Designing Distributed Multi-Agent System for Aggregate and Final

Assembly of Complex Technical Objects on Ramp-up Stage

Petr Skobelev

2,3

, Valery Eliseev

1

, Igor Mayorov

1,3

, Vitaly Travin

2

,

Alexey Zhilyaev

1,2

and Elena Simonova

1,2

1

Smart Solutions, Ltd, Samara, Russia

2

Samara National Research University, Samara, Russia

3

Samara State Technical University, Samara, Russia

Keywords: Assembly Workshops, Planning and Scheduling, Distributed Problem Solving, Multi-Agent Technology,

Multi-Agent System, Adaptive Scheduling, Knowledge Base, Decision Making, Real-Time.

Abstract: The paper covers the problem of aggregate and final assembly of complex technical objects at the ramp-up

stage. New models, methods and tools for distributed scheduling are proposed, including modified version

of virtual market with new classes of agents. The new feature of multi-agent scheduler considers knowledge

base technology which helps to specify each operation in more detailed and individual way. The paper

describes first system prototype for adaptive planning at the ramp-up stage and the main directions of future

system development.

1 INTRODUCTION

The problem of production scheduling for

workshops of aggregate and final assembly of

complex technical objects is now often solved with

the help of classical models, methods and means of

production planning, such as SAP, BAAN, etc.

(Cox, 2000, Herrmann, 2006).

However, during development of new versions

of complex technical objects on ramp-up stage a

number of special problems can arise (Klocke,

2016):

• composition of the product and production

technology are finalized only during

assembly;

• failures in the work of suppliers (non-

compliance, non-delivery of parts or delay in

delivery);

• workers do not yet have the required

competencies;

• reassessment of labor productivity;

• unforeseen time spent on decision-making;

• urgent additional orders, etc.

As a result, significant delays occur in the plant's

operation, which are especially evident in aggregate

assembly workshops and at the final assembly line.

In this connection, this paper considers an

approach to designing a distributed multi-agent

system (MAS) for workshops of aggregate and final

assembly lines. This system is capable of flexibly

rearranging the work of assembly shops in case of

unforeseen events.

The first part of this paper covers the problem of

ramp-up production scheduling for complex

technical objects assembly. The second part

substantiates ways of solving the problem using the

knowledge base and multi-agent technology. The

third part provides a formalized formulation of the

planning task, based on maximizing the overall

satisfaction of agents in auction-like negotiations.

The fourth part describes the basic method of

adaptive agent planning and considers architecture

of the distributed multi-agent scheduling system.

The fifth part describes the architecture of the multi-

agent system and its components. The sixth part

demonstrates the possibility of using knowledge

base for adaptive planning. The conclusions propose

further steps for development of the system.

This project develops and advances the results of

the ARUM project under the EU Program "Factories

of the Future", during which the first prototype of

this kind of system was created (Leitão, 2013).

250

Skobelev, P., Eliseev, V., Mayorov, I., Travin, V., Zhilyaev, A. and Simonova, E.

Designing Distributed Multi-Agent System for Aggregate and Final Assembly of Complex Technical Objects on Ramp-up Stage.

DOI: 10.5220/0006636202500257

In Proceedings of the 10th International Conference on Agents and Artificial Intelligence (ICAART 2018) - Volume 1, pages 250-257

ISBN: 978-989-758-275-2

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 DESCRIPTION OF THE

PROBLEM AND THE

PROPOSED APPROACH TO ITS

SOLUTION

The problem of forming schedules of the aggregate

and final assembly lines includes:

• formation of production schedules using

various criteria, preferences and constraints;

• forecast of the possibility of performing

schedules with available resources;

• adaptive re-scheduling of assembly in case of

unforeseen events in real time;

• identification of bottlenecks and resource re-

allocation between workshops;

• optimization of production schedule by

comparing options and initial conditions;

• control of implementation of production

schedules, etc.

Complexity of this processes is caused by NP-

hard nature of combinatorial search, nonlinearity of

decision making space, interdependences of

operations in technological processes, specific

individual features of matching rules for assigning

operations to resources, including competencies of

workers, and a number of other features.

