FDTD Modeling and Simulation of Organic Light Emitting Diode

with Improved Extraction Efficiency using Moth-eye Anti Reflective

Coatings

B. M. Chaya, M. Venkatesha, Shruthi Neduri and K. Narayan

Department of Electronics and Communication Engineering, Sai Vidya Institute of Technology,

Rajanukunte, Bangalore, India

Keywords: Organic Light Emitting Diode, Anti Reflective Coatings, Light Extraction Efficiency.

Abstract: In this work modeling of two dimensional fluorescence based bottom emitting Organic Light Emitting

Diode (OLED) using Moth eye Anti Reflective Coatings (ARC) is presented. The Finite Difference Time

Domain (FDTD) mathematical modeling has been used to analyze the light extraction efficiency from

fluorescence based Organic Light Emitting Diode (OLED). The OLED structure has been simulated by

using 2D Moth-eye Anti Reflective coatings. The Finite Difference Time Domain (FDTD) method is used

to model and simulate the OLED structure. An enhancement of Light Extraction Efficiency (LEE) has been

achieved by inserting Moth-eye Anti Reflective coatings on the surface of the glass substrate which reduces

reflection and increases the transmission. Comparative study is carried out between hexagonal photonic

crystals and Moth eye Anti reflective coatings by placing these nanostructures on the substrate of OLED.

The improvement in the far field intensity of OLED structure is achieved by optimizing the angular

distribution of light through the substrate with moth eye anti reflective coatings.

1 INTRODUCTION

Organic Light Emitting Diode (OLED) is an

luminescence based device which is formed using

organic layers to produce light emission. The

excitons excitation is achieved by driving voltage as

dc source below 10 Volts (Tang and VanSlyke,

1987). The radiative decay of exciton is achieved

due to singlet, Hence the name Fluorescence based

OLED. In the OLED stack the device efficiency is

achieved by varying the electron transport layer. In

order to improve the extraction efficiency, various

transport layers are used with different work

functions as in (Do et al., 2003).

In order to various losses that exist in OLED,

many experiments were conducted in the literature.

In order increase the device performance the

Photonic Crystals (PC) is placed upon glass

substrate to realize low power consumption using

Nano imprint lithography technique which showed

better performance than conventional OLEDs (Lee

et al., 2003).

The Silicon Nitride (SiN) Photonic Crystals (PC)

are used to control light which is acting as a

dielectric medium to extract maximum amount of

photons which is trapped in high index guided

structures. Various approaches have been reported in

the literature to improve efficiency and extract

modes outside the OLED.

However different experiments on Organic LEDs

are carried out to address substrate losses using

different structures of the Photonic crystals and

using different substrates as reported in (Kim et al.,

2004). The light extraction efficiency has been

achieved by incorporating dielectric Nano particles

placed at the substrate and scattering efficiency is

calculated by using Mie theory as discussed in

(Mann et. al., 2017).

The Anti reflective coatings can be used on the

backside of the glass substrate to achieve

enhancement in the luminescence and was fabricated

by Magnesium Fluoride (Saxena et al., 2008) In the

recent advancements the Moth eye Antireflective

coatings were introduced to used it for display

applications, such as solar cells (Tan et al., 2017).

The light out coupling efficiency is enhanced by

using Bio inspiring concept of moth eye anti

reflective coatings. This is used to suppress

266

Chaya, B., Venkatesha, M., Neduri, S. and Narayan, K.

FDTD Modeling and Simulation of Organic Light Emitting Diode with Improved Extraction Efficiency using Moth-eye Anti Reflective Coatings.

DOI: 10.5220/0006651702660272

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 266-272

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

reflection and extract maximum modes outside the

OLED compared to Conventional approaches of

OLED. (Zhou et al., 2014).

This research work is being carried out aiming at

increasing the light extraction efficiency of OLED.

In this paper an OLED with moth eye Anti reflective

coatings are used with glass as a substrate and by

using point dipole source to increase the number of

photons in the emissive layer. In this work, we are

addressing substrate losses that exist when light is

coupling out into the air. This is done by

incorporating moth eye Anti reflective coatings

between air medium and the substrate. Comparative

study is carried out for different structures of OLED.

