Identification of Corrosive Substances through Electrochemical Noise

using Wavelet and Recurrence Quantification Analysis

Lorraine Marques Alves

1

, Romulo A. Cotta

1

, Adilson Ribeiro Prado

2

and Patrick Marques Ciarelli

1

1

Federal University of Espírito Santo, Av. Fernando Ferrari, 514, Vitória-ES, Brazil

2

Federal Institute of Espírito Santo, Rodovia ES 010, km 6, 5, Serra-ES, Brazil

lorraine_ma@hotmail.com, rcottauk@gmail.com, adilsonnp@ifes.edu.br, patrick.ciarelli@ufes.br

Keywords:

Corrosion, Electrochemical Noise, Wavelet Transform, Recurrence Quantification Analysis.

Abstract:

There are many types of corrosive substances that are used in industrial processes or that are the result of

chemical reactions and, over time or due to process failures, these substances can damage, through corrosion,

machines, structures and a lot of equipment. As consequence, this can cause financial losses and accidents.

Such consequences can be reduced considerably with the use of methods of identification of corrosive sub-

stances, which can provide useful information to maintenance planning and accident prevention. In this paper,

we analyze two methods using electrochemical noise signal to identify corrosive substances that is acting on

the metal surface and causing corrosion. The first method is based on Wavelet Transform, and the second one

is based on Recurrence Quantification Analysis. Both methods were applied on a data set with six types of

substances, and experimental results shown that both methods achieved, for some classification techniques, an

average accuracy above 90%. The obtained results indicate the both methods are promising.

1 INTRODUCTION

Corrosive substances are substances that by chemi-

cal action cause severe damage on contact with li-

ving tissue or, in case of leakage, damage materials or

even destroy structures, means of transport and may

cause many hazardous situations (Javaherdashti et al.,

2013). Corrosive materials include acids, anhydri-

des, alkalis, halogens salts, organic halides and other

substances that are widely used. Sulfuric acid, for

instance, is widely used in manufacturing, for many

chemical processes, and in automotive and industrial

truck batteries. Sodium hydroxide is another corro-

sive material that is used in the purification of petro-

leum products, and in the manufacture of soap, pulp

and paper (Allegri, 2012).

The health effects of corrosive substances are wor-

rying factors in the industrial environment. Effects of

direct contact vary from irritation causing inflamma-

tion to a corrosive effect causing ulceration and, in

severe cases, chemical burns. Ignition of combustible

materials may occur because some corrosive materi-

als are oxidizers and some corrosives are unstable and

tend to decompose when heated (Allegri, 2012). The-

refore, the detection and monitoring of corrosive sub-

stances are of great importance for the preservation of

health and prevention of industrial accidents.

The corrosion effect of these substances can be a

source of unplanned costs. The global cost of corro-

sion is estimated around U$ 2.5 trillion, equivalent to

3.4% of world GDP (Gross National Product) (Koch

et al., 2016). This factor added to probability of acci-

dents highlight the importance of researches and de-

veloping of technology in this field. Fortunately, due

to the simultaneous occurrence of oxidation and re-

duction reactions during the corrosion process, it is

possible to measure the current and electrical poten-

tial fluctuations on the surfaces that are suffering this

process. These measured signals are called electro-

chemical noise (ECN) (Fofano and Jambo, 2007).

ECN signals have been used in corrosion monito-

ring processes for many years. But, only in the last

decade that the real potencial of these signals, com-

bined with methods of useful features extraction, has

become clearer (Al-Mazeedi and Cottis, 2004). An

example of an application of ECN signals is the iden-

tification of corrosive substances, that can be useful

to troubleshoot faults in industrial processes, assist in

maintenance planning and even avoid accidents.

In this paper, we compare two techniques for fea-

tures extraction of the ECN signals based on the wa-

velet transform and RQA (Recurrence Quantification

Analysis), associated to machine learning techniques

in order to create an intelligent system capable of de-

718

Alves, L., Cotta, R., Prado, A. and Ciarelli, P.

Identification of Corrosive Substances through Electrochemical Noise using Wavelet and Recurrence Quantification Analysis.

