Customer Co-Creation in Smart Production Ecosystems

Opportunities and Challenges for MDE

Deepak Dhungana

Siemens Corporate Technology, Siemens AG Austria, Vienna Austria

Keywords:

Customer Co-creation, Open Configuration, Smart Production Ecosystem, Model Consolidation.

Abstract:

The traditional role of customers as passive consumers is gradually changing and consumers are actively

participating in co-creation of the products they buy. This shift in paradigm has implications on how products

should be modeled and the tools around Model-driven Engineering (MDE) must consider new ways of dealing

with open-innovation, thereby preserving the privacy and intellectual property rights of the product sellers. In

this paper, we discuss how MDE can help in setting up a smart production ecosystem, enabling the interaction

between product sellers and consumers and identify some challenges in this context. Some new research

directions for MDE are outlined.

1 INTRODUCTION

With the increasing demand for individualized pro-

ducts, there is an ongoing struggle of the companies to

deal with flexibility in product design and production

processes. Many research initiatives in this area aim

to revolutionize the future of industrial production,

e.g., the Smart Manufacturing Leadership Coalition

(SMLC)

1

, the Industrial Internet Consortium

2

, Indus-

trie 4.0

3

etc. Product designers and factories are

therefore exposing a high degree of flexibility yiel-

ding more choices for customers and enabling inno-

vative ecosystems. We refer to such collaborative net-

works of product designers, factory equipment ven-

dors, factory operators, and consumers of the products

as Smart Production Ecosystems. We have described

smart production ecosystems in detail in a recent pu-

blication (Dhungana et al., 2017b). In this paper we

focus on customer co-creation in such a ecosystem.

In a smart production ecosystem, the traditio-

nal roles of customers and product sellers are re-

defined. With access to unprecedented information,

customers are no longer passive consumers but active

co-producers and engage in behaviors that streng-

then their relationship with the product, company or

brand (Piller et al., 2005). Customer co-creation is be-

coming increasingly popular among companies, and

intensive communication with customers is generally

1

https://smartmanufacturingcoalition.org/

2

https://industrialinternetconsortium.org/

3

https://www.plattform-i40.de/

seen as a determinant of the success of a new service

or product (Gustafsson et al., 2012).

Customer co-creation can take many different

forms. Typically online brainstorming, open expert

communities, innovation groups or idea contests are

adopted by companies to drive open innovation and

engage external parties in solving internal problems

(Piller et al., 2010b). In this paper, we discuss the

idea of customer co-creation at the point of sales and

its implications for model driven engineering (MDE).

Typically, customers select and configure the pro-

ducts they require using a configurator tool. Confi-

gurators rely on formal models of how products can

be built, the kind of variability offered and the ru-

les governing the composition of the parts (Sabin and

Weigel, 1998). Such knowledge models are captu-

red using models e.g., feature models (Kang et al.,

1990) which are predefined, tested and released for

sales purposes. As these models contain crucial in-

formation about the product (design, engineering and

manufacturing details), they are typically not publis-

hed or disclosed to public – a configurator application

displays only the relevant information to the custo-

mers.

However, when allowing for customer co-creation

the customers not only select the required features to

configure the product based on the set of available op-

tions, but they may wish to add new features (request

for model changes) or may wish to modify configura-

tion rules in unforeseen ways. In doing so, the con-

Dhungana, D.

Customer Co-Creation in Smart Production Ecosystems - Opportunities and Challenges for MDE.

DOI: 10.5220/0006731206250631

In Proceedings of the 6th International Conference on Model-Driven Engineering and Software Development (MODELSWARD 2018), pages 625-631

