Foot Plantar Pressure Monitoring with CYTOP Bragg Gratings

Sensing System

Débora Vilarinho

1

, Antreas Theodosiou

2

, Maria F. Domingues

1,3

,

Paulo Antunes

1,3

,

Kyriacos Kalli

2

,

Paulo André

4

and Carlos A. F. Marques

1,3

1

Physics & I3N, University of Aveiro, Campus Universitário de Santiago, 3810-193 Aveiro, Portugal

2

Cyprus University of Technology, Nanophotonics Research Laboratory, Limassol, 3036, Cyprus

3

Instituto de Telecomunicações, Campus Universitário de Santiago, 3810-193 Aveiro, Portugal

4

Instituto de Telecomunicações and Department of Electrical and Computer Engineering, Instituto Superior Técnico,

Technical University of Lisbon, 1049-001 Lisbon, Portugal

Keywords: Gait Plantar Pressure, Physical Rehabilitation, Polymer Optical Fiber Sensors, Bragg Gratings, CYTOP.

Abstract: In this paper, a polymer optical fiber (POF) sensing solution to monitor the pressure induced in the foot plantar

surface is investigated. The paper shows the design and implementation of a platform with an array of 5

polymer optical fiber Bragg gratings (POFBGs) placed in key points to monitor the pressure on the foot

surface during gait cycles and the body center mass displacements. The results showed a great response

compared with solutions using silica optical fibers. A much high sensitivity and repeatability were achieved

using the CYTOP fiber as well as proving that the advantages of POF is a viable and useful solution for this

type of application for a future implementation of an integrated “in-shoe” CYTOP POFBGs sensor network.

1 INTRODUCTION

Polymer optical fiber (POF) sensors received high

attention recently due to their unique properties

compared to the conventional silica optical fiber

(SOF) sensors (Webb, 2015). Advantages such as

higher flexibility in bending, biocompatibility

(Bischoff, 1972), higher failure strain (Large et al.,

2009), higher fracture toughness, and lower

production cost, are significant for many sensing

applications. The lower Young’s modulus of POF

(Griffiths, 1948) provides enhanced sensitivity to

POF sensors when are used for strain, stress and

force, pressure, and acoustic wave detection. The

material properties of polymers can be chemically

modified by adding other organic compounds to

achieve specific desirable characteristics. An

example is the perfluorinated POF, commercially

known as CYTOP, which the carbon-hydrogen bonds

have been replaced with carbon-fluorine bonds to

reduce the fiber attenuation (Ando et al., 1994).

There is an innumerable of applications where POF

technology is used (Marques et al., 2017).

On the other hand, the development of efficient

solutions for healthcare sensor applications

(regarding size, weight and energy consumption) is

an important research focus given the rapid

technological advances in healthcare monitoring

equipment, microfabrication processes and wireless

communication (Razak et al., 2012). In that way, the

analysis of foot plantar pressure has been investigated

by researchers on biomedical applications (Tao et al.,

2012; Postolache et al., 2015). For monitoring

activities of daily life, an in-shoe foot plantar

wearable monitoring system must be efficient,

flexible, mobile and low cost. Some of the smart

insole implementation based on piezo resistive

sensors and wireless data communication modules for

walking gait rehabilitation monitoring are reported in

(Postolache et al., 2015; Vito et al., 2014). The

important features often reported for this kind of

solutions are their high resolution data acquisition,

free, robust of wireless communication, real time

processing and with low power consumption

(Postolache et al., 2015). However, electronic devices

present some drawbacks, including fragility, long

term instability, inconsistency and excessive drift.

Additionally, their output is restricted to a small

sensing area requiring the use of more sensors to

monitor larger areas (Roriz et al., 2014).

The plantar pressure distribution on the foot

plantar surface is a reliable and important indicator

with regards to foot health condition and gait pattern,

from which, information like the wellbeing of the

Vilarinho, D., Theodosiou, A., Domingues, M., Antunes, P., Kalli, K., André, P. and Marques, C.