DOI: 10.5220/0006252007180723

In Proceedings of the 6th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2017), pages 718-723

ISBN: 978-989-758-222-6

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

tect different types of corrosive substances in aqueous

solution. The results obtained in the experiments in-

dicate that both approaches are promising.

2 ELECTROCHEMICAL NOISE

DATA ANALYSIS

One of the biggest challenges in the analysis of elec-

trochemical noise is related to the stochastic nature

of the corrosion process, which result in most cases

in nonstationary signals. The nonstationarity of elec-

trochemical noise signals can be observed in two pri-

mary ways: by fluctuations in the variation of the

potential or current and by the variation of statisti-

cal properties of the signal over time. One approach

that has been used for ECN analysis is the wavelet

transform. This method overcomes the limitations of

the Fourier transform, since it enables the decomposi-

tion of the signal into diferente frequency components

for different time intervals (Cottis et al., 2015). RQA

is another approach to the analysis of ECN data that

allows characterization of data by similarity matrix,

containing the distances between subsequent measu-

rements in the time series. Many variables can be de-

rivated from the similarity matrix and has been used to

identify corrosion type and process monitoring (Hou

et al., 2016).

2.1 Wavelet Transform Analysis

In conventional Fourier analysis is not possible to find

in what period of time certain frequency band of a sig-

nal occurred, because this information is lost during

the transform. A way to overcome this problem is to

use the wavelet transform. Wavelet can distinguish

the local characteristics of a signal on different scales

and, by translations, they cover all the region in which

the signal is studied. This locality property of wave-

lets is an advantage over the Fourier Transform in the

analysis of nonstationary signals, being a more effi-

cient tool, and applicable to the study of ECN signals

(Aballe et al., 1999; Cottis et al., 2015).

For the analysis of discrete signals from sampled

corrosive processes, it is conventionally used the Dis-

crete Wavelet Transform (DWT) to obtain the coef-

ficients values of different frequency bands for each

time interval. These values are obtained by convolu-

tion of the sampled signal by functions that are displa-

ced and dilated versions of a wavelet function (or mot-

her wavelet). Thus, the original signal can be writ-

ten as a sum of wavelet functions (φ

J,n

(t) e ψ

J,n

(t))

weighted by their corresponding coefficients, called

detail (d

J,n

) and smooth coefficients (s

J,n

). These

coefficients indicate the correlation between the wa-

velet function and the corresponding signal segment

(Aballe et al., 1999), as shown in Equations 1 to 3:

x(t) ≈

∑

n

s

J,n

∗ φ

J,n

(t) +

∑

n

d

J,n

∗ ψ

J,n

(t)+

∑

n

d

J−1,n

∗ ψ

J−1,n

(t) + ... +

∑

n

d

1,n

∗ ψ

1,n

(t),

(1)

s

J,n

=

Z

x(t)φ

∗

J,n

(t)dt, (2)

d

J,n

=

Z

x(t)ψ

∗

J,n

(t)dt, (3)

where n = 1...N, N is the length of the discrete signal

and J stands for the decomposition level of DWT.

The coefficient matrix generated by DWT can be

difficult to interpret for some ECN signals. A more

useful way to represent the results of the wavelet

transform in the analysis of electrochemical noise is

through the concept of coefficient energy distribution.

Thus, the contribution of each energy level of decom-

position is calculated regarding the total energy of the

signal. In this context, the signal energy may be cal-

culated by (Aballe et al., 1999):

E =

N

∑

n=1

x

2

n

, (4)

where E is the total energy of signal, x

n

is the signal

values in the instants n = 1,2,3,..., N and N is the

length of the discrete signal.

From the total energy E, the fraction of energy

of each detail coefficient (E

d

j

) and of smooth coeffi-

cient (E

s

j

) can be calculated, respectively, according

to Equations 5 and 6, where J are the levels used in

the decomposition of the signal through the DWT.