2 OLED STRUCTURE

2.1 Design of OLED

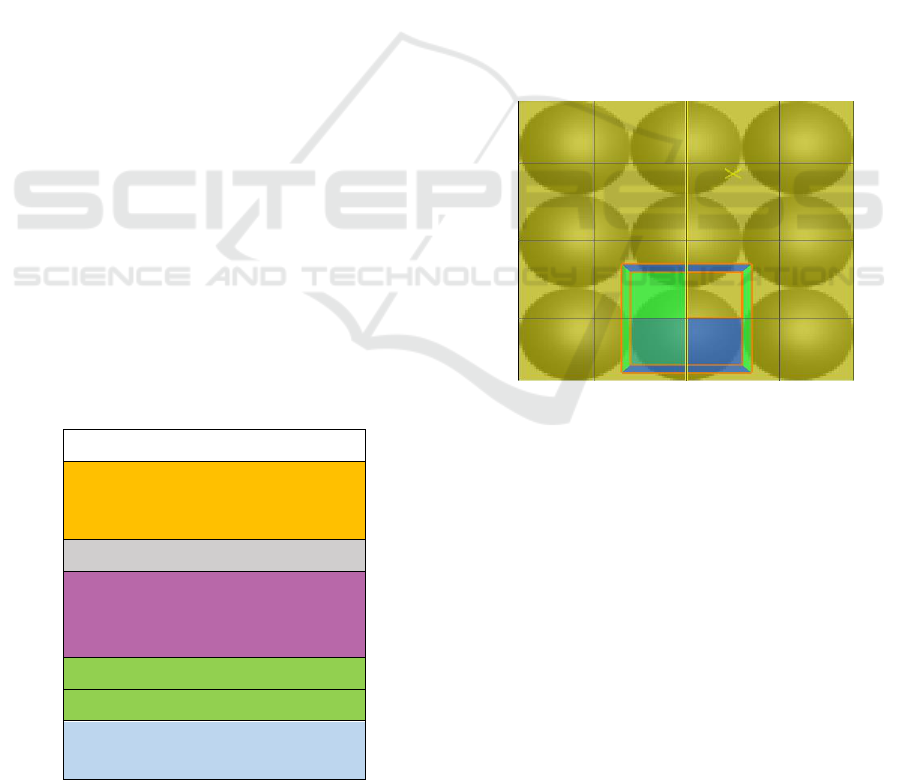

Figure 1, shows the structure of Organic Light

Emitting Diode (OLED) which is modeled using

Lumerical FDTD (Finite Difference Time Domain).

The proposed structure uses glass substrate. The

device structure consists of thin active organic layers

integrated into injected electrons and holes. These

transport and organic Layers which is about 200nm

is placed between anode and cathode layer. In this

structure, the Moth eye Anti reflective coatings are

placed between air medium and the Glass substrate.

This OLED designed is proposed in this paper to

achieve maximum light out coupling from the

fluorescence based green light emitting device. The

green light is due to the organic layers present in the

device which is aiming to emit light at green

wavelength at 540nm.

Air

Moth Eye Reflective Coatings,

Pitch=300nm, Radius of

curvature=100nm

Glass Substrate

Anode ITO =120nm

HIL=CuPc=15 to 30nm

HTL=TPD=40nm

α-NDP =30nm

Alq3=60nm

HBL=BCP=30nm

Cathode=Al=100nm

Figure 1: Fluorescence based OLED.

2.2 Modeling of Moth Eye Anti

Reflective Coatings

The Moth eye Anti Reflective coatings very

important in various display applications like LEDs,

photo detectors and solar cells, where reflection loss

is to be minimized. This structure is inspired by Bio

mimic array and reduces the internal reflectance

outside their operating wavelength(Cho et al., 2017).

The eye of a Moth insect has a periodic

nanostructure in coating layer are tapered and air

fraction decreases in the coating towards the

substrate

We set x span and y span to be 0.5um for the

simulation region, which includes only one unit cell.

Since the structure exhibits both symmetry and

periodicity.