ISBN: 978-989-758-283-7

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

625

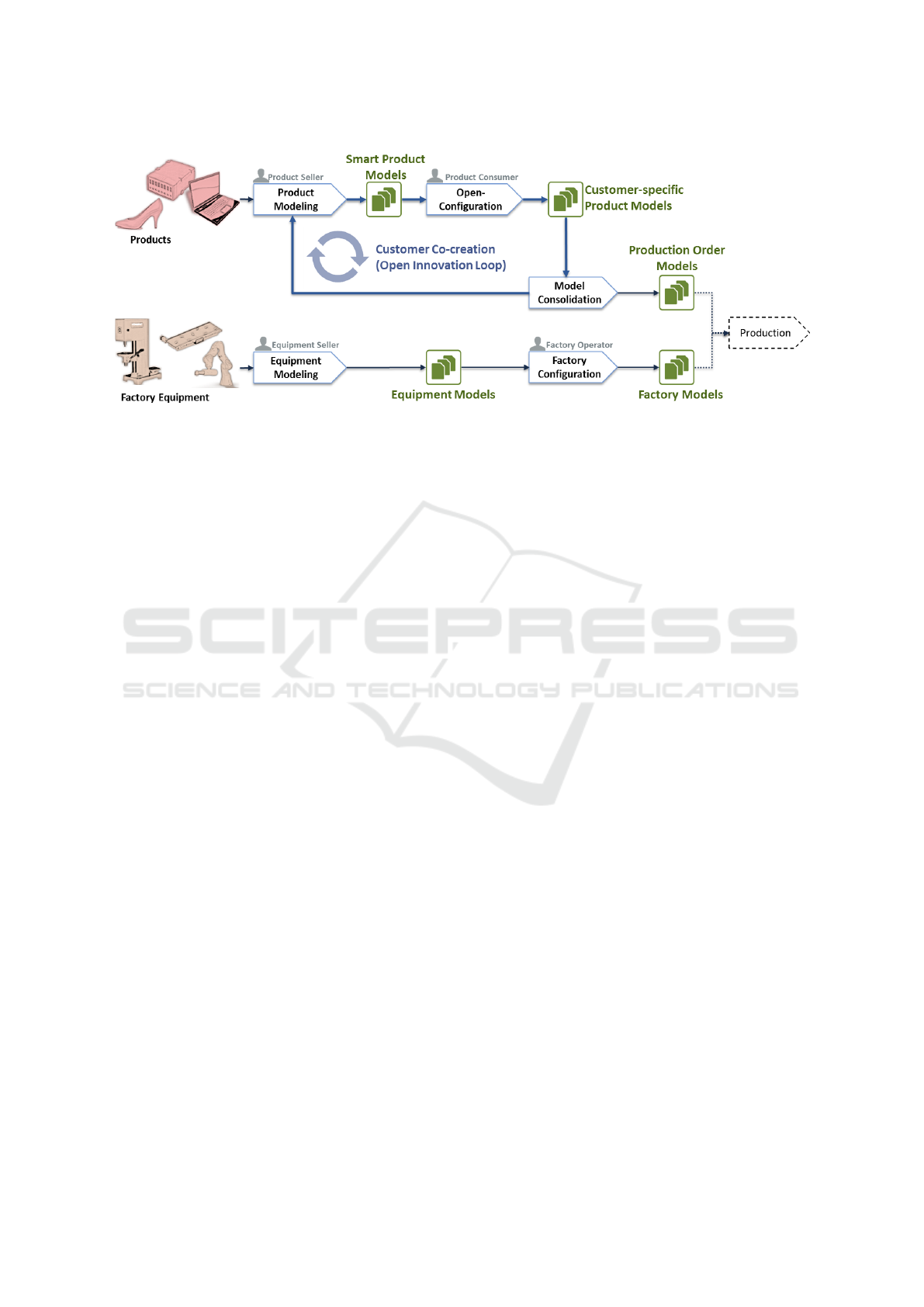

Figure 1: The role of different types of models and their interactions in a smart production ecosystem.

ventional idea of MDE to consider models as univer-

sal truth is shaken. The model then becomes a star-

ting point for the customers to build upon. Models

need to change at runtime, these need to be validated

on the fly, and more importantly – these models are

no longer hidden artifacts – as they need to be freely

shared with customers. Customer co-creation there-

fore poses additional challenges for MDE and we dis-

cuss some of the tricky ones in this paper:

• Supporting open-innovation in a model driven

smart production ecosystem.

• Supporting privacy-preserving interactions bet-

ween producers and consumers.

In general, the challenges described in this paper

are not specific to open-innovation or customer co-

creation – these issues tend to arise in most commu-

nity driven approaches, where MDE is adopted as a

key enable for knowlegde representation and collabo-

ration.

2 SMART PRODUCTION

ECOSYSTEM

A smart production ecosystem is a network of fac-

tory equipment vendors, factory operators, product

sellers and consumers (cf. Figure 1), interacting with

each other through a common marketplace (Dhun-

gana et al., 2017b). Interaction between stakeholders

occurs through the publication and sharing of artifacts

(models) to the marketplace.

In contrast to a conventional marketplace, in a

smart production ecosystem, the products to be pro-

duced and the production facilities are both put on

sale and the customers decide where the production

should take place. Automated marketplace servi-

ces are available to ensure the producibility of the

products in selected production facilities (Dhungana

et al., 2017a).

Automation and optimization of interactions in

such innovative markets and networks means the dif-

ferent players in the ecosystem must themselves be

smart, act smart and rely on the smartness of others.

A smart production ecosystem relies on four pillars:

Smart Products refer to goods that are put for sale

to the consumers. They are smart because they are not

only aware of their features and materialistic proper-

ties but also know how they can be manufactured, thus

they are aware of the requirements a factory must ful-

fill to produce them. Smart products are smart enough

to control their own production. A smart product mo-

del is shared through a common marketplace.

