Development of Mid-IR Fiber Bundle for Thermal Imaging

Andrea Ventura, Joris Lousteau, Fedia Ben Slimen, Nicholas White and Francesco Poletti

Optoelectronics Research Centre, University of Southampton, Southampton, SO17 1TW, U.K.

Keywords: Thermal Imaging, Infrared Fibers, Coherent Bundle, Modelling.

Abstract: We present and discuss the fabrication and characterization of a Mid-Infrared (Mid-IR) transparent flexible

bundle based on 1200 fibers whose cores consist of a Ge

30

As

13

Se

32

Te

25

chalcogenide glass and the cladding

of a Fluorinated Ethylene Propylene (FEP). The Mid-IR fiber bundle was manufactured using the stack and

draw method. The high index contrast between the glass and the cladding allows for strong field confinement

of the well guided modes within the chalcogenide glass core transparent across the Mid-IR. Higher order

modes, which could be prone to cross talk, suffered high losses thanks to the high attenuation offered by the

polymer cladding. Additionally, the FEP cladding confers the bundle mechanical flexibility. Following a

qualitative thermal imaging assessment, we also present and discuss the experimental loss measurements of

the fiber bundle and we compare them to values obtained through modelling to conclude on the potential

prospect of the manufactured bundle and its possible improvements.

1 INTRODUCTION

Over the last two decades, Mid-IR detector

technology and other Mid-IR optical components

such as lens and material have undergone significant

development and improvement in terms of

performance and reliability. Thermal imaging is now

slowly becoming a standard inspection technique in

fields such as defence, security, industrial processes,

medical and physiological activities monitoring.

Thermal imaging relies on the detection of infrared

radiation (IR) emitted by any physical body held at a

temperature above 0 K. Mid-IR detectors based either

on InSb technology or on the Microbolometer

detectors offer high sensitivity/detectivity in the Mid-

IR region (1-5.5 µm) and in the wavelength range

between 8-14 µm, respectively (Infrared Detectors,

2017). In some cases the main restriction to a

widespread use of thermal imaging is the lack of a

flexible imaging bundle for the inspection of remote

access area or purely for its practicality and

convenience. Although a boroscope approach is

achievable, a Mid-IR transmitting coherent fiber

bundle is the most adapted solution thanks to its

flexibility. “Coherent” fiber bundle consists in arrays

of optical fibers where each fiber represents a pixel,

where “coherent” implies a direct pixel matching

between the bundle ends. If compared to boroscope

approach the fiber bundle is insensitive to vibrations

due to the absence of moving optics and allows to

change the viewing angle quickly. Despite its

technological importance there are currently no

infrared high resolution fiber bundles commercially

available. In order to realise a coherent fiber bundle

that operates in the Mid-IR region, both the bundle

material and the bundle structure play an important

role. Numerous attempts were made to develop such

device (Rave, 2000; Gopal, 2004; Zhang, 2015;

Chenard, 2017; Nishii, 1991). These works involved

different Mid-IR transmitting materials and hollow

core fiber structure. Perhaps the most significant

work reported in terms of performances is that of

Nishii et al. (1991). Although, the final bundle

appears to be bulky and not fully coherent, Nishii et

al. (1991) demonstrated a high spatial resolution

bundle for temperatures low as 25 ºC. The objective

of this work is to develop a coherent fiber bundle a

few meters long with low loss, high spatial resolution

and efficient for temperatures between 20 and 200 °C.

As mentioned before, in the literature different Mid-

IR fiber bundles have been reported, but they still

have limitations such as size, resolution, high losses

and flexibility. We present the fabrication of a

coherent Mid-IR fiber bundle whereby by exploiting

a pertinent choice of materials we aimed at reducing

the pixel and the pitch dimensions without inducing a

severe crosstalk.

Ventura, A., Lousteau, J., Slimen, F., White, N. and Poletti, F.

Development of Mid-IR Fiber Bundle for Thermal Imaging.