Foot Plantar Pressure Monitoring with CYTOP Bragg Gratings Sensing System.

DOI: 10.5220/0006533700250029

In Proceedings of the 11th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2018) - Volume 1: BIODEVICES, pages 25-29

ISBN: 978-989-758-277-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

25

spinal cord or regarding the foot ulcerations evolution

(in case of patients with diabetes) can be inferred. In

the particular case of diabetes, the patients tend to

develop foot ulcerations, which can be detected by

high/abnormal forefoot plantar pressure (Morag and

Cavanagh, 1999). By mapping the ground reaction

forces or pressures during gait it is possible to

understand the effect induced in the body (Razak et

al., 2012).

Many works have been published to explore the

plantar pressure distribution but have rarely

addressed the application of fiber Bragg gratings

(FBGs) on plantar pressure measurement. Also,

optical fiber sensing technology has already been

used to monitor static plantar pressure values (Hao et

al., 2003; Liang et al., 2016; Suresh et a.l, 2015).

Nevertheless, till the date, just one reports on

dynamic continuous measurements during gait were

presented using silica optical fiber technology

(Domingues et al., 2017).

In this paper, we propose a fiber-optic sensors

network based on CYTOP POFBGs to monitor the

plantar pressure. It has the advantages of a simple

architecture (only using five sensing elements),

relative low cost, temperature insensitivity high

stability and sensitivity. Moreover, using polymer

fiber technology, it also provides the necessary

resistance to be damaged or broken the system during

the gait movement as can easily happen using silica

optical fiber. It can be used in the measurement of

human plantar pressure distribution to monitor and

understand whether the foot posture needs to be

corrected or not.

2 INSOLE DEVELOPMENT AND

RESULTS

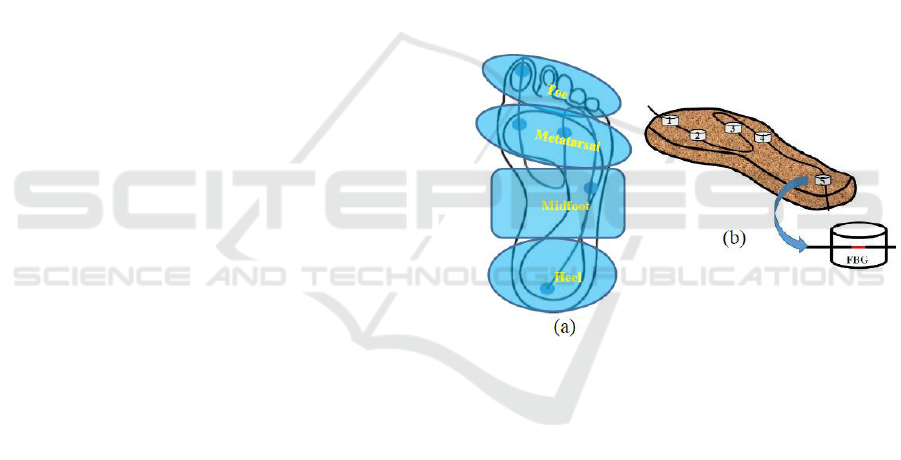

The optical platform is composed of a cork sole, with

1.0 cm thickness, in which POFBG sensors will be

incorporated in critical points of analysis (heel,

midfoot, metatarsal and toe areas, Fig. 1 (a)) to

monitor the plantar pressure (Wearing et al., 1999), as

shown in Fig. 1 (b). The cork sole was then designed

and machined in order to incorporate the network of

5 FBG sensors, which were distributed in the key

points for the plantar pressure analysis (heel, midfoot,

metatarsal and toe areas) (Razak et al., 2012; Tao et

al., 2012), as shown in Fig. 1. The material chosen to

embed the sensors was the cork due to its excellent

properties for this application, namely thermal

isolation, malleability and a near zero Poisson ratio

(Silva et al., 2005).