Ramp-up stage is bringing additional complexity

by high dynamics of production, when various

events are constantly taking place: new orders are

emerging, composition of products is changing,

technological processes are being refined, supply

terms are broken, work centers fail or defects are

detected.

This complexity and high dynamics of

scheduling process, which is event-driven in this

case by definition, leads to the fact that traditional,

centralized, hierarchically organized, sequential

methods and algorithms of combinatorial type

cannot effectively solve this problem with

acceptable quality and within the required time for

practical applications in the workshops.

For practical solution of the problem the paper

proposes new distributed solution based on models,

methods and algorithms for adaptive scheduling

(Rzevski, 2014).

First of all, in this solution, instead of one "large"

central scheduler for aggregate and final assembly

shops, a distributed "system of systems" is proposed.

It is built as a multi-level network of "small" stand-

alone operational planners for individual workshops

with a plan horizon of up to a month, working in

coordination with the end-to-end scheduler of

aggregate and final assembly workshops with a

horizon of up to 3-6 months.

Secondly, to solve the problem of ramp-up

management, it is suggested to use multi-agent

technology which utilizes the concept of an "agent"

– an autonomous software object capable of

perceiving the situation, making decisions and

interacting with others (Skobelev, 2014). Solution of

any complex task in the multi-agent system is

formed by self-organization of agents through

interaction of dozens and thousands of agents of

demand-and-resource network (DR-network),

continuously competing and cooperating with each

other (Vittikh, 2003).

The schedule of workshops is created as a self-

organizing network of orders and resources,

adaptively changing depending on events in real

time. In the process of self-organization, software

agents of orders and resources search for each other,

at first choosing the best free options, and then

resolving conflicts until the system is balanced and

none of the options can improve the overall

performance of the system. Then the calculation

process stops, and the solution is given to the user.

This process more naturally describes the way

experienced managers and dispatchers usually form

schedules, finding a balance of interests among all

concerned parties. The transition from combinatorial

search for the optimal schedule to the search for an

"acceptable" (reasonable) schedule corresponding to

the current situation (reflecting the balance of

interests of orders and resources at the given

moment) allows to create quality schedules.

Thirdly, vitally important knowledge is need to

be accumulated when such systems are implemented

and used. However, this knowledge is often difficult

to formalize. It can be used to improve the quality of

planning, for example, information on the possibility

of parallelizing part of technological operations or

reinforcing them by adding more workers in order to

accelerate the work, or knowledge about the

competencies of workers, their compatibility in

shifts, etc.

For this purpose, the paper proposes using the

Knowledge Base (KB) for accumulation,

formalization and use of these parts of knowledge,

as storage of such knowledge is currently not

provided by any of the corporate systems. Such a

KB can be based on domain ontology as a semantic

network of classes of concepts and relations – a

technology that is actively developed within the

Semantic Web to describe the content of Internet

resources (Skobelev, 2012).

Designing Distributed Multi-Agent System for Aggregate and Final Assembly of Complex Technical Objects on Ramp-up Stage

251

Application of KB will make the developed

system open to users and allow them to customize

the resource matching and scheduling rules within

much wider limits than in traditional systems, to

adapt the system during its use, to reduce labor

intensity and the cost of operating the system.

3 FORMALIZED PROBLEM

STATEMENT OF SCHEDULING

BASED ON MULTI-AGENT

TECHNOLOGY

In the formal problem statement of managing the

production schedule, it is assumed that each of the

orders and resources has its own criteria, preferences

and limitations, and their importance can change

during execution of tasks, and the purpose of the

schedule is to find the maximum possible agreement

between these agents, taking into account

peculiarities of their current situation.

For this purpose, it is proposed to use multi-

agent technology to automate the processes of

identifying and resolving conflicts between agents of

orders placed in the common pool of resources.

Within the proposed multi-agent technology, the

problem of searching for a consensus can be

formulated through the notion of "satisfaction" of

agents of orders and resources, showing how much

the observed criteria for selecting solution options

differ from the ideal ones, given as wishes or based

on experience of practitioners (Mayorov, 2015).

