Integrating Fuzzy Cognitive Mapping and Bayesian Network

Learning for Supply Chain Causal Modeling

Behnam Azhdari

Department of Management, Khark Branch, Islamic Azad University, Shohada St. Khark Island, Boushehr, Iran

Keywords: Integrated Method, Supply Chain Management, Supply Chain Performance, Causal Bayesian Network.

Abstract: In this study, by integrating fuzzy cognitive mapping (FCM) and causal Bayesian network (CBN) learning, a

model of causal links among supply chain enablers, supply chain management practices and supply chain

performances is developed. For FCM development, fuzzy causal knowledge of a panel of experts in SCM is

elicited. Also, an industry survey data used in a Bayesian learning process to create a CBN. By applying

analytical modifications, the resultant CBN model is modified to reach better fit indices, suggesting a new

approach in Bayesian learning. Integrating FCM and CBN models, resulted in more valid causal relations that

are based on these two different methodologies. The findings of this study support the notion that SC enablers,

especially IT technologies, don't have direct impact on SC performance. Also it is revealed that in any tier of

supply chain concepts; there may be some important intra-relations which worth further studies.

1 INTRODUCTION

Although organizational performance is important,

today's business competition is mostly among supply

chains and not just between individual organizations.

Supply chain enablers are required tools to practice

effective supply chain management. So, to improve

SC performance, it is necessary to study the impact of

SC enablers and SCM practices on SC performance.

In recent years the investigation to find out the

relation between these concepts of supply chains is at

the heart of interest of many academics and SCM

practitioners. Despite the role of SC enablers and

SCM practices, there is a scarcity in literature about

effects of these SC elements on SC performance,

especially in developing countries.

The goal of this research is to develop an approach

based on causal Bayesian networks (CBN) modeling

to model the causal relations between SC enablers,

SCM practices and SC performance in some Iranian

supply chains. Iran is now at a challenging path to free

itself from the sanctions and oil based economy, so

any improvement in its supply chains may be vital to

this path. This model has been developed for a local

case.

The reminder of this paper is as follows. In section

2, influential papers about relations between SC

enablers, SCM practices and performance will be

reviewed. In section 3, the research constructs and

fuzzy cognitive mapping methodology are described.

Afterwards, data gathering and measurement

instrument are discussed. In section 4, causal

Bayesian network modelling is deliberated. Finally,

FCM and CBN models will be integrated in order to

reach a more valid causal model. In section 5, the

results and implications will be discussed.

Conclusions and study limitations and also future

research suggestions are discussed in Section 6.

2 RELATIONSHIPS BETWEEN

SC ENABLERS, SCM

PRACTICES AND SC

PERFORMANCE

Studying the relations between SC enablers and SCM

practices and their effect on performance is matter of

interest to many academics and SCM practitioners. A

review of these works is depicted in Table 1. As this

table shows, the authors of these studies were more

focused on organizational performance (Narasimhan

and Jayanth, 1998; Frohlich and Westbrook, 2001;

Tan et al., 2002; Li and Lin, 2006).

In one of the first papers in this context that

considers SC performance, Shin et al., (2000) worked

Azhdari, B.

Integrating Fuzzy Cognitive Mapping and Bayesian Network Learning for Supply Chain Causal Modeling.

DOI: 10.5220/0006556900590070

In Proceedings of the 7th International Conference on Operations Research and Enterprise Systems (ICORES 2018), pages 59-70

ISBN: 978-989-758-285-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

59

on the effect of supply chain management

orientations on SC performance. They concluded that

improvement in supply chain management

orientation, including some SC practices, can

improve both the suppliers’ and buyers’ performance.

In other study, Lockamy and McCormack (2004)

investigated the relationships between SCOR model

planning practices with SC performance. According

to the results of this paper, planning processes are

critical in all SCOR supply chain planning decision

areas and collaboration is the most important factor in

the plan, source and make planning decision areas.

Lee et al., (2007) also studied the relationships

between three SC practices, including supplier

linkage, internal linkage and customer linkage, and

SC performance. They concluded that internal

linkage is a main factor of cost-containment

performance and supplier linkage is a crucial

indicator of performance reliability as well as

performance. In another work, Sezen (2008)

investigated the relative effects of three SCM

practices including supply chain integration, supply

chain information sharing and supply chain design on

supply chain performance. He concluded that the

most important effect on resource and output

performances belongs to supply chain design. In

addition he concluded that information sharing and

integration are correlated with performance, but their

effect strength are lower than supply chain design. In

one of the newest works in this area, Ibrahim and

Ogunyemi (2012) tested the effect of information

sharing and supply chain linkages on supply chain

performance. Their results showed that supply chain

linkages and information sharing, positively related to

flexibility and efficiency of supply chain.

Seemingly the first article, in which authors

consider the effects of both SC enablers and SCM

practices on SC performance, is the study of Li et al.,

(2009). They investigated the relations between three

factors including IT implementation as an important

SC enabler, supply chain integration as an SCM

practice, and SC performance. As a result, they

suggested that IT implementation has no direct

impact on SC performance, but it improves SC

performance through its positive impact on SC

integration. Zelbst et al., (2010) theorized and

assessed a structural model that includes RFID

technology utilization and supply chain information

sharing as antecedents to supply chain performance.

The results of aforementioned study indicates that

although RFID technology does not directly affect SC

performance, its utilization leads to improve

information sharing among supply chain members,

which in turn leads to improve SC performance.

Qrunfleh and Tarafdar (2015) examine alignment

between supply chain management (SCM) practices

and information technology (IT) utilization and its

impact on supply chain performance and firm

performance by using structural equation modeling.