E

d

j

= 1/E

N/2 j

∑

n=1

d

2

j,n

. (5)

E

s

j

= 1/E

N/2 j

∑

n=1

s

2

j,n

. (6)

Another recently developed ECN analysis tool is

the concept of entropy associated with wavelet trans-

form (Moshrefi et al., 2014). While the transform

coefficients indicate the transient behavior of the sig-

nal, the concept of entropy is used to measure this

degree of variability. Thus, the concept of entropy

based on wavelet analysis reveals the degree of or-

der/disorder of ECN signals, which will vary accor-

ding to the conditions of the corrosion process. The

entropy of a discrete random variable x with probabi-

lity p(x

i

) can be defined by:

H(x) = −

n

∑

i=1

p(x

i

)log(p(x

i

)), (7)

Identification of Corrosive Substances through Electrochemical Noise using Wavelet and Recurrence Quantification Analysis

719

where p(x

i

) is estimated as the kernel density.

As the energy, entropy of the wavelet transform

decomposition levels provides information to analyze

the ECN signals that cannot be obtained through tem-

poral analysis of the signals.

2.2 Recurrence Quantification Analysis

RQA is a developed approach for the analysis of dy-

namic systems and is based on the Recurrence Plots

(RP) study. Recurrence matrix is the starting point for

the discussion of the RQA theory. The formal con-

cept of recurrence was introduced by Henri Poincaré

in 1890 and, in a simplistic way, it states that an initial

state or configuration of a mechanical system, sub-

jected to conserved forces, will reoccur again in the

course of the time evolution of the system (Bergelson,

2000). The RP method was developed for the visuali-

zation of the dynamic’s trajectories in the phase space

of dynamic systems. A recurrence plot is a graphical

representation of a N ×N matrix, whose elements are

given by Equation 8:

RM

i, j

= H(ε − ||x

i

− x

j

||),i, j = 1, 2,..., N, (8)

where N is the number of states in phase space, ε is a

predefined threshold radius, x

i

and x

j

are the points in

phase space occorring at time i and j, ||.|| denotes the

Euclidean norm of the vectors, and H represents Hea-

viside function. If the distance between x

i

and x

j

falls

within the threshold radius, then RM

i, j

= 1, otherwise,

RM

i, j

= 0 (Hou et al., 2016). In this paper, the matrix

will be obtained on the time series of electrochemical

noise data, similarly at (Hou et al., 2016).

The threshold value ε must be chosen correctly,

since this value influences directly in the recurrence

analysis. If ε is too large, almost all points will be

identified as a recurrence point. On the other hand, if

ε is too small, there may be too few recurrence points

impairing the disclosure of recurrence structure (Mar-

wan et al., 2007). In this paper, the ε value was fixed

as 20% of the standard deviation of the original data

segment, like used in (Hou et al., 2016).

Variables derived from the recurrence matrices,

such as the recurrence rate (R), determinism (D), en-

tropy (E) and average diagonal line length (L) are

used to represent quantitatively recurrence plot (Mar-

wan et al., 2007).

Given a N × N recurrence matrix RM

i, j

(ε),i, j =

1,2,..., N, then recurrence rate R (Equation 9) is the

measure concerning the density of recurrence points

and corresponds to the correlation definition for cases

where the number of points is very large.

R =

1

N

2

N

∑

i, j=1

RM

i, j

(ε). (9)

Determinism D is a measure of system predicta-

bility. According to Equation 10, P(l) is the number

of diagonals with length l in RP, and l

min

is the smal-

lest size for a row to be considered a diagonal (usually

l

min

= 2). In other words, the value of D is the reason

between the number of points belonging to diagonals

and the number of recurrence points.

D =

∑

N

l=l

min

lP(l)

∑

N

i, j=1

RM

i, j

(ε)

. (10)

The average length L of the diagonal lines is the

number of points belonging to diagonals divided by

the number of diagonals in RP, and it can be computed

from Equation 11.

L =

∑

N

l=l

min

lP(l)

∑

N

l=l

min

P(l)

. (11)

Finally, E (Equation 12) measures the Shannon

entropy of the probability p(l) = P(l)/N

l

to find a dia-

gonal line with length l and reflects the complexity of

the recurrence matrix with respect to diagonal lines.