The following list of agents is proposed for

building production schedules (Table 1).

Thus, the model of a manufacturing enterprise is

specified through a network of linked demands and

resources (DR-network), in particular, orders and

resources (relating to execution of work on

technological processes – operations and

transitions): resources are represented by assembly

stations, work centers, and workers of specific areas

of expertise. Orders at this level are production

assignments to workers for assembly of

technological assembly units (TAU) and assembly

units (AU). Further, larger structural subdivisions

are considered – sections, production shops with

sections and orders at the level of aggregate

assembly shops with corresponding inter-shop links.

At the top level, there is final assembly in the final

assembly shop with cooperation in adjacent

production and supply.

Table 1: The main classes of MAS agents and their

functions.

Agent class

Agent functions

Order agent

Selects the technological process (from

alternative ones), monitors the plan and

the fact

Technological

process agent

Plans tasks, monitors timeframes and

results obtained within the process

Division agent

Manages the load of employees within

divisions (shops, stations, workers)

Task agent

Searches for the best worker according

to the list of competencies and conforms

the terms of task fulfillment, monitors

its execution

Resource agent

Plans tasks suitable for the employee or

equipment, monitors the load and

results

Product agent

Evaluates the results, does not allow for

idling

Enterprise

agent

Finds and corrects bottlenecks in plans

and analyzes risks

In the proposed approach, each department of

assembly production at the level h (assembly line,

workshop, enterprise a s a whole) is given specific

types of agents of resources, tasks, operations,

technical processes, products (TAU and AU), the

state of which is described through functions of

satisfaction u

res h

j

by indicators (criteria functions) i

from the set {x

i

h

} with the weight

res h

ij

,

characterizing how much their values for the given

indicators deviate from the desired values of x

ij

id h

for

resource j in subdivision h. The indicators are

brought together in an additive way into a unified

satisfaction function. In this model, the target

function of resource agents (res) in subdivision at

level h of enterprise structure on satisfaction from

range [0,1] is piecewise linearly dependent on

indicators x

i

h

, on their values at the previous level of

organization h-1 and the values of satisfaction of

resource agents. Similarly, functions with the weight

task h

mn

of satisfaction of tasks u

task h

n

at the level h

can be given, where the set {y

n

h

} and {z

p

h

} is

considered as indicators for agents of products u

prod

.

For each of the agents of resources, tasks, products,

and enterprise agent, importance (priorities) {w

j

res

h

}, {w

n

task h

}, {w

p

prod h

}, respectively, can be

introduced. Superposition of satisfaction functions is

related to functions of bonus-penalties.

The enterprise agent is considered the only one at

each level h of enterprise structure. The task of

building an enterprise plan is to maximize

satisfaction of agents for level of enterprise structure

h=1,..., H, including agents of resources, tasks and

products (1):

ICAART 2018 - 10th International Conference on Agents and Artificial Intelligence

252

where x

res h*

, y

task h*

, z

prod h*

, s

dep h*

are the

"optimal" (for this situation) values of variable

resources, tasks, products and enterprise for level h.

For the lower level of enterprise structure the

functions of satisfaction components f

ij

h=1

do not

depend on the previous values,

,

The variables x, y, z, s lie in the range of the

following indicators: D

I

resources, D

M

work on

technological processes, D

K

products, and D

L

enterprise agent, where I, M, K, L are dimensions of

the corresponding spaces.

Evaluation of their states is performed by agents

using the functions of satisfaction and bonus-penalty

multi-component functions.

Evaluation of the quality of planning in

operational schedulers is carried out using the main

criteria:

• minimization of production end time and

compliance with delivery dates of each object;

• maximization of the number of produced

object for the given planning horizon;

• minimization of time spent on production of

each TAU and AU;

• minimization of delays and storage time for

assembled aggregates, TAU and AU between

operations;

• maximum concurrency of TAU production,

allowed by technical processes;

• ensuring uniformity of equipment load in each

workshop and reducing downtime;

• uniformity of work load of employees and

minimization of additional shifts;

• decreasing the amount of work in progress at

the end of the period.