Smart Equipment refer to devices in a factory,

which publish their production skills as services and

can be deployed as autonomous service providers in a

factory. Whenever any device is put for sale, the as-

sociated equipment model describing the capabilities

of the device is shared in the marketplace.

Smart Factories are configurations of smart devi-

ces which can work together, to fulfill a certain pro-

duction order. Factories offer their production ca-

pabilities through a marketplace – enabling sales of

factories as services. Smart factory models are used

in combination with smart product models to check

whether a certain product is producible in any given

factory.

Smart Customers are consumers of the smart pro-

ducts. Smart customers interact with the marketplace

by configuring the products they wish to buy, the-

reby not being limited by the set of predefined opti-

ons or features. As the marketplace allows for open-

innovation, the customers are partners in co-creation

of the products that are offered in such a marketplace.

IndTrackMODELSWARD 2018 - MODELSWARD - Industrial Track

626

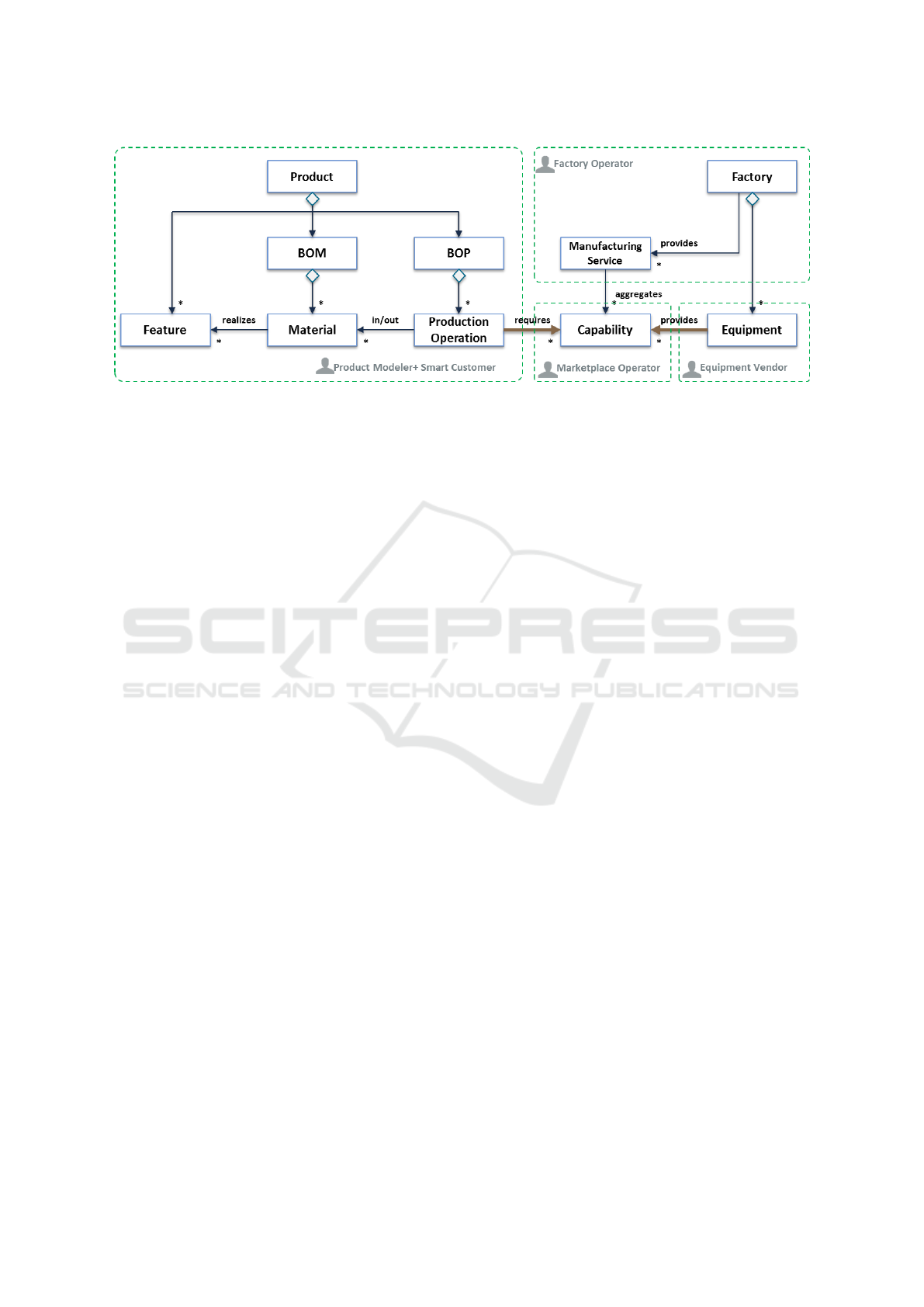

2.1 Sharing Knowledge through Models

Models are shared through a common marketplace,

as a means to drive the creation and transfer of value

through the ecosystem. Figure 2 depicts a high level

meta-model used to describe/define the artifacts in the

ecosystem. Several models are based on this meta-

model as described below.