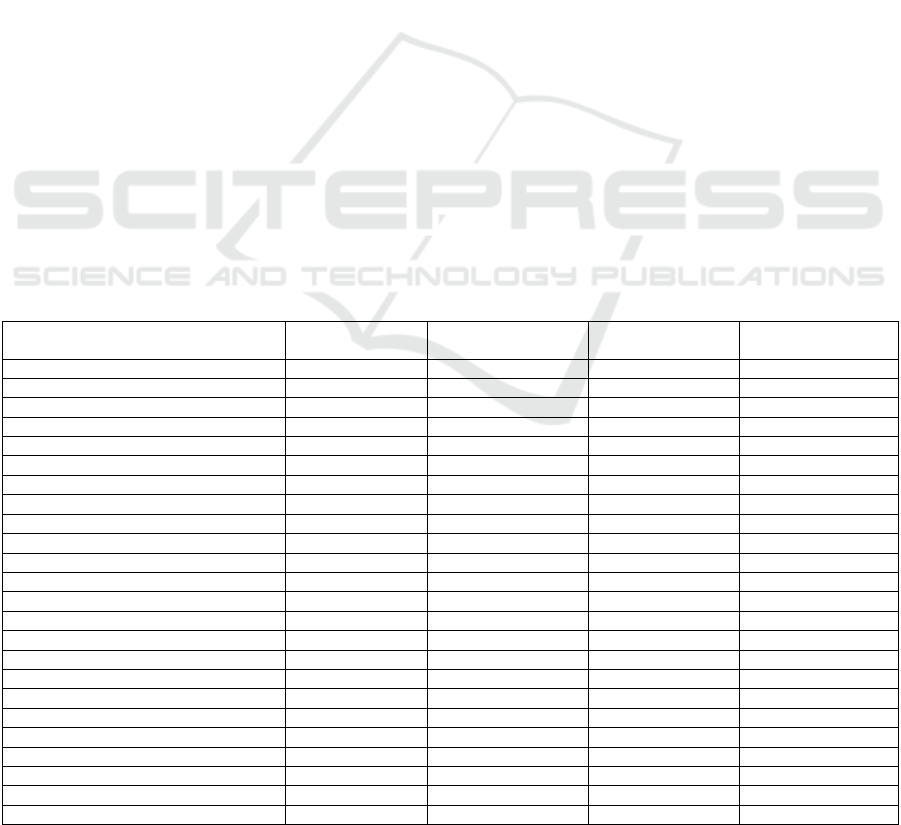

Table 1: Relationships between SC Enablers, SCM practices and SC performance in the literature.

References

Scope of SC

enablers

Scope of SCM

practices

Methodology

Scope of performance

measurement

Narasimhan and Jayanth (1998)

-

Narrow

SEM

Organization

Shin et al., (2000)

-

Narrow

SEM

Supply chain

Frohlich and Westbrook (2001)

-

Narrow

ANOVA

Organization

Tan et al., (2002)

-

Wide

Correlation

Organization

Lockamy III and McCormack (2004)

-

Narrow

Regression

Supply chain

Li and Lin (2006)

Wide

Wide

Regression

-

Li et al., (2006)

-

Wide

SEM

Organization

González-Benito (2007)

Narrow

Narrow

SEM

Organization

Sanders (2007)

Narrow

Narrow

SEM

Organization

Zhou and Benton Jr. (2007)

Narrow

Narrow

SEM

-

Li et al., (2007)

-

Narrow

SEM

Organization

Lee et al., (2007)

-

Narrow

Multiple regression

Supply chain

Johnson et al, (2007)

Wide

-

Regression

Organization

Devaraj et al., (2007)

Narrow

Narrow

SEM

Organization

Sezen (2008)

-

Narrow

Regression

Supply chain

Li et al, (2009)

Wide

Narrow

SEM

Supply chain

Bayraktar et al., (2009

(

-

Wide

SEM

Organization

Hsu (2009)

-

Wide

SEM

Organization

Davis-Sramek et al., (2010)

Narrow

-

Regression

Organization

Zelbst et al., (2010)

Narrow

Narrow

SEM

Supply chain

Sundram et al., (2011)

-

Wide

PLS

Supply chain

Hamister (2012)

-

Wide

PLS

Supply chain

Ibrahim

and

Ogunyemi (2012

(

-

Narrow

Regression

Supply chain

Amr Youssef and Islam El-Nakib (2015)

-

Wide

Regression

Organization

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

60

This study shows that inter-firm SCM practices – IT

use external alignment and information SCM

practices – IT use infrastructural alignment are

positively associated with supply chain performance

and firm performance. Tatoglu et al., (2016) study the

impact of supply chain management and information

systems (IS) practices on operational performance of

small and medium-sized enterprises operating in two

neighboring emerging country markets of Turkey and

Bulgaria. They also investigate moderating effects of

both SCM–IS-linked enablers and inhibitors on the

links between SCM and IS practices and operational

performance of SMEs. The results of regression

analyses indicated that SCM and IS practices as well

as SCM–IS-related enabling factors positively

influenced SMEs’ operational performance.

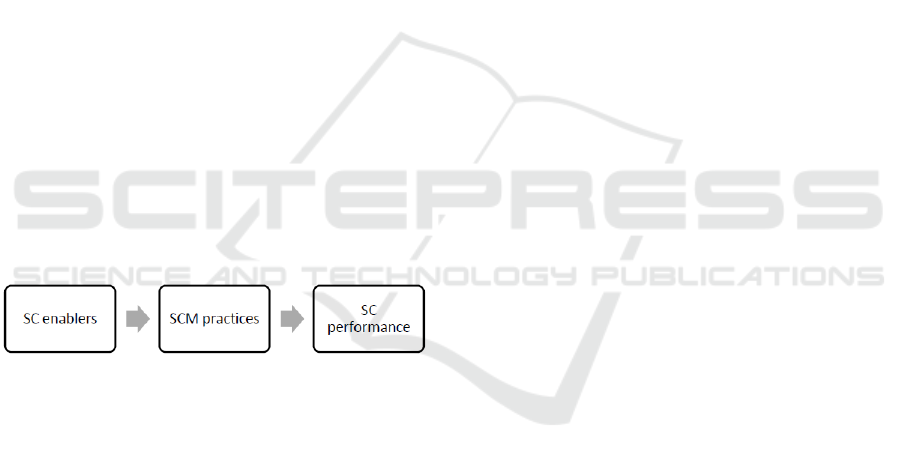

2.1 Conceptual Model

Although there is no doubt about the importance of

the relations between SC enablers, SCM practices and

SC performance, not many studies can be found in the

literature which cover these relations in a whole

model. Thus, this research develops a basic

conceptual model of relationships among SC

enablers, SCM practices and SC performance (Figure

1). As depicted in this model, based on the literature

(Li et al., 2009; Zelbst et al., 2010), this research

suggests that SC enablers have direct impact on SCM

practices and no direct impact on SC performance.

Figure 1: Proposed basic conceptual model.

3 RESEARCH METHODOLOGY

3.1 Identifying Constructs

In this section, the method of identifying the

“constructs” which are required for FCM

questionnaire and also for Bayesian networks survey

instrument has been explained.

3.1.1 Constructs of SC Enablers and SCM

Practices

As discussed in the literature review, not all

researchers have consensus about the definition of SC

enablers and SCM practices. Even, in some instances

one SC enabler is confused with SCM practice and

vice versa. Thus, in order to achieve a valid list of SC

enablers and SCM practices, and eliminating

ambiguous statements for content validity, Q-sort

methodology was used. The Q-sort method is an

iterative process in which the degree of agreement

between judges forms the basis of assessing construct

validity and improving the reliability of the constructs

(Li et al., 2005). To apply Q-sort method, six

researchers and experts were questioned, to classify

the specified initial items into SC enabler and SCM

practice categories. To assess the reliability of the Q-

sort results, the item placement ratios were used

(Boon-itt and Himangshu, 2005).

Q-sort resulted in 20 SC enablers out of 22 and 44

SCM practices out of 54 initial items. The judges'

agreement for these items was more than 70%, which

is above the recommended value of 65% (Li et al.,

2005). Furthermore, information network, advanced

manufacturing technology, and logistic infrastructure

were classified as SC enablers while they are cited in

the literature as SCM practices. This identification

seems rational because it's more consistent with SC

enabler definition.

