131

User Height

User Height

User Height

U

s

e

r

H

e

i

g

h

t

Figure 9

U

s

e

r

H

e

i

g

h

t

Figure 10

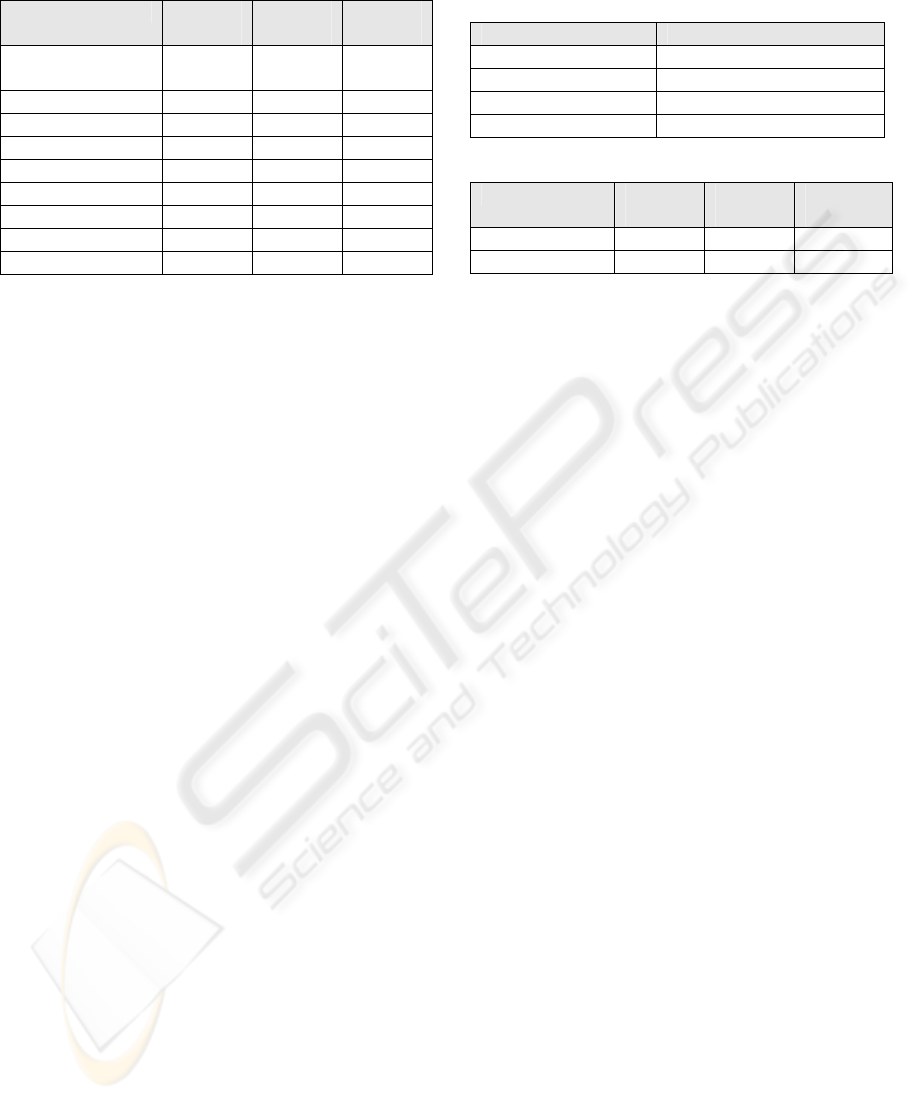

7 EVALUATION

The online office furniture store is an example

application to validate the design of our I

3

DA. The

tables (Table1, Table2, Table3) below summarize

our experiences in the development of the

assembler.

