A Low Cost Wireless System to Monitor Plantar Pressure using

Insole Sensor: Feasibility Approach

Renato Varoto

1

, Gustavo Casagrande Oliveira

2

, Adolfo Victor Freire de Lima

2

,

Matheus Missola Critter

2

and Alberto Cliquet Jr.

1,2

1

Department of Orthopedics and Traumatology, University of Campinas (UNICAMP), Campinas, Brazil

2

Department of Electrical and Computer Engineering, University of São Paulo (USP), São Carlos, Brazil

Keywords: Plantar Pressure Monitoring, Insole Pressure Sensor, Baropodometry, Java Application, Bluetooth Device.

Abstract: Plantar pressure analysis is an important strategy applied in clinical, orthopaedics, sports and rehabilitation

studies. In this context, this work describes the development and application of wireless system to monitor

plantar pressure. This system is composed by a data acquisition module based on low cost electronic

instrumentation, high resolution insole flexible pressure sensor and Java application for data real-time

visualization. To verify the feasibility and effectiveness of the system, workbench tests were realized and a

healthy subject performed pilot trials based on static and dynamic activities on the biomechanics platform.

According to the preliminary results, this system is effective to show the interaction between the foot and

floor in static and dynamic conditions, presenting a measurement range of pressure of 0-300kPa and rapid

response, among other features. Thus, this system is a feasible tool for quick and practical mapping of plantar

pressure.

1 INTRODUCTION

Plantar pressure monitoring is an important tool

applied in clinical, sports and rehabilitation studies.

The systems that include this technology can identify

pathologies, characterize gait cycles and evaluate

standing posture (Hills et al., 2001; Girard et al.,

2010; Bellizzi et al., 2011; Kaercher et al. 2011;

Chapman et al., 2013; Ledoux et al., 2013; Robinson

et al., 2013; Melvin et al., 2014).

Many researchers have developed self-

constructed plantar pressure measurement systems

(Castro and Cliquet, 2000; Smith et al., 2002; Saito et

al., 2011; Crea et al., 2014; Motha, Kim and Kim,

2015; Tan et al., 2015). However, the development of

these self-constructed devices requires time and a

validation procedure. An alternative is the use of

commercial pressure measurement systems.

Nowadays, some commercial systems stand out in

the analysis of motion and gait. Freemed

Baropodometric Platform (Sensor Medica SAS,

Guidonia Montecelio, Rome, Italy) allows assessing

balance, and detecting the foot loads and patient's

posture during walking/running and standing.

The Medilogic Insole (T&T Medilogic

Medizintechnik GmbH, Schönefeld, Brandenburg,

Germany) uses flexible insoles with up to 200

resistive sensors to detect the plantar pressure

distribution. This system is an acceptable tool for

measuring ground reaction forces in work activities,

except for kneeling positions (Koch et al., 2016).

The Pedar System (Novel GmbH, Munich,

Bavaria, Germany) is a measuring system for

monitoring pressure between the foot and footwear.

Elastic insoles with up to 99 capacitive sensors that

cover the entire plantar surface detect the pressure.

The F-Scan System (Tekscan, Inc., Boston, MA,

USA) employs flexible tactile resistive sensor (up to

954 sensels) to obtain dynamic information about foot

function and gait.

Flexible tactile sensor for measuring pressure

distribution consists of two flexible substrates joined

by adhesive and dielectric layers. Electrodes of both

substrates establish a matrix of rows and columns,

and each intersection forms a sensing element (SE)

that changes its electrical resistance (R

s

) when force

is applied to it (Test & Measurement, 2014; Podoloff

et al., 1991).

For flexible pressure sensor is recommended to

follow the 100/70 Rule. Thus, 100% of the force

should be concentrated within the sensing area of

Varoto R., Oliveira G., de Lima A., Critter M. and Cliquet Jr. A.

A Low Cost Wireless System to Monitor Plantar Pressure using Insole Sensor: Feasibility Approach.