Towards a final list of SC enablers and SCM

practices, content analysis was used to identify

similar statements and merge some similar items to

definitive ones. As a result, 7 SC enablers and 8 SCM

practices were identified.

3.1.2 SC Performance

One of the most significant factors in measuring SC

performance is its comprehensiveness (Beamon,

1999). According to some authors, (Bhagwat and

Sharma, 2007; Chae, 2009; Shepherd and Günter,

2006), models such as BSC and SCOR can be very

effective for SC performance measurement to

embrace all important supply chain performance

dimensions. Afterwards, to identify important SC

performance measures, supply chain management

processes from SCOR model was used, which

includes plan, source, make and deliver. The return

process was excluded, due to its limited

implementation in many cases which we were

involved.

3.2 Fuzzy Cognitive Mapping

Fuzzy cognitive maps are fuzzy-graph structures for

representing causal reasoning. Their fuzziness allows

hazy degrees of causality between hazy causal objects

(Kosko, 1986). A fuzzy causal map composed of

nodes that represent concepts of interest and weighted

arrows indicating different causal relationships with

different strengths among these concepts. Fuzzy

Integrating Fuzzy Cognitive Mapping and Bayesian Network Learning for Supply Chain Causal Modeling

61

cognitive map models can be developed by experts

and/or computationally (Stach et al., 2010).

To integrate the qualitative knowledge of SCM

experts and practitioners with quantitative Bayesian

network model from field data, expert-based FCM

was used to develop the initial model of interest. To

achieve this goal, a group of 14 participating experts

were selected, half of them with good experience in

managing supply chains and the other half with good

academic background. These experts were asked to

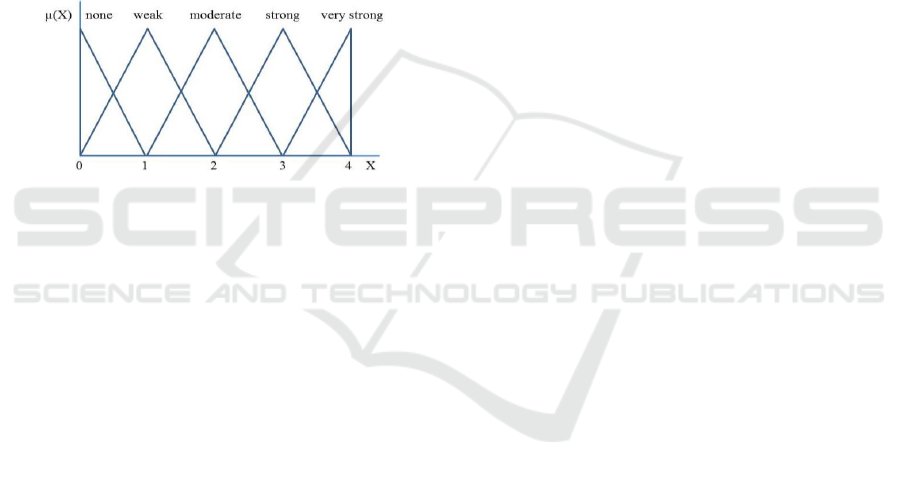

fill out a matrix questionnaire regarding the impacts

of SC enablers on SCM practices as well as the

impacts of SCM practices on SC performance with

linguistic terms of "none", "weak", "moderate",

"strong" and "very strong". Each of these linguistic

terms treated as fuzzy triangular number with

membership functions as depicted in Figure 2.

Figure 2: Linguistic term set of five labels with its

semantics.

3.2.1 Aggregated Fuzzy Cognitive Map

The average of each fuzzy relationship weight

correspondent to all experts was calculated, with the

assumption that all experts are equally credible. The

final combined connection matrix had fuzzy

triangular numbers. Thus, for a fuzzy cognitive map

with linguistic weights, a simple procedure was used,

in which fuzzy numbers of the matrix were compared

to fuzzy number of "weak". If any fuzzy numbers of

this matrix was identified as strongly greater than

"weak", its corresponding relation in FCM

connection matrix was labeled as "strong" and if

identified as moderately greater than "weak", its

corresponding relation in FCM connection matrix

was labeled as "moderate". For comparing fuzzy

numbers, a fuzzy ranking method was used based on

possibility and necessity theory (Dubois and Prade,

1983) as follows:

A

p

and A

n

has been defined as auxiliary functions for

comparing two fuzzy numbers (Menhaj, 2006):

)()( uAuA

xu

P

(1)

( ) 1 ( )

n

ux

A u A u

(2)

Therefore A

p

is a fuzzy set which is possibly greater

than or equal to fuzzy number A. Also, A

n

is a fuzzy

set which is necessarily greater than or equal to A. So

for a fuzzy triangular number A(l, c, r), A

p

and A

n

are computed as:

0

( ) ( ) ,

1

p

ul

A u A u l u c u U

uc

(3)

0

( ) 1 ( ) ,

1

n

uc

A u A u c u r u U

ur

(4)

For comparing two fuzzy numbers A and B, П

B

(A

p

)

and П

B

(A

n

) were used:

( ) ( ( ) ( ))

( ) ( ( ))

pp

B

v

v

uv

A B v A v

B v A u

(5)

( ) ( ( ) ( ))

( ) ( (1 ( )))

nn

B

v

v

uv

A B v A v

B v A u

(6)

П

B

(A

p

) indicates the possibility that the maximum

value of V (the reference set of B) is greater than or

equal to the minimum value of U (reference set of A).

Also, the value of П

B

(A

n

) indicates the possibility that

the maximum value of V (reference set of B) is

greater than or equal to the maximum value of U

(reference set of A). So two rules can be developed

for comparing fuzzy numbers of A and B (Menhaj,

2006):

Rule 1. If

)(

pB

A

is greater than

)(

pA

B

then B is greater than A.

Rule 2. If

)(

nB

A

is greater than

)(

nA

B

then

B is greater than A.

A simple combination of Rules 1 and 2 can be used

to compare two fuzzy numbers of A and B:

• If B was identified as greater than A, based on

both above rules, it will be suggested that B is

strongly greater than A.

• If B was identified as greater than A, based on just

one of above rules, it will be suggested that B is

moderately greater than A.