Thus, the planning task is formulated for agents

as the task of maximizing total satisfaction (1),

provided that decisions taken by the agents are

consistent. The recursiveness of the task by

department level and the non-linearity with respect

to the solutions at the previous level allow for an

iterative solution with the help of "nested" network

multi-agent schedulers of aggregate and final

assembly shops.

4 THE BASIC METHOD OF

ADAPTIVE PLANNING

At the heart of the developed multi-agent planning

technology lies the concept of "virtual market" of a

DR-network of any department, production line or

shop, where order agents can buy resource services

at a virtual price.

Within the virtual market of the system, orders

receive a certain stock of virtual currency for

purchases of finished products (components) or

resource services, and resources sell their services

on a time-based or other basis. Order agents can

enter into virtual contracts with resource agents, but

then, if necessary, they can reconsider their

decisions, compensating each other for possible

losses from the break of contacts. In the long term,

virtual money can be directly linked to real money

and micro-contracts during order execution to reflect

the state of production in real time.

The basic method of adaptive planning based on

the example of initial planning of TAU in the

operational planner of the workshop is as follows:

1. The order agent for production of a new TAU

loads its execution technology from the KB and

creates an agent of technological process (tasks).

2. The technological process agent creates agents

of child tasks (operations within the technological

process), setting tasks for them.

3. Agents of tasks begin searching for free (or

busy, if they are not available) resources in the scene

of the shop, which will cost the least amount of

virtual money, providing the maximum profit due to

the bonus part of the penalty function.

4. If the resource is already occupied by other

tasks, the conflict is fixed and its resolution begins.

Designing Distributed Multi-Agent System for Aggregate and Final Assembly of Complex Technical Objects on Ramp-up Stage

253

5. In case of a conflict, the task already placed on

the resource is asked to give way, but if the new

placement is worse, then the required compensation

is calculated according to the function of bonuses

and fines.

6. If the required compensation is too high, the

incoming task itself starts to look for a new

placement. And if the compensation is acceptable, it

pays for the departure of the previous task.

7. This process continues until there is a dynamic

stop, when no agent can improve its condition

(satisfaction function).

8. At this point, the Enterprise Agent identifies

the agent with the worst criteria for the system as a

whole.

9. The selected worst agent is given a command

to break ties and be dis-scheduled from related

orders / resources.

10. The selected agent receives an increased

importance coefficient for the worst criterion in its

satisfaction function, which will cause selection of

other options when it is rescheduled.

11. The agent tries to be rescheduled – if

successfully, the process proceeds to the next

criterion and the corresponding agent.

12. If not successfully, the agent reports the sum

of virtual currency, which he needs in order to reach

a new criterion value.

13. The enterprise agent assesses availability of

this sum in the system and, if necessary, adds the

virtual currency to the agent.

14. As a result, the worst agents iteratively "pull

up" their criteria to new values, compensating for

the losses of other agents at the expense of the

virtual budget.

15. The process ends when all the criteria of the

system as a whole fall into the comfort zone or when

they can no longer change.

16. Otherwise, control is transferred to the user

for further manual improvement.