DOI: 10.5220/0006246402070214

In Proceedings of the 10th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2017), pages 207-214

ISBN: 978-989-758-216-5

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

207

sensor, and 70-85% of the sensing area should be

loaded. It is advisable to use a load actuator to

distribute and to point the load (Flexiforce® Force

Sensor Design & Integration Guide, 2015).

Price, Parker and Nester (2016) evaluated

Medilogic, F-Scan and Pedar systems in relation to

validity and repeatability. According to them, Pedar

system presented greatest accuracy and repeatability

when compared to Medilogic and F-Scan systems.

Using bench tests and subjects walking on a

treadmill, McPoil, Cornwall and Yamada (1995)

compared Emed (Novel GmbH, Munich, Bavaria,

Germany) and F-Scan systems. High level of validity

and reliability were reached by Emed whereas F-Scan

was not satisfatory for certain measurements. Similar

results were obtained by Hsiao, Guan and Weatherly

(2002) through bench experiments.

This paper describes the development and

application of wireless system to monitor plantar

pressure. The system is composed by a data

acquisition module based on low cost electronic

instrumentation (less than US$20.00), high resolution

flexible pressure sensor and Java application for data

visualization. This system was designed for quick and

practical mapping of plantar pressure, representing an

auxiliary tool for orthopaedics and biomechanical

studies. To verify the feasibility of the system,

workbench tests were realized and a healthy subject

performed pilot trials based on static and dynamic

activities on biomechanics platform.

2 MATERIAL AND METHODS

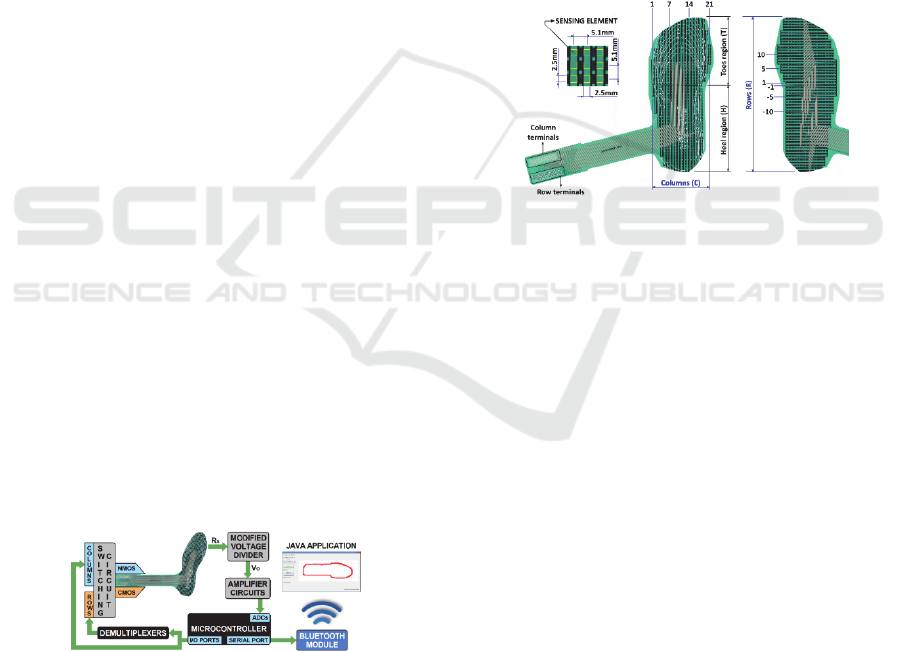

The system is composed by insole pressure sensor,

data acquisition module and Java application. The

microcontroller associated with the switching circuit

selects a SE, doing a scanning procedure, and

performs analog to digital conversion of voltage from

amplifier circuits (Figure 1).

Figure 1: Block diagram of the system.

The switching circuit, including modified voltage

dividers, convert R

s

into voltage (V

O

). Furthermore,

the microcontroller provides serial data to Bluetooth

module that sends it to Java application.