• If B was identified as less than or equal to A,

based on both above rules, it will be suggested that

B is not greater than A.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

62

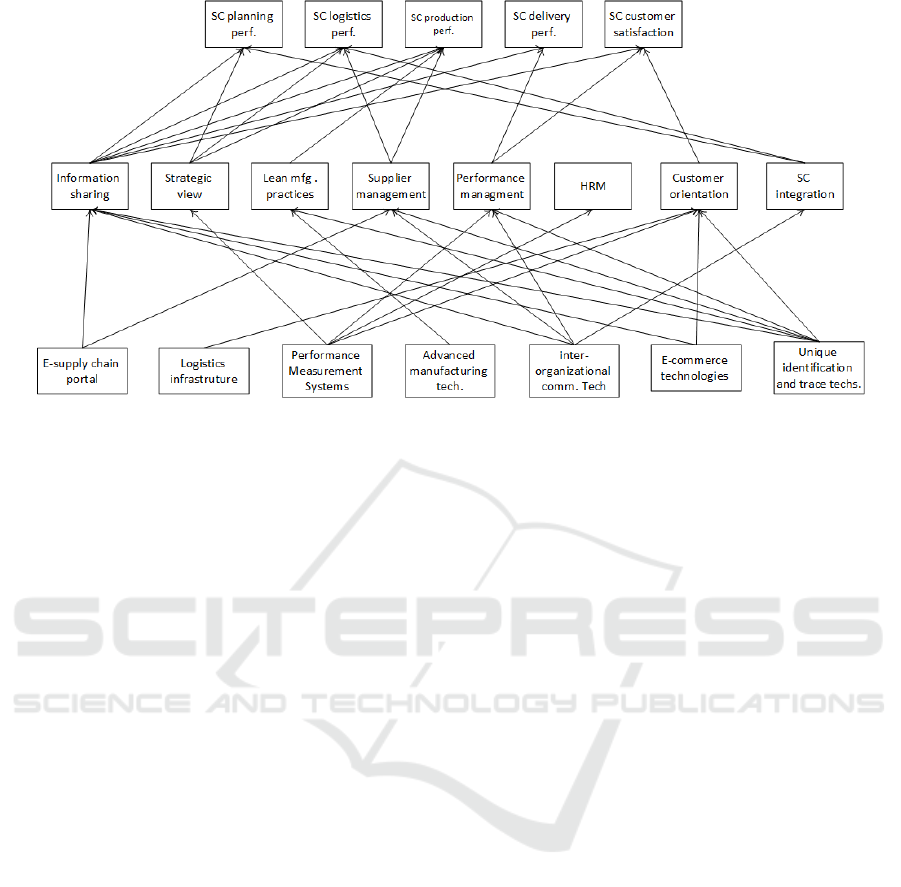

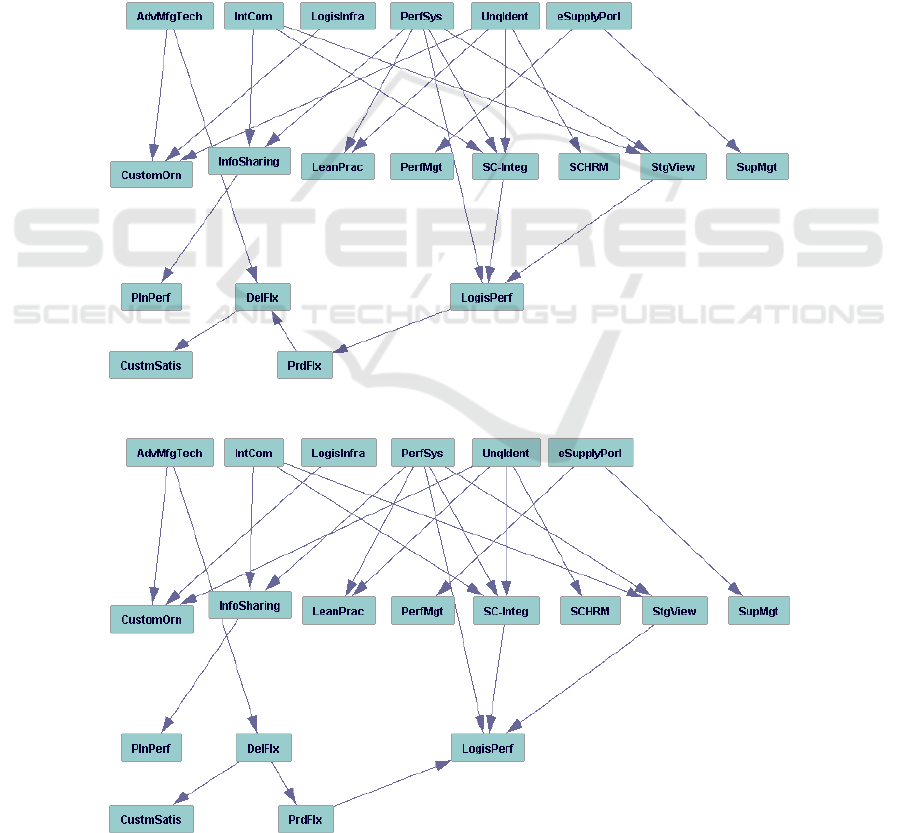

Figure 3: Aggregated FCM model of strong causal effects.

By using above procedure, the final FCM

connection matrix was reached with linguistic terms

and final FCM graph based on this matrix was

acquired, depicted in Figure 3. For simplicity, only

strong relations are shown.

3.3 Data Collection

Prior to data collection, an initial survey instrument

was pre-tested for content validity. A panel of 4

researchers' participated in FCM phase were asked to

evaluate the questionnaire, regarding ambiguity,

appropriateness, and completeness. By reviewing a

few resulted comments, the survey questionnaire was

modified and finalized.

Our target sample was collected from

manufacturers of 10 products classes, covered by

IranCode® products classification system. It was

suggested that the firms with more products are

suitable to be selected as the sample. Herein the firms

were sorted, based on the number of their registered

products in IranCode®. Then, by using stratified

random sampling, a sample of 2000 firms was

selected and they were asked to fill out the

questionnaire. In order to make the submissions as

convenient as possible, participants were offered

several options for returning the questionnaire (via

email, via mail, or via fax). After four weeks, for

following up the procedure, personalized reminder e-

mails were sent to potential participants. Finally, out

of 2000 surveys mailed, 199 valid responses were

received, resulting in a response rate of 11.63%,

which is acceptable as some other studies in this field

(Ou et al., 2010; Li and Lin, 2006).

Non-response bias was assessed by performing a

t-test on the scores of early and late responses. The

responses were divided into two groups: 142

responses (71.4%) received within 3 weeks after

mailing, and 57 ones (28.6%) received four weeks

later and even more. The result of t-test between early

and late respondents indicated no significant

difference between the two groups.

As this study relied on single respondents and

perceptual scales to measure dependent and

independent variables, the presence of common

method variance was assessed (Kim et al., 2012). A

model was run without the method factor and it was

compared to the one with method factor added

(Bagozzi, 2011). Since the method factor failed to

change substantive conclusions, it was concluded that

the amount and extent of method variance is not a

threat to the validity of the measurement model.

Sample responses included 24% food products

manufacturers, 19.8% road making machinery and

construction materials manufacturers, 12.8%

chemical manufacturers, 11.2% medical and

cosmetic manufacturers, 9.6% industries general

necessities manufacturers, 8.6% auto parts

manufacturers and 13.8% other manufacturers. Of all

respondents, 28% were CEO, President, Vice

President or Director, 22% were production managers

and RandD managers, 19% were sales managers,

procurement managers and supply managers, and

remaining 17% of respondents were other manager.

So this composition reveals that most of respondents

were knowledgeable about firm’s supply chain

management.

