Orientation Beautification of Reverse Engineered Models

S. Gauthier

1,2

, W. Puech

1

, R. B

´

eni

`

ere

2

and G. Subsol

1

1

LIRMM Laboratory, CNRS, Univ. Montpellier, Montpellier, France

2

C4W, Montpellier, France

Keywords:

Reverse Engineering, Beautification, Geometric Constraints.

Abstract:

Today, it has become more frequent and relatively easy to digitize the surface of 3D objects and then to

reconstruct a boundary representation (B-Rep). However, the obtained results suffer from various inaccura-

cies, mainly caused by noisy data. In this paper, we present an efficient method to detect and rectify many

regularities approximately present in an object. We propose to extract global parallelism and orthogonality

constraints, then locally and independently adjust the geometric primitives (planes, cylinders, spheres, cones).

We first retrieve orientations from primitives (normals, axes), then compute an orthonormal coordinate system.

Finally, we adjust each primitive orientation according to spherical coordinates. Our objective is to design a

fast and automatic method, which is seldom seen in reverse engineering. Experimental results applied on

reverse engineered 3D meshes show the efficiency and the robustness of our proposed method.

1 INTRODUCTION

An industrial reverse engineering application aims to

reconstruct an object as a combination of geometric

primitives, from a digitized 3D mesh or a 3D point

cloud (Benk

˝

o et al., 2001)(B

´

eni

`

ere et al., 2013). For

mechanical objects, we search for geometric primi-

tives such as planes, spheres, cylinders and cones, but

also tori and more generally developable or ruled sur-

faces. To reconstruct the original geometry, we must

take into account the shape of each primitive and their

relationships with each other. But an objects shapes

can be very complex, and the measured data can of-

ten be noisy. It then requires a post-processing step

to adjust and regularize the primitive parameters ac-

cording to some practical, applicative or design rules

based in general on parallelism, orthogonality, quan-

tization of parameters and regularity. This is known

as the beautification step (Langbein et al., 2001).

Moreover, the objective of a reverse engineering

process is also to retrieve the design intent of an ob-

ject. In this paper, we propose a method to adjust the

different orientations present in a reverse engineered

model. We first use the geometric primitive orien-

tations to detect parallelism and orthogonality con-

straints. Then, we extract an implicit orthonormal co-

ordinate system from the object, which is then used to

adjust the orientations according to some geometric

dimensioning and tolerancing constraints (GD&T).

This allows us to adjust each primitive independently

according to global orientation constraints, avoiding

many problems such as error propagation for exam-

ple.

This paper is organized as follows. Previous work

in this topic is presented in Section 2. In Section 3,

we present in detail our orientation beautification pro-

cess. In Section 4, we apply our proposed beautifica-

tion on reverse engineered 3D models and we show

that our method improves the obtained results. Fi-

nally, in Section 5, we conclude and propose direc-

tions for future research.

2 PREVIOUS WORK

In reverse engineering, several methods propose to

extract geometric primitives with minimal user help

(Buonamici et al., 2017). They result in providing a

reverse engineered model, i.e. a set of geometric pa-

rameterized primitives (segments of planes, spheres,

cylinders, cones, tori) but they do not formally take

into account geometric constraints like parallelism,

orthogonality or concentricity, which are induced by

the design process (Wang et al., 2012). For this pur-

pose, it is possible to apply a separate step called

beautification (Langbein et al., 2002).

The beautification method proposed in (Langbein

et al., 2004) consists in detecting many regularities

that are approximately present in the reverse engi-

neered model, like constant angles (resp. distances)

Gauthier, S., Puech, W., Bénière, R. and Subsol, G.

Orientation Beautification of Reverse Engineered Models.

DOI: 10.5220/0006606000910100

In Proceedings of the 13th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2018) - Volume 1: GRAPP, pages

91-100

ISBN: 978-989-758-287-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

91

between pairs of directions (resp. positions) for ex-

ample. Then, a selection of a constraint subset is

applied to reduce the complexity and ensure that the

constraint system have at least one solution. Finally,

other constraints are iteratively added to the system

until a fully constrained model is obtained. The dif-

ficulty in this method is to guarantee the consistency

of the constraint subset. Indeed, at each step, many

verifications are required to ensure that there are no

contradictions between the constraints.

In (Li et al., 2011), the beautification process is as-

sociated with a RANSAC approach to iteratively add

new geometric primitives and adjust them to respect

global alignments. At each step, the primitive extrac-

tion algorithm is more accurate, but a large number

of primitives needs to be adjusted. Since this method

investigates primitives by pairs, this can lead to an un-

desired error accumulation across primitives.

The beautification process proposed by (Kov

´

acs

et al., 2015) consists in detecting local and global

symmetry and continuity constraints between the

primitives. In this method, a constrained fitting is pro-

posed to respect continuity constraints, like tangency,

between the primitives. Moreover, a Gaussian sphere

of plane orientations is used to determine dominant

clusters. A grid is then constructed to detect symme-

tries and adjust the primitives. The Gaussian sphere

used in this method is very interesting, since it allows

to extract global orientations. A keypoint to highlight

is the constrained fitting method, which is compre-

hensively analyzed in (Benk

˝

o et al., 2001).

To simplify the beautification step, we propose

to detect global constraints, which are easier to sat-

isfy. In this paper, we present a new method which

deals with object orientations, and particular angle

constraints, including parallelism and orthogonality.

3 BEAUTIFICATION PROCESS

In the following, we assume that we have extracted

geometric primitives (planes, spheres, cylinders and

cones) and their parameters from a digitized 3D mesh.

We used the method described in (Gauthier et al.,

2017) but many other methods are available (Buon-

amici et al., 2017).