The boundary condition chosen is as follows:

•x-min bc = x-max bc = antisymmetric

•y-min bc = y-max = symmetric

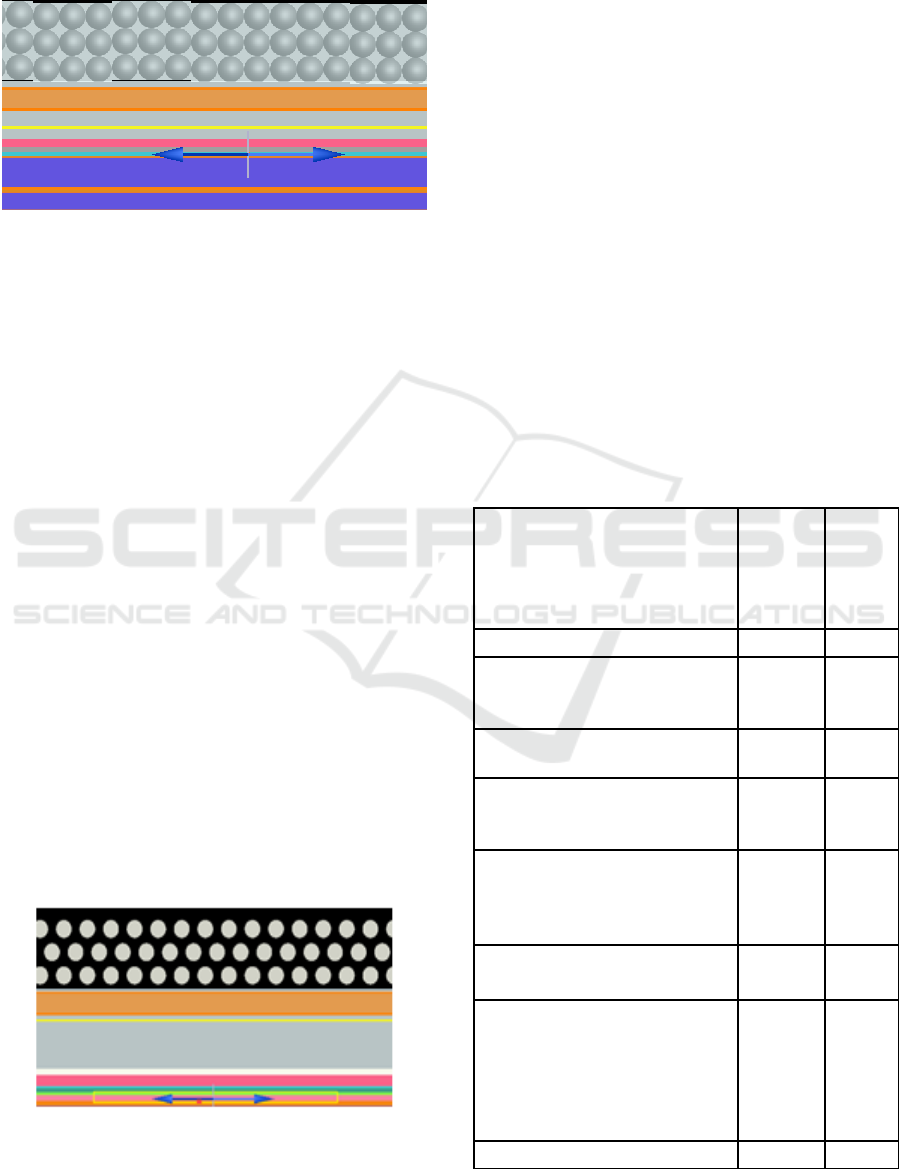

Figure 2: Modeling of Moth-eye anti reflective coatings

(ARC) with pitch chosen to be 300nm and radius of

curvature of 100nm.

In this simulation, the reflectance with respect to

wavelength is measured and get insight of where

Electromagnetic energy is absorbed and where

photoelectrons are created. FDTD simulation

method is used to model this Moth-eye gold

nanostructure.

2.3 Modeling of OLED using Moth Eye

Anti Reflective Coatings

The OLED device structure is modeled and

simulated as shown in the Figure 3 using various

materials as shown in Table 1. The modeling is done

by using Lumerical FDTD (Finite Difference Time

Domain). The device structure consists of thin active

FDTD Modeling and Simulation of Organic Light Emitting Diode with Improved Extraction Efficiency using Moth-eye Anti Reflective

Coatings

267

organic layers which are integrated with moth-eye

anti reflective coatings using Silicon Nitride material

and glass substrate.