Equipment Models refer to formal descriptions of

the factory components that can provide production

capabilities in a factory. Equipment sellers publish

the set of capabilities provided by their equipment

as Equipment Models. Each concrete equipment is

a self-contained modular unit that can execute pro-

duction operations autonomously. A common onto-

logy is shared between all the stakeholders (Capa-

bility Ontology) which is used to describe the skills

of the equipment available in the marketplace (Dhun-

gana et al., 2017b).

Factory Models refer to formal descriptions of the

production facilities. A factory is seen as a specific

configuration of the set of equipment deployed in its

premises. In the marketplace, Factory Models are cre-

ated though the selection and configuration of availa-

ble Equipment Models. Typically, a factory consists

of production equipment, storage systems, transport

systems in a specific topology.

Smart Product Models refer to goods that are put

for sale to the consumers. Products are seen as digi-

tal first-class citizens that maintain their Bill of Ma-

terial (BOM), their Bill of Process (BOP), informa-

tion about their variability as feature models, and a

mapping between the customer view and manufac-

turing view depicting the mapping between feature

variability and BOM variability). The materials of

the product’s BOM use this information to steer their

own production and their step-wise transformation to-

wards concrete product instances or product batches,

i.e., smart products (Dhungana et al., 2015).

Customer-specific Product Models represent the

output of the product open-configuration process car-

ried out by the product consumers. A configurator

presents the features to the consumers and captures

the intent of the customer to either select/deselect

an existing feature, add a new feature to the model,

change existing rules, or even change the manufactu-

ring process by changing the BOM of the product.

Production Order Models are individualized,

consolidated product models that have been revised,

adapted and amended after the costumers have parti-

cipated in a open configuration process.

2.2 Customer Co-creation and MDE

The task of a conventional Product Configurator is to

guide a customer through the derivation of a concrete

product that meets their requirements from the pro-

duct family representation (Sabin and Weigel, 1998).

Such configurators are limited in what they offer to

the customers – very often the customer may wish to

have new features or variations of existing features,

which may be technically feasible but not supported

by the configurator at hand. This may be intentio-

nal from the perspective of product sellers, as they

often try to reduce the complexity of the their portfo-

lio and the simplify the production processes later on.

But with the advancements of lot-size-one production

facilities, there is often no technical reason to forbid

the customer from configuring unique products - even

outside the range of currently supported variants. This

kind of product configuration practices are referred to

as open-configuration and have been discussed in re-

cent papers (Felfernig et al., 2014). We are therefore

working on smart factories (Dhungana et al., 2017b),

which can produce any product as long as the product

itself is smart enough to steer its own production.