DOI: 10.5220/0006639502590265

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 259-265

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

259

2 BUNDLE FABRICATION AND

CHARACTERIZATION

We designed and chose the materials for

manufacturing the Mid-IR transmitting bundle

according to the following general guideline. The

core material must have:

• Transparency in the Mid-IR region (2-20

µm)

• High refractive index

• Low losses

Some advantages for the bundle fabrication could be

obtained using a cladding material with features such

as:

• Low refractive index

• High optical attenuations across the Mid-IR

• Low Young modulus

The high optical attenuations of the cladding material

allow to minimize the cross talk between individual

cores while its low Young modulus provides

flexibility to the overall structure. Furthermore, the

high index contrast between the core and the cladding

allows for a strong electromagnetic field confinement

inside the low loss core. This strategy ensures

practical Mid-IR transmission of low order optical

modes for thermal imaging. The materials used in the

present work have these characteristics. In fact, the

core and the cladding materials were in chalcogenide

Vitron IG3 glass and FEP polymer respectively.

2.1 Core Material: Chalcogenide

Vitron IG3

As core material we chose the chalcogenide Vitron

IG3 glass Ge

30

As

13

Se

32

Te

25

which is a commercial IR

transmitting glass provided by Vitron (Schott). This

glass has large transmission spectrum (2 - 12 µm),

high refractive index (2.832 at 2 µm) and it is

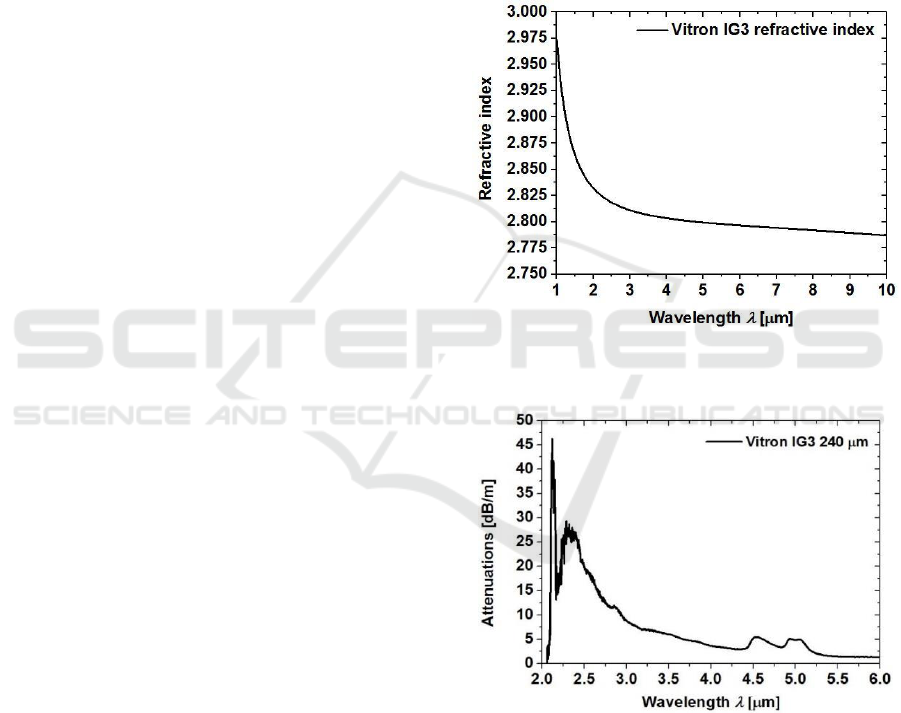

thermally stable. The refractive index n of Vitron IG3

glass as a function of wavelength is shown in Figure

1 (Vitron IG3, 2014). Vitron IG3 glass exhibits a

glass transition temperature (Tg) at approximately

275 °C (Vitron IG3, 2014). In order to measure the

Vitron IG3 glass attenuations the cut-back method

was applied on an uncladded Vitron IG3 glass fiber

of 240 µm of diameter. The uncladded Vitron IG3

glass fiber was obtained by drawing a Vitron IG3

glass rod of 12 mm of diameter. 39 transmission

measurements were done and each cut was of 10 cm.

The transmission of the uncladded Vitron IG3 glass

fiber was measured by using the ARCoptix Mid-IR

FTIR spectrometer. It has a Mercury Cadmium

Tellurite (MCT) detector that covers a wavelength

range between 2 and 6 µm (ARCoptix FT-IR Rocket

data sheet, 2015). The Thorlabs SLS202L tungsten

light source (wavelength range: 450 to 5500 nm) that

emits IR light was used. Its emission is similar to a

black body radiator at 1900 K (Stabilized Tungsten

Light Sources, 2017). By using FC/PC connectors,

one of the two ends of the fiber was connected to the

Thorlabs SLS202L tungsten light source whereas the

other end of the fiber was connected to the FTIR

spectrometer. The uncladded Vitron IG3 glass fiber

attenuations in dB/m measured using FTIR

spectrometer are shown in Figure 2.