E = −

N

∑

l=l

min

p(l)lnp(l). (12)

In previous studies, authors suggest that corrosive

events can be distinguished by the values of these fe-

atures. For example, uniform corrosion can be as-

sociated with high values of R and low values of D,

whereas localized corrosion is associated with low va-

lue of R and high value of D (Montalban et al., 2007;

Garcia-Ochoa and Corvo, 2015).

3 MATERIALS AND METHOD TO

COLLECT THE DATA

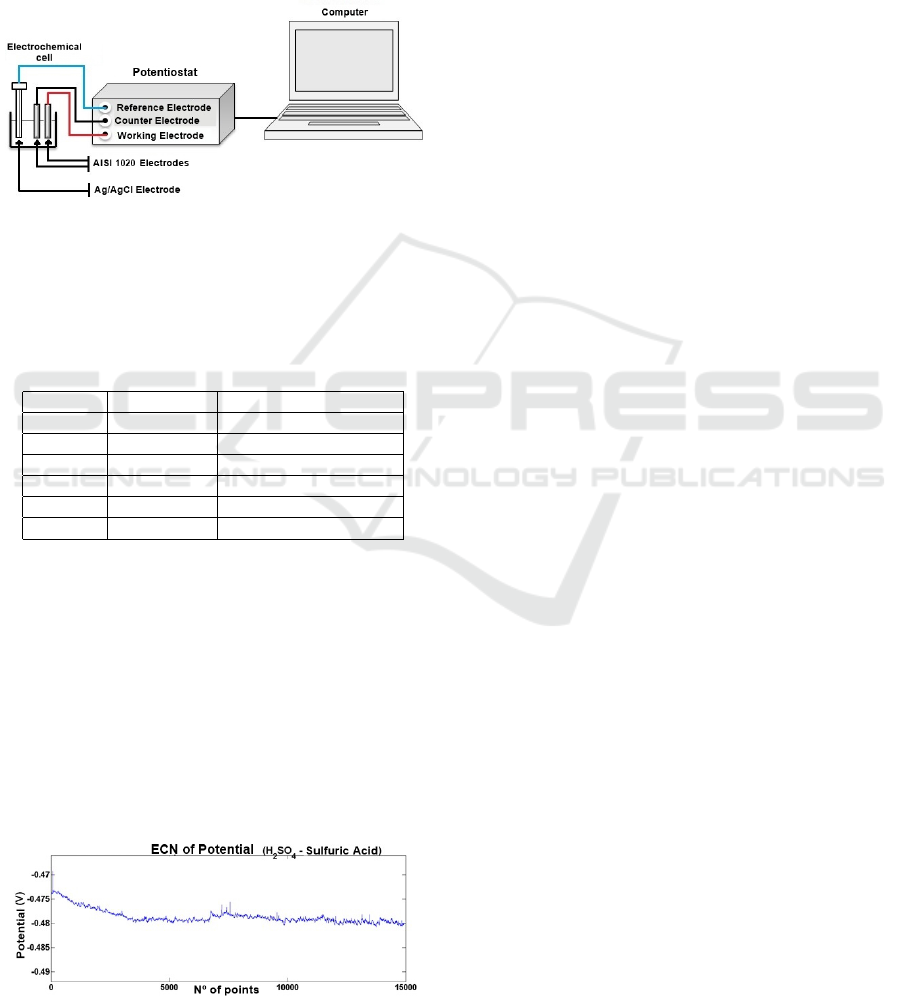

Corrosion analysis, through signal processing, con-

sists in the mounting of an experimental apparatus,

called electrochemical cell, and it is used an A/D

(analog/digital) converter for the measurements of

electrochemical noise. In this work, potential signals

were measured and stored. Electrochemical cell is

an experimental apparatus consisting of an inert me-

tal immersed in an aqueous solution containing ions

in different oxidation states. The cell used in this

study consists of two steel electrodes AISI 1020 used

as working electrodes and counter electrodes. These

electrodes are nominally identical and coated with ter-

mocontract, and they have exposed area to solution

equal to 18mm

2

.