5 FBGs were inscribed and multiplexed into a

CYTOP polymer optical fiber cable (Thorlabs, 2017)

using point-by-point technique (Theodosiou et al,

2016). In this case, we obtained 4th order gratings

from 600 periods making a total FBG length of 1.2

mm. The FBG´s wavelengths range was from 1530 to

1570 nm according with our interrogation system.

Considering the load pressure applied in the gait

movement, the FBGs were encapsulated in epoxy

resin (Liquid Lens

TM

) cylinders structures (1.0 cm

diameter and 0.5 cm height). Each sensing element

consists of such cylindrical epoxy structure with the

FBG at the middle position.

To compensate any temperature change, an FBG

temperature sensor (Yuan et al., 2012) was

incorporated in the insole, in order to guarantee that

the thermal isolation provided by the cork is

effectively obtained and the FBG plantar pressure

sensors are not affected by the body temperature, or

any external temperature changes.

Figure 1: Schematic representation of: (a) the foot plantar

main areas; (b) physical distance between FBGs in the

CYTOP fiber and the sensors network implemented for the

insole.

For the calibration and plantar pressure

monitoring, the FBG sensing network was connected

to a portable interrogation system constituted of a

miniaturized broadband optical ASE module (B&A

Technology Co., As4500), an optical circulator

(Thorlabs, 6015-3) and an optical spectrometer

(Ibsen, I-MON 512E-USB). The latter operates at a

maximum rate of 960 Hz, with a wavelength

resolution of 5 pm, responsible for the acquisition of

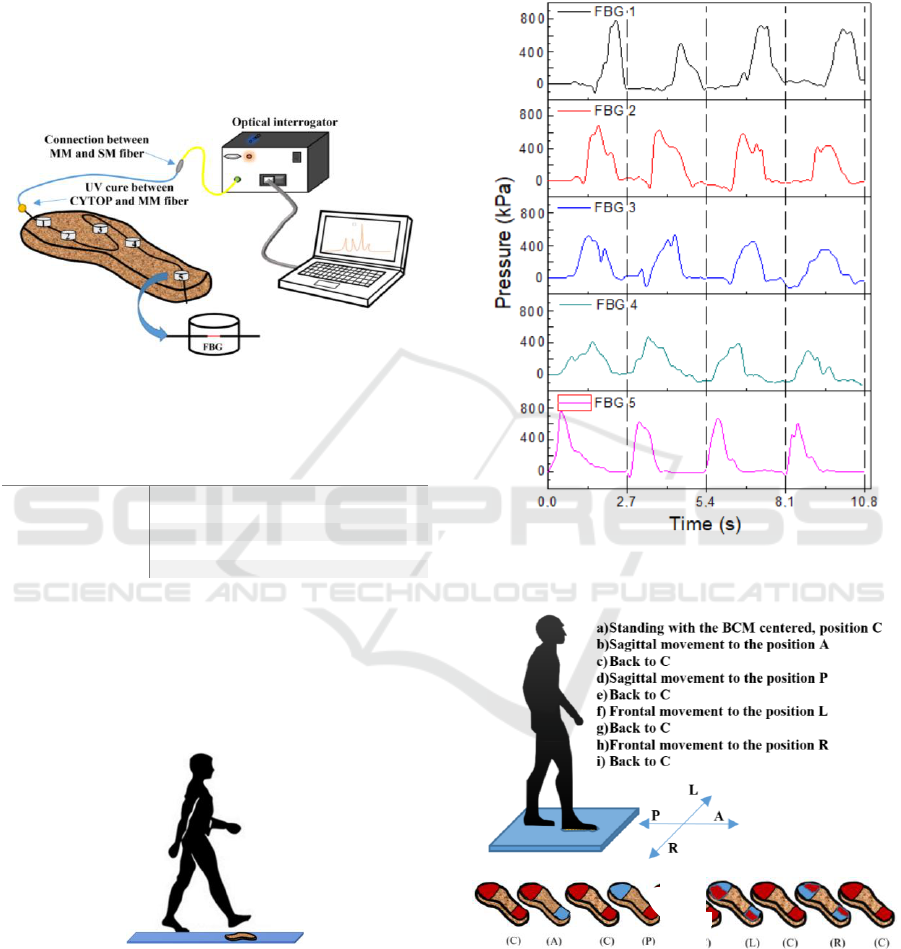

the Bragg wavelength shift. Fig. 2 shows the fixed

platform monitoring system. To avoid multiple

reflections in the final optical spectra, a multimode

(MM) fiber was connected between CYTOP and

singlemode (SM) fiber before connect to the

interrogation system. The array of 5 FBG sensing

elements were calibrated to different pressure load

BIODEVICES 2018 - 11th International Conference on Biomedical Electronics and Devices

26

values ranging from 10 N up to 150 N. The load sets

were applied independently in each sensing point

(from FBG 1 to FBG 5), using a probe with a diameter

of 10 mm. For these elements, the sensitivity

coefficients achieved were 8.31±0.20 pm/kPa (FBG

1), 7.99±0.28 pm/kPa (FBG 2), 8.51±0.23 pm/kPa

(FBG 3), 7.71±0.31 pm/kPa (FBG 4), and 8.20±0.15