Figure 1: Refractive index of Vitron IG3 glass at different

wavelengths provided by Vitron (Vitron IG3, 2014).

Figure 2: Vitron IG3 glass attenuations measured using

FTIR spectrometer on an uncladded fiber of 240 µm of

diameter.

According to Snopatin et al. (2009), the functional

groups [OH]

-

and GeH absorb at 2.92 and 4.95 µm

respectively. The bands that appear at 2.32 and 4.52

µm are attributed to SeH bond vibration (Snopatin,

2009). As the wavelength increases, the attenuations

decrease (Figure 2); the uncladded Vitron IG3 glass

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

260

fiber displays typical loss values of 5 dB/m for

wavelength ranging from 3 to 6 µm. Between 2 and 3

µm the uncladded fiber presents loss higher than 10

dB/m.

2.2 Cladding Material: Fluorinated

Ethylene Propylene (FEP)

As cladding material, we chose the FEP polymer. It

has similar chemical and electrical properties as the

Teflon PTFE, however it is thermoplastic; the latter

property allows to draw it into a fiber, while its low

Young modulus allows to realise flexible fibers or

bundles. Moreover, FEP polymer has a low refractive

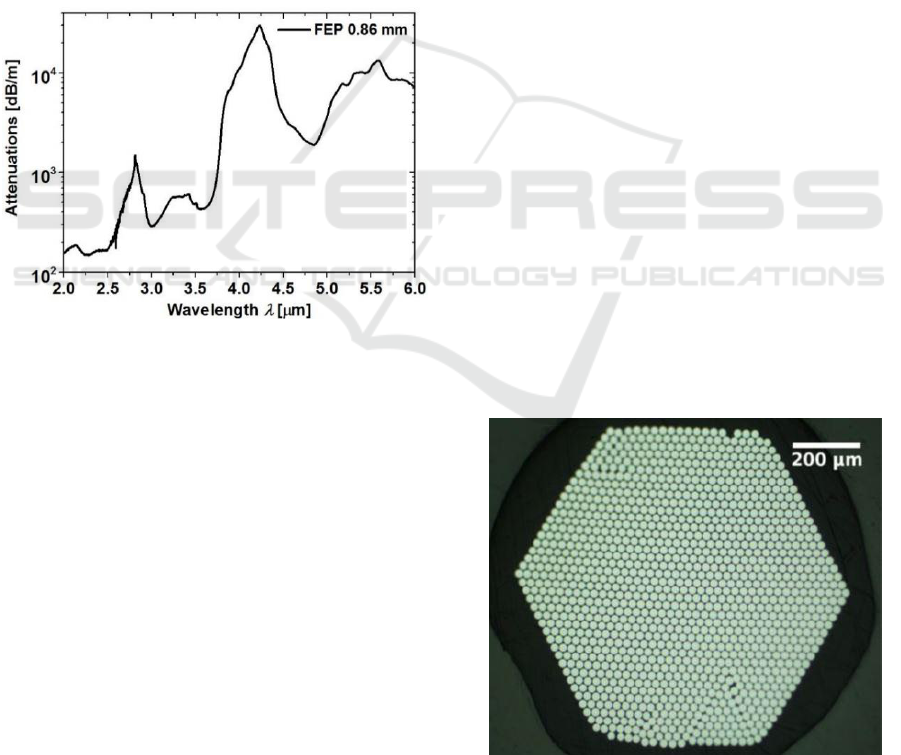

index (n=1.341) (FEP Handbook). Figure 3 shows the

FEP polymer attenuations in dB/m unit measured on

a 0.86 mm thick sample using a Varian 670 FTIR

spectrometer.

Figure 3: FEP attenuations measured using FTIR

spectrometer on a sample 0.86 mm thick.

From Figure 3 it is possible to notice that the FEP

polymer optical losses are high, tipically above 1000

dB/m in the wavelength range between 4 and 6 µm.

According to Galante et al. (2010), the absorption at

4.23 µm is due to the CF2 and the band at 5.57 µm is

due to terminal double bonds –CF=CF2 in the

polymer chain.

2.3 Bundle Fabrication

A chalcogenide bundle with 1200 fibers was

manufactured by using the stack and draw technique.