According to the American Institute of Iron and

Steel and International Society of Automotive En-

gineers, 1020 steel consists of about 0.18 to 0.23%

ICPRAM 2017 - 6th International Conference on Pattern Recognition Applications and Methods

720

carbon (C), 0.3 to 0.6% manganese (Mn), at most

0.040% phosphorus (P) and 0.050% sulfur (S). Car-

bon steel 1020 is among the most used metals in the

industry. The reference electrode used to collect data

was silver/silver chloride (Ag/AgCl). The electroche-

mical cell is connected to the potentiostat interface,

and this is connected to the computer, where the data

can be stored. Figure 1 shows a diagram with the in-

struments used for data collection.

Figure 1: Experimental apparatus configuration.

Table 1 shows the substances used in this work

and their applications. We have chosen substances

which are common in industrial environments.

Table 1: Used reagents and their concentrations (values in

mol/L) in aqueous solutions.

Substance Concentration Application

KCl 0.2, 0.4 and 0.6

Fertilizer production

NaOH 0.1, 0.2 and 0.3 Boilers

KOH 0.1, 0.2 and 0.3

Petrochemical industry

NaCl 0.2, 0.6 and 1.0

Cooling water

FeCl

3

0.1, 0.2 and 0.3

Coagulant in water treatment

H

2

SO

4

0.2, 0.3 and 0.4

Fertilizer production

The acquisition of the signals was obtained using

a potentiostat AUTOLAB

R

PGSTAT 101 Metrohm

model. This instrument is equipped with three con-

nections: working electrode, counter electrode and re-

ference electrode. The reference electrode used was

Ag/AgCl. To analyze the ECN measurements, for

each reagent was performed three different concen-

trations, totalizing 18 measurements with 60 minutes

each. The sampling frequency used was 4Hz, such

that each measurement has 14400 points. Figure 2

shows an example of measured signal.

Figure 2: Potential ECN signal.

4 EXPERIMENTS AND

DISCUSSION

The experiments were divided into two phases. In the

first phase was defined the size of data segments, that

is, the number of points of each sample before ex-

tracting the features. In the second phase, the classifi-

cation algorithms are trained with the features extrac-

ted by wavelet and RQA to identify the type of cor-

rosive substance. In both phases, the accuracy metric

was used as quality measure. The value of the accu-

racy is calculated by the ratio of the number of sam-

ples correctly classified by the total number of sam-

ples, multiplied by 100%.