Table 1: Type of models that can be built by the 3D

assembler

Type of model Built by Assembler

Table Yes

Bookcase Yes

Cabinet Yes

Drawer Unit Yes

Room Yes

*Yes: model can be built by the assembler

Table 2: Validation of the efficiency of the assembly model by considering the number of user interactions (UIs) required to

change all components in an assembly – No. of UIs required in per-components basis (changing each component

individually) and the no. of UIs required in per-object basis (changing the assembly product model)

Model Action Total

components

Total

Objects

No. of UIs

(Per-Component )

No. of UIs

(Per-Object )

Table with four

legs

Change attributes of table top

and four legs in different values

5 1 x Frame

4 x Legs

5 5

Bookcase with

three shelves

Change attributes of a frame and

three shelves in different values

8 1 x Frame

3 x Shelves

8 4

Drawer Unit with

three drawers

Change attributes of a frame and

three drawers in different values

20 1 x Frame

3 x Drawers

20 4

Cabinet with three

shelves and two

doors

Change attributes of a frame,

three shelves and two doors in

different values

10 1 x Frame

3 x Shelves

2 x Doors

10 6

ICEIS 2004 - HUMAN-COMPUTER INTERACTION

132

Table 3: Actions on model - Show the flexibility of model assembly

1. Functions on model

Function Apply to

Primitive

Apply to

Part

Apply to

Product

Change position &

rotation

Yes Yes Yes

Change model Style Yes Yes Yes

Change Texture Yes Yes Yes

Change Size Yes Yes Yes

Delete model Yes Yes Yes

Combine models No No Yes

Duplicate model No No Yes

Save model to file No No Yes

Load model from file No No Yes

*Yes: Action can apply to *No : Action cannot apply to

2. Additional functions on specific model

Model Function

Drawer unit Change number of drawers

Bookcase and Cabinet Change number of shelves

Drawer unit Open drawer

Cabinet Open door

3. Constraints on model

Function Apply to

Primitive

Apply to

Part

Apply to

Product

Slide on Surface Yes Yes Yes

Slide on floor No No Yes

*Yes: Action can apply to *No : Action cannot apply to

8 CONCLUSION AND FUTURE

WORK

We described a framework of a web-based

interactive 3D assembler (I

3

DA) system. An initial

prototype of the system, applied to a virtual furniture

store, is implemented. A number of different kinds

of furniture are built, modified and recorded. Based

on the experiences in the experiment, we believe that

the system is general and flexible enough to build

approximate models of real assembling products.

Our experiments show that the number of user

interactions required for design and modification is

greatly reduced, proving that the system can

assemble models in a more intuitive and efficient

way. Further work will be done to extend the

functionality and usability of I

3

DA, and to apply it to

different areas of e-commerce.

ACKNOWLEDGEMENT

This project was partially supported by the Hong

Kong Polytechnic University Research Grand

A.PC54.

REFERENCES

Blanchebarbe, P., Diehl, S., 2001. A Framework for

Component Based Model Acquisition and Presentation

Using Java3D. In Web3D 2001, 6

th

International

Conference on 3D Web Technology, Paderbon,

Germany, ACM 2001. 117-125.

IKEA, 2003. Office IKEA Planning tools.

http://www.ikea.co.uk/ms/en_GB/rooms_ideas/office/

office_planner.html

Java3D, 2004. Sun Microsystems Inc. The Java3D API.

http://java.sun.com/products/java-media/3D/

Jayaram, S., Connacher, H., Lyons, K., 1997. Virtual

Assembly using Virtual Reality Techniques.

Computer-Aided Design. 29(8): 575-584.

Lescinsky, G., Touma, C., Golddin, A., Fudim, M., Cohen,

A., 2002. Interactive Scene Manipulation in The

virtue3D System. In Web3D 2002, 7

th

International

Conference on 3D Web Technology, Arizona, USA,

ACM 2002. 127-135.

Nousch, M., Jung, B., 1999. CAD on the World Wide

Web: Virtual Assembly of Furniture with BEAVER.

In VRML’99, Fourth Symposium on the Virtual Reality

Modeling Language, Paderbon, Germany, ACM 1999.

113-119.

Varlamis, I., Vazirgiannis, M., Lazaridis, I., Papageorgiou,

M., Panayiotopoulos, T., 2000. Distributed Virtual

Reality Authoring Interfaces for the WWW: the

VRSHOP case. In ICME 2000, IEEE International

Conference on Multimedia and Expo (I). 191-194.

VRML, 1997. Web3D Consortium. The Virtual Reality

Modeling Language Specification ISO/IEC

DIS14772-1:1997.

http://www.web3d.org/technicalinfo/specifications/vr

ml97

X3D, 2003. Web3D Consortium. X3D Task Group

Overview. http://www.web3d.org/x3d.html

INTERACTIVE 3D PRODUCT ASSEMBLER FOR THE WWW - A CASE STUDY OF A 3D FURNITURE STORE

133