The fibers were made with Vitron glass IG3 core and

FEP polymer cladding. A Vitron IG3 glass preform

of 12 mm of diameter was inserted in FEP polymer

tube with external diameter equal to 14 mm and then

placed into the drawing tower furnace under dried Ar

atmosphere. Approximately 170 meters of fibers of

300 ± 8 µm in diameter were drawn at a speed of 2.1

m/min. This substantially high diameter variation is

attributed to bubbles in the FEP polymer cladding.

The Vitron IG3 glass appears to be crystal free and

pristine. After the fiber fabrication, a stack of 1200

fiber sections, 120 mm long each, was realised and

then it was inserted in an additional FEP tube with

external diameter equal to 14 mm. This preform was

drawn into two different fiber bundles of 1.1 and

0.675 mm of outer diameter, corresponding to

individual core diameter of 22 µm and 13 µm,

respectively. The overall yield was about 6 meters in

length. Following fabrication, the fiber bundle was

cut into sections of various lengths, ranging from 95

cm to 123.5 cm, to be characterized individually.

Thermal images of a heating element were performed

by using the fiber bundles and their attenuations were

measured.

2.4 Bundle Characterization

In order to optimize the signal transmission, the ends

of the fiber had first to be polished. This was achieved

using a special jig designed in-house. The polishing

procedure was carried out using a Logitech PM5

machine. Figures 4 and 5 show the optical

micrographs of polished bundles of 22 µm and 13 µm

in core diameter by using a Nikon Eclipse

microscope. Overall, in the bundle structure the fibers

are orderly stacked as in the original preform. A few

pixels are missing or slightly out of position but

further improvements are readily achievable by

further increasing the density of the original preform.

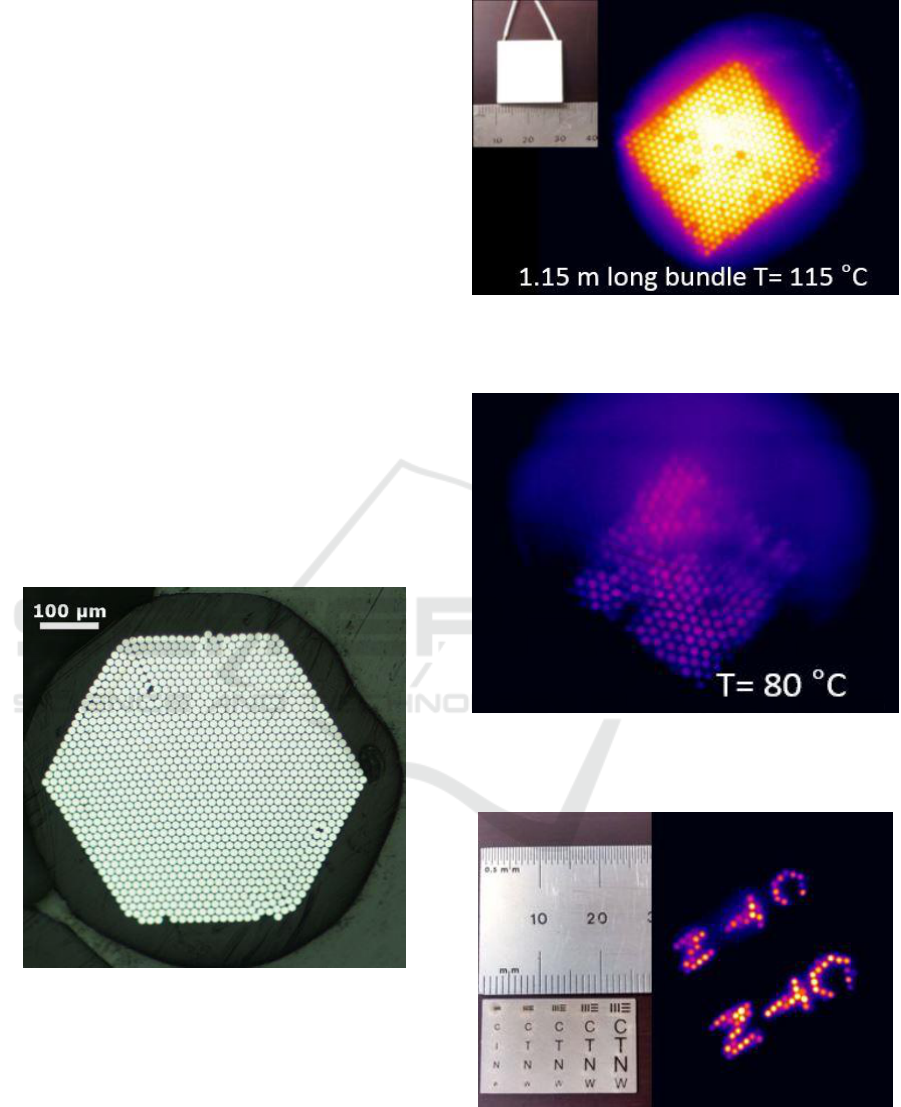

Qualitative thermal imaging assessments were

carried out with a 1.15 m long Vitron IG3 fiber

bundle, as follows.

