Titanium Dioxide based Electrochromic Iris

Preparation, Characterization and Application

C. Kortz, A. Hein and E. Oesterschulze

Physics and Technology of Nanostructures, University of Kaiserslautern, Erwin-Schroedinger-Strasse 46,

67663 Kaiserslautern, Germany

Keywords:

Miniaturized Iris, Electrochromism, Viologen, Titanium Dioxide.

Abstract:

The miniaturization of a classical iris consisting of blades which are moved towards the path of light is limited,

due to the size of the actuators and the additional space needed for blade storage when the iris is completely

open. To overcome these limitations we present a fast switching, non-mechanical micro iris based on elec-

trochromic molecules, namely viologens, which are adsorbed onto a titanium dioxide nanoporous electrode.

Measurements of the energy consumption, the response time and the spectral light transmission are presented.

The complete fabrication route and the life time of the device are discussed in detail.

1 INTRODUCTION

The realization of a miniaturized iris comes to interest

since more and more commercially available hand-

held electronics were equipped with integrated cam-

eras. Due to the small size of these cameras a classical

blade iris cannot be integrated. An active iris is indis-

pensable for both the intensity and in particular the

depth of focus control.

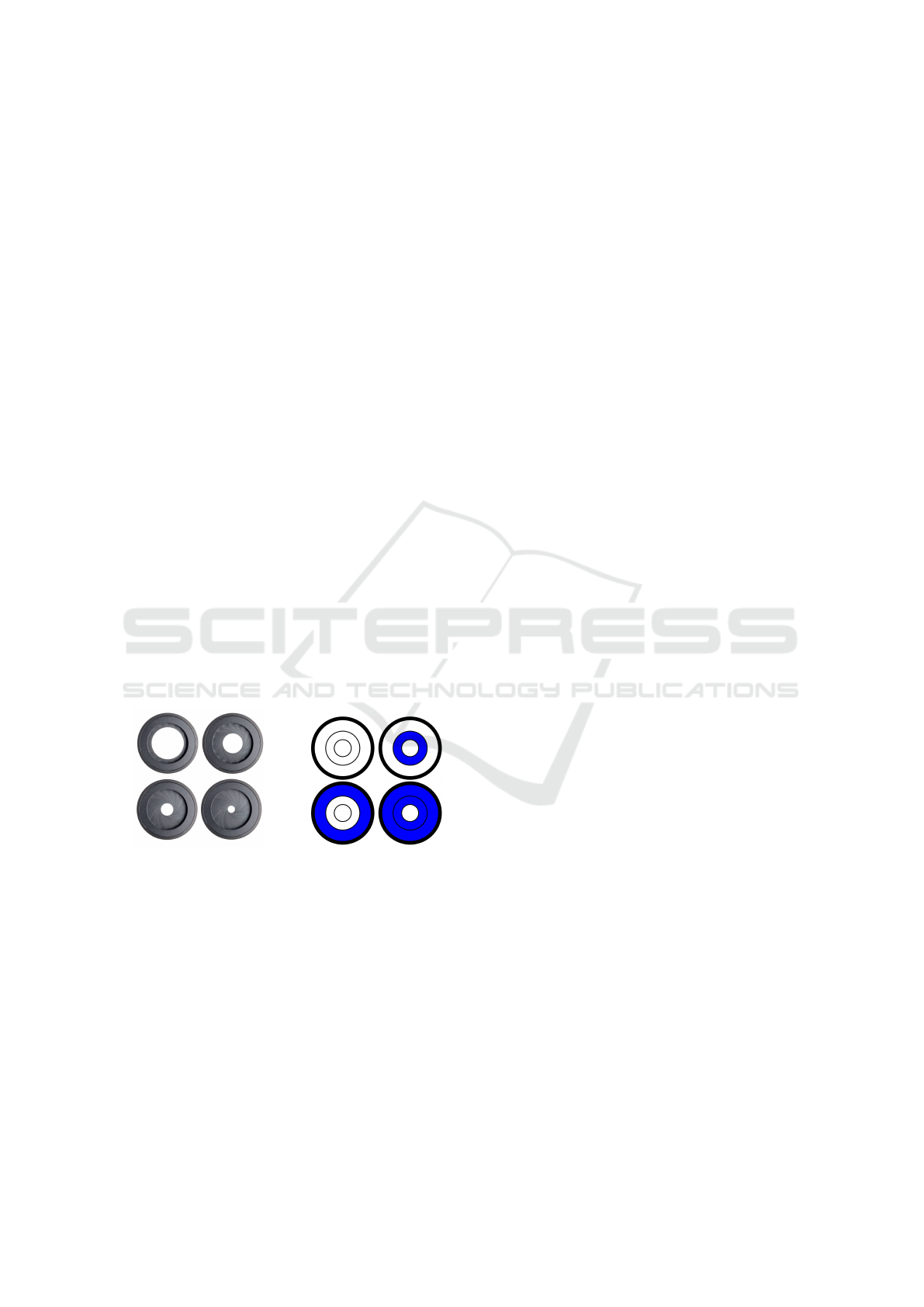

a) b)

Figure 1: a) Images of a classical iris. In the upper left

corner the iris is completely open and only the blade storage

is left to be seen. This extra space is too big for micro iris

applications for integrated camera systems. b) A schematic

view of an electrochromic iris: the device can be switched

completely transparent, only a small area around the iris is

needed for sealing. This device can be miniaturized to fit

the conditions in integrated optics.

The major reason why there is no iris integrated

in small cameras is the required space. Especially

when the iris is completely open the blades have to be

moved outside the path of light and have to be stored

in an additional ring shaped space (see Fig. 1a)),

which is not available in micro optical devices.

Different solutions were presented to build up

miniaturised iris devices based on microelectrome-

chanical systems (MEMS), liquid displacement tech-

niques and electrochromic devices (Syms et al., 2004)

(Kimmle et al., 2011) (Deutschmann et al., 2015).

MEMS based iris devices have a similar working

principle as a classical blade iris (Yu et al., 2012). A

shutter is moved towards the path of light to realize

the iris function. The advantage of MEMS based de-

vices is the fast switching time. They can be miniatur-

ized easily but the dimensions of the device are much

larger than the path of light and high voltages of more

than 80 V are needed to move the blades. So they do

not fit the conditions for integrated optics in battery

powered hand-held electronics.

Another approach is to move light absorbing liq-

uids, like oil or ink into the path of light to create an