3.1 Overview of the Process

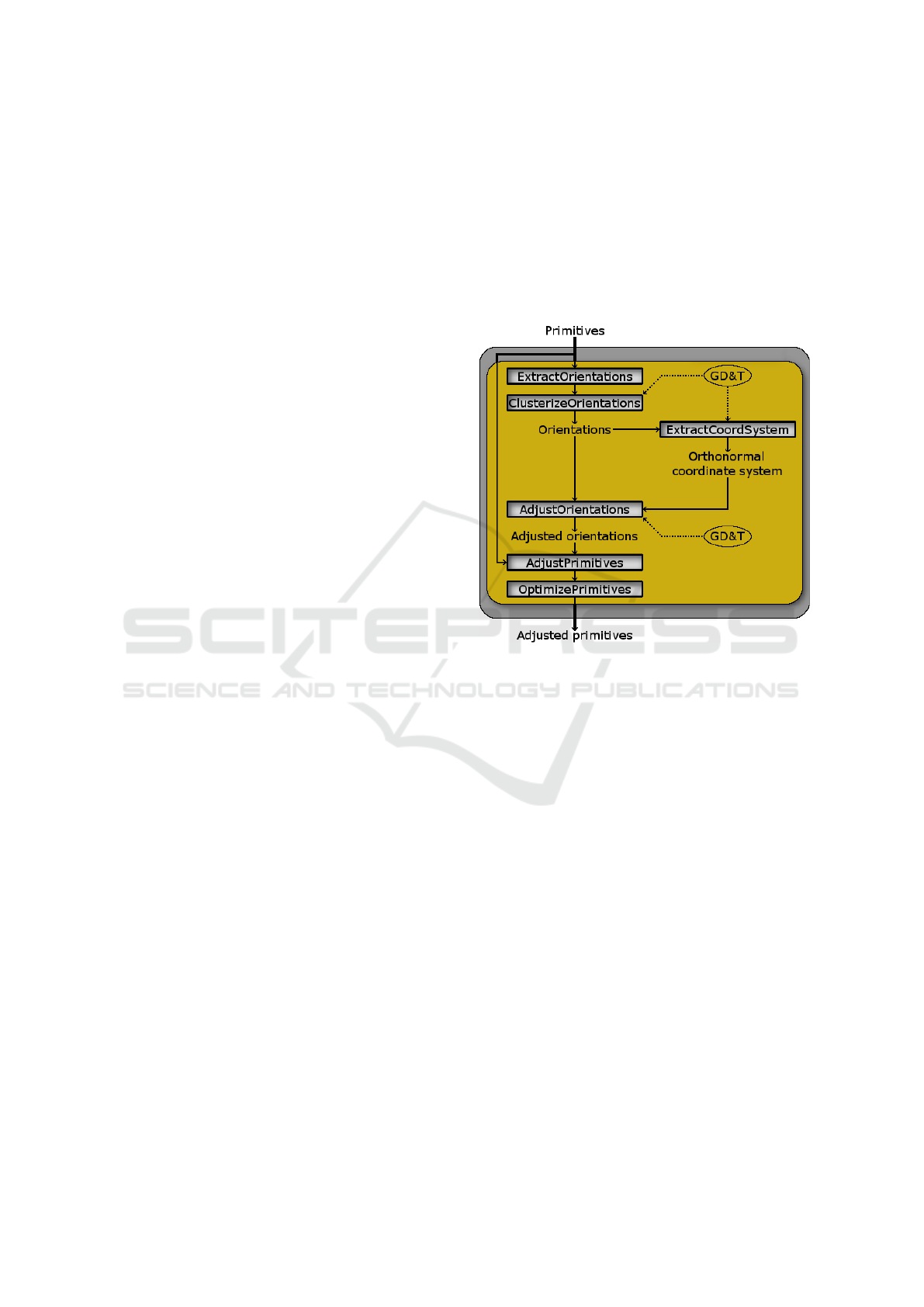

As illustrated in Fig.1, our proposed method is com-

posed of six steps. First, we extract orientations di-

rectly from the parameters of geometric primitives,

but also from other geometric features such as the

intersections between planes and we clusterize them

into orientation groups (Section 3.3). These orienta-

tion groups allow us to compute an intrinsic orthonor-

mal coordinate system from the object (Section 3.4).

Then, we use this coordinate system to adjust the

orientation clusters (Section 3.5), according to some

geometric dimensioning and tolerancing parameters

(Section 3.2). Finally, we can adjust each primitive

according to these adjusted orientations, and optimize

them without orientation modification (Section 3.6).

Figure 1: Overview of the beautification process.

3.2 Geometric Dimensioning and

Tolerancing (GD&T)

Geometric Dimensioning and Tolerancing (GD&T)

is a system defining engineering tolerances. It is

used by designers when they model (3D) mechan-

ical objects. There are several standards available

worldwide, like ASME (https://www.asme.org/)

and ISO (https://www.iso.org/), but these are

too complex to use in a reverse engineering process.

Thus, we define very simplified rules using simple ge-

ometric tolerances.

We are going to use two tolerance parameters in

order to control our orientation beautification process:

• Tolerance: Angle tolerance to define two similar

orientations.

• Quantization: Array of possible angles between

an orientation and a plane of an orthonormal co-

ordinate system, which is implicitly defined by the

model itself (see Section 3.4).

GRAPP 2018 - International Conference on Computer Graphics Theory and Applications

92

3.3 Orientation Extraction and

Clustering

3.3.1 Orientation Extraction

In a 3D object, we can intuitively find several orienta-

tions (see Fig.2). These are mostly defined by the pa-

rameters of the geometric primitives (e.g. the axis of

a cylinder or the normal to a plane), but they may also

be given by other geometric features, such as intersec-

tion lines between planes or alignments between the

centers or the apices of identical primitives for exam-

ple.

Figure 2: Orientation extraction from other informations: a)

Original 3D mesh, b) Extracted primitives, c) Intersection

lines between planes.

These geometric features are very important as the

reverse engineering process can fail to extract some

primitives and their associated parameters.

3.3.2 Orientation Clustering

Extracted orientations often suffer from inaccuracies,

mostly caused by noise in the reverse engineered

model. We then have to clusterize similar orienta-

tions into groups. In our method, similar orientations

correspond to pairs of lines with an angle less than

Tolerance (see Section 3.2).

We first need to separate orientation vectors into

similar vector sets, with a clustering algorithm. The

clustering process is straightforward. We perform the

three steps until all the orientation vectors have been

processed:

• Take an orientation vector at random which is not

clustered. It will create a new cluster/group.

• Retrieve similar orientation vectors according to

the tolerance and add them to the group.

• Iterate this last step by comparing the orientation

vectors with all the ones belonging to the cluster

until there are no vectors left to add.

Then, for each group, we can compute an average

orientation by:

C =

∑

n

i=1

ω

i

V

i

∑

n

i=1

ω

i

, (1)

where C is the average orientation, V

i

a normalized

orientation vector from the similar vector set and ω

i

the weight associated to V

i

, corresponding to the area

of the geometric primitive.

And a group weight W

c

by:

W

c

=

n

∑

i=1

ω

i

. (2)

Implicitly, this clustering groups parallel orienta-

tions, according to the tolerance. This allows us to

extract global constraints of parallelism, since all the

parallel primitives are grouped at the same time. This

is an important point in our process, which simplifies

the global adjustment of the orientations and avoids

many problems like error propagation. Indeed, many

processes can begin by a particular primitive and ad-

just the neighbors by propagation (Chen and Feng,

2015). But the first primitive, often the most accu-

rate one, is not necessarily the best one to minimize

a global error. With our process, each primitive is

adjusted independently and according to global infor-

mations.