pm/kPa (FBG 5). Table 1 summarizes all sensitivity

coefficients for all CYTOP FBGs.

Figure 2: Schematic representation of the fixed platform

monitoring system.

Table 1: Calibration of the FBG sensors to pressure.

FBG number

Sensitivity (pm/kPa)

1

8.31±0.20

2

7.99±0.28

3

8.51±0.23

4

7.71±0.31

5

8.20±0.15

After the calibration, two sets of studies were

implemented in order to verify the reliability of both

the fixed platform and the insole developed.

The pressure induced in the sensing elements

during a normal gait movement was analyzed with the

platform fixed at the ground, as showed in Fig. 3.

Figure 3: Schematic diagram of the protocol implemented

for gait analysis using the fixed platform.

The response of each sensing element to the

pressure during a gait cycle was repeated and

acquired 4 times. The feedback of the platform to the

displacement of the body center of mass (BCM) was

also evaluated. In Fig. 4, the acquired data is

presented, from which it is possible to verify that the

sensing network response is similar for the 4

passages, confirming the repeatability of the sensor’s

response.

Figure 4: Pressure obtained during the 4 steps and the

resulting curve of all the sensors response sum for each step.

.…

Figure 5: Schematic diagram of the protocol implemented

for the analysis of the BCM displacement; b) descritive

protocol on the foot (the subject remained in each position

for 3 seconds - the pressure on each foot location is colored

to red in the scheme).

The BCM displacements, in the body sagittal and

frontal planes of motion, were also analyzed using the

…..

(a)

(b)

Foot Plantar Pressure Monitoring with CYTOP Bragg Gratings Sensing System

27

same platform. For that purpose, a female subject

with 55 kg, was asked to place her foot on the sensing

platform and to execute a series of BCM movements

(with a ~3 seconds duration each), starting by

standing still with the BCM centered (C), followed by

an anterior (A) position and then back to the original

position (C) from which goes to posterior (P) position

and then resting again at the center (C). After the

sagittal displacement, a frontal displacement was

executed, in which the subject moved the BCM first

to the left (L), back in the center (C) and then to the

right (R), and finally back in the center (C). In Fig. 5,

the implemented protocol is schematized.