Figure 4: Vitron IG3 fiber bundle 22 µm core micrography

(10X).

Development of Mid-IR Fiber Bundle for Thermal Imaging

261

A rectangular heating element, shown in the inset of

Figure 6 was imaged on the input of the Vitron IG3

fiber bundle. Then, the output of the fiber bundle was

imaged by using a thermal camera Xenics Onca-

MWIR with InSb detector, which operates in a selected

wavelength range between 3.6 and 4.9 µm due to a

filter. The images were focused by using chalcogenide

lenses with antireflection coating. Figure 6 shows that

for a heater temperature T= 115 °C the fiber bundle

1.15 m long transmits the infrared radiation. As one

can see on the heating element image, the edges are

sharp and well defined. Figure 7 shows that the

minimum heater temperature for which we could

obtained a clear image is for T = 80 °C. In fact, in

order to transmit infrared radiation for a heater

temperature lower than 80 °C the bundle attenuations

must be decreased by purifying or by changing the

core material. A metal target with inscribed letters

was placed between the heating element and the input

of the bundle in order to investigate the bundle

resolution (Figure 8); the image shows that the

resolution of the bundle is not yet satisfactory as some

of the letters are not well transmitted and do not appear

clearly. For this reason, in a future fabrication the

resolution will be increased from 1200 to 3600 pixels.

Figure 5: Vitron IG3 fiber bundle 13 µm core micrography

(10X).

The Vitron IG3 fiber bundle attenuations were

measured using the cut-back method. 4 transmission

spectra were measured by using the ARCoptix Mid-

IR FTIR spectrometer and each cut was of 20 cm.

Two different core diameters were investigated. For

each core diameter two sets of cut-back

measurements were carried out on to two distinct

bundle lengths, respectively in order to analyse the

reproducibility of the measurements (Table 1).

Figure 6: Thermal images of the heating element shown in

the insert and held at T=115°C by using a chalcogenide

bundle of 1.1 mm of outer diameter.

Figure 7: Thermal images of the heating element held at

T=80°C by using a chalcogenide bundle of 1.1 mm of outer

diameter.

Figure 8: Thermal images of the heating element by using

the metal target with inscribed letters shown in the indent

to investigate the bundle resolution.

In the present work the 22 µm core bundles labelled

bundle 1 and bundle 2 in Table 1 and the 13 µm core

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

262

bundles labelled bundle 3 and bundle 4 in Table 1

were compared in terms of attenuations. The Vitron

IG3 fiber bundle losses calculated from the cut-back

measurements are plotted in Figures 9-10.

Table 1: The bundle label and its corresponding core

diameter.

Bundle

Core diameter

[µm]

Initial length

[cm]

1

22

123.5

2

22

100.5

3

13

101

4

13

95

Figure 9: Attenuation of bundle 1 (black curve) and

attenuation of bundle 2 (red curve).

Figure 10: Attenuation of bundle 3 (blue curve) and

attenuation of bundle 4 (green curve).

The attenuations for the Vitron IG3 fiber bundles of

equal diameter are not the same. This is due to an

error in the losses measurements induced from the

polishing quality and from the bundle coupling with

the tungsten light source and the FTIR spectrometer.

This error is ±1 dB/m. A FTIR spectrum was

calculated by averaging spectra of bundles with the

same diameters. Figure 11 reports the losses of the

Vitron IG3 uncladded fiber and the mean from a

series of two spectra at 22 µm and 13 µm core

diameter. The fiber bundle with 13 µm core diameter

presents two more pronounced peaks: at λ = 4.23 µm

due to the CF2 absorption in the FEP and at λ = 5.57

µm due to terminal double bonds CF=CF2 in the FEP

chain (Galante, 2010).

Figure 11: Bundles (orange and green curves) and Vitron

IG3 glass uncladded fiber (violet curve) losses.