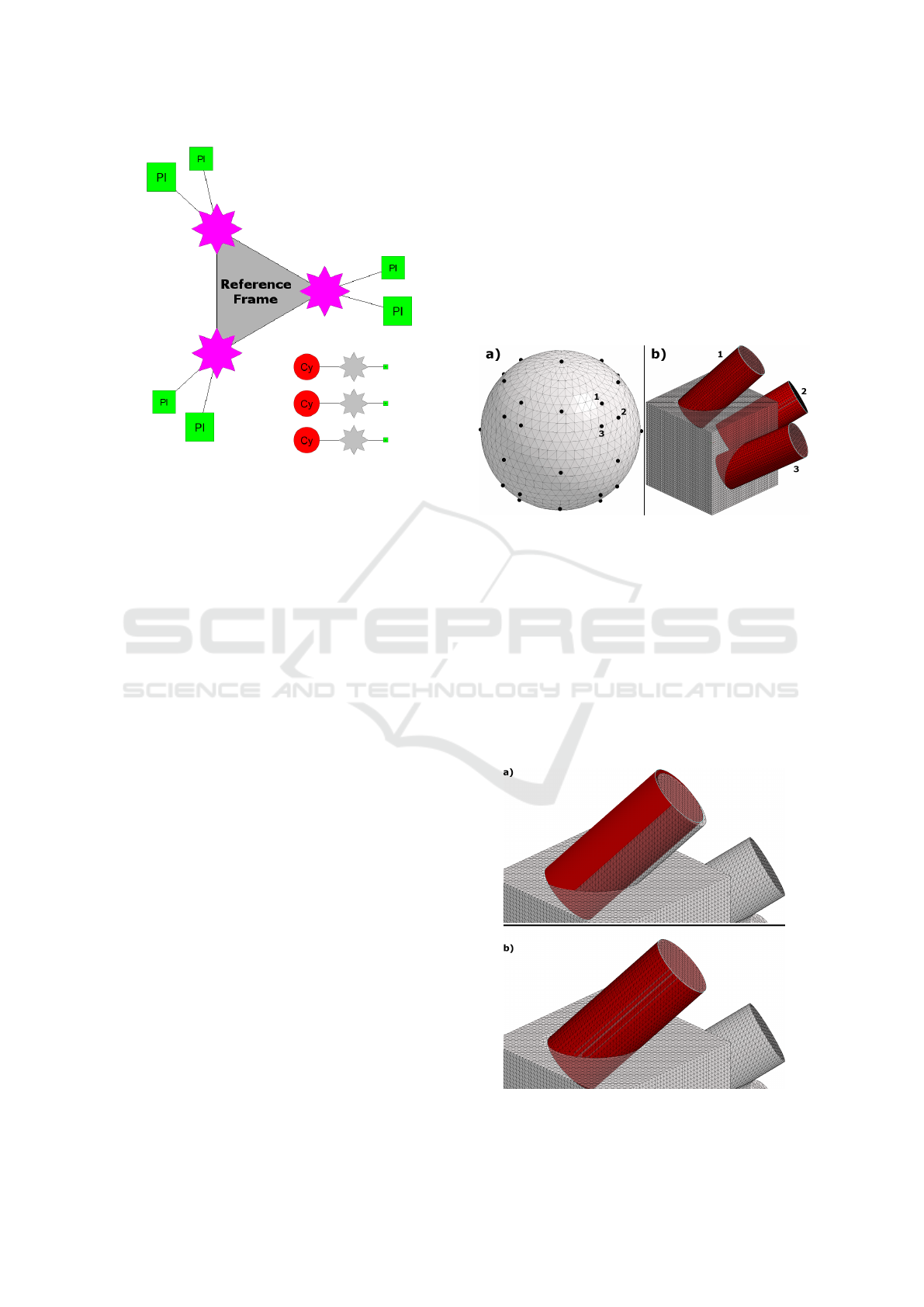

3.4 Model Reference Frame Extraction

We use the orientation clusters to construct the orien-

tation graph, as illustrated in Fig.3:

• A primitive node represents a primitive which is

defined by an orientation (green squares for planes

and red circles for cylinders). Its value is given by

the primitive area.

• A cluster node (grey and purple stars) represents

an orientation cluster. Its value is given by the

weight W

c

.

• An edge between a primitive node and a cluster

node represents the inclusion of the primitive ori-

entation in the cluster. These edges represent the

parallelism constraints.

• An edge between two cluster nodes is added when

the orientation of two clusters are orthogonal, ac-

cording to the tolerance parameter.

This graph allows us to display parallelism and

orthogonality relationships between all the oriented

primitives of the reverse engineered model. We can

Orientation Beautification of Reverse Engineered Models

93

Figure 3: Orientation graph from Fig.2.b.

now detect all the cycles of 3 cluster nodes. The cycle

with the highest sum of cluster weights is the one that

maximizes the covered area of the object (see Fig.3).

If we take this cycle, we find a set of three orthogo-

nal orientations which are related at best to the prim-

itives. This defines a reference frame intrinsic to the

model which could be considered as the frame used

by the CAD operator to design the object. This frame

will then be used to define all the allowed orientations

with respect to the quantization parameter. If there is

no cycle, we take the maximal segment of 2 clusters

and we compute the cross-product between the two

cluster orientations to complete the reference frame.

If, unfortunately, there is neither a cycle nor a seg-

ment, we take the maximal orientation cluster as the

reference frame only axis.

3.5 Orientation Quantization

In this section, we aim to adjust all the primitive ori-

entations, according to the global frame and the quan-

tization parameter (see Section 3.2). If we assume that

the reference frame was the one used by the designer,

we can use spherical coordinates to quantify orienta-

tions and we get the following:

x = ρsinφcos θ

y = ρsinφsin θ

z = ρcosφ

, (3)

where the vector (x, y, z) is an allowed orientation vec-

tor, ρ its norm and (φ, θ) a couple of angles from

Quantization (see Section 3.2). Each possible couple

(φ, θ) defines a different reference orientation.

Note that the order of the frame axes is important

for spherical coordinates. Since we do not know ex-

actly the original order, we must take into account the

3 possible systems of spherical coordinates by permu-

tating O

x

, O

y

and O

z

. Each cluster orientation is then

adjusted according to the closest allowed orientation

(i.e. the one defining the smallest angle with the clus-

terized orientation whatever the order of axes). This

implies that all the primitives belonging to this cluster

should be adjusted with respect to the cluster orien-

tation. Fig.4 illustrates the 3 possible systems on a

specifically designed object.

Figure 4: a) Gaussian sphere of allowed orientations and b)

Cylinders along the 3 possible systems for 45

◦

rotations.

3.6 Primitive Adjustment

The last step of our method consists in adjusting each

geometric primitive by using its quantified orienta-

tion. It is not sufficient to modify the orientation pa-

rameter of the primitive by applying a 3D rotation

leaving the other parameters unchanged. We have to

apply a constrained optimization on each primitive,

with respect to the fitted mesh, as illustrated in Fig.5.