Figure 3: Modeling of OLED using Moth eye Reflectors

(XY View).

The thickness of organic layers is about 200nm

and is positioned between anode and cathode. The

Moth-eye Anti reflective coatings are made of

silicon Nitride material is of around 400 nm

thickness. The total stacking height of OLED

structure is of the order of 1500 nm.

The modelling is done for the proposed structure

shown in Figure 1. The moth-eye Anti-reflectors

coatings are used to reduce the internal reflectance

on the surface of the substrate.

These coatings are used upon the surfaces to

improve the out coupling efficiency of the devices.

The Moth-eye Antireflective coatings nanostructures

increase the efficiency of Organic Light Emitting

Diode .This structure is inspired by Bio mimic array

and operating at 540nm and reduces the internal

reflectance outside their operating wavelength.

2.4 Modelling of OLED using Two

Dimensional Hexagonal Photonic

Crystals

Figure 4, shows the modelled Photonic Crystal (PC),

used in OLED.

The photonic crystal is used for modeling for

different OLED structures as discussed in

Figure 4: Modeling of OLED using Hexagonal Photonic

Crystal (XY View).

literature work. The PC used in this work has lattice

constant of 300nm and radius is of 100nm. The

simulation is done using Photonic crystal made up of

Silicon Nitride which has refractive index of 1.9.The

Brillouin zone chosen is in the form of a hexagon.

Hence it is called as Hexagonal Lattice Brillion

Zone (Joannopoulos et al.,2008).

This modelling is done using lumerical FDTD

for the design shown in Figure 1 using materials

shown in Table 1. This is simulated using Photonic

crystals to make the comparative study with the

OLED structure with Moth eye Anti reflective

coatings placed on the surface of the glass substrate.

3 OLED MATERIALS

The various materials used in OLED structure are

shown in the Table 1.

The work function for various materials used in

OLED are carefully chosen depending on the energy

levels at metal organic interface abiding by Mott

Schottky limit (Novotny et al., 2006).

Table 1: Materials used in the OLED Structure.

Materials

Work

Function

Refra-

ctive

index

(n)

Anode –ITO- Indium Tin Oxide

4.7eV

1.806

Cathode- Al- Aluminium

4.1eV

1.031

Hole Blocking Layer (HBL)-

BCP-(2, 9 Dimethyl-4, 7-

diphenyl-1, 10 phenanthroline

3.2eV

1.686

Hole Injection layer(HIL)-CuPC-

(Copper (II) phthalocyanine)

3.1eV

0.47

Hole Transport layer(HTL)-TPD-

(N, N’-Bis (3-methylphenyl)-N,

N’-diphenylbenzidine)

2.6eV

1.67

Alq

3

-Tris(8-

hydroxyquinoline)aluminum

HOMO-

5.62eV

LUMO-

2.85eV

1.68

α-NDP- N,N`- diphenyl-

benzidine

2.5eV

1.82

Photonic crystals–SiN-Silicon

Nitride-(Lattice Constant

=350nm)

Moth Eye Anti Reflective

coatings

(pitch=300nm, radius=100nm)

----

1.9

Glass Substrate

----

1.53

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

268

The thickness variations and Organic Layers

with the HOMO (Highest Occupied Molecular

Orbital) and LUMO (Lowest Unoccupied Molecular

Orbital) levels of organic molecules are given. The

most commonly used HIL is CuPC (Copper (II)

phthalocyanine) is used to improve the carrier

injection efficiency. The HTL used here is

TPD (N, N’-Bis (3-methylphenyl)-N, N’-

diphenylbenzidine).

The hole transport layer and hole injection layer

placed above organic layers. The hole injection layer

is used to improve the carrier injection efficiency,

and serves two purposes, first, it provides a path for

smooth travel of injected holes up to emitting layer.

Second, it functions like electron blocker to confine

electrons within an emitting layer.