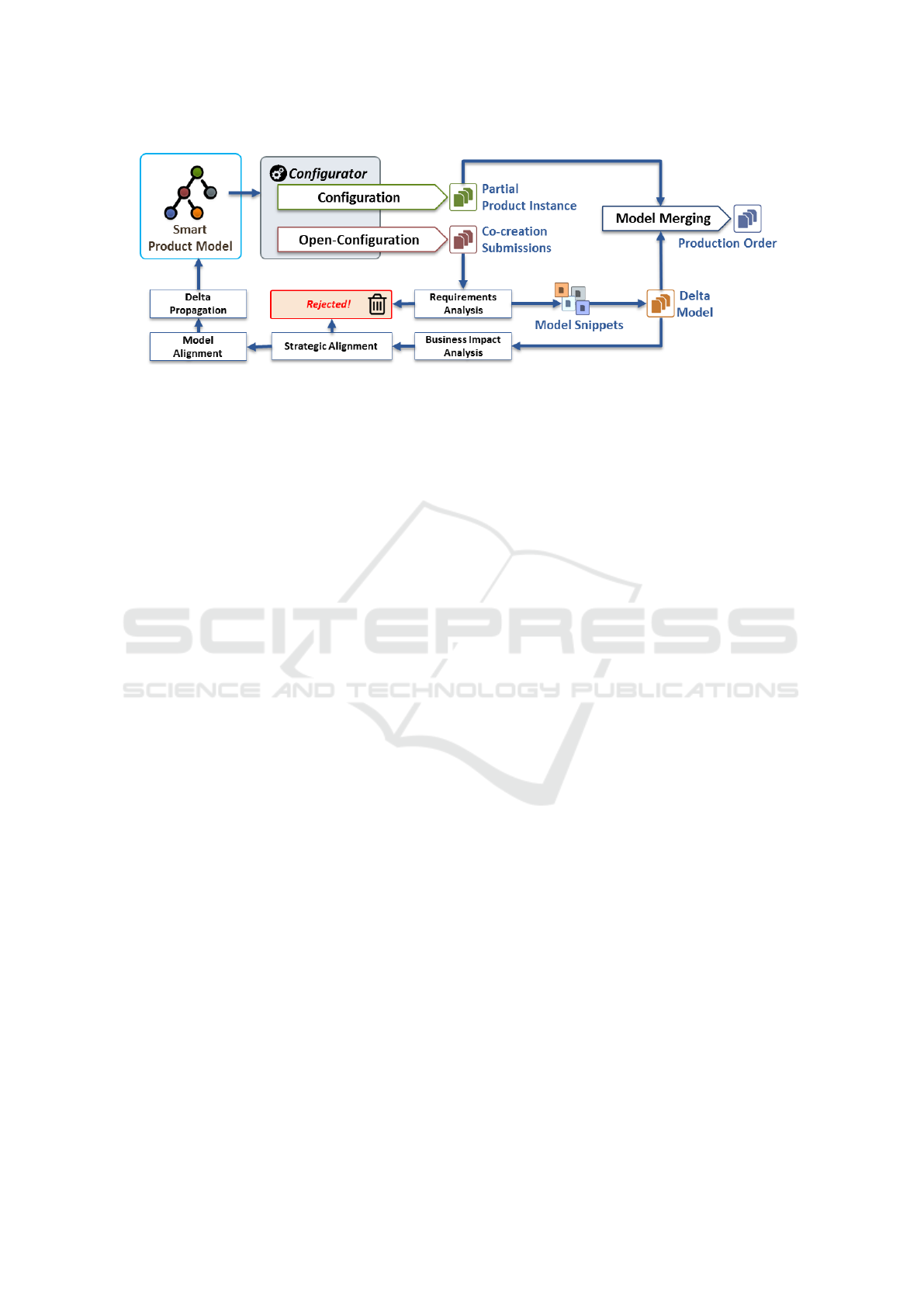

The result of a co-creation enabled configuration

process is two-fold (cf. Figure 3): a formal mo-

del of the product representing partial configuration

of the product required by the customer and a set of

ideas/requests for additional features and attributes of

the product. In a later step, the ideas/requests (sub-

missions) are analyzed and mapped to modeling en-

tities, so that MDE can be adopted all the way from

configuration to production.

The partial product instance generated as a result

of the configuration process could be sent to the fac-

tory as-is but it would reflect only a subset of the cu-

stomer requirements. A in depth analysis of the co-

creation submissions is needed to fulfil all the requi-

rements.

2.2.1 Analysis of Co-Creation Submissions

As depicted in Figure 3, co-creation at the point of

sales implies that the product has already been deve-

loped and it already supports most of the customer re-

quirements. By empowering the customer to submit

new requirements (e.g., new sensors, new colors, new

features), there are not only benefits but also the over-

all task of analyzing the customer requirements and

producing the unique variants becomes more challen-

ging. Model-based requirements elicitation (Dhun-

gana et al., 2011) can be adopted in such cases to

gain contextual and enable automated analysis met-

hods e.g., feature unweaving (Stoiber et al., 2010).

Customer Co-Creation in Smart Production Ecosystems - Opportunities and Challenges for MDE

627

Figure 2: UML meta model of products and factories, depicting the stakeholders who create the partial models. The Mar-

ketplace Operator models the Capabilities, which are the bridge between Products, Factories and Equipment. Adapted from

(Dhungana et al., 2017b).

The analysis of the requirements is to have a clear

understanding of whether the new requirement arti-

culated by the customer is feasible from a technical

perspective. Given the feasibility of production and

the agreement with the customer about the incurring

costs, the customer-specific variant can be approved

for production. In other cases, the customer-idea may

be rejected.

Adoption of MDE at this phase means automated

transfer of the new knowledge to the next steps in the

process chain. In particular, this could be achieved by

generation of partial models (comparable with model

snippets (Ramos et al., 2007)) that can be merged with

the formal partial model resulting from regular pro-

duct configuration. Model snippets in our approach

represent the differences between the offered variabi-

lity of the product-line and the additional wish of the

customer. Feedback (feature request from smart cu-

stomers) is broken into one or more model snippets,

which are then merged into one delta model (delta =

difference between product model released by the ow-

ner and the merge result of the snippets resulting from

a open configuration process).