iris (Kimmle et al., 2011). The advantage is that in

this case the storage does not have to be ring shaped

around the optical path, but can be designed freely.

Nevertheless an additional space and actuators have

to be provided (M

¨

uller et al., 2012).

2 STATE OF THE ART

One approach to create a non-mechanical iris was us-

ing electrochromic molecules which change their ab-

sorption by applying a chemical potential (Roth et al.,

2011). Multiple designs and molecules were tested

(Deutschmann and Oesterschulze, 2014). The latest

iris was based on two complementary electrochromic

molecules, which were dissolved in the electrolyte en-

capsulated between two transparent conducting ox-

50

Kortz, C., Hein, A. and Oesterschulze, E.

Titanium Dioxide based Electrochromic Iris - Preparation, Characterization and Application.

DOI: 10.5220/0006552200500054

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 50-54

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

ide (TCO) coated glass sheets used as electrodes

(Deutschmann et al., 2015). If a voltage is applied

between these two electrodes the liquid turned from

transparent to almost black. This coloring process is

reversible, without any need for storage space. To

create the iris, the TCO layers were structured by

UV lithography. The dissolved electrochromophores

were only colored if the potential was applied at the

desired rings which form the iris shape (see Fig. 1b)).

A diffusional blurring of the iris structure was ob-

served which slightly influenced the iris function

(P

¨

atz et al., 2014).

The optical properties and the space and power

requirements of this non-mechanical iris were satis-

factory for integrated optics. But this design suffered

from long response times. Especially, the bleaching

took at least 20 s and longer. However, for consumer

electronics response times in a sub-second range are

required.

3 EXPERIMENTAL PROCEDURE

A transparent electrochromic iris device is realized

using two TCO coated glass substrates. These glasses

were cleaned in an ultrasonic bath using acetone, iso-

propanol and DI water for 5 min each and dried un-

der nitrogen flux. Alignment marks and contact pads

made of 10 nm Cr and 90 nm Au were added to the

TCO layer using magnetron sputtering and lift-off-

technique. In the next step, a paste containing tita-

nium dioxide (TiO

2

) nanoparticles with a diameter of

10-15 nm (Solaronix Ti-Nanoxide T/SP) was applied

by doctor-blading technique. To get the final porous

structure, the samples had to be heated up to 450

◦

C

on a hot plate and subsequently to 550

◦

C with a ramp

of 10

◦

C/min in a vacuum furnace. This temperature

was held for 2 h and the samples were cooled natu-

rally. The shape of the iris was created by laser struc-

turing. With this procedure the TiO

2

and the TCO

layers were structured in the same step. After this

preparation of the working electrode it was immersed

in a solution containing the viologen and kept there

for several hours.