4 METHODOLOGY

The Finite Difference Time Domain (FDTD)

method is most widely used method to solve

Maxwell's equations and simulate Nano-photonic

devices(Gedney,2011). FDTD method is used to

investigate and analyze the light propagation. Light

of UV, Visible and IR regions propagating through

different layers with complex geometries can be

analyzed and simulated with the help of FDTD

(Taflove,1995). Thus it is possible to analyze the

propagation of Electromagnetic wave inside the

structure(Sullivan,2013).

Since the OLED device configuration is limited

for single wavelength at 540nm, the optical

thickness of Moth eye is given by(Cho BJ et

al.,2017),

n

2

*d=λ/4 (1)

Where, d= geometrical thickness of the film,λ=

peak wavelength of light emitted by

OLED,n

2

=refractive index of the coating material..

Therefore, d=λ/4*n

2

Where, d= geometrical Thickness of the film, λ=

peak wavelength of light emitted by OLED.

Under these conditions destructive interference

occur and cancel each other and light is coupled out.

For a single homogeneous layer with refractive

index n, will suppress reflectance between

substrate(n

s

) and air (n

a

) for normal incident of light

and optical thickness λ/4, If, n=(n

s

n

a

)

0.5

is fulfilled.

The Far field analysis accounts for the reflection

and refraction that would occur at the Far-field

substrate air interface. The fraction of source power

transmitted into far field is derived.

A point dipole power source is used to generate

charge carriers. The power radiated by an electric

dipole in homogenous material is calculated

(Novonty et al., 2006)

c

pnP

3

||

4

4

2

0

0

(2)

Where,

0

(Cm)=dipole moment and

0

magnetic

permeability,

c

=speed of light.

When the light emerges out of substrate, it would

undergo refraction, reflection at the interface of

substrate and air. This is analyzed by Far Field

analysis.

The mathematical formulation for the electric field

at far field is as shown below:

The Substrate air interface relation is derived by

Fresnel's law(Chutinan et al., 2005),

2

0

2 2 2 2 2

0

22

0

1 . 1 1 1

0

1

| | . sin

2

1

( | | .| | ) sin

2

s s s p

n E d d

n T E T E d d

(3)

Where,

0

= Absolute permittivity,

0

= Absolute

Permeability,

n

1

=Refractive index of air,

n

2

=

Refractive index of Substrate,

s

T

and

P

T

are

calculated as below using Fresnel equations,

2 2 2

1

2

2

| | ( .| | .| | )

s s s p

d

E T E T E

d

(4)

Where,

s

T

and

P

T

are Fresnel transmission power

coefficients in far field,

s

E

and

P

E

are Fresnel

Electric field coefficients in far field.

2

E

= Electric

field beyond the far field interface. The Finite

difference Time Domain (FDTD) method is used

for solving Maxwell’s equations in complex

geometries.

FDTD Modeling and Simulation of Organic Light Emitting Diode with Improved Extraction Efficiency using Moth-eye Anti Reflective