2.1 Insole Pressure Sensor and

Apparatus for Characterization of

Its Sensing Element

In this work, Medical Sensor 3000 (Tekscan, Inc.,

Boston, MA, USA) was used as insole pressure

sensor. This sensor presents a foot-shaped area, and it

can be trimmed to some sizes according to the

reference lines. Top substrate has 60 electrodes that

extend in widthwise in relation to the foot (rows). In

lengthwise direction, bottom substrate presents two

electrode sets - named as toes region (T) and heel

region (H) - with 21 and 18 electrodes, respectively

(columns). For convenience, columns were numbered

from terminal side and rows were numbered from the

border of two regions of bottom substrate, positive

values for T and negative values for H (Figure 2).

Figure 2: Bottom and top views of Medical Sensor 3000.

Columns and rows have width of 2.5mm and

inter-electrode spacing of 5.1mm. The intersections

between columns and row in sensor area create 954

SEs with area of 6.25mm

2

. Force applied to opposite

sides of the sensor changes the resistance of pressure-

sensitive resistive material of each SE as a function of

the force magnitude (Medical Sensor 3000; Podoloff

et al., 1991).

Medical Sensor 3000 trimmed for U.S. footwear

size 8 (26cm) were available for the developed

system. Thus, this sensor presents 52 rows (1 – 23 and

-1 – -29) and 29 columns (T3 – T18 and H4 – H16)

monitored by electronic circuit.