It is clear that the bundle losses are higher than the

Vitron IG3 glass uncladded fiber due to the high

cladding attenuations. The bundle losses are of the

order of 10 dB/m in the wavelength range between 3

and 6 µm. This loss value is high but still compatible

with meter length applications. In the wavelength

range between 2 and 3 µm the fiber bundle presents

higher attenuations. The peak at a wavelength of λ =

2.32 µm in the IG3 uncladded fiber attenuation

spectrum is more pronounced than for the bundle

spectra; this could be related to an impurity

absorption from the uncladded fiber that is

unprotected because it has no cladding. In Figure 11

it is shown that the attenuations of the two bundles

(13 µm and 22 µm) are almost comparable. These

results gives us some information for future work; the

Vitron IG3 fiber bundle has high attenuations (10

dB/m) in fact it will be useful to use a chalcogenide

glass with lower losses for future bundle fabrication

to decrease the overall attenuations. The effect of the

fiber diameter on the fiber attenuations was also

investigated with a modelling study.

Development of Mid-IR Fiber Bundle for Thermal Imaging

263

3 MODELLING OF OPTICAL

FIBERS

The modelling study has been performed by using

Comsol Multiphysics 5.2, which is a software for

modelling and simulating Multiphysics problems

(COMSOL Multiphysics, 2017). Comsol

Multiphysics is based on the Finite Element Method

(FEM) (Rahman, 2013).

3.1 Modelling

The study of the modes propagation in an optical fiber

made of Vitron IG3 glass core and FEP polymer

cladding was performed by using the Finite Element

Method (FEM). Five different scenarios were

investigated by changing the core diameter to the

following values: 9, 13, 15, 19 and 25 µm. The

attenuation effects in dB/m across every single fiber

were calculated from the imaginary part of the

complex propagation constant. The cladding diameter

was fixed to 40 µm. A Perfectly Matched Layer

(PML) was applied to the fiber geometry to avoid any

reflection of the electric and magnetic fields

(Berenger, 1994). In Comsol, the PML diameter was

fixed at 60 µm and its parameters, i.e. the scaling

factor and the curvature parameter, were set to 4 and

2 respectively. The fiber model was studied for three

different wavelengths: 3 µm, 4 µm and 5 µm. The real

part of the complex refractive index n of the Vitron

IG3 glass was loaded from the Comsol material

library and its behaviour is shown in Figure 1. The

extinction coefficient k of the Vitron IG3 glass was

calculated from the FTIR loss measurements (Figure

2). For what concerns FEP polymer cladding

material, the real part of the refractive index (n) was

set to 1.341. The extinction coefficient k of the FEP

polymer was calculated from the FTIR loss

measurements (Figure 3). A mesh with 55028

elements was used for this model. Considering the

range of temperature of interest and the sensitivity of

the thermal camera, an arbitrary loss value of 20

dB/m was considered. As first approximation, the

overall losses of the Vitron IG3 glass core and FEP

polymer cladding fiber were calculated from the

average attenuations of the modes that have losses

less than 20 dB/m. Figure 12 shows the results

obtained, where it is clear that the fiber losses

simulated decrease when increasing the core

diameter. The modelling study show that the loss

difference between bundles of 13 and 25 µm core

diameter is of the order of 1 dB/m. This observation

suggests that it should be possible to develop a fiber

bundle with an even smaller core size, without a

substantial increase in loss. The difference in terms of

attenuations between the FEM simulations and the

experimental results are due to two approximations.

Firstly, for the modelled loss calculation we have

considered the average attenuations of the modes that

have losses less than 20 dB/m. Secondly, the bundle

coupling with the tungsten lamp and FTIR

spectrometer as well as the polishing quality

influence the experimental results, with an error of ±1

dB/m on the measurements. In order to improve the

losses calculation in the modelling study, a method

that takes into account the individual mode profile is

undergoing.

Figure 12: Average losses at different core diameters

calculated by using Comsol Multiphysics: core diameter

equal to 9 µm (black curve), core diameter equal to 13 µm

(blue curve), core diameter equal to 15 µm (red curve), core

diameter equal to 19 µm (green curve) and core diameter

equal to 25 µm (violet curve).