Coatings

269

5 RESULTS

5.1 Far Field Intensity of OLED

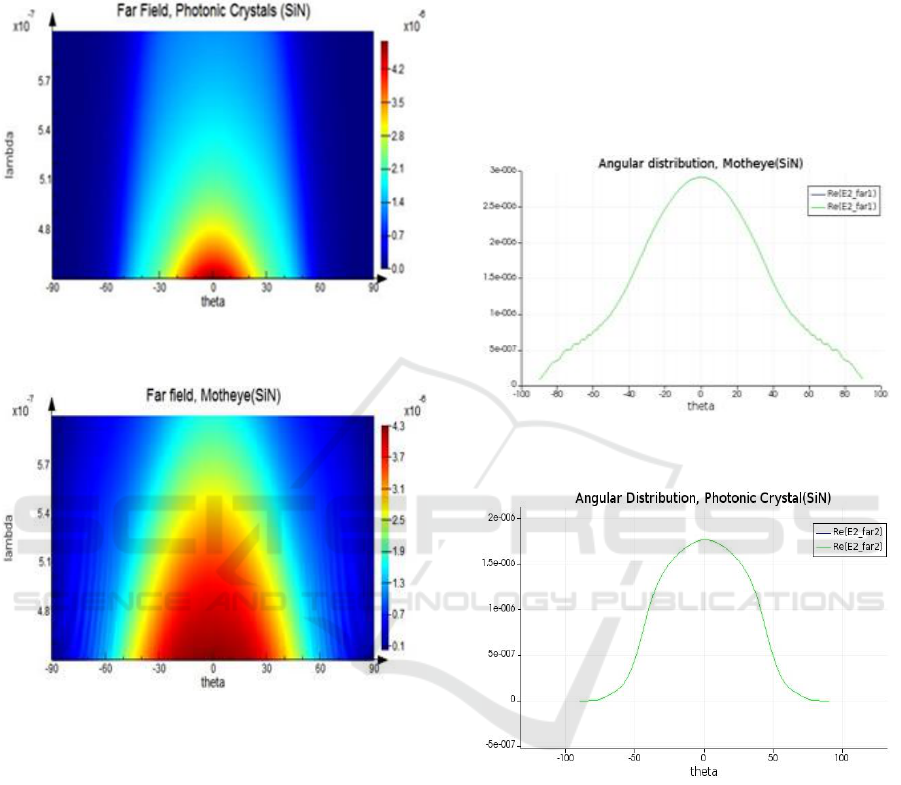

Figure 5(a): Far field Intensity of OLED with Photonic

crystals using SiN Material.

Figure 5(b): Far field Intensity of OLED with Moth eye

Anti Reflective surface with SiN Material.

Figure 5, shows the maximum Light extraction

efficiency from the modeled OLED structure that

escapes into air.

is the angle at which light

emerges out of OLED. This angle is with respect to

the normal to the interface surface. Figure 5(a)

indicate the light emerges out in the range of -30

0

to

+ 30

0

,

when Photonic crystal is placed upon the

substrate. That is range of light emergence is spread

out for near 80

0

.

However the intensity of light is subtended. In

comparison Figure 5(b) shows that light emerges out

with wider range of -50

0

to +50

0

. Also the light

emitted is much more bright when moth eye ARC is

placed upon the substrate.

This indicates that by introducing Moth eye

antireflection coatings on the substrate of OLED, the

emission of light is spread over greater range of

angle and also intensity of light is greater at 540nm.

This is because the Moth eye has a periodic

nanostructure in coating layer are tapered and air

fraction decreases in the coating towards the

substrate, whereas the Photonic crystals has planar

coating layer.

5.2 Angular Distribution of OLED at

540nm

Figure 6(a). Angular Distribution of OLED with Moth eye

Anti Reflective surface with SiN Material.

Figure 6(b). Angular Distribution of OLED with Photonic

crystals with SiN Material.

The Angular distribution outputs are shown for

OLED structures with moth eye and photonic

crystals in figs 6(a) and 6(b).

The output is obtained for the modelling

strucutre shown in figure 3, and the simulation is

done using FDTD method.

It is observed that, the far field intensity for

OLED with moth eye structure is 3 µV/m and that of

OLED with PC is 1.8µV/m. Both the OLED

structures are simulated for Silicon Nitride material.

Hence there is an significant improvement in the

far field intensity in extracting light out coupling

efficiency from an OLED.

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

270

However the presence of Moth-eye structure has

channelized more light through the same angle of

emission which otherwise would have been lost due

to TIR within OLED and reducing internal

reflection.