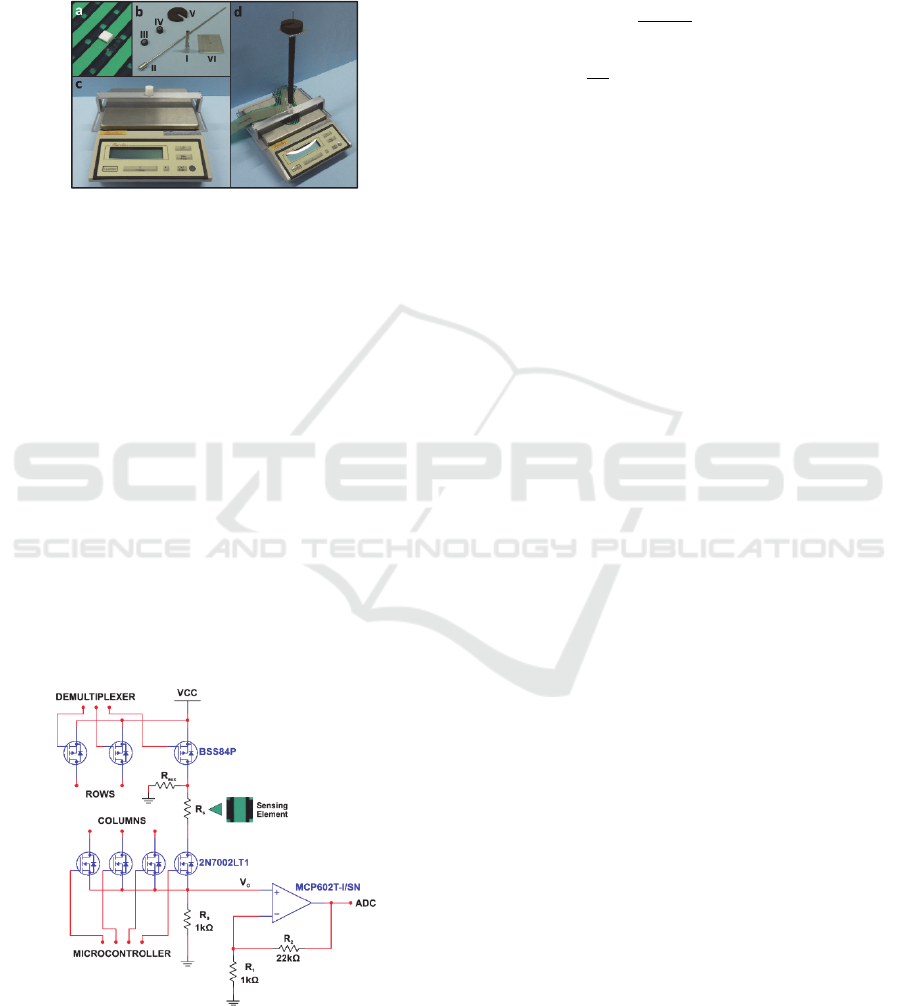

According to the 100/70 Rule, a squared load

actuator of 4.84mm

2

(PVC) was used to concentrate

and to point the load within the SE. This load actuator

was fixed on SE analyzed by double-sided tape

(Figure 3a).

The structure showed in figure 3c was built in

digital precision weight scale AS2000C (Marte

Científica, São Paulo, SP, Brazil) to allow application

of loads on the sensor, avoiding shear forces. For this,

a polymer sleeve associated with a shaft of 50mm was

fixed on its top (Figure 3b). The lower end of the shaft

acts on the load actuator, while the upper end receives

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

208

the support of loads. The applied loads resulting from

the weight of: the support (7.3g), 10 blocks of 5g

(

+0,7g

-0,4g

), 15 blocks of 10g (

+0.4g

-1.0g

), support plate of 21.4g

and two blocks of 100g (±0.1g). Moreover, the load

due to the weight of the shaft (12.8g) was also

considered.

Figure 3: a) Load actuator fixed on SE; b) I - shaft, II -

support of loads, III - 5g block, IV - 10g block, V - 100g

block, VI - support plate; c) Custom built structure in

weight scale; d) All loads applied to the SE; sensor fixed on

weight scale plate.

Thus, 30 load levels were used for the

characterization of SE (Figure 3d). The weight scale

determined the exact value of each level during the

application.

2.2 Data Acquisition Module

Data acquisition circuit was based on the modified

voltage divider associated with the noninverting

amplifier (Figure 4). As noted in the workbench tests

(described hereafter) a linear relationship can be

adopted between applied pressure and electrical

conductance (C

s

) of the SE, and the R

s

varies between

dozens of MΩ and 100kΩ for pressure range of 0 to

900kPa.

Figure 4: Schematic of data acquisition circuit, including

switching circuit to select each SE. Whole circuit has eight

sets with four NMOS and one operational amplifier.

About the modified voltage divider, V

O

is given

by equation 1. Since R

0

is much lower than R

s

the

equation 2 can be adopted. Thus, V

O

is proportional

to C

S

, which establishes a linear relationship between

applied pressure and V

O

. The noninverting amplifier

provides a gain of 10V/V.

V

O

=

R

0

R

0

+R

S

VCC

(1)

V

O

=

1

R

S

R

0

VCC = C

S

R

0

VCC (2)

MOSFETs form the switching circuit. The

electronic switching that selects the SE of insole

pressure sensor is made by row and column. The rows

and columns are energized when PMOS (null base

voltage) and NMOS (positive base voltage) are turned

on, respectively. Thus, R

S

is selected when both

switches are closed.

The microcontroller ATmega48 (Atmel

Corporation, San Jose, California, USA) triggers both

switches of each data acquisition circuit. It was used

four ports (PD6, PB7, PD5 and PB6) to select the

column, and each port was associated to an NMOS.

To determine the row, four ports (PB0, PB1, PB2

and PB3) act in four inputs of two demultiplexers, and

two ports (PB4 and PD7) enable one of these

demultiplexers. Each one of 32 outputs of

demultiplexers was associated to one PMOS.

Finally, the operational amplifiers provides an

amplified signal for each 10-bit analog to digital

converter (ADC0 to ADC7) of the microcontroller.

In addition to selecting row and column, when the

microcontroller is powered on, three functions are

initialized: ADCs, I/O ports (configured as outputs)

and serial port.