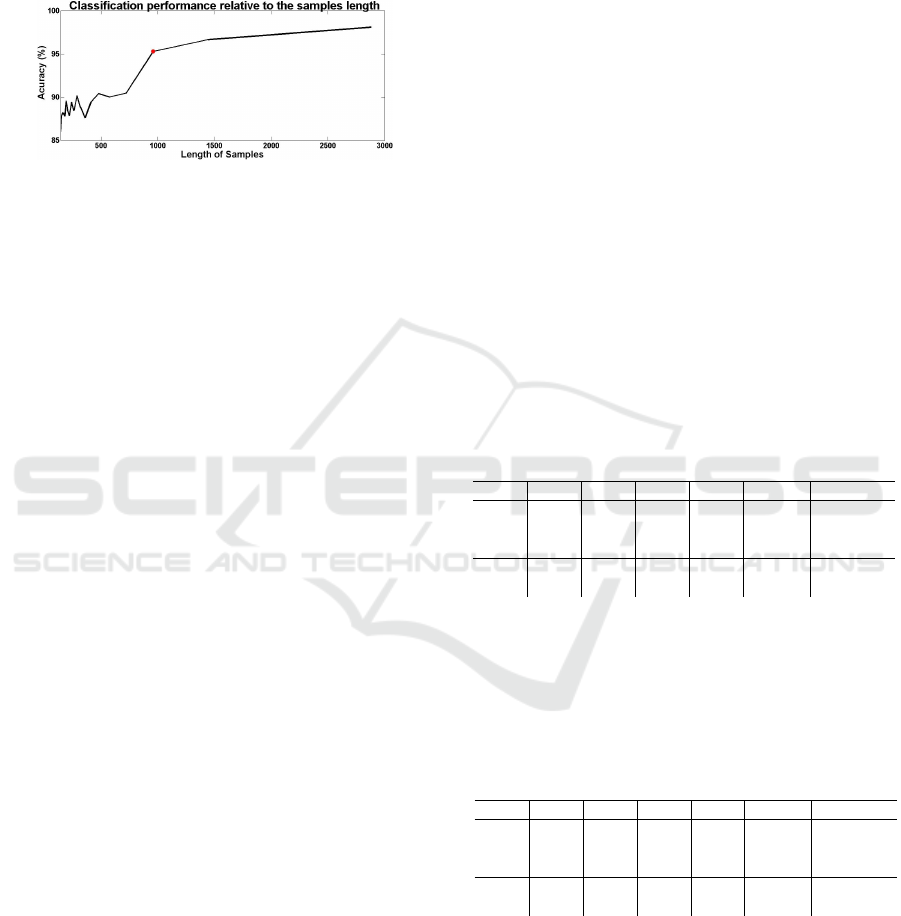

4.1 Size of Data Segments

The features used to identify the type of substance are

extracted of several data segments. Therefore, it is

important to define its size, because few points per

segment supply little information, but, if is used many

points per segment, it will be impossible to evaluate

properly the proposed method. Thus, we evaluated

non-overlapping data segments in the range of 144 to

2880 points, with increments of 144 points. For this

experiment was used a total of 14400 points equally

distributed in all six classes, where 70% of the points

were used to train and the others 30% to test.

The first step of wavelet analysis method is to

remove the mean of each time series and to define

the corresponding wavelet family (father and mother)

(Aballe et al., 1999). The features used in this expe-

riment were computed from signal of potential with

Wavelet Transform of Daubechies (db4) with decom-

position at 8 levels. The main property of the Daube-

chies function is that it is a wavelet highly localized

in time, wich is good for electrochemical noise stu-

dies, where short time duration events are the norm

(Bertocci et al., 1997). The features extracted of each

non-overlapping data packets of ECN signal of po-

tential were: energy, entropy, detail and smooth coef-

ficients, as described in Section 2.1, resulting in a fe-

ature vector with 27 elements. These features were

selected with SBS algorithm (Sequential Backward

Feature Selection), which is a search algorithm that

starts with a complete set of features and for each ite-

ration removes the feature with the least impact on the

accuracy. Thus, only the most significant features are

kept (Dutra, 1999). After computing the features, they

were normalized by the mean and standard deviation.

To classification, we used a MLP (Multi-Layer

Perceptron) with 20 neurons in the hidden layer, le-

arning rate equal to 0.001 and 1000 training epochs

using Levenberg-Marquardt algorithm (Marquardt,

Identification of Corrosive Substances through Electrochemical Noise using Wavelet and Recurrence Quantification Analysis

721

1963) for training. Figure 3 shows the accuracy va-

lues obtained for different numbers of points using

wavelet transform features. It is observed that the gre-

ater the number of points per segment, the better is the

accuracy.

Figure 3: Accuracy × sample length.

Ideally, a good choice is a large number of points

per segment (sample). However, the higher number of

points is, the smaller is the number of samples avai-

lable for training and testing. A compromise between

the two quantities is 960 points per segment, as indi-

cated in Figure 3. Therefore, we can have a reasona-

ble number of samples per class.

4.2 Corrosive Substances Identification

For these experiments, the features were extrac-

ted from non-overlapping data segments (samples)

of 960 points each, from electrochemical noise of

potential signals. Wavelet Transform of Daube-

chies (db4) with decomposition at 8 levels was

used to compute the energy and entropy, and de-

tail and smooth coefficients, resulting in a feature

vector with 27 elements. Similarly, RQA was

also used to extract features. The measures des-

cribed in Section 2.2 were extracted through the

RQA software 13.1 routines package, available at

http://homepages.luc.edu/∼cwebber/. Therefore, for

each sample was obtain a vector with 4 elements.

After this step, the samples were stratified into 3

folds of data, each one with 45 samples to each class.

Then, for each classifier were obtained 3 results from

3 tests, and each result was achieved using 2 folds

for training/validation and 1 fold for testing. For each

result was used a different fold for testing. The featu-

res were normalized by the mean and standard devi-

ation computed in the training folds. In this work we

used the following classifiers: MLP, PNN (Probabilis-

tic Neural Network) (Masters, 1995), kNN (k Nearest

Neighbor) (Duda et al., 2000), Decision Tree (Quin-

lan, 1988) and SVM (Support Vector Machines) (The-

odoridis and Koutroumbas, 2008) with linear (SVM-

L) and radial basis function (SVM-RBF) kernel.