The viologen we used in our experiments had a

phosphonate anchor group to ensure a surface occu-

pancy on the TiO

2

nanoporous layer, as seen in Fig. 2.

After the fictionalization was completed, the samples

were rinsed in ethanol and dried under nitrogen flux.

To build up a working device a second TCO coated

glass was bonded to the working electrode using a

UV-structurable spacer (Ordyl, Elga Europe). The

later carrying the cavity for the electrolyte. This cav-

ity could be filled and sealed hermetically to prevent

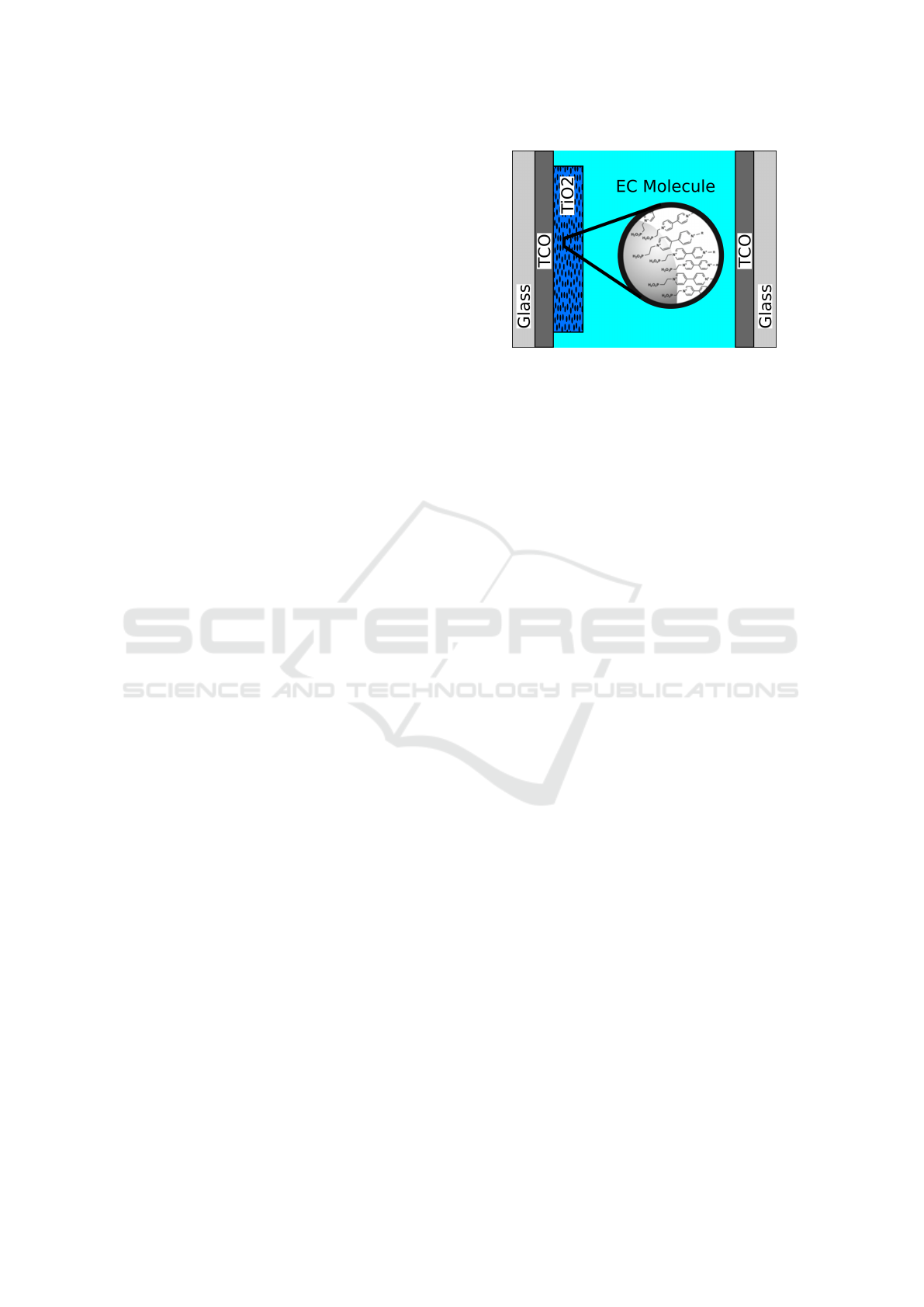

Figure 2: Schematic illustration of the electrochemical cell

device: the working electrode with nanoporous TiO

2

and

attached viologen on the left and the counter electrode on

the right side. The electrolyte in between provides charge

exchange among the electrodes.

oxygen and moisture infiltration.

Our goal is to realize an iris that fits all restric-

tions of miniaturized integrated camera systems for

consumer applications, which are:

• low space requirements;

• low power consumption;

• fast switching;

• high contrast;

• long lifetime.

These challenging restrictions are the major reasons

why integrated cameras are not equipped with an iris

yet.

4 RESULTS AND DISCUSSION

Each of the following sections addresses one of the

mentioned challenges. The newly developed solu-

tions, achievements and the current state of the re-

search are discussed in detail.

4.1 Structuring

The structuring of TiO

2

based electrochromic devices

is challenging, because the preferred UV lithography

techniques fail due to side reactions between the pho-

toresist and the TiO

2

nanoparticles during exposure.

For our device we chose to transfer the iris structure

into the nanoparticle layer by laser ablation (Roth,

2013).