Figure 5: Constrained optimization with locked orientation:

a) Reoriented cylinder, b) Constrained optimization.

GRAPP 2018 - International Conference on Computer Graphics Theory and Applications

94

In this step, the orientation is fixed but all the other

parameters (a 3D point for a plane, a 3D point and

a radius for a cylinder, the apex and the angle for a

cone) are optimized. We used the formulas proposed

in (Shakarji, 1998).

4 EXPERIMENTAL RESULTS

In this section, we applied our method on the

digitized mesh of a case study to show each

step in detail. After, we performed some ex-

periments on more complex digitized 3D meshes.

All of these results were obtained with the same

parameters: Tolerance = 1

◦

and Quantization =

{0

◦

, 30

◦

, 45

◦

, 60

◦

, 90

◦

, 120

◦

, 135

◦

, 150

◦

}.

4.1 Case Study: Lattice

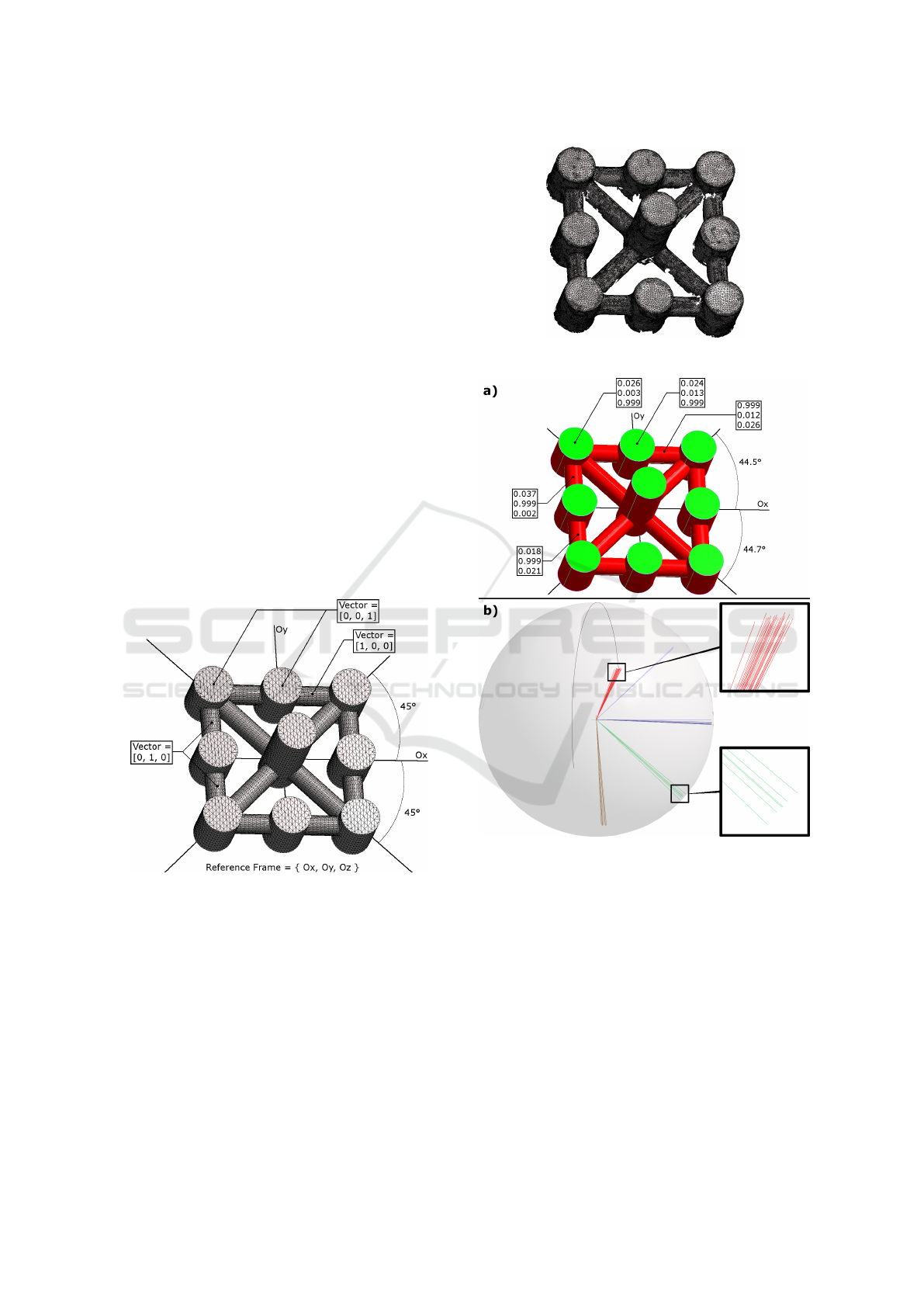

Using a CAD application, we designed a lattice-

shaped object which is mainly composed of cylinders,

as illustrated in Fig.6. We designed it with particular

orientations, according to the reference frame XY Z.

Figure 6: 3D CAD mesh of Lattice.

Then, we printed it using a professional 3D printer

(Ultimaker3), which is accurate to within 20 microns.

Finally, we have digitized it with a structured light

scanner (IMetric), which is accurate to within 10 mi-

crons (see Fig.7). No post-processing was performed.

We extracted the geometric primitives (i.e. the

type of primitives and their parameters) with the

method described in (Gauthier et al., 2017) and we

obtained all of the 21 cylinders . Nevertheless, when

we display the parameters of the axes, we can observe

that they have slightly deviated with respect to the the-

oretical directions, as illustrated in Fig.8.

Figure 7: 3D digitized mesh of Lattice.

Figure 8: Lattice: a) Extracted primitives and b) Gaussian

sphere of orientations, without orientation beautification.