Improvement of the current state of agents is

performed through proactive interaction between

order agents, task agents and resource agents within

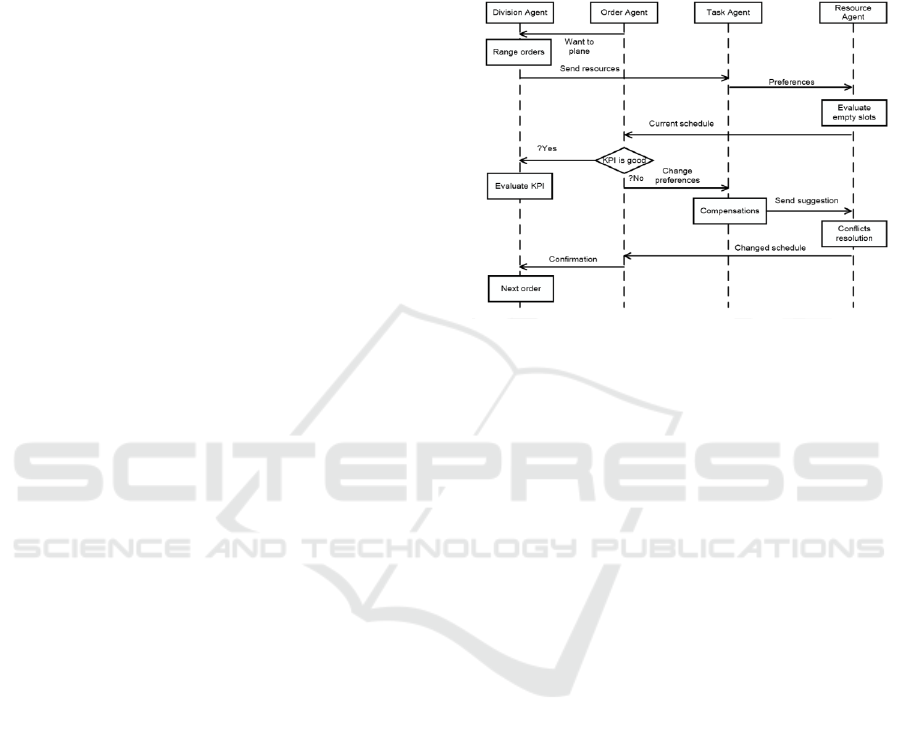

the proactivity protocol (Figure 1).

Division agent, having received a message from

the order agent, ranks the order list according to the

delay fine in the descending order. Then, during

evaluation of the schedule, the division agent

updates all of its indicators, the total profit, and

normalized criteria values. The list is dynamically

rebuilt as a result of the algorithm performance.

The tasks search for a more profitable position in

the resource schedule, while each resource plans

more profitable tasks in the oncoming process.

Changes in the positions of task agents are made

on the basis of the compensation method. In this

method, permutations occur in those cases where

compensation to the displaced agent from the

shifting one exceeds the decrease of its objective

function.

Figure 1: The part of simplified protocol proactive

improvement of schedule.

The conditions for completion of the event

scheduling algorithm are as follows:

• the stop occurs when the system reaches the

balance of satisfaction between conflicting

agents (orders and resources, as well as

others), when none of the proposals can

increase the value of indicators;

• changes in agents' indicators and agent

satisfaction associated with them does not

exceed the specified threshold (set in the

settings);

• termination of negotiations between

conflicting agents in case of refusal by the

parties to further negotiate due to lack of

options or achievement of the state of full

"nirvana" (specified special zone of

satisfaction);

• the allotted number of iterations or the

specified time for proactive improvement has

been exceeded;

• failure to reach the specified by the user

indicators, with a message to the user about

the need for manual intervention to resolve

conflicts.

As a result, the created schedule is built in the

process of self-organization of shop agents, which

allows for flexible and quick adaptation of the

schedule depending on events.

ICAART 2018 - 10th International Conference on Agents and Artificial Intelligence