5.3 Simulation Outputs for OLED

Structure without Moth Eye ARC

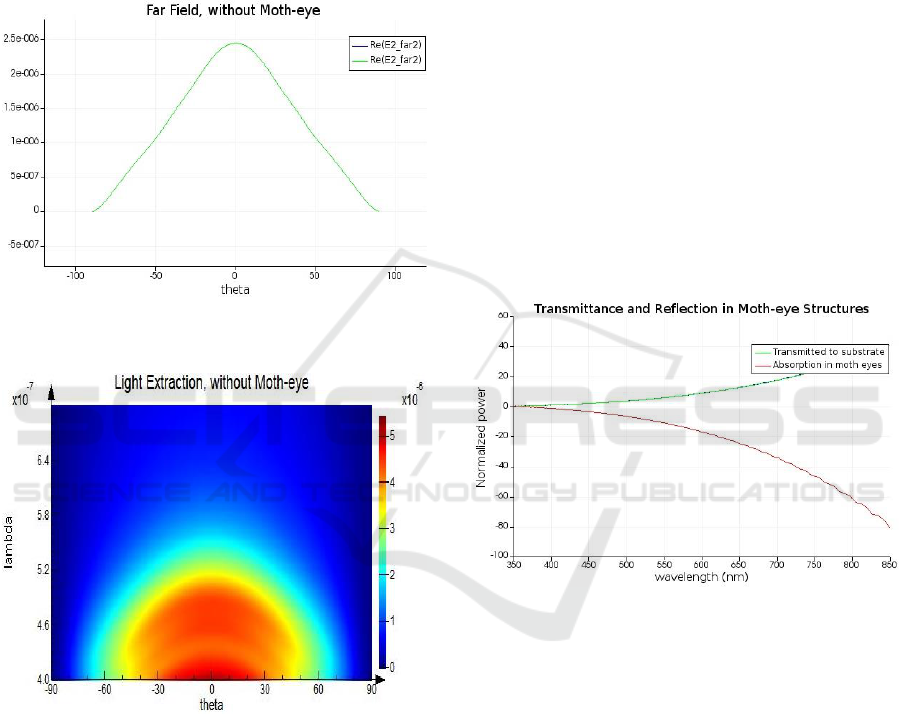

Figure 7(a). Angular Distribution for OLED without Moth

eye ARC.

Figure 7(b). Far field Intensity for OLED without Moth

eye ARC.

The simulation was carried out for the OLED

structure without using Moth eye Structure on the

surface of the glass substrate. This OLED structure

has no Nano structure placed on the surface of the

glass substrate. The far field intensity is observed to

be 2.5µV/m as shown in the Figure 7(a) and 7(b).

Hence we observe that, by placing Moth eye ARC

better light coupling is achieved.

5.4 Moth Eye Anti Reflective Coatings

Transmission and Reflectance

Curves

The Moth eye Anti Reflective coatings are used to

increase the transmission and to suppress the

reflection that occur while light is out coupling from

the glass substrate and outside OLED.

Figure 8 shows the amount of light transmitted

from the substrate. This simulation output is

obtained for the modelling of moth eye structure as

shown in Figure 2.

In fact such a light source can be monolithically

integrated with Lab-on-a-Chip sensor systems.

Fabrication of such an OLED structures can find

future applications used as a integrated light source

for optical Lab-on-a-Chip based bio-sensors.

Hence, there is a improved light extraction

efficiency for the structure with Moth eye ARC on

the substrate compared to the OLED structure with

Photonic crystals

Figure 8. Transmittance and Reflectance curves.

Figure 8 shows amount of light absorbed by the

moth eye ARC i.e., anything that transmits light is

all absorbed in the substrate. The moth eye ARC are

used because of its periodic nanostructure and are

tapered.

The optimized output for different OLED

structures with different materials are simulated and

the far field intensity values for the same is tabulated

at a wavelength of 540nm as shown in Table 2.

FDTD Modeling and Simulation of Organic Light Emitting Diode with Improved Extraction Efficiency using Moth-eye Anti Reflective

Coatings

271

Table 2: Optimized output obtained for different OLED

structures and different materials.

Parameters

Materials

Far field

intensity

achieved

OLED with

Moth eye Anti

Reflective

coatings

Gold(Au)

3.5 µV/m

Silicon

Nitride(SiN)

2.9 µV/m

Al

2

O

3

3.2 µV/m

OLED with

Photonic

crystals placed

on substrate

Gold(Au)

1.3 µV/m

Silicon

Nitride(SiN)

1.75 µV/m

Al

2

O

3

1.33 µV/m

OLED

structure

without any

Nano structure

-----

2.5 µV/m

6 CONCLUSIONS

In this work, two dimensional Finite Difference

Time Domain (FDTD) modeling of Fluorescence

based OLED using glass substrate has been

presented. An enhanced far field intensity of 3.5µ

Vm

-1

has been achieved for a wavelength of 540 nm

by placing Moth eye Anti reflective coatings

between the substrate and the air medium. The moth

eye Antireflective coatings are placed on the surface

of the substrate of OLED will enable maximum light

out coupling efficiency compared to Conventional

OLED structure. This Anti reflective coatings

reduces reflection and increases transmission of

light.