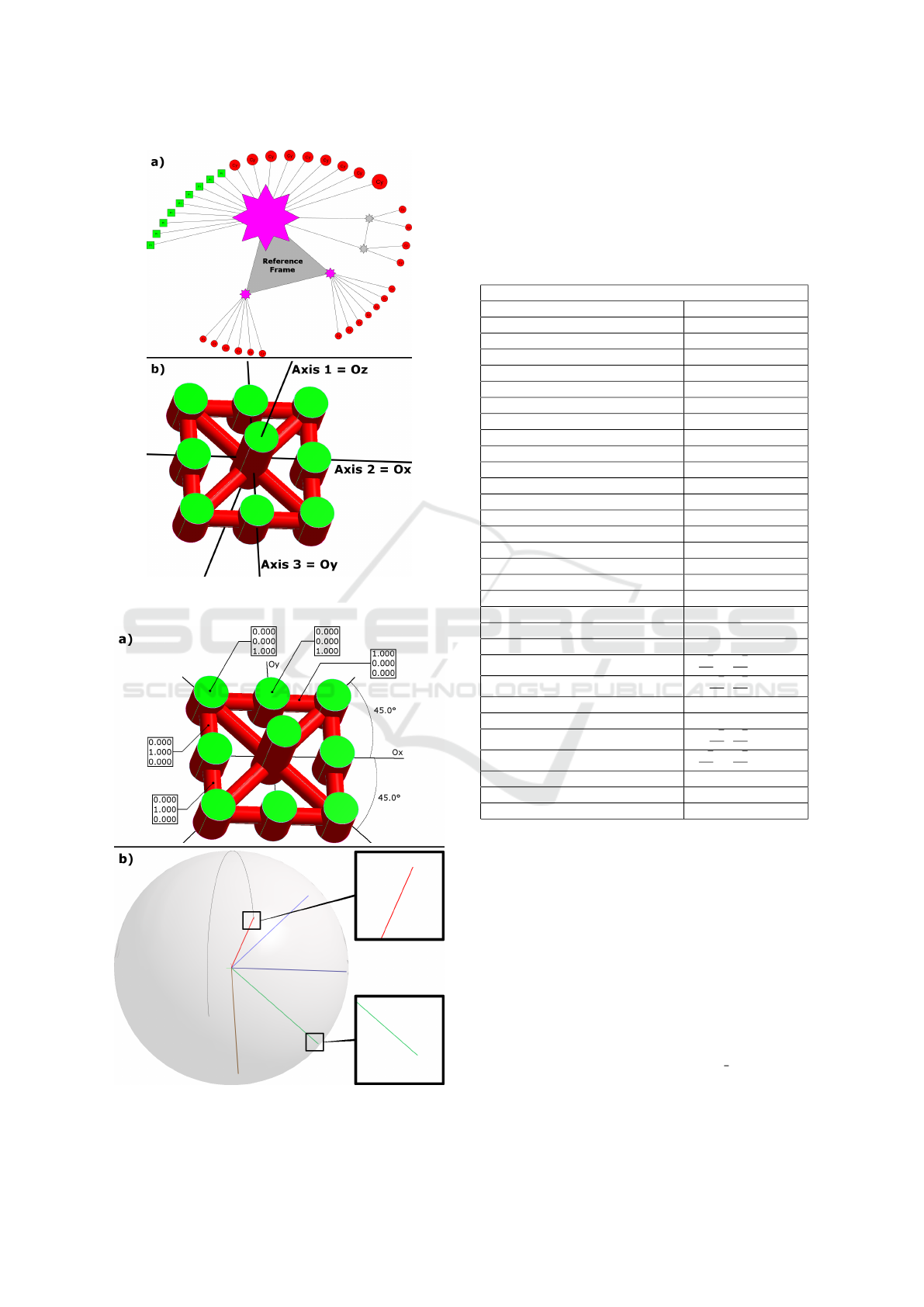

We applied our orientation beautification pro-

cess and we can see in Fig.9 the constructed graph

(Fig.9.a) and the computed reference frame (Fig.9.b).

The orientation graph contains two cycles of 3 cluster

nodes, corresponding to possible coordinate systems.

Our algorithm finds a reference frame corresponding

to XY Z, which is the coordinate system used while

designing the object.

In Fig.10, we show final results after beautifica-

tion. Note that the adjusted orientations exactly cor-

respond to the designed ones (Fig.6), and so respect

the particular angles of 45 degrees.

Orientation Beautification of Reverse Engineered Models

95

Figure 9: Lattice: a) Constructed orientation graph and b)

Computed reference frame.

Figure 10: Lattice: a) Adjusted primitives and b) Gaussian

sphere of orientations, with orientation beautification.

Table 1 summarizes the different extracted orien-

tations. The first column corresponds to the orienta-

tions from the extracted primitives in Fig.8.a, and the

second column shows the orientations of the adjusted

primitives in Fig.10.a.

Table 1: Results of our beautification on Lattice. See Fig.8.a

for the first column and Fig.10.a for the second column.

Orientation

Before After

V

1

= [0.026, 0.003, 0.999] [0, 0, 1] = C

1

V

2

= [0.024, 0.013, 0.999] [0, 0, 1] = C

1

V

3

= [0.015, 0.012, 0.999] [0, 0, 1] = C

1

V

4

= [0.023, −0.007, 0.999] [0, 0, 1] = C

1

V

5

= [−0.020, −0.004, −0.999] [0, 0, −1] = C

1

V

6

= [0.014, 0.010, 0.999] [0, 0, 1] = C

1

V

7

= [0.016, −0.005, 0.999] [0, 0, 1] = C

1

V

8

= [0.012, −0.014, 0.999] [0, 0, 1] = C

1

V

9

= [0.022, −0.012, 0.999] [0, 0, 1] = C

1

V

10

= [−0.018, −0.011, −0.999] [0, 0, −1] = C

1

V

11

= [−0.022, −0.016, −0.999] [0, 0, −1] = C

1

V

12

= [−0.018, 0.005, −0.999] [0, 0, −1] = C

1

V

13

= [−0.021, 0.002, −0.999] [0, 0, −1] = C

1

V

14

= [−0.024, 0.000, −0.999] [0, 0, −1] = C

1

V

15

= [−0.028, 0.001, −0.999] [0, 0, −1] = C

1

V

16

= [−0.018, 0.020, −0.999] [0, 0, −1] = C

1

V

17

= [−0.022, 0.026, −0.999] [0, 0, −1] = C

1

V

18

= [−0.029, 0.021, −0.999] [0, 0, −1] = C

1

V

19

= [−0.999, 0.026, 0.034] [−1, 0, 0] = C

2

V

20

= [−0.999, 0.012, 0.026] [−1, 0, 0] = C

2

V

21

= [−0.037, −0.999, 0.002] [0, −1, 0] = C

3

V

22

= [0.686, −0.728, −0.015] [

√

2

2

, −

√

2

2

, 0] = C

4

V

23

= [0.732, 0.682, 0.017] [

√

2

2

,

√

2

2

, 0] = C

5

V

24

= [−0.013, −0.999, 0.015] [0, −1, 0] = C

3

V

25

= [−0.018, −0.999, −0.021] [0, −1, 0] = C

3

V

26

= [0.732, 0.682, 0.006] [

√

2

2

,

√

2

2

, 0] = C

5

V

27

= [0.687, −0.726, −0.004] [

√

2

2

, −

√

2

2

, 0] = C

4

V

28

= [−0.036, −0.999, 0.003] [0, −1, 0] = C

3

V

29

= [−0.999, 0.027, 0.014] [−1, 0, 0] = C

2

V

30

= [−0.999, 0.031, 0.035] [−1, 0, 0] = C

2

Before beautification, the Lattice digitized mesh

contains 30 different orientations. After the clustering

step, we obtain only 5 different orientations. Finally,

after the orientation adjustement, we obtain orienta-

tions which exactly correspond to the designed ones.