Integrating Fuzzy Cognitive Mapping and Bayesian Network Learning for Supply Chain Causal Modeling

63

3.4 Measurement of Variables

3.4.1 Measures of SCM Practices and SC

Enablers

Eight SCM practices were identified and seven SC

enablers to include in survey instrument, as

mentioned in Table 3. The scale items for measuring

these constructs are derived from past studies and

applying Q-sort methodology as described in

previous sections. In case of SCM practices the

respondents were asked to indicate that what extent

these scale items were implemented in SCM of their

core products, relying on five-point scales ranging

from 1 = ‘not at all implemented’ to 5 = ‘fully

implemented’. In case of SC enablers, the

respondents were asked to indicate their perceptions

of relative importance of these enablers in SCM of

their core products on five-point scales ranging from

1= ‘of no importance’ to 5 = ‘of major importance’.

3.4.2 SC Performance

As mentioned in FCM part of this study, the measures

of SC performance was used according to supply

chain management processes of SCOR model,

including scale items for measuring ‘SCM planning’,

‘logistics performance’, ‘supply chain production

performance’, ‘supply chain delivery performance’,

and ‘customer delight performance’. The respondents

were asked to indicate on a 6-point scale, ranging

from 1= ‘definitely worse’ to 6= ‘definitely better’,

on how their core products supply chain had

performed relative to their major competitors or their

overall industry on each of these supply chain

performance criteria.

3.5 Reliability and Validity

In addition to content validity, mentioned in previous

sections, the adequacy of a measure requires that

three essential components be established:

unidimensionality, reliability and validity (O'Leary-

Kelly and Vokurka, 1998). Validity itself includes

convergent validity and discriminant validity. So

CFA was used for measurement model relevant tests.

As the measurement model had more than four-point

scales, based on Bentler and Chou (1987)

recommendation, the maximum likelihood method of

LISREL was used for calculating model fit indexes,

that is a more common and reliable method (Bentler

and Chou, 1987). For assessing model fitting, two

critical indexes of CFI and SRMR was used as

recommended by Hu and Bentler (1999) for less than

250 samples. The models were identified with CFI ≥

0.95 and SRMR ≤ 0.09 as acceptable (Hu and Bentler,

1999).

In the first stage, unidimensionality was tested,

that involves establishes a set of empirical indicators

relates to one and only one construct (O'Leary-Kelly

and Vokurka, 1998). A single factor LISREL

measurement model was specified for any construct.

If a construct had less than four items, two-factor

model were tested by adding the items of another

construct, making model fit indexes obtainable (Li et

al., 2005). A CFA was conducted to separate

measurement models of each construct, such as

information sharing, strategic view in supply chain

management and lean manufacturing practices. It was

found that fitting indexes of some constructs were

unsatisfactory. Then, the standardized residuals

matrix of LISREL results were used to identify which

items must be deleted to obtain better fit indexes for

each model. Large standardized residuals indicate

that a particular relationship is not well accounted by

the model (Schumacker and Lomax, 2004). During

this iterative procedure, one item out of measurement

items of strategic view in supply chain management,

lean manufacturing practices, performance

management, general enablers, logistics and supply

performance, and delivery performance were

dropped. Additionally, two items out of eight

measurement items of integration were dropped.

Table 5 shows the analysis results of the final

structural model of all constructs.

In the second stage, the reliability analysis was

conducted by using composite reliability (7) which is

less sensitive to number of items of constructs

(Fornell and Larcker, 1981).

ρ

,

(7)

As depicted in Table 3, all of model constructs have

an acceptable level of reliability, except production

performance which its reliability index (ρ) is less than

0.7 cut-off criteria. SCP31 item was dropped from SC

production performance construct to improve its

reliability. So this construct finally reached the value

of 0.9, which is a good level.

In the third stage for analysing construct validity,

the convergent validity and discriminant validity

were assessed. Convergent validity relates to the

degree to which multiple methods of measuring a

variable provide the same results (O'Leary-Kelly and

Vokurka, 1998). Based on Fornell and Larcker (1981)

recommendation, the average variance extracted

(AVE) was used to analyse convergent validity. An

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

64

Table 2: Constructs properties for unidimesionality, reliability and convegent validity.

Constructs

χ

2

df

CFI

SRMR

ρ

AVE

General SC enablers

57.70

26

0.97

0.05

0.84

0.65

Information sharing

22.24

8

0.95

0.06

0.78

0.73

Strategic view in supply chain management

6.47

5

0.99

0.03

0.76

0.62

Lean manufacturing practices

0.57

2

1.00

0.01

0.82

0.72

Supplier management

22.24

8

0.95

0.07

0.70

0.66

Performance management

7.43

2

0.96

0.05

0.70

0.59

SC Human resources management

33.45

8

0.96

0.04

0.72

0.75

Customer orientation

33.45

8

0.96

0.04

0.89

0.82

Supply chain integration

31.84

9

0.97

0.05

0.89

0.75

SC planning performance

41.12

10

0.96

0.04

0.90

0.95

SC logistics and supply performance

41.12

10

0.96

0.04

0.80

0.82

SC production performance

41.12

10

0.96

0.04

0.42

0.51

SC delivery performance

41.12

10

0.96

0.04

0.90

0.95

SC customer delight performance

41.12

10

0.96

0.04

0.86

0.89

AVE greater than 0.5 is desirable because it suggests

that on average, the latent construct accounts for a

majority of the variance in its indicators (MacKenzie

and Podsakoff, 2011). Based on this criterion, as

shown in Table 5 all research constructs have

acceptable convergent validity.

For a measure to have discriminant validity, the

variance in the measure should reflect only the

variance attributable to its intended latent variable

and not to other latent variables (O'Leary-Kelly and

Vokurka, 1998). In analysing discriminant validity

for SC management practices, as recommended by

Shiu et al. (2011) both procedures of Fornell and

Larcker (1981), and Bagozzi and Phillips (1982) were

used. Based on the first procedure, the average

variance extracted (AVE) of any construct must be

bigger than the correlation between that construct and

any other constructs of the model. On the basis of the

second procedure, the difference in chi-square value

between the unconstrained CFA model and the nested

CFA model was examined where the correlation

between the target pair of constructs is constrained to

unity. Based on these two procedures it was found out

that all constructs have discriminant validity except

the constructs of “Human resources management”

and “Supplier management” which is one of

limitations of this study.

3.6 Building Causal Bayesian Network

Because of its descriptive and practical power, causal

modelling approaches, like structural equation

modelling, are being used to model inter-relationships

of SCM concepts in many researches (Narasimhan

and Jayanth, 1998; Bayraktar et al., 2009; Zelbst et

al., 2010). In this study Bayesian network learning

algorithms was used. Because as stated by

Heckerman (1997), a Bayesian network is an efficient

way for learning causal relationships, and hence can

be used to gain deeper understanding about a problem

domain and to predict the consequences of

intervention, which is not available in other

approaches like SEM or PLS. Furthermore, a

Bayesian network model has both causal and

probabilistic semantics, which is an ideal

representation for combining prior knowledge and

data (Anderson and Vastag, 2001).