With this method, the nanoparticle layer and the

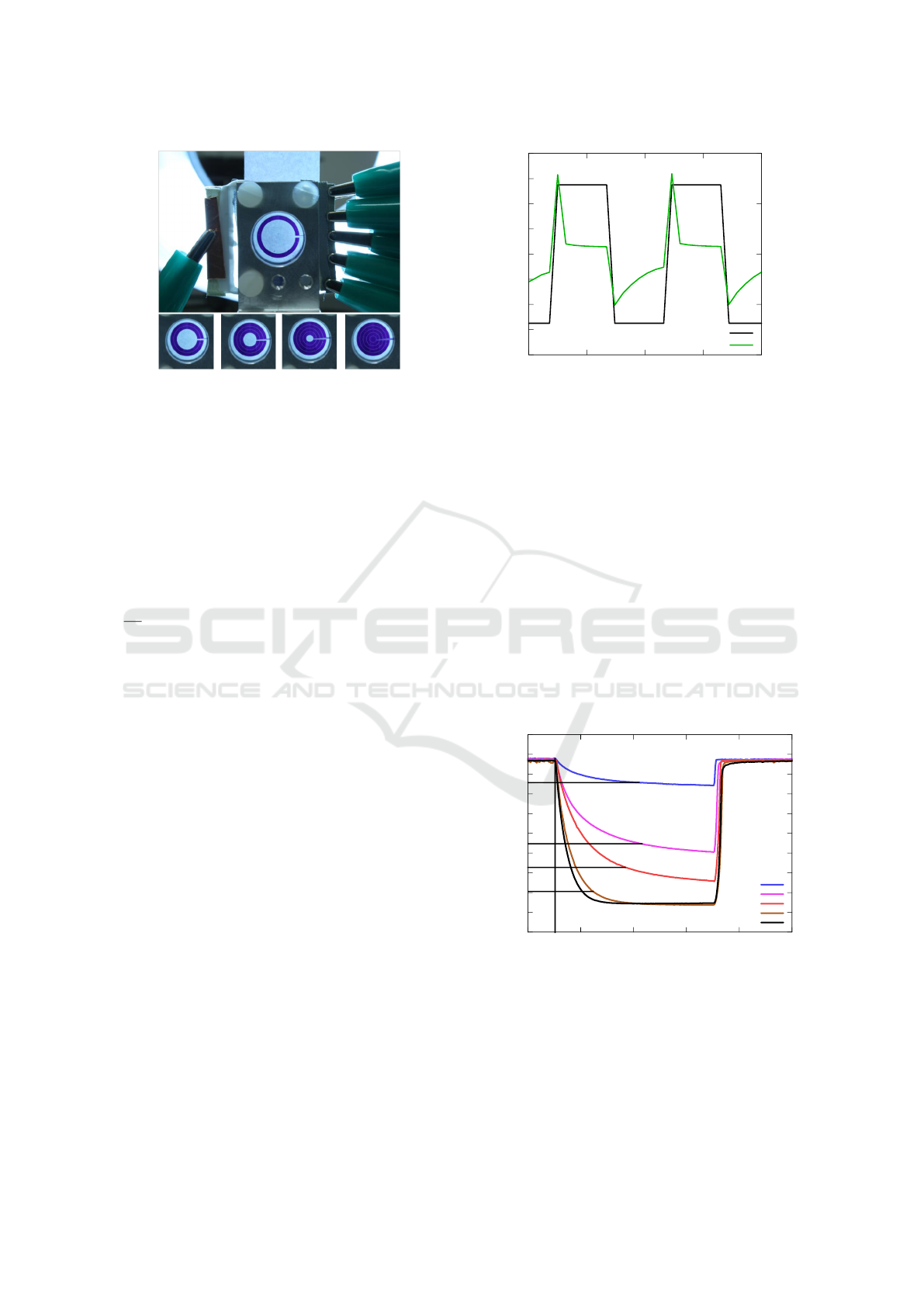

TCO layer were structured simultaneously. As seen

in Fig. 3 the different iris rings are separated clearly

Titanium Dioxide based Electrochromic Iris - Preparation, Characterization and Application

51

Figure 3: Images of a TiO

2

based iris in different switching

states (Roth, 2013).

from each other revealing a sharp edge. The conduc-

tor track to the contact pads on the right side interrupts

the outer rings.

4.2 Electrical Requirements

The electrical response was investigated operating the

working electrode in a cuvette using a commercially

available Ag/AgCl reference electrode and a Pt wire

as counter electrode. The electrolyte consisted of

1

mol

l

LiClO

4

salt solved in propylene carbonate. To

secure that no oxygen affects the measurement, the

electrolyte was bubbled for at least 15 min with nitro-

gen before use. The electric potential was applied and

the current was measured by a potentiostat (Refer-

ence600, Gamry Instruments). The potential between

the working electrode and the electrolyte leads to a

change in the redox state of the viologen. When a

negative potential is applied, the viologen molecules

are reduced and they change their color from trans-

parent to absorbing, resulting in a negative current.

Reversing the potential leads to the oxidation of the

viologen and they turn transparent again, resulting in

a positive current. This process is fast and reversible.

To keep the redox state no further current is needed; a

phenomenon that is called memory effect.