Indeed, the resulting orientations are either colinear

to coordinate system axis, or rotated by 45 degrees

around Oz.

4.2 Other Digitized Meshes

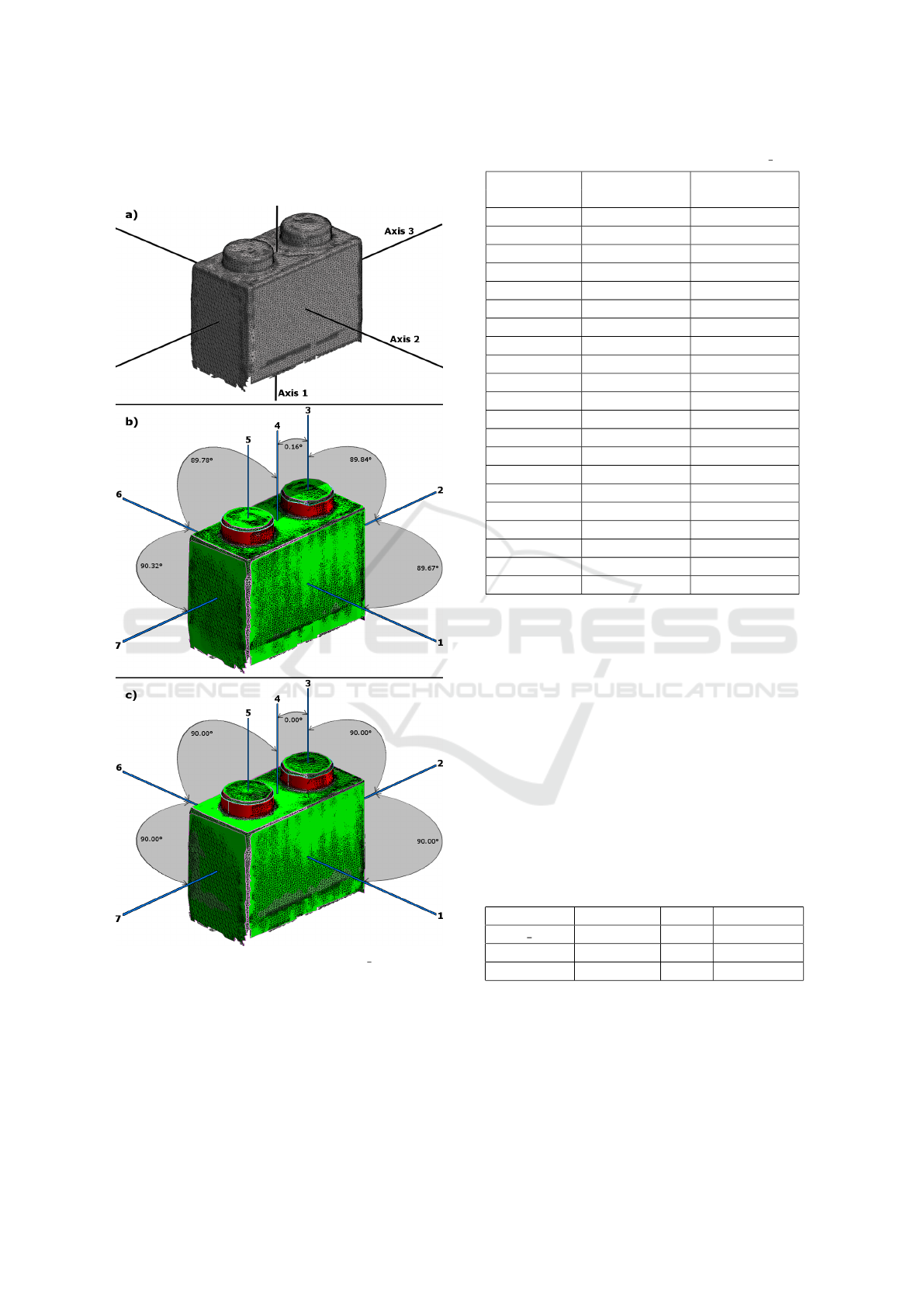

Fig.11 shows some angles between the different ori-

entations of the digitized object Lego

small (struc-

tured light scanner accurate to within 10 microns), be-

fore (Fig.11.b) and after (Fig.11.c) the beautification

step. We can see that no two orientations are exactly

GRAPP 2018 - International Conference on Computer Graphics Theory and Applications

96

parallel or orthogonal at first, but our beautification

process can satisfy these constraints.

Figure 11: Local orientation angles on Lego small: a) 3D

mesh and computed orthonormal coordinate system, b) An-

gles before beautification, c) Angles after.

Angles formed by pairs of orientations are sum-

marized in Table 2, before and after the global orien-

tation beautification.

We can see that our process correctly adjusts ori-

entations to satisfy parallelism and orthogonality. We

can also observe that our method does not round an-

Table 2: Local results of our beautification on Lego small.

Orientation Angle before Angle after

couple beautification beautification

1 - 2 89.67

◦

90.00

◦

1 - 3 90.36

◦

90.00

◦

1 - 4 90.19

◦

90.00

◦

1 - 5 89.93

◦

90.00

◦

1 - 6 0.41

◦

0.00

◦

1 - 7 90.28

◦

90.00

◦

2 - 3 89.84

◦

90.00

◦

2 - 4 89.88

◦

90.00

◦

2 - 5 90.02

◦

90.00

◦

2 - 6 89.71

◦

90.00

◦

2 - 7 0.68

◦

0.00

◦

3 - 4 0.16

◦

0.00

◦

3 - 5 0.46

◦

0.00

◦

3 - 6 89.94

◦

90.00

◦

3 - 7 89.54

◦

90.00

◦

4 - 5 0.30

◦

0.00

◦

4 - 6 89.78

◦

90.00

◦

4 - 7 89.58

◦

90.00

◦

5 - 6 89.51

◦

90.00

◦

5 - 7 89.72

◦

90.00

◦

6 - 7 90.32

◦

90.00

◦

gles, as illustrated in Table 2 in bold. Indeed, we can

believe that these angles were rounded because the

initial object is accurate enough to almost respect the

parallelism and orthogonality constraints.

Table 3 shows the computational time and the

mean of corrected orientation angles, in degrees, for

each presented object. As we can see, our presented

method is fast: only one second to process hundreds

of primitives. This is thanks to our global constraint

detection and local independent primitive adjustment.

Therefore, our beautification process is suitable for an

industrial application like reverse engineering. More-

over, these results were obtained according to the in-

put tolerances, which allows a certain flexibility and

adaptability in primitive adjustments.

Table 3: Mean angle correction of orientations.