In this work, Different OLED structures have

been designed with different materials. It is found

that OLED with Moth eye Anti Reflective coatings

with gold nano particles has increased far field

intensity compared to other materials.

ACKNOWLEDGEMENT

The authors would like to thank Science and

Engineering Research Board, Department of Science

and Technology (DST-SERB) Government of India

for funding this research work. File No.

YSS/2015/000382

REFERENCES

Tang, C. and VanSlyke, S. 1987. Organic electrolumines-

cent diodes. Applied Physics Letters, 51 (12), p.913.

Do, Y., Kim, Y., Song, Y., Cho, C., Jeon, H., Lee, Y.,

Kim, S. and Lee, Y. 2003. Enhanced light Extraction

from Organic Light Emitting

Diodes with 2D

SiO

2

/SiN

x

Photonic

Crystals. Advanced Materials, 15

(14), pp. 1214-1218.

Lee, Y., Kim, S., Huh, J., Kim, G., Lee, Y., Cho, S., Kim,

Y. and Do, Y. 2003. A high-extraction- efficiency

Nano patterned organic light-emitting diode, Applied

Physics Letters, 82(21), p.3779.

Kim, Y., Song, Y., Y. W., & Lee, Y. H. 2004. Enhanced

light extraction efficiency from organic light emitting

diodes by insertion of a two- dimensional photonic

crystal structure. Journal of Applied Physics. 96(12),

7629.

Mann V., Rastogi V.2017. Dielectric nanoparticle for the

enhancement of OLED light Extraction efficiency.

Journal of Optics Communications. 387, 202-207.

Saxena K, Mehta Singh D, Kumar Rai V, Srivastava R,

Chauhan G, Kamalasanam M N.2008. Journal of

Luminescence.128, 525-530.

Tan G., Lee J H., Lan Y., Wei MK., Peg L H, Chen I-

Chun, Wu S. T., 2017. Optica.4(7),678-683.

Zhou L., Ou Q D.,Chen J D.,Shen S.,Tang J X.,Li Y Q.,

Lee S. T., 2014. Light Manipulation for organic Opto

Electronics using Bio-inspired moth’s eye Nano

Structure. Journal of Scientific Reports.10, DOI:

10.1038/srep04040.

Joannopoulos, J., Johnson, S., Winn, J. and Meade, R.

2008. Photonic Crystals, Molding The Flow ofLight.

2nd ed. Princeton: Princeton University Press.

Novotny, L. and Hecht, B.2006. Principles of Nano-

Optics, Cambridge, Cambridge University Press.

Chutinan, A. et al., 2005. Theoretical Analysis on light-

extraction efficiency of organic light-emitting diodes

using FDTD and mode- expansion methods, Organic

Electronics. 6(1), pp.3-9.

Gedney S D.2011. Introduction to the Finite-Difference

Time Domain (FDTD) Method for Electromagnetics,

Morgan and Claypool Publishers

Sullivan D M., 2013., Electromagnetic using the FDTD

method, IEEE Wiley Press, 2nd ed., 54.

Taflove A., 1995. Computational Electrodynamics: The

Finite-difference Time-domain Method, Artech House,

Norwood, MA.

Guo K W.2016.Broadband Anti reflection film with Moth

eye like structure for flexible display applications,

JSM Environ Sci Eco ,4(2),1031.

Hedavati M K, Elbahari M., 2016. Anti Reflective

Coatings Conventional Stacking Layers and Ultra Thin

Plasmonic Meta Surfaces.9, 497.

Han Z W, Wang Z, Feng X M, Li B, Mu Z, Zhang J Q,

Niu S C, ren L Q. 2016. Anti Reflective surfaces

inspired from biology: A review. Biosurface and

Biotribology,2,137.

Cho B J, Park J S, Huang J M,Ko J H.2017. Supression of

reflection peaks caused by moth eye type nano

structures for nano structures for anti reflectin

applications studied by using FDTD simulation,

Journal of Information Display.18(3),137-144.

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

272