To build a Bayesian network the data needs to be

categorical. This way, the categorical measurements

for each concept can be obtained by applying k-

means cluster analysis (McColl-Kennedy and

Anderson, 2005).

In this study, Two-state categorization for the

constructs of SC enabler and SCM practices, and

three-state categorization for the constructs of SC

performance were applied. For Bayesian causal

modelling, TETRAD IV was used which is a package

that created by Spirtes et al., (1993) at Carnegie

Mellon University. This software offers a remarkable

graphical user interface and facilitates building,

evaluating, and searching for causal models

(Landsheer, 2010).

In causal modelling process, first the categorical

data was entered to TETRAD IV package. In next

step, by using its knowledge module, the order of

variables was specified. In Figure 4, SC enablers are

specified at first order and SCM practices at second

and SC performance measures at last. In addition, it

was specified that in each group of SC enablers and

SCM practices, no inter-relationships be allowed by

software, avoiding hyper-complex network.

4 RESULTS

Running the PC algorithm with prior knowledge, as

described in previous section, resulted in the model of

Integrating Fuzzy Cognitive Mapping and Bayesian Network Learning for Supply Chain Causal Modeling

65

Figure 4. The resulted model (Figure 4) has degree of

freedom of 148, chi-square of 545 and BIC of -238.

At the first glance, it can be seen that advanced

manufacturing technology such as SC enabler has

direct impact on SC performance (delivery

flexibility). In this model, delivery flexibility is

antecedent of production flexibility and customer

satisfaction. In addition, production flexibility is

antecedent of logistics performance. This research

suggests that the production flexibility must be

antecedent of delivery performance, so this relation in

resultant model was modified. The resultant model

(Figure 5) have degree of freedom of 148, chi-square

of 546 and BIC of -236 which are totally better than

previous model fit indices, verifying the

modifications.

4.1 Combining Causal Bayesian

Network with FCM Model

As described earlier, FCM methodology was used to

extract qualitative knowledge of SCM experts and

practitioners about study variables. Therefore it was

concluded that the resulted FCM model depicts the

strengths of causal relations of SCM constructs.

Additionally, a quantitative causal Bayesian network

model was built which is extracted from survey data

of current state of study variables. Furthermore, to

increase more internal validity, these models were

combined into an integrated model. This one is based

on two different methodologies with two different

types of input, one based on causal relations and the

other one based on current state of study variables.

Figure 4: Output of PC algorithm with prior knowledge.

Figure 5: Final Bayesian network model with modified arrows of SC performance indices.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

66

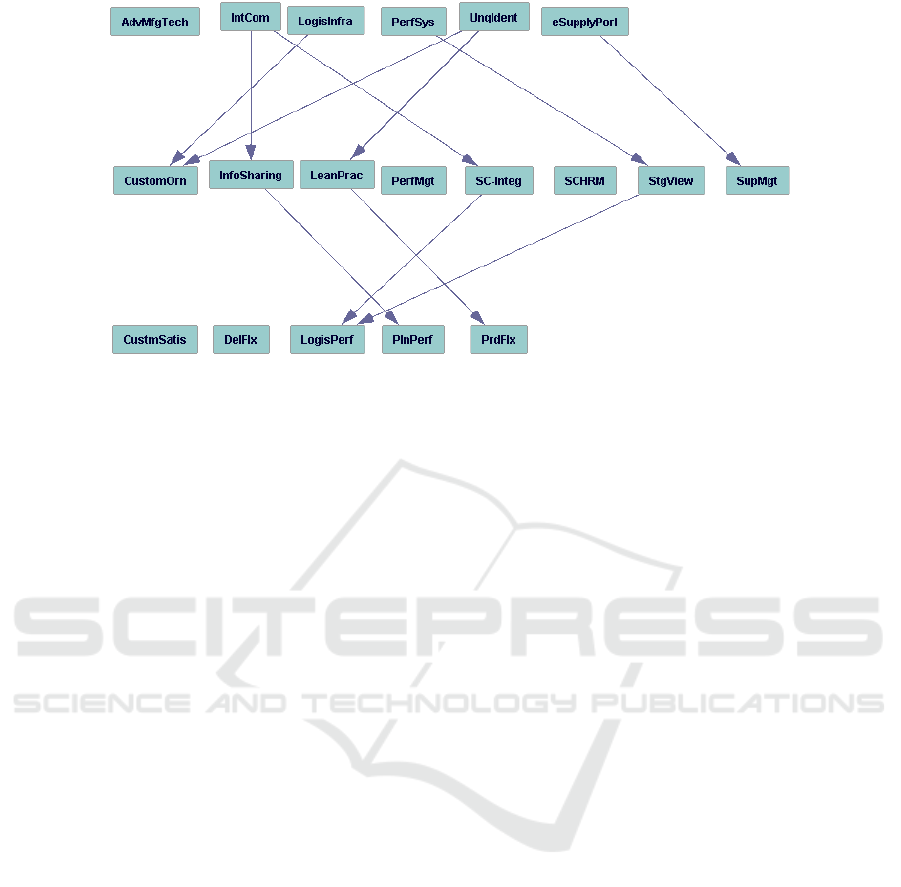

Figure 6: Final integrated causal model.

According to the integrated model, any causal

relations presented in both models were kept while

the others were dropped. The final model, depicted in

Figure 6, is the one which its causal relations are

based on both prescribed methodologies. This final

model has degree of freedom of 160, chi-square of

687 and BIC of -159 which is better than previous

ones from the point of view of BIC fit indexes.

Consequently, it can be claimed that this final model

has more internal validity than the two primary

models.

5 DISCUSSION AND

IMPLICATIONS

Our model contributes to the SCM body of

knowledge by modelling causal relations between SC

enablers, SCM practices, and SC performance. As a

general outcome, the findings of this study support

the notion that SC enablers, especially IT

technologies, don't have direct impact on SC

performance (Li et al., 2009; Zelbst et al., 2010). By

focusing on CBN model (Figure 6), it can be observed

that there may be some exceptions, like direct impact

of advanced manufacturing technologies on SC

delivery performance. However, this needs to be

more investigated. Specific findings and relevant

managerial implications of this research can be

summarized as follows:

The results provide evidence that inter-

organizational communication technologies have

direct impact on information sharing which is in line

with findings of Li and Lin (2006). Also, information

sharing has direct impact on supply chain planning.

Supply chain integration has direct impact on

logistics performance. So it can be suggested that the

impact of inter-organizational communication

technologies on planning performance in supply

chain is depending on level of the information

sharing. Also inter-organizational communication

technologies have causal impact on logistics

performance conditional on the level of supply chain

integration. In the case of unique identification

technologies, it can be seen that this enabler has

causal impact on production flexibility conditional on

the level of lean practices in supply chain. Based on

FCM model it is expected that strategic views have

more effect on SC performances but as a result of

CBN modelling we find out that this SCM practice

direct impact is just on logistics performance.