One of the restrictions for miniaturized iris de-

vices is low power consumption. As seen in Fig. 4

the maximum current needed to change the color of

the device was approximately 0.8 mA at a potential

of 0.55 V. This leads to a total maximum power of

0.44 mW, which can easily be provided by battery

power. As can be seen in Fig. 4 the current drops

rapidly after reaching its maximum value.

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

0 5 10 15 20

-1

-0.5

0

0.5

1

voltage [V]

current [mA]

time [s]

voltage against Ag/AgCl

current

Figure 4: Electrical response of the electrochromic working

electrode. A step potential was applied against a Ag/AgCl

reference electrode and the current was measured.

4.3 Electro-Chromophoric Response

The electro-chromophoric response was also mea-

sured in the previously described setup using a

Ag/AgCl reference electrode and a Pt counter elec-

trode in the same electrolyte. To observe the col-

oration, a homogeneous filter with an unstructured

working electrode was investigated. This filter was

illuminated by a white light source (KL 1500 LCD,

Schott) and the transmitted light was analyzed us-

ing an integrating sphere and a spectrometer (Flame,

Ocean Optics). To characterize the performance of

our device, the transmitted intensity was integrated

from 450 nm to 750 nm and recorded time-resolved.

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50

transmission [%]

time [s]

-0.3 V

-0.35 V

-0.4 V

-0.5 V

-0.55 V

Figure 5: Time-resolved transmission through a homoge-

neous electro-chromic filter operated at different potentials.