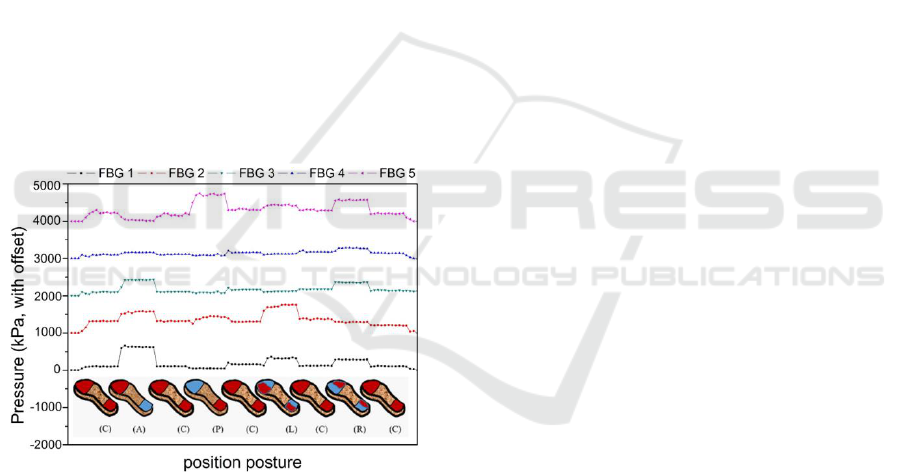

During the protocol implementation, the Bragg

wavelength shift induced in the sensing network was

acquired and the correspondent pressures were

collected. Fig. 6 presents the response of each sensor,

during the different moments of the tests performed.

From the positive feedback of the fixed platform

during the performed tests, it becomes evident that the

method implemented is an adequate solution for

pressure monitoring during gait. Moreover, from the

analysis of the pressures registered during the stance

phase, it is also possible to infer and monitor the

plantar pressures of individuals.

Figure 6: Representation of the pressures detected during

the BCM displacements (the pressure on each foot location

is colored to red in the scheme).

The main advantages obtained with POF

technology when compared with silica fiber

technology (Domingues et al., 2017) are the

following: much higher sensitivity; high flexibility;

easy to handling with fiber when installed to the cork

insole where silica fiber breaks many times due to the

lack of acrylate protection in the fiber after FBGs

inscription.

3 CONCLUSIONS

In this paper, we propose a fiber-optic sensors

network based on CYTOP POFBGs to monitor the

plantar pressure. It has the advantages of a simple

architecture (only using five sensing elements),

relative low cost, temperature insensitivity, high

stability and sensitivity. Moreover, using POF

technology, it also provides the necessary resistance

to be damaged or broken the system during the gait

movement as can easily happen using silica optical

fiber. The measurement of human plantar pressure

distribution, to monitor and understand whether the

foot posture needs to be corrected or not, was

demonstrated in this work. In order to improve the life

quality of physically weakened citizens and increase

the mobility of elder citizens, an integrated “in-shoe”

CYTOP POFBGs sensor network, which is able to

monitor health conditions by observing physiological

parameters in the foot, is in progress using this

technology.

ACKNOWLEDGEMENTS

This work was funded by FCT/MEC through national

funds and when applicable co-funded by FEDER—

PT2020 partnership agreement under the project

UID/EEA/50008/2013. Carlos Marques and Maria F.

Domingues acknowledge the financial support from

FCT through the fellowships SFRH/BPD/109458/

2015 and SFRH/BPD/101372/2014, respectively.

REFERENCES

D. J. Webb, "Fibre Bragg grating sensors in polymer optical

fibres", Measurement Science and Technology 26,

092004 (2015).

F. Bischoff, "Organic polymer biocompatibility and

toxicology", Clinical chemistry 18, 869 (1972).

M. C. J. Large, J. Moran, L. Ye, "The role of viscoelastic

properties in strain testing using microstructured

polymer optical fibres (mPOF)", Measurement Science

and Technology 20, 034014 (2009).

J. G. A. Griffiths, Tables of physical and chemical

constants. By G. W. C. Kaye and T. H. Laby. The

Analyst 73 (1948) 704.