Although more causal relations in integrated

model are expected, it been observed that many of

extracted relations in FCM are not in the final

Bayesian network and vice versa, but not in the

integrated model. Specially, there is not any

antecedent for SC HRM and performance

management as SCM practice, and customer

satisfaction and delivery flexibility as SC

performance aspects. By comparing the final

Bayesian network model as depicted in Figure 5 and

integrated model of Figure 6, this study can suggest

some explanations that describe why many expected

causal links are absent in final model. First, in fuzzy

cognitive mapping stage of this study, the

questionnaire is limited to inter-relations between SC

enablers and SCM practices and also between SCM

practices and SC performance aspects but not any

intra-relations. As can be seen in Figure 6, intra-

relations in tier of SC performance criteria can reveal

some critical causal relations. In this figure, customer

satisfaction is under impact of delivery flexibility and

Integrating Fuzzy Cognitive Mapping and Bayesian Network Learning for Supply Chain Causal Modeling

67

production flexibility is antecedent of delivery

flexibility. These relations imply that in any tier of

supply chain concepts, there may be important intra-

relations which worth further studies and neglecting

them may blur final results. Second, direct relations

between SC enablers and SC performance aspects

were not considered. It has been witnessed that

advanced manufacturing technology may have direct

impact on delivery flexibility.

6 CONCLUSION AND

LIMITATIONS

This research studied a model of causal relations in

the context of supply chain management, by applying

two different methodologies of FCM and causal

Bayesian network modelling and combing resultant

models in an integrated one. Both models revealed

important causalities between study variables of

interest, and integrating them provide us more valid

causal relations.

This study has some limitations that are the

starting points for further research, regarding

methodologies and scopes. First, the sample

population was drawn from the members of the

IranCode

®

. Although this sample covered a wide

range of firms in terms of industry, size, and

geography, it cannot be claimed that the results of this

research can be generalized, especially because the

response rate was not high and this study was based

on a self-assessment of the single participants from

sample firms. So, further studies can be carried on for

narrower groups of industries with larger sample

sizes. Causal sufficiency is a determinant in

probabilistic causal modelling. Thus, it is needed to

identify any other contributing variable in a study of

causal relation of two variables. This motivates doing

a research of a SCM causal modelling with more

comprehensive list of SCM elements. Moreover, to

avoid burdening of experts, the FCM modelling was

restricted to causal relations between SC enablers and

SCM practices and also between SCM practices and

SC performance indicators. In CBN model, some

important intra-relations of SCM element's tier worth

further study. Particularly studying intra-relations

between SCM practices may reveal many interesting

results which contribute to better understand

dynamics of SCM practices. The set of SC

performance aspects were selected based on

reachable data and some indicators were eliminated

because of measurement model validity. Hereafter,

more definitive and comprehensive SC performance

measurement will contribute to attaining more valid

SCM causal models in future studies. The major

strength of Bayesian networks is that probabilistic

inference can be made directly from the conditional

probabilities (Blodgett and Anderson, 2000). Further

studies that consider these conditional probabilities of

CBN may consists of some valuable contributions to

more detailed understanding of causal relations in

SCM context.

Despite these limitations, this study has the

following contributions to the development of the

literature and practice. The first contribution of this

study is a comprehensive list of supply chain enablers

and supply chain management practices which is

useful for further studies in this area, and as

mentioned by Li et al., (2005), which were not

realized before. Second, an expert-based FCM with

fuzzy ranking methodology was created by using

possibility and necessity theory (Dubois and Prade,

1983) to transform fuzzy numbers to linguistic terms,

which is a new approach in this context. Third, a

causal Bayesian network model was created from

field data of Iranian industries and then using the

TETRAD IV tools, modified this model to reach

better fit indices, such an analytical modification

towards a better model to fit indices is a new approach

in methodology. Forth, a simple rule was used to

combine FCM and CBN models and extract an

integrated model which is a new effort in this context.

At last, with CBN analysis, it was found out that in

any tier of supply chain elements there are some intra-

relations that may have important impact on SCM

study and supply chain design and management.

REFERENCES

Anderson, R. D., and Vastag, G., 2004. Causal modeling

alternative in operations research: overview and

operation. European Journal of Operational Research,

156, 92-109.

Bagozzi, R. P., 2011. Measurement and Meaning in

Information Systems and Organizational Research:

Methodological and Philosophical Foundations. MIS

Quarterly, 35(2), 261-292.

Bagozzi, R. P., and Phillips, L., 1982. Representing and

testing organizational theories: a holistic construal.

Administrative Science Quarterly, 27, 459-489.

Bayraktar, E., Demirbag, M., Koh, S. L., Tatoglu, E., and

Zaim, H. , 2009. A causal analysis of the impact of

information systems and supply chain management

practices on operational performance: Evidence from

manufacturing SMEs in Turkey. Int. J.

ProductionEconomics, 122(1), 133-149.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

68

Beamon, B. M. , 1999. Measuring supply chain

performance. International Journal of Operations and

Production Management, 19(3), 275-292.

Bentler, P. M., and Chou, C.-P., 1987. Practical Issues in

Structural Modeling. Sociological Methods Research,

16(1), 78-117.

Bhagwat, R., and Sharma, M. K., 2007. Performance

measurement of supply chain management: A balanced

scorecard approach. Computers and Industrial

Engineering, 53(1), 43-62.

Blodgett, J. G., and Anderson, R. D., 2000. A Bayesian

network model of the consumer compliant process.

Journal of Service Research, 2(4), 321-338.

Boon-itt, S., and Himangshu, P., 2005. Measuring Supply

Chain Integration Using the Q-Sort Technique. In

Research Methodologies in Supply Chain Management

(pp. 47-58). Heidelberg: Physica-Verlag.

Chae, B., 2009. Developing key performance indicators for

supply chain: an industry perspective. Supply Chain

Management: An International Journal, 14(6), 422-

428.

Davis-Sramek, B., Germain, R., and Karthik, l., 2010.

Supply chain technology: the role of environment in

predicting performance. Journal of the Academy of

Marketing Science(38), 42-55.

Devaraj, S., Krajewski, L., and Wei, J. C., 2007. Impact of

eBusiness technologies on operational performance:

The role of production information integration in the

supply chain. Journal of Operations Management,

25(6), 1199-1216.

Dubois, D., and Prade, H., 1983. Ranking fuzzy numbers in

the seting of possibility theory. Information Sciences,

30(3), 183-224.

Fornell, C., and Larcker, D. F., 1981. Evaluating structural

equation models with unobservable variables and

measurement error. Journal of Marketing Research,

18(1), 39-50.

Frohlich, M. T., and Westbrook, R., 2001. Arcs of

integration: an international study of supply chain

strategies. Journal of Operations Management, 19(2),

185-200.

González-Benito, J., 2007. Information technology

investment and operational performance in purchasing

The mediating role of supply chain management

practices and strategic integration of purchasing.