254

5 ARCHITECTURE OF THE

BASIC MULTI-AGENT

SYSTEM

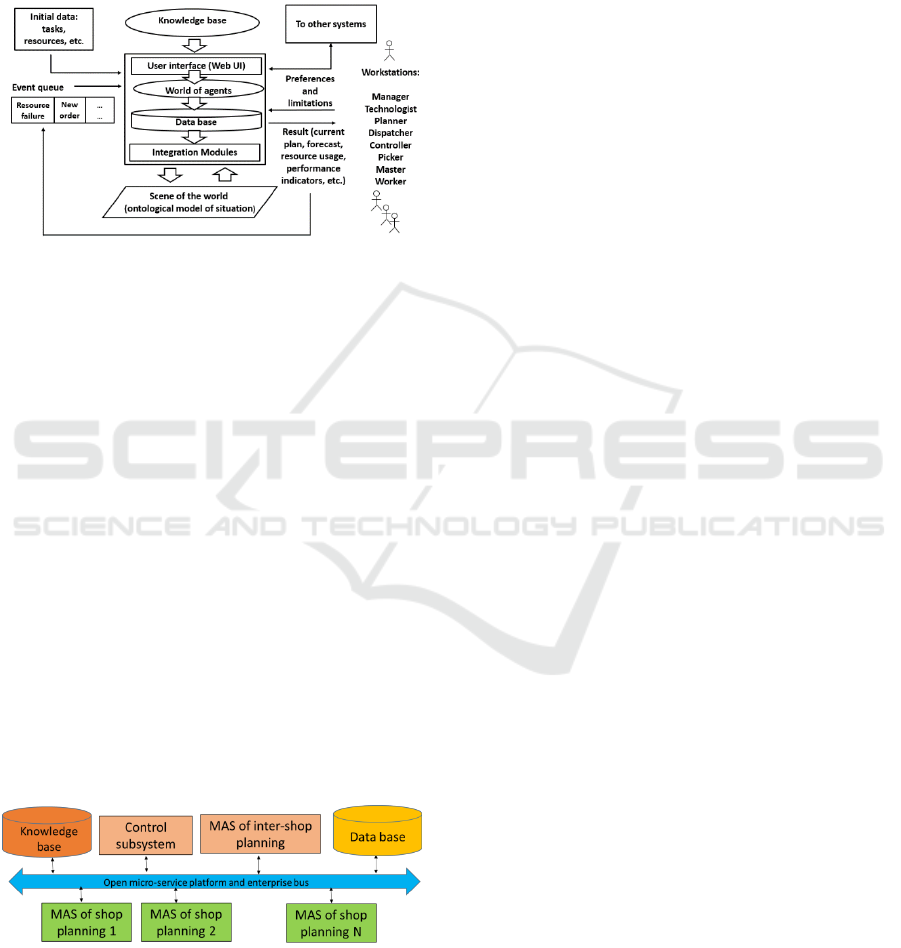

The architecture of the multi-agent scheduler is

presented in Figure 2.

Figure 2: The architecture of the multi-agent scheduler.

The following most important components are

found in the architecture of the basic multi-agent

scheduler:

• World of agents consists of instances of agent

classes to be executed. Agents are

asynchronous software objects (programs)

operating as a state machines.

• Event queue provides accumulation of events

coming from the real world, as well as their

processing.

• The World Scene is a semantic model of the

current situation, built by the agents of the

system on the basis of ontology.

• Application components make it possible to

perform additional functions for third-party

systems and user interfaces.

The distributed multi-agent system contains two-

level "system of systems". This system is based on

the network-centric interaction of planning modules

(schedulers) used at the inter-shop (strategic) and

workshop (operational) levels (Figure 3).

Figure 3: Network-centric system architecture.

The module of end-to-end inter-shop planning

forms the work schedule for a group of aggregate

and final assembly shops with a time horizon of one

quarter. Information on the capacity of equipment

and the total number of employees of a certain

category is taken into account as limitations for

orders execution.

At the shop level, there are operational planners,

each of which is responsible for scheduling a certain

workshop. The operational planning module has

more detailed information about the resources of its

workshop, including peculiarities of technological

processes, the composition and characteristics of

equipment and personnel. The technological

processes considered at this level can have a greater

degree of granularity and additional requirements for

characteristics of equipment and employees.

6 USING THE KNOWLEDGE

BASE FOR ADAPTIVE

PLANNING

The main purpose of the Knowledge Base (KB) is

formalization of the problem domain in order to

provide all the necessary information to systems that

solve applied problems, in particular, planning and

managing resources, by aggregating knowledge

from various information sources and providing the

user with the most complete information on the

object and the current situation in production.

The purposes of using KB are the following:

• customization of MAS scheduler for the

specific features of each workshop;

• extension of matching rules for assigning

tasks to resources (add criteria "on the fly");

• ensuring openness of the system and reducing

the costs of its operation.