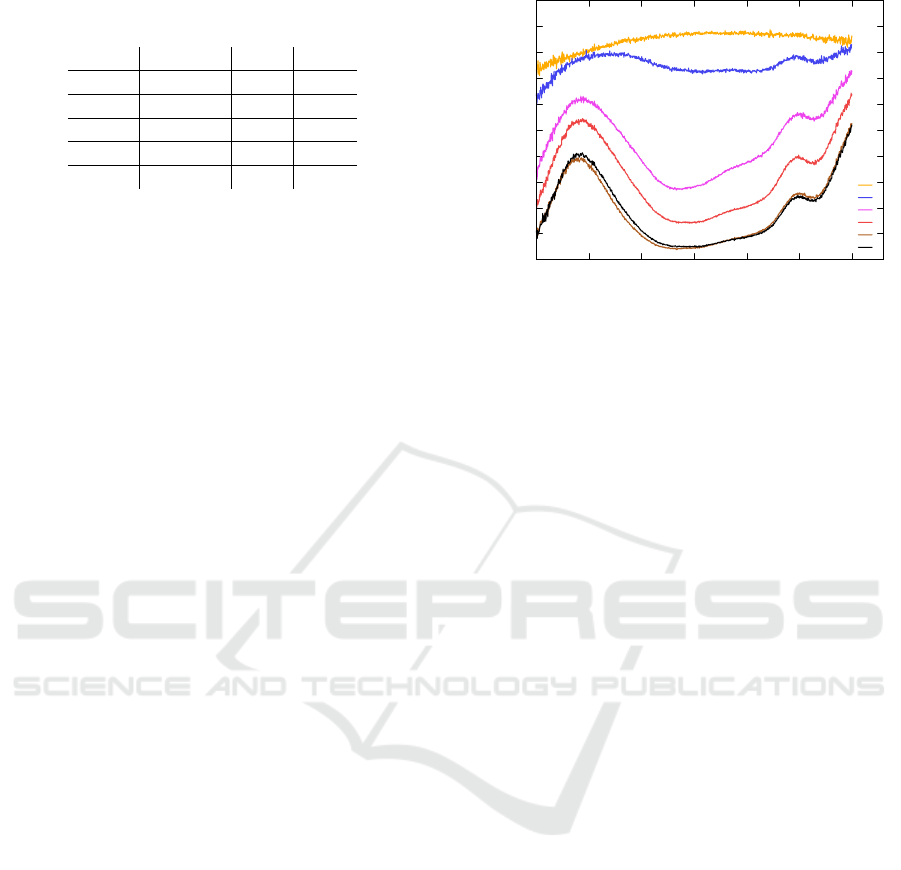

Figure 5 shows the integrated intensity, where

100% stands for the light transmitted through the

measurement setup without the working electrode.

The maximum transmission through the working

electrode was 88% in the transparent state. The min-

imum transmission T

min

was 14% in the opaque state

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

52

Table 1: Results taken from Fig. 5: minimum transmission

and response time at different applied potentials.

U [V] T

min

[%] t

c

[s] t

b

[s]

-0.3 73.8 16.0 0.2

-0.35 40.5 15.7 0.8

-0.4 25.5 13.4 1.2

-0.5 13.3 7.2 1.6

-0.55 13.7 5.2 1.5

at a potential of -0.55 V.

The response time was defined as the time where

90% of the equilibrium transmission is reached, indi-

cated by the horizontal lines in Fig. 5. We observed

a response time for coloration of t

c

= 5.0 s and for

bleaching of t

b

= 1.5 s when applying a potential of

±0.55 V.

The equilibrium transmission in the opaque state

can be controlled by the thickness of the TiO

2

layer,

the species and amount of EC-molecules adsorbed

onto the TiO

2

surface and the applied voltage. The

different T

min

responding to different applied poten-

tials are shown in Fig. 5, too. It is obvious that the

time for coloration is larger for low potentials al-

though the change in transmission is also low. The

resulting t

b

values do not strongly vary. The results

are summarized in Tab. 1.

The main reason why we do not reach 0% in

the colored state is the spectral characteristic of the

used viologen molecule. As can be seen in Fig. 6

the absorption deviates from the neutral behavior at

the wavelengths range from 450 nm to 750 nm. Es-

pecially around 500 nm and 750 nm large transmis-

sion in the colored state can be observed which is

characteristic for viologen molecules. This can af-

fect the function of the iris, especially the depth of

focus control, which was discussed in detail in (P

¨

atz

et al., 2014). The depth of focus differs compared to

a classical iris depending on the transmission through

the opaque region. Thus an effective aperture diame-

ter has to be defined to achieve comparable depth of

focus results.