Mesh Primitives Time Correction

Lego small 9 <1s 0.39

◦

Aerospace 115 1s 0.64

◦

Watertight 306 1s 0.71

◦

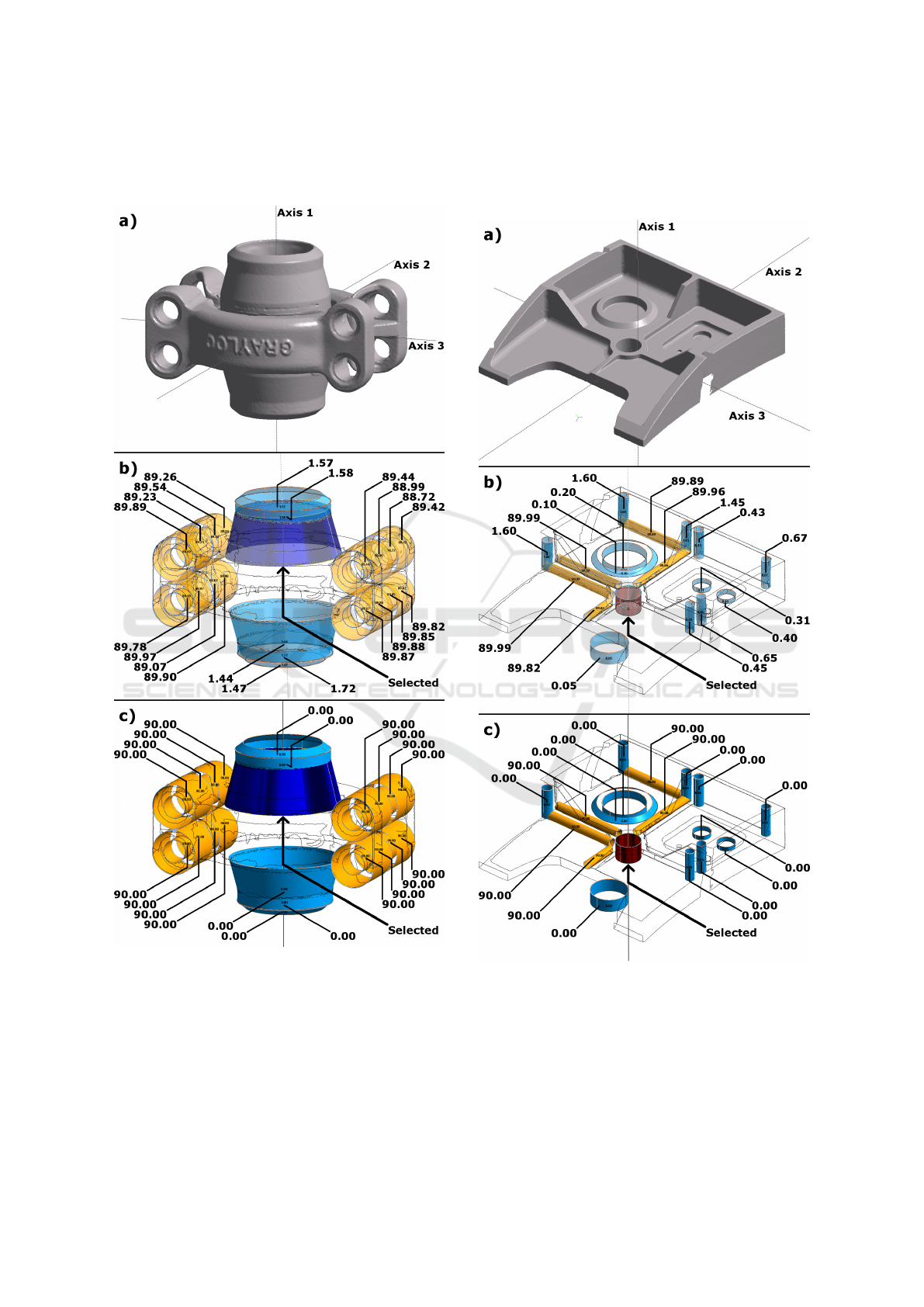

Fig.12 shows a complex object, Watertight (un-

known scanner). As illustrated in Fig.12.a, we suc-

cessfully extracted a reference frame corresponding

to the main and side holes. Since the digitized 3D

mesh is noisy, we extracted many inaccurate orien-

tations before beautification and therefore different

angles between primitive orientations (see Fig.12.b).

Orientation Beautification of Reverse Engineered Models

97

After beautification, we obtain more regular orienta-

tions and angles, according to GD&T (see Fig.12.c).

Figure 12: Beautification on Watertight: a) 3D mesh and

computed reference frame, b) c) Angles between selected

and other orientations b) Before beautification and c) After.

Fig.13 shows another object, Aerospace (struc-

tured light scanner accurate to within 10 microns). As

illustrated in Fig.13.a, the computed orthonormal co-

ordinate system most likely corresponds to the one

used by the designer. This object contains several dif-

ferent orientations which are neither parallel nor or-

thogonal (see Fig.13.b). After beautification, many

orientations become exactly parallel or orthogonal, as

illustrated in Fig.13.c.

Figure 13: Beautification on Aerospace: a) 3D mesh and

computed reference frame, b) c) Angles between selected

and other orientations b) Before beautification and c) After.