The following configurations were tested for each

technique in order to maximize the accuracy on the

training set and, possibly, also on the test set. MLP

was trained using Levenberg-Marquardt algorithm,

learning rate of 0.001, 1000 epochs and evaluated dif-

ferent numbers of neurons in the hidden layer (1 to

50 neurons). Different values of standard deviation

were tested for PNN (0.1 to 1.0, with steps of 0.1).

For kNN, we employed Euclidean distance and we

varied the value of k (1 to 10). For SVM-L and SVM-

RBF, different values of cost c were evaluated (0 to

10, with steps of 0.5). Moreover, different values of

gamma (0.001 to 0.025, with steps of 0.005) were eva-

luated for SVM-RBF. For the decision tree was used

standard Matlab implementation, which does not have

parameters to tune. For each test, the parameters of

each technique were adjusted in order to maximize

the accuracy on the training folds, and these parame-

ters were used to classify the samples of the test fold.

Table 2 shows the values of the accuracy obtained

by each technique in each test fold when using wave-

let transform to feature extraction. The best result for

each fold is highlighted. As can be seen, MLP achie-

ved mean accuracy slightly better than those obtained

by the other classifiers, followed by SVM with linear

kernel.

Table 2: Classification results of each technique when using

wavelet to feature extraction (accuracy values are in per-

cent).

Test MLP PNN kNN Tree SVM-L SVM-RBF

1 95.56 71.97 90.48 84.76 87.66 87.66

2 97.14 75.00 94.29 89.52 94.28 92.38

3 95.87 68.94 86.67 81.90 91.42 90.47

Mean 96.19 71.97 90.48 85.40 91.12 90.17

Std. 0.008 0.030 0.030 0.038 0.033 0.023

Similarly, Table 3 shows the classification results

of each technique when using the features extracted

by RQA. As can be seen, decision tree achieved mean

accuracy slightly better than those obtained by the ot-

her classifiers.

Table 3: Classification results of each technique when using

RQA to feature extraction (accuracy values are in percent).

Test MLP PNN kNN Tree SVM-L SVM-RBF

1 91.11 94.44 94.44 97.78 83.33 86.67

2 92.22 88.89 90.00 92.22 88.88 91.11

3 78.89 86.67 88.89 87.78 81.11 78.89

Mean 87.41 90.00 91.11 92.59 84.44 85.56

Std. 0.074 0.040 0.029 0.050 0.040 0.061

The results in Tables 2 and 3 indicate that both ap-

proaches, wavelet transform and RQA, present a high

accuracy to perform detection of corrosive substan-

ces, but the best mean accuracy of wavelet transform

was slightly better than the results obtained by RQA.

Furthermore, we observed that MLP performance was

better when using features extracted by wavelet trans-

form, while decision tree was more effective when

ICPRAM 2017 - 6th International Conference on Pattern Recognition Applications and Methods

722

using features of RQA. This indicates some classi-

fiers are more appropriate to some type of features

than others. The authors did not find works with si-

milar objectives, but in the task of identifying types

of corrosion, as in (Jian et al., 2013) and (Hou et al.,

2016), that also use ECN signal, the accuracy is in the

range of 90% to 100%.

5 CONCLUSIONS

This paper presented an approach to identify some ty-

pes of reagents on metal surface through electroche-

mical noise signals using wavelet transform and re-

currence quantification analysis. Comparing the two

techniques, we noticed that both had a similar perfor-

mance, but wavelet transform was able to provide a

slightly higher average accuracy. For the classifiers

evaluated, we noted that MLP achieved an average

accuracy above 95% to perform the task. In relation

to the classification stage, the feature vector obtained

from the RQA is smaller, and requires less processing

capacity.

Therefore, the results of this study highlight the

importance of using wavelet transform and RQA for

electrochemical noise analysis. In future work, we in-

tend to analyze the combination of these methods, ot-

her algorithms and other features in order to improve

the results.