4 CONCLUSIONS

The stack and draw method was applied to achieve

two flexible coherent Mid-IR chalcogenide bundles

of 1.1 and 0.675 mm of diameter. The Vitron IG3

fiber bundle attenuations were measured using the

cut-back method. The results obtained from this study

have highlighted that the Vitron IG3 fiber bundle

presents high losses (10 dB/m), but its structure is

regular and the pixels are orderly stacked. The

attenuations measured for the different core diameters

(13 and 22 µm) were comparable. Thermal images

show that a 1.15 m long bundle allows thermal

imaging of objects at temperature higher than 80 °C.

In fact, for a target at temperature equal to 115 °C the

Vitron IG3 bundle (1.15 m long) transmits well the

IR radiation and the target contours are well defined

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

264

and sharp. The behaviour of a chalcogenide fiber

losses for different diameters was simulated by using

the FEM. Results obtained from the modelling study

also give an indication of the influence of the core size

in the fiber attenuations. The typical difference

between the loss of the 13 and 25 µm core diameter

fiber is only of 1 dB/m. This opens the possibility to

achieve a new chalcogenide fiber bundle with even

smaller core diameter and without substantial

increase in optical losses. It is then possible to include

a higher number of pixels (from 1200 to 3600) while

maintaining the bundle outer diameter small enough

to ensure mechanical flexibility, which will be the

focus of the future work.

REFERENCES

ARCoptix FT-IR Rocket data sheet, 2015. Available at:

http://www.arcoptix.com/pdf/Data%20Sheet%20-%20

Arcoptix%20FTIR%20Rocket.pdf (Accessed: 13

February 2017).

Berenger J.P., 1994. A Perfectly Matched Layer for the

Absorption of Electromagnetic Waves, Journal Of

Computational Physics 114, pp. 185-200.

Chenard, F., Alvarez, O., D. Gibson, D., Brandon Shaw, L.,

Sanghera, J., 2017. Mid-Infrared Imaging Fiber

Bundle, SPIE 10181, (2017).

COMSOL Multiphysics, 2017. Avilable at: https://www.

comsol.com/comsol-multiphysics (Accessed: 11 April

2017).

FEP Handbook. Available at: http://www.rjchase.com/

fep\_handbook.pdf, (Accessed: 19 Dicember 2016).

Galante, A.M.S., Galante, O.L., Campos, L.L., 2010. Study

on application of PTFE, FEP and PFA fluoropolymers

on radiation dosimetry, Nuclear Instruments and

Methods in Physics Research 619, pp. 177-180.

Gopal, V., Goren, A., Gannot, I., 2004. Coherent hollow-

core waveguide bundles for infrared imaging, Opt.

Eng. 5 (43), pp. 1195-1199.

Infrared Detectors, 2017. Available at: http://www.

hamamatsu.com/resources/pdf/ssd/infrared_kird0001e.

pdf (Accessed: 10 May 2017).

Nishii, J., Yamashita, T., Yamagishi, T., Tanaka, C., Sone,

H., 1991. Coherent infrared fiber image bundle,

Applied physics letters 59 (21), pp. 2639-2641.

Rahman, B. M., Agrawal, A., 2013. Finite Elements

Modeling Methods for Photonics, Artech house.

Rave, E., Nagli, L., Katzir, A., 2000. Ordered bundles of

infrared-transmitting AgClBr fibers: optical

characterization of individual fibers, Optics Letters 25

(17), pp. 1237-1239.

Snopatin, G.E., Shiryaev, V.S., Plotnichenko, V.G.,

Dianov, E.M., Churbanov, M.F., 2009. High-Purity

Chalcogenide Glasses for Fiber Optics, Inorganic

Materials 45 (13), pp. 1439-1460.

Thorlabs. Stabilized Tungsten Light Sources, 2017.

Available at: https://www.thorlabs.de/drawings/b291

d2ea04f972b3-2DD86186-AF3B-B06B-E3D8818282

5A3929/SLS201L_M-Manual.pdf (Accessed: 2 June

2017).

Vitron IG3, 2014. Available at: http://www.vitron.de/

datasheets/VITRON\%20IG-3\%20Datenblatt\%20Ju

ni\%202014\%20.pdf (Accessed: 19 Dicember 2016).

Zhang, B., Zhai, C., Qi, S., Guo, W., Yang, Z., Yang, A.,

Gai, X., Yu, Y., Wang, R., Tang, D., Tao, G., Luther-

Davies, B., 2015. High-resolution chalcogenide fiber

bundles for infrared imaging, Optics Letters 40 (19),

pp. 4384-4387.

Development of Mid-IR Fiber Bundle for Thermal Imaging

265