2.2.2 Generation of Production Orders

A smart production marketplace enables “anytime

anywhere production”. This means, the specification

of how a product can be manufactured is incorporated

in the product model itself. This is an integral part of

the production order. In a scenario, where customers

are involved in the co-creation of the product they buy,

a reconciliation step is required to analyze the produ-

cibility of customer-specific variant (Dhungana et al.,

2017a). Given the technical producibility of the pro-

duct, production order can be generated and assigned

to a factory with the required capabilities.

The challenge from the perspective of MDE is

then to (semi-)automatically merge the customer-

specific product model (delta model resulting from

open configuration) and the partial product instance

resulting from conventional configuration. Together

they result in a production order - which can be auto-

nomously handled by a smart factory. Model merging

is not new to MDE and specially in product line en-

gineering model merging has been used for managing

evolution (Dhungana et al., 2008). Techniques for fe-

ature model merging (Segura et al., 2008) could also

be adopted to deal with the generation of production

orders.

2.2.3 Business Impact Analysis

Now that the customer-specific variant of the pro-

duct has been manufactured, it is often useful to un-

derstand the market potential of this product variant.

The primary goal of enabling customer co-creation

is to identify features of the product that are inte-

resting/relevant for all customers. This means, after

each open-configuration meaningful variable features

need to be elicited, analyzed, documented and valida-

ted. The business impact of the new features needs

to be analyzed and the evolution of the reference pro-

duct model can be planned. Customer involvement

in co-creation does not always imply that the propo-

sed variant of the product or the suggested new featu-

res should be automatically included in the reference

product. As argued by (Bonev and Hvam, 2012), it is

already a difficult task to come up with precise busi-

ness calculations when using an “old-fashioned” con-

figurator. The task of business impact analysis gets

slightly more complicated with new ideas generated

by customers at the point of sales.

Some support for evolution of product lines on fe-

ature level has been discussed by (Pleuss et al., 2012).

IndTrackMODELSWARD 2018 - MODELSWARD - Industrial Track

628

Figure 3: Modeling artefacts and processes involved in customer co-creation at the point of sales – depicting “Open Innovation

Loop” supported by MDE)

Techniques such as feature unweaving (Stoiber et al.,

2010) can be adopted to extract variable features from

a given software requirements model. This is often re-

ferred to as product line scoping, which is the strate-

gic decision of the business owner to include/exclude

certain variants of the product in the standard port-

folio (Schmid, 2002). Delta based model transforma-

tion (Diskin et al., 2011) can be helpful in propagating

the change to the reference model, once the business

decisions have been taken.

3 CHALLENGES AND

OPPORTUNITIES

As shown in the discussion in this paper and several

other papers on related topics (Dhungana et al., 2015),

(Dhungana et al., 2017b), (Dhungana et al., 2017a),

models form a backbone for formalizing and sharing

knowledge in a smart production ecosystem. Howe-

ver, still a lot of work needs to be done to fully unfold

the potential of MDE in this area. It is important to

address these issues, as these may be some of the inhi-

biting factors for widespread adoption of MDE in this

context, cf. embedded toolkits for user co-design (Pil-

ler et al., 2010a).

3.1 Open Innovation and MDE

One of the basic aspiration of open innovation is

to harvest new product ideas/features from a larger

crowd. This means open innovation relies on a open

world assumption – whatever is not known at mo-

deling time is not true. This is contradictory to the

principles of MDE – where a closed world assump-

tion is the basic model of operation. Extensibility

of models is therefore a key requirement (sometimes

meta-model extensions) to support model-based open

innovation scenarios.

Innovative modeling paradigms are therefore one

of the pressing needs to unfold the potential of MDE

in this area. Several extensibility paradigms known

to software engineering could be adopted for MDE.

For example, plugin-based software extension para-

digm could be adopted to define the concept of model-

plugins, which could be integrated to the parent mo-

del and integrated at runtime. Feature oriented de-

velopment of models (not just software) could be

adopted to directly reflect the application scenarios in

open-innovation. Extensibility of model interpreters

is just as important as extensibility of the models for

enacting the models at runtime.

3.2 Digital Rights Management in MDE

Product design specifications, factory capabilities and

details of factory components typically represent cru-

cial intellectual properties of their owners (product

sellers, factory operators, factory vendors). For a

smooth operation of the smart production ecosystem,

all these entities must be formally modeled and shared

(published in marketplaces) between the stakehol-

ders. However, due to the crucial nature of the in-

formation, voluntary sharing of such models and in-

formation is very unlikely.