In the transparent state we see a high transmission

which is constant over a large spectral range but drops

at 500 nm and shorter wavelengths. This behavior can

be explained by the absorption of the TCO, TiO

2

and

the viologen in its transparent state.

4.4 Hermetic Sealing

The device consists of two TCO coated glass sheets

with the mesoporous structure carrying the viologen

and the electrolyte in between. It was critical for the

electrolyte to be sealed leak proof and bubble free in

0

10

20

30

40

50

60

70

80

90

100

450 500 550 600 650 700 750

transmission [%]

wavelength [nm]

0 V

-0,3 V

-0,35 V

-0,4 V

-0,5 V

-0,55 V

Figure 6: Spectral transmission through a homogeneous vi-

ologen functionalized TiO

2

layer on a TCO substrate at dif-

ferent potentials.

the cavity between the glass sheets. But not only the

loss of the electrolyte destroys the function of the de-

vice, the penetration of oxygen and water affects the

switching, too. So even without a leakage, the func-

tionality of the device was reduced after days when

a non-hermetic sealant was used. So we included an

oxygen proof sealing made of UV curing adhesive.

This raised the durability of our cell from days to

months in first tests. Further investigations have to

be made in this field of interest to realize a durable

electrochromic device with the smallest possible di-

mensions.

5 CONCLUSION

A new approach to realize a non-mechanical miniatur-

ized iris based on viologen adsorbed onto nanoporous

TiO

2

was presented. The laser structuring of the

nanoporous TiO

2

layer showed satisfactory results

and the power consumption of the electrochromic

layer was suitable for battery powered devices. The

minimum transmission in the colored state reached

14% and could be varied by the applied potentials

which led to different response times of the elec-

trochromic layer. For long live stability a hermetical

sealing was used to ensure an oxygen and moisture

free electrolyte. This was realized by UV curing ad-

hesives.

ACKNOWLEDGEMENTS

We thank the German national research foundation

(DFG) for their financial support (project OE220/12-

2). We also acknowledge the nano structuring center

Titanium Dioxide based Electrochromic Iris - Preparation, Characterization and Application

53

(NSC) Kaiserslautern for their technical support and

Prof. Walder and Dr. Ciobanu for their assistance

and supply with the electrochromic molecules and the

electrolyte.

REFERENCES

Deutschmann, T., Kortz, C., Walder, L., and Oesterschulze,

E. (2015). High contrast electrochromic iris. Opt.

Express, 23(24):31544–31549.

Deutschmann, T. and Oesterschulze, E. (2014). Integrated

electrochromic iris device for low power and space-

limited applications. Journal of Optics, 16.

Kimmle, C., Schmittat, U., Doering, C., and Fouckhardt, H.

A. A. (2011). Compact dynamic microfluidic iris for

active optics. Microelectronic Engineering, 88:1772–

1774.

M

¨

uller, P., Feuerstein, R., and Zappe, H. A. (2012). In-

tegrated optofluidic iris. Journal of Microelectrome-

chanical Systems, 21:1156–1164.

P

¨

atz, D., Deutschmann, T., Oesterschulze, E., and

Sinzinger, S. (2014). Depth of focus analysis of opti-

cal systems using tunable aperture stops with a mod-

erate level of absorption. Applied optics.

Roth, S. (2013). Elektrochrome Absorber f

¨

ur die spektral-

laterale Filterung in der Mikrooptik. PhD thesis, Uni-

versity of Kaiserslautern.

Roth, S., Ignatowitz, M., M

¨

uller, P., M

¨

onch, W., and Oester-

schulze, E. (2011). Non-mechanical variable aper-

tures based on poly(3,4-ethylenedioxythiophene) (pe-

dot). Microelectronic Engineering, 88:2349–2351.

Syms, R. R. A., Zou, H., Stagg, J., and Veladi, H. (2004).

Sliding-blade mems iris and variable optical attenua-

tor. Journal of Micromechanics and Microengineer-

ing, 14(12):1700.

Yu, H., Guangya, Z., Du, Y., Mu, X., and Chau, F. S. A.

(2012). Mems-based tunable iris diaphragm. Journal

of microelectromechanical systems, 21:1136–1145.

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

54