The formalized model of knowledge in KB is

represented as classes of concepts and relations that

form semantic network of the domain. The

knowledge base technology is used in this case in

order to more accurately specify the requirements

that should be taken into account for individual

planning of each operation within the technological

process and to separate this knowledge from the

source code of the system in order to enable users to

independently expand or modify this information.

For ease of use, three levels of domain

description are distinguished: "ontology",

"ontological model", and "situation" ("scene)".

The key element within KB is ontology, which at

the basic level should, first of all, provide a

vocabulary of concepts for representation and

exchange of knowledge, as well as the multiple

relationships (relations) established between the

Designing Distributed Multi-Agent System for Aggregate and Final Assembly of Complex Technical Objects on Ramp-up Stage

255

concepts in this vocabulary. Attributes are

introduced for concepts and relationships, in order to

expand the possibility of describing subject areas by

including in ontology not only objects, but also their

qualitative and quantitative characteristics.

The ontological model describes real workshop

as a set of equipment, workers, technological

processes and operations, etc.

The scene describes instances of concepts and

relations with specific attribute values at the given

point in time (a set of facts).

The ontology consists of the following sections:

• organizational structure of the enterprise,

describing the list of departments, employees,

their professions, positions, competencies;

• infrastructure model of the enterprise,

describing the main technical means

(equipment, tools, materials, production sites,

facilities, characteristics of material objects,

physical and technical principles of operation,

etc.);

• technological processes of assembly,

describing the processes of the main activities

(production technology);

• manufactured products and provided services,

key indicators of quality and efficiency of

service delivery;

• professional specialization and competence of

workers;

• other knowledge required to plan operations

of technological processes.

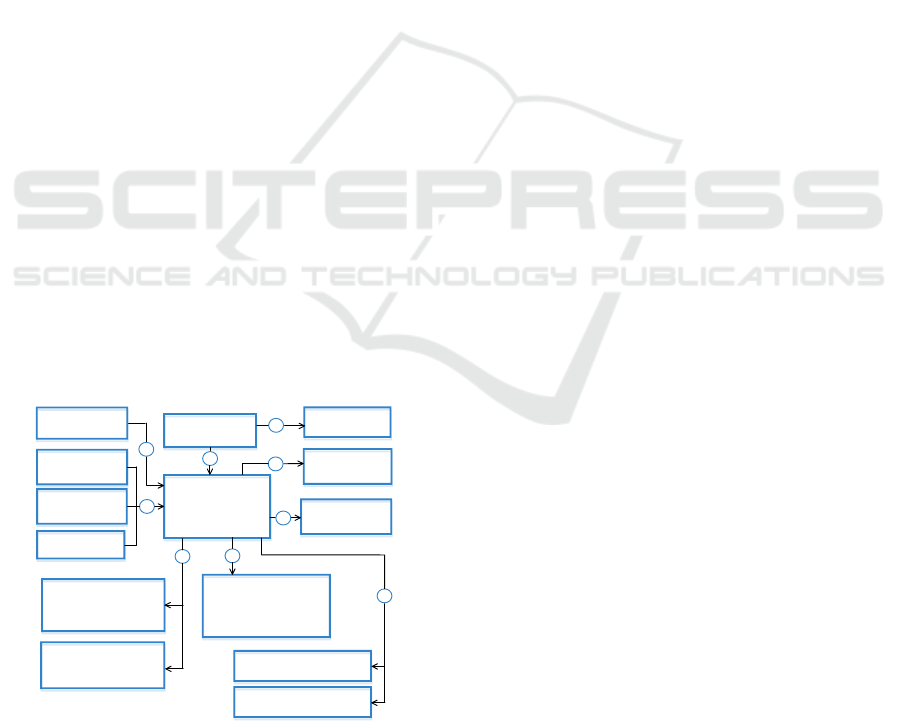

The main part of the knowledge base for

planning is the concept "Task" and its instances for

performing specific technological operations (Figure

4).