Future research in this area therefore need to con-

sider privacy-preserving ways of modeling the infor-

mation – so that the intellectual property rights are

preserved but enough information is shared. Spe-

cial audit methods can be adopted to ensure the pro-

duction of intellectual property developed specially

for one customer (Clements et al., 2013). Some ot-

her examples of items in the research agenda are:

• Encrypted sharing of models and other entities in

the ecosystem and analysis operations on encryp-

ted models (without having to fully decrypt).

• Tools and techniques for detecting violation of di-

gital rights management based on the analysis of

Customer Co-Creation in Smart Production Ecosystems - Opportunities and Challenges for MDE

629

published models of products, factories and fac-

tory components.

3.3 Model Synchronization vs.

Knowledge Synchronization

A growing amount of companies is using model-

engineering techniques (MDE) for developing and

maintaining their product lines and software models.

The possibilities of describing complex systems at

different levels of abstraction and viewpoints seem to

be especially suited for product and production mo-

dels. This separation of concerns and thus, hetero-

geneity among the different partly overlapping mo-

dels, requires an increased effort in keeping those

models consistent. In complex environments, soft-

ware artifacts are modeled in different languages and

with different underlying meta-models. When models

from different vendors of factory HW and SW com-

ponents are used, the situation gets even more chal-

lenging. For the combination of or communication

between those models, MDE develops model virtua-

lization and transformation methods to support opera-

tions in a common meta-model language.

One of the most important transformation opera-

tors here is model synchronization (Giese and Wag-

ner, 2009): Since several developers are working on

the same product configurator model but may model

it from different viewpoints (e.g., product viewpoint

and factory viewpoint), changes or updates to mo-

dels can happen concurrently and must be propagated

to all other related models to solve potential incon-

sistencies. Therefore, dedicated approaches for bi-

directional model synchronization are required.

A number of model synchronization approaches

have been developed a in the last years (e.g., based on

Triple Graph Grammars (Hildebrandt et al., 2013) or

answer set programming (Cicchetti et al., 2011)), but

most of these approaches are based on syntactic syn-

chronization. Instead of focusing on model synchro-

nization, new ways of knowledge synchronization in

such ecosystems could be adopted to support mul-

tidimensional interactions in the ecosystem. There

are still open research questions concerning standar-

dization in the meta-model languages, and robust-

ness, performance and applicability of synchroniza-

tion methods in industrial environments.

4 SUMMARY AND

CONCLUSIONS

This paper presented a glimpse of some of the topics

of our research in the area of MDE. In our attempt

to establish a full-fledged model-based solution for

smart production ecosystems, we have encountered

some challenges in supporting customer co-creation

– which has been briefly discussed in this paper. The

focus of this paper was therefore not to present a so-

lution but rather to discuss the opportunities and chal-

lenges for MDE in the context of open innovation.

Adoption of MDE for a community based system

such as the smart production ecosystem have been

promising but some key features are currently difficult

to implement because of the lack of mature industrial

solutions to deal with privacy preserving interacti-

ons with models. Additionally, several other areas of

MDE need further maturity in terms of robustness of

the concepts and supporting tools, e.g., model snippet

merging, synchronization of models across organiza-

tional boundaries.

REFERENCES

Bonev, M. and Hvam, L. (2012). Analyzing the accuracy of

calculations when scoping product configuration pro-

jects. In Foundations of Intelligent Systems - 20th In-

ternational Symposium, ISMIS 2012, Macau, China,

December 4-7, 2012. Proceedings, pages 331–342.

Cicchetti, A., Di Ruscio, D., Eramo, R., and Pierantonio, A.

(2011). Jtl: A bidirectional and change propagating

transformation language. In Malloy, B., Staab, S., and

van den Brand, M., editors, Software Language Engi-

neering, volume 6563 of Lecture Notes in Computer

Science, pages 183–202. Springer Berlin Heidelberg.

Clements, P. C., Krueger, C. W., Shepherd, J., and Winkler,

A. (2013). A ple-based auditing method for protecting

restricted content in derived products. In 17th Interna-

tional Software Product Line Conference, SPLC 2013,

Tokyo, Japan - August 26 - 30, 2013, pages 218–226.

Dhungana, D., Falkner, A. A., Haselb

¨

ock, A., and Schrei-

ner, H. (2015). Smart factory product lines: a confi-

guration perspective on smart production ecosystems.

In Proceedings of the 19th International Conference

on Software Product Line, SPLC 2015, Nashville, TN,

USA, July 20-24, 2015, pages 201–210.