Industrial Management and Data Systems, 107(2), 201-

228.

Hamister, J. W., 2012. Supply chain management practices

in small retailers. International Journal of Retail and

Distribution Management, 40(6), 427-450.

Heckerman, D., 1997. Bayasian networks for data mining.

Data Mining and Knowledge Discovery, 1(1), 79-119.

Hsu, C. C., Tan, K. C., Kannan, V. R., and Keong Leong,

G., 2009. Supply chain management practices as a

mediator of the relationship between operations

capability and firm performance. International Journal

of Production Research, 47(3), 835-855.

Hu, L.-t., and Bentler, P. M., 1999. Cutoff criteria for fit

indexes in covariance structure analysis: Conventional

criteria versus new alternatives. Structural Equation

Modeling: A Multidisciplinary Journal, 6(1), 1-55.

Ibrahim, S. E., and Ogunyemi, O., 2012. The effect of

linkages and information sharing on supply chain and

export performance: An empirical study of Egyptian

textile manufacturers. Journal of Manufacturing

Technology Management, 23(4), 441-463.

Johnson, P. F., Klassen, ,. R., Leenders, M. R., and

Awaysheh, A., 2007. Utilizing e-business technologies

in supply chains: The impact of firm characteristics and

teams. Journal of Operations Management, 25(6),

1255-1274.

Kim, D.-Y., Kumar, V., and Kumar, U., 2012. Relationship

between quality management practices and innovation.

Journal of Operations Management, 30(4), 295–315.

King, G., Honaker, J., Joseph, A., and Scheve, K., 2001.

Analyzing Incomplete Political Science Data: An

Alternative Algorithm for Multiple Imputation.

American Political Science Review, 95(1), 49-69.

Kosko, B., 1986. Fuzzy cognitive maps. International

Journal of Man-Machine Studies, 24(1), 65-75.

Landsheer, J. L., 2010. The Specification of Causal Models

with Tetrad IV: A Review. Structural Equation

Modeling: A Multidisciplinary Journal, 17(4), 703-711.

Lee, C. W., Kwon, I.-W. G., and Severance, D., 2007.

Relationship between supply chain performance and

degree of linkage among supplier, internal integration,

and customer. Supply Chain Management: An

International Journal, 12(6), 444-452.

Li, G., Yang, H., Sun, L., and Sohal, A. S. , 2009. The

impact of IT implementation on supply chain

integration and performance. Intnational Journal of

Production Economics, 120(1), 125-138.

Li, S., Rao, S. S., Ragu-Nathan, T. S., and Ragu-Nathan, B.,

2005. Development and validation of a measurement

instrument for studying supply chain management

practices. Journal of Operations Management, 23, 618-

641.

Lockamy III, A., and McCormack, K., 2004. Linking

SCOR planning practices to supply chain performance:

An exploratory study. International Journal of

Operations and Production Management, 24(12),

1192-1218.

MacKenzie, S. B., and Podsakoff, P. M., 2011. Construct

measurement and validation procedures in mis and

behavioral research: integrating new and existing

techniques. MIS Quarterly, 35(2), 293-334.

McColl-Kennedy, J. R., and Anderson, R. D., 2005.

Subordinate-manager gender combination and

perceived leadership style influence on emotions, self-

esteem and organizational commitment. Journal of

Business Research, 58, 115-125.

Menhaj, M. B., 2006. Fuzzy computations. Tehran, Iran:

Amirkabir University of Technology.

Narasimhan, R., and Jayanth, J., 1998. Causal Linkages in

Supply Chain Management: An Exploratory Study of

North American Manufacturing Firms. Decision

Sciences, 29(3), 579-605.

Integrating Fuzzy Cognitive Mapping and Bayesian Network Learning for Supply Chain Causal Modeling

69

O'Leary-Kelly, S. W., and Vokurka, R. J., 1998. The

empirical assessment of construct validity. Journal of

Operations Management, 16, 387-405.

Ou, C. S., Liu, F. C., Hung, Y. C., and Yen, D. C., 2010. A

structural model of supply chain management on firm

performance. International Journal of Operations and

Production Management, 30(5), 526-545.

Qrunfleh, S., and Tarafdar, M., 2015. Supply chain

management practices–IT utilization alignment: impact

on supply chain performance and firm

performance. International Journal of Business

Information Systems 5, 18(4), 364-389.

Sanders, N. R., 2007. An empirical study of the impact of

e-business technologies on organizational collaboration

and performance. Journal of Operations Management,

25 (6), 1332-1347.

Schumacker, R. E., and Lomax, R. G., 2004. A beginner's

guide to structural equation modeling (2nd ed.).

Mahwah: Lawrence Erlbaum Associates.

Sezen, B., 2008. Relative effects of design, integration and

information sharing on supply chain performance.

Supply Chain Management: An International Journal,

13(3), 233-240.

Shepherd, C., and Günter, H., 2006. Measuring supply

chain performance: current research and future

directions. International Journal of Productivity and

Performance Management, 55(3), 242-258.

Shin, H., Collier, D. A., and Wilsom, D. D., 2000. Supply

management orientation and supplier/buyer

performance. Journal of Operations Management, 18,

317-333.

Shiu, E., Pervan, S. J., Bove, L. L., and Beatty, S. E., 2011.

Reflections on discriminant validity: Reexamining the

Bove et al. (2009) findings. Journal of Business

Research, 64, 497-500.

Stach, W., Kurgan, L., and Pedrycz, W., 2010. Expert-

Based and Computational Methods for Developing

Fuzzy Cognitive Maps. In M. Glykas (Ed.), Fuzzy

Cognitive Maps Advances in Theory, Methodologies,

Tools and Applications (Vol. 247, pp. 23-41). Berlin

Heidelberg: Springer-Verlag.

Sundram, V. P., Ibrahim, A. R., and Govindaraju, V. C.,

2011. Supply chain management practices in the

electronics industry in Malaysia: Consequences for

supply chain performance. Benchmarking: An

International Journal, 18(6), 834-855.

Tan, K. C., Lyman, S. B., and Winser, J. D., 2002. Supply

chain management: a strategic perspective.

international journal of operations and productions

management, 22(6), 614-631.

Tatoglu, E., Bayraktar, E., Golgeci, I., Koh, S. L.,

Demirbag, M., and Zaim, S., 2016. How do supply

chain management and information systems practices

influence operational performance? Evidence from

emerging country SMEs. International Journal of

Logistics Research and Applications, 19(3), 181-199.

Zelbst, P. J., Green Jr, K. W., Swer, V. E., and Baker, G.,

2010. RFID utilization and information sharing: the

impact on supply chain performance. Journal of

Business and Industrial Marketing, 25(8), 582-589.

Zhou, H., and Benton Jr., W. C., 2007. Supply chain

practice and information sharing. Journal of Operations

Management, 25, 1348-1365.

Zhu, B., He, C., and Liatsis, P., 2012. A robust missing

value imputation method for noisy data. Applied

Intelligence, 36(1), 61-74.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

70