1

Product

name: wing

Task

name: drilling holes

number: 205.0005

labor intensity: 52

Group Task

code: 205.00060

Previous Task

code: 205.0001

Auxiliary equipment

type: drill

model: VD-500

Main equipment

type: assembly station

model: P019

Assembly unit

name: TAU 5702

Assembly unit

name: TAU 5802

Employee

personnel number: 00075

Employee requirement

profession: assembler

rank: 4

number: 2

Material

type: sealant

Next Task

code: 205.0015

Assembly unit

name: TAU 5608

3

2

5

6

5

Employee

personnel number: 00105

4

8

7

Figure 4: Relations in the concept "Task".

The presented relations in the concept "Task" are

used by agents in resource management system in

the following way:

• "Previous" (1) and "Next" (6) – allow the

agent to find the previous task with the request

to move earlier or reschedule, to find the next

task, and to send its agent a delay message;

• "Input objects" (2) and "Output objects" (5) –

show which agents should be in the scene to

start the task execution, and also what will be

the output as the result of task execution;

• "Part-Whole" (3) – shows that the task is a

part of a compound problem, the agent of

which receives parameters of the plan and the

fact of the task;

• "Employee Requirements " (4) – defines the

requirements for the performer of the task;

• "Who did it last time?" (7) – finds employees

who have already performed such tasks;

• "Required resource" (8) – specifies a resource,

predetermined by the manufacturing process.

The developed approach to MAS prototype

makes it possible to add new rules of matching "on

the fly", taking into account the complexity factors

revealed during planning for the workshops.

7 CONCLUSIONS

Further developments will be aimed at

implementation of schedulers of workshops and

their coordinated interaction in distributed system of

system for factory scheduling.

The transition from one centralized "global"

scheduler to a distributed MAS solution based on a

network of MAS schedulers of workshops will

ensure further expansion of the system, better

efficiency, flexibility and performance, productivity,

scalability and reliability of the system.

Further research will be focused on measuring

adaptability, quality and efficiency of scheduling.

ACKNOWLEDGEMENTS

This paper was prepared with the financial support

of the Ministry of Education and Science of the

Russian Federation – contract №14.578.21.0230,

project unique ID is RFMEFI57817X0230.

ICAART 2018 - 10th International Conference on Agents and Artificial Intelligence

256

REFERENCES

Cox, J., Spencer, M., 2000. The Constraints Management

Handbook. SRC PRESS. London.

Herrmann, J. (ed.), 2006. Handbook of Production

Scheduling. Springer. Switzerland.

Klocke, F., Stauder, J., Mattfeld, P., 2016. Modeling of

Manufacturing Technologies During Ramp-up.

Procedia CIRP, vol. 51, pp. 122-127. Elsevier.

Leitão, P., Barbosa, J., Vrba, P., Skobelev, P., Tsarev, A.,

Kazanskaia, D., 2013. Multi-agent System Approach

for the Strategic Planning in Ramp-up Production of

Small Lots. In IEEE SMC 2013, the IEEE

International Conference on Systems, Man and

Cybernetics. IEEE Computer Society, Washington,

DC, USA, pp. 4743-4748.

Rzevski, G., Skobelev P., 2014. Managing complexity.

WIT Press. Boston.

Skobelev, P., 2014. Multi-Agent Systems for Real Time

Adaptive Resource Management. In Industrial Agents:

Emerging Applications of Software Agents in Industry.

Elsevier.

Vittikh, V., Skobelev, P., 2003. Multiagent Interaction

Models for Constructing the Demand-Resource

Networks in Open Systems. Automation and Remote

Control, vol. 64, issue 1, pp. 162-169.

Skobelev, P., 2012. Activity ontology for situational

management of enterprises in real-time. Ontology of

Designing, vol. 1, issue 3, pp.6-38.

Mayorov, I., Skobelev, P., 2015. Towards

thermodynamics of real timescheduling. International

Journal of Design & Nature and Ecodynamics, vol.

10, issue 3, pp. 213-223. WIT Press.

Designing Distributed Multi-Agent System for Aggregate and Final Assembly of Complex Technical Objects on Ramp-up Stage

257