ACKNOWLEDGEMENTS

Lorraine Marques Alves would like to thank CAPES

for the scholarship granted.

REFERENCES

Aballe, A., Bethencourt, M., Botana, F., and Marcos, M.

(1999). Using wavelets transform in the analysis

of electrochemical noise data. Electrochimica Acta,

44(26):4805–4816.

Al-Mazeedi, H. and Cottis, R. (2004). A practical evalu-

ation of electrochemical noise parameters as indica-

tors of corrosion type. Electrochimica Acta, 49(17–

18):2787–2793.

Allegri, T. (2012). Handling and Management of Hazar-

dous Materials and Waste. Springer Science & Busi-

ness Media.

Bergelson, V. (2000). The multifarious poincaré recurrence

theorem. Descriptive set theory and dynamical sys-

tems, 1:31–57.

Bertocci, U., Gabrielli, C., Huet, F., and Keddan, M. (1997).

Noise resistance applied to corrosion measurements.

Electrochemical Society Journal, 144:31–37.

Cottis, R. A., Homborg, A., and Mol, J. (2015). The rela-

tionship between spectral and wavelet techniques for

noise analysis. Electrochimica Acta, pages 277–287.

Duda, R., Hart, D. G., and Stork, P. (2000). Pattern Recog-

nition. Wiley Interscience, New York, 1nd edition.

Dutra, L. (1999). Feature extraction and selection for ers-

1/2 insar classification. International Journal of Re-

mote Sensing, pages 993–1016.

Fofano, S. and Jambo, H. (2007). Corrosion: fundamentals,

monitoration and control. Ciencia Moderna, Brazil,

1nd edition.

Garcia-Ochoa, E. and Corvo, F. (2015). Using recurrence

plot to study the dynamics of reinforcement steel cor-

rosion. Protection of Metals and Physical Chemistry

of Surfaces, 51(4):716–724.

Hou, Y., Aldrich, C., Lepkova, K., Suarez, L., and Kinsella,

B. (2016). Monitoring of carbon steel corrosion by use

of electrochemical noise and recurrence quantification

analysis. Corrosion Science, pages 63–72.

Javaherdashti, R., Nwaoha, C., and Tan, H. (2013). Cor-

rosion and Materials in the Oil and Gas Industries.

CRC Press.

Jian, L., Weikang, K., Jiangbo, S., Ke, W., Weikui, W.,

Z.Weipu, and Zhoumo, Z. (2013). Determination of

corrosion types from electrochemical noise by artifi-

cial neural networks. international Journal of Elec-

trochemical Science, 8:2365–2377.

Koch, G., Varney, J., Thompson, N., Moghissi, O., Gould,

M., and Payer, J. (2016). International measures of

prevention, application and economics of corrosion

technologies study (impact). Technical report.

Marquardt, D. W. (1963). An algorithm for least-squares

estimation of nonlinear parameters. Journal of

the Society for Industrial and Applied Mathematics,

11(2):431–441.

Marwan, N., Romano, M., Thiel, M., and Kurths, J. (2007).

Recurrence plots for the analysis of complex systems.

Physics reports, 438:237–329.

Masters, T. (1995). Advanced algorithms for Neural Net-

works: A C++ Sourcebook. John Wiley and Sonsl,

New York, 1nd edition.

Montalban, L., Henttu, P., and Piche, R. (2007). Recur-

rence quantification analysis of electrochemical noise

data during pit development. International Journal of

Bifurcation and Chaos, 17:3725–3728.

Moshrefi, R., Mahjani, M., and Jafarian, M. (2014). Appli-

cation of wavelet entropy in analysis of electrochemi-

cal noise for corrosion type identification. Electroche-

mistry Communications, 48:49–51.

Quinlan, J. (1988). Decision trees and multivalued attribu-

tes. Oxford University Press, New York, 11nd edition.

Theodoridis, S. and Koutroumbas, K. (2008). Pattern Re-

cognition. Elsevier, San Diego, 4nd edition.

Identification of Corrosive Substances through Electrochemical Noise using Wavelet and Recurrence Quantification Analysis

723