S. Ando, T. Matsuura, S. Sasaki, "Perfluorinated polymers

for optical waveguides", Chemtech 24, 20 (1994).

C. A. F. Marques, D.J. Webb, P. Andre, “Polymer optical

fiber sensors in human life safety, “Optical Fiber

Technology 36, 2017, 144-154 (2017).

A. Razak, A. Hadi, A. Zayegh, R. Begg and Y. Wahab,

“Foot plantar pressure measurement system: A review”,

BIODEVICES 2018 - 11th International Conference on Biomedical Electronics and Devices

28

Sensors 12(7), 9884-9912 (2012).

W. Tao, T. Liu, R. Zheng and H. Feng, “Gait analysis using

wearable sensors”, Sensors 12(2), 2255-2283 (2012).

O. Postolache, J. Pereira, V. Viegas, L. Pedro, P. Girão, R.

Oliveira and G. Postolache, “Smart walker solutions for

physical rehabilitation”, IEEE Instrumentation and

Measurement Magazine 18(5), 21-30 (2015).

L. de Vito, O. Postolache and S. Rapuano, “Measurements

and sensors for motion tracking in motor

rehabilitation”, IEEE Instrumentation and

Measurement Magazine 1(6), 30-38 (2014).

P. Roriz, L. Carvalho, O. Frazão, J. Santos and J. Simões,

“From conventional sensors to fibre optic sensors for

strain and force measurements in biomechanics

applications: A review”, Journal of Biomechanics 4(6),

1251-1261 (2014).

E. Morag and P. R. Cavanagh, "Morag E, Cavanagh PR.

Structural and functional predictors of regional peak

pressures under the foot during walking," Journal of

biomechanics, vol. 32, no. 4, pp. 359-370, 1999.

J. Z. Hao et al., “Design of a foot-pressure monitoring

transducer for diabetic patients based on FBG sensors,”

Lasers and Electro-Optics Society, LEOS 2003, The

16th Annual Meeting of the IEEE, 1 (2003).

T. C. Liang, J. J. Lin, and L. Y. Guo, “Plantar pressure

detection with fiber Bragg gratings sensing system,”

Sensors 16(10), 1766 (2016).

R. Suresh et al., “Development of a high resolution plantar

pressure monitoring pad based on fiber Bragg grating

(FBG) sensors,” Technol Health Care 23(6), 785–794

(2015).

M. F. Domingues, C. Tavares, C. Leitão, A. Frizera-Neto,

N. Alberto, C. Marques, A. Radwan et al. "Insole

optical fiber Bragg grating sensors network for dynamic

vertical force monitoring." Journal of Biomedical

Optics 22, no. 9, pp. 091507-091507, 2017.

S. C. Wearing et al., “A comparison of gait initiation and

termination methods for obtaining plantar foot

pressures,” Gait Posture 10(3), 255–263 (1999).

S. P. Silva et al., “Cork: properties, capabilities and

applications,” Int Mater Rev 50(6), 345–365 (2005).

Thorlabs, “Graded-Index Polymer Optical Fiber (GI-

POF).” [Online]. Disponível: https://www.thorlabs.

com/catalogPages/1100.pdf. [available: 19-Jun-2017].

A Theodosiou, A Lacraz, M Polis, K Kalli, M Tsangari,

“Modified fs-laser inscribed FBG array for rapid mode

shape capture of free-free vibrating beams” IEEE Phot.

Techn. Lett. 28, 1509, (2016)

W. Yuan, A. Stefani, O. Bang, “Tunable polymer Fiber

Bragg Grating (FBG) inscription: Fabrication of dual-

FBG temperature compensated polymer optical fiber

strain sensors,” IEEE Photon. Technol. Lett. 24, 401

(2012).

Foot Plantar Pressure Monitoring with CYTOP Bragg Gratings Sensing System

29