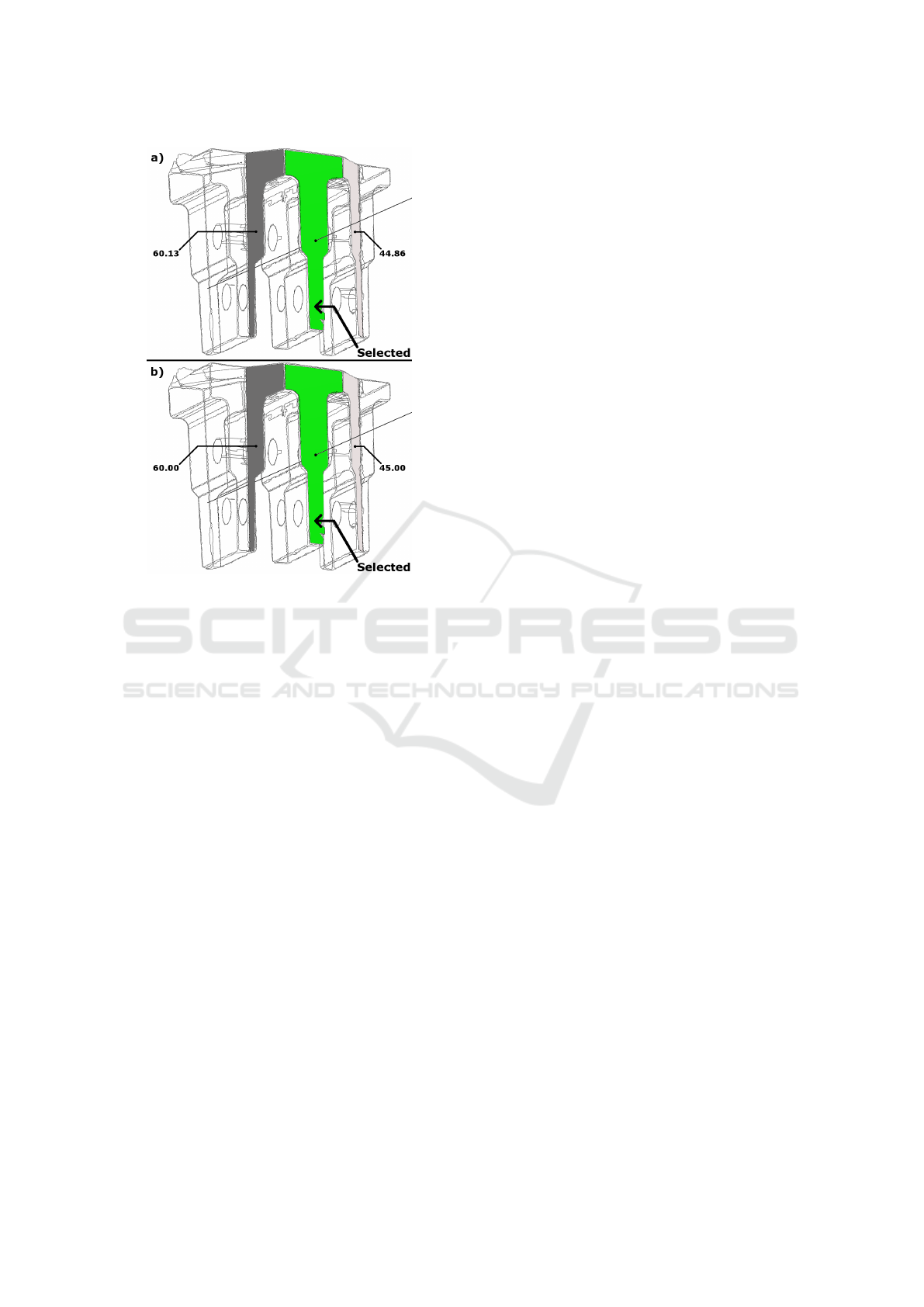

As illustrated in Fig.14, we notice that our beau-

tification does not only improve parallelism and or-

thogonality, but also other particular angles.

GRAPP 2018 - International Conference on Computer Graphics Theory and Applications

98

Figure 14: Aube: Angles between selected and other orien-

tations a) Before beautification and b) After.

5 CONCLUSION

In this paper, we presented a new beautification

method to optimize orientations of geometric primi-

tives detected in a digitized 3D object. We first detect

global parallelism and orthogonality constraints, then

compute an intrinsic orthonormal coordinate system,

we cluster all the orientations of the detected prim-

itives with respect to tolerance and quantization pa-

rameters, and finally adjust orientations using spher-

ical coordinates. We also apply a constrained opti-

mization of geometric primitives to guarantee the ad-

justment accuracy.

Computing an orthonormal coordinate system in-

trinsic to the object is essential, as it allows us to de-

fine global and consistent constraints of parallelism

and orthogonality for all the primitives at the same

time. Thanks to these constraints, we can indepen-

dently adjust the orientation of each geometric primi-

tive and avoid major problems like error propagation

for example. This process is a step towards a fully

automatic reverse engineering process, which aims to

retrieve the initial intent of the designer.

We have implemented the method in the 3D en-

vironment of the C4W society and tested it on sev-

eral different objects. The process is fast (a few

seconds) and it allows us to reduce the number of

orientations. We can see from our results that the

computed reference coordinate system on each ob-

ject most likely corresponds to the one used to design

it. Moreover, primitive orientations can be sucess-

fully adjusted with respect to numerous particular an-

gle values.

In future work, we propose to extend our method

to adjust not only orientations but other primitive pa-

rameters such as radius for spheres and cylinders, or

apex and angle for cones. Then we will extend it to

adjust the geometric primitive positions, respecting

several alignments and intersections.

REFERENCES

B

´

eni

`

ere, Subsol, Gesqui

`

ere, LeBreton, and Puech (2013).

A comprehensive process of reverse engineering from

3d meshes to cad models. Computer-Aided Design,

45(11):1382 – 1393.

Benk

˝

o, Martin, and V

´

arady (2001). Algorithms for re-

verse engineering boundary representation models.

Computer-Aided Design, 33(11):839 – 851.

Buonamici, Carfagni, and Volpe (2017). Recent strate-

gies for 3d reconstruction using reverse engineering:

a bird’s eye view. In Advances on Mechanics, Design

Engineering and Manufacturing (JCM 2016), pages

841–850. Springer International Publishing.

Chen and Feng (2015). Idealization of scanning-derived tri-

angle mesh models of prismatic engineering parts. In-

ternational Journal on Interactive Design and Manu-

facturing (IJIDeM), pages 1–17.

Gauthier, Puech, B

´

eni

`

ere, and Subsol (2017). Analysis of

digitized 3d mesh curvature histograms for reverse en-

gineering. Computers in Industry, 9293:67 – 83.

Kov

´

acs, V

´

arady, and Salvi (2015). Applying geometric con-

straints for perfecting cad models in reverse engineer-

ing. Graphical Models, 82:44 – 57.

Langbein, Marshall, and Martin (2002). Numerical meth-

ods for beautification of reverse engineered geometric

models. In Geometric Modeling and Processing. The-

ory and Applications. GMP 2002. Proceedings, pages

159–168.

Langbein, Marshall, and Martin (2004). Choosing con-

sistent constraints for beautification of reverse engi-

neered geometric models. Computer-Aided Design,

36(3):261–278.

Langbein, Mills, Marshall, and Martin (2001). Recognizing

geometric patterns for beautification of reconstructed

solid models. In Proceedings International Confer-

ence on Shape Modeling and Applications, pages 10–

19.

Li, Wu, Chrysathou, Sharf, Cohen-Or, and Mitra (2011).

Globfit: Consistently fitting primitives by discover-

ing global relations. ACM Trans. Graph., 30(4):52:1–

52:12.

Orientation Beautification of Reverse Engineered Models

99

Shakarji (1998). Least-squares fitting algorithms of the nist

algorithm testing system. In Journal of Research of

the National Institute of Standards and Technology,

pages 633–641.

Wang, Gu, Yu, Tan, and Zhou (2012). A framework for 3d

model reconstruction in reverse engineering. Comput.

Ind. Eng., 63(4):1189–1200.

GRAPP 2018 - International Conference on Computer Graphics Theory and Applications

100