Dhungana, D., Falkner, A. A., Haselb

¨

ock, A., and Taupe,

R. (2017a). Enabling integrated product and factory

configuration in smart production ecosystems. In 43rd

Euromicro Conference on Software Engineering and

Advanced Applications, SEAA 2017, Vienna, Austria,

August 30 - Sept. 1, 2017, pages 266–273.

Dhungana, D., Haselb

¨

ock, A., and Taupe, R. (2017b). A

marketplace for smart production ecosystems. In

IndTrackMODELSWARD 2018 - MODELSWARD - Industrial Track

630

World Mass Customization and Personalization Con-

ference, MCPC’17, Aachen Germany, November 20 -

21, 2017.

Dhungana, D., Neumayer, T., Gr

¨

unbacher, P., and Rabiser,

R. (2008). Supporting the evolution of product line

architectures with variability model fragments. In Se-

venth Working IEEE / IFIP Conference on Software

Architecture (WICSA 2008), 18-22 February 2008,

Vancouver, BC, Canada, pages 327–330.

Dhungana, D., Seyff, N., and Graf, F. (2011). Research

preview: Supporting end-user requirements elicitation

using product line variability models. In Requirements

Engineering: Foundation for Software Quality - 17th

International Working Conference, REFSQ 2011, Es-

sen, Germany, March 28-30, 2011. Proceedings, pa-

ges 66–71.

Diskin, Z., Xiong, Y., Czarnecki, K., Ehrig, H., Hermann,

F., and Orejas, F. (2011). From State- to Delta-Based

Bidirectional Model Transformations: The Symmetric

Case, pages 304–318. Springer Berlin Heidelberg,

Berlin, Heidelberg.

Felfernig, A., Stettinger, M., Ninaus, G., Jeran, M., Rei-

terer, S., Falkner, A. A., Leitner, G., and Tiihonen,

J. (2014). Towards open configuration. In Procee-

dings of the 16th International Configuration Works-

hop, Novi Sad, Serbia, September 25-26, 2014., pages

89–94.

Giese, H. and Wagner, R. (2009). From model transforma-

tion to incremental bidirectional model synchroniza-

tion. Software and System Modeling, 8(1):21–43.

Gustafsson, A., Kristensson, P., and Witell, L. (2012). Cu-

stomer cocreation in service innovation: a matter of

communication? Journal of Service Management,

23(3):311–327.

Hildebrandt, S., Lambers, L., Giese, H., Rieke, J., Greenyer,

J., Sch

¨

afer, W., Lauder, M., Anjorin, A., and Sch

¨

urr,

A. (2013). A survey of triple graph grammar tools.

ECEASST, 57.

Kang, K., Cohen, S., Hess, J., Novak, W., and Peterson,

A. (1990). Feature-oriented domain analysis (foda)

feasibility study. Technical Report CMU/SEI-90-TR-

021, Software Engineering Institute, Carnegie Mellon

University, Pittsburgh, PA.

Piller, F., Ihl, C., and Steiner, F. (2010a). Embedded toolkits

for user co-design: A technology acceptance study of

product adaptability in the usage stage. In 2010 43rd

Hawaii International Conference on System Sciences,

pages 1–10.

Piller, F., Ihl, C., and Vossen, A. (2010b). A typology of

customer co-creation in the innovation process.

Piller, F., Schubert, P., Koch, M., and Moeslein, K. (2005).

Overcoming mass confusion: Collaborative customer

codesign in online communities. 10.

Pleuss, A., Botterweck, G., Dhungana, D., Polzer, A., and

Kowalewski, S. (2012). Model-driven support for pro-

duct line evolution on feature level. Journal of Systems

and Software, 85(10):2261–2274.

Ramos, R., Barais, O., and J

´

ez

´

equel, J.-M. (2007). Mat-

ching Model-Snippets, pages 121–135. Springer Ber-

lin Heidelberg, Berlin, Heidelberg.

Sabin, D. and Weigel, R. (1998). Product configuration

frameworks - A survey. IEEE Intelligent Systems,

13(4):42–49.

Schmid, K. (2002). A comprehensive product line scoping

approach and its validation. In Proceedings of the

24th International Conference on Software Engineer-

ing. ICSE 2002, pages 593–603.

Segura, S., Benavides, D., Ruiz-Cort

´

es, A., and Trinidad,

P. (2008). Automated Merging of Feature Models

Using Graph Transformations, pages 489–505. Sprin-

ger Berlin Heidelberg, Berlin, Heidelberg.

Stoiber, R., Fricker, S., Jehle, M., and Glinz, M. (2010). Fe-

ature unweaving: Refactoring software requirements

specifications into software product lines. In 2010

18th IEEE International Requirements Engineering

Conference, pages 403–404.

Customer Co-Creation in Smart Production Ecosystems - Opportunities and Challenges for MDE

631