In relation to the serial port, the following

configurations were set: double transmission speed,

data transmission enabled, no parity, asynchronous

communication, one stop bit and word of 8 bits.

Moreover, according to the maximum baud rate of

Bluetooth module (115.2kbps), the baud rate was set

to 111.1kbps (clock of 8MHz).

The Bluetooth module HC-06 (Guangzhou HC

Information Technology Co., Ltd., Guangzhou,

Guangdong, China) transmits data from the

microcontroller to other devices. This module

receives a serial word in its RX port and sends it to

paired devices. The transmission protocol is based on

a start byte (255) followed by a data vector, it being

made the synchronization between the transmitter and

receiver for each start byte.

Entire electronic circuit was mounted on two

double-face printed circuit boards, which also work

as custom-built connector for insole pressure sensor.

A Low Cost Wireless System to Monitor Plantar Pressure using Insole Sensor: Feasibility Approach

209

Two demultiplexers, 32 PMOS and SMD resistors

were mounted in the top board. Bottom board

received the microcontroller, 32 NMOS, four

operational amplifiers and Bluetooth module. Data

acquisition module is powered by one 9V battery.

2.3 Java Application

The software written in Java Programming Language

creates an image corresponding to the applied

pressure in sensor. The BlueCove Application

Programming Interface (API) used allows receiving

data from the data acquisition module. This API is a

Java library for Bluetooth.

This software consists of two main classes. The

PalmilhaThird class contains the main method, which

runs when the software is started. It creates a visible

window that displays the program’s graphic user

interface (GUI) by invoking the constructor of the

second main class, JFrame. JFrame specifies all the

methods and components that will be available in the

program’s GUI. It also has two inner classes:

Bluetooth, which handles Bluetooth communication,

and MainPanel, which creates an image representing

the SEs inside the GUI.

JFrame’s constructor invokes the initComponents

method, which initializes all the components of the

GUI and configures its layout. Among the GUI’s

components, there are buttons that invoke methods.

In the image, which is also a component of the GUI

and is created by the MainPanel inner class, each

pixel represents one SE, and its value and color are

associated with the acquired pressure data, ranging

from white (null pressure) to full intensity red

(maximum pressure). MainPanel calculates the

difference between the SE output value and the

associated reference value. The bigger the difference,

the more intense the red color of the pixel will be.

Using RGB triplet, the colors belong to red scale from

(255,255,255) to (255,5,5), that is, green and blue

intensity values are associated and vary according to

the pressure.

This application reads data provided from the

Bluetooth connection and refreshes the images

(25Hz) simultaneously, because it is composed in

threads. Control of the image’s pixels is performed in

the tmain thread, which is created by the JFrame’s

constructor and runs parallel to the bt thread. This

thread is created using the Bluetooth inner class after

a connection to a Bluetooth device was established.

Bluetooth has methods that perform the search for,

establish and close a connection to Bluetooth devices

(through default password 1234 for Bluetooth module

HC-06), and read the SEs output values. The latter

method saves the output values in a vector, for future

comparison with the reference values, and

implements a protocol to accelerate reception of

repeated bytes, as it was observed that the “zero” byte

is received frequently. In this protocol, if a byte is

repeated more than four times, it’s transmitted as a

sequence of 4 bytes. The first byte holds the flag value

(254), the second holds the value of the repeated byte,

and the third and fourth byte hold the MSB and LSB

of the number of times the value was repeated.

2.4 Workbench Tests for Sensor

Characterization and Verification

of System Performance

First stage of workbench tests was based on applying

30 load levels within one SE of sensor. For each load

values the R

s

was measured by means of a digital

multimeter 17B+ (Fluke Corporation, Everett, WA,

USA), allowing to observe the relationship between

pressure and R

s

. This activity was repeated five times,

and mean and standard deviation (SD) were

calculated for the R

s

and pressure. The relationship

between the C

s

and the pressure was also established.

According to the position numbering (row,

column) described previously, analyzed SE was (-

26,11H) – region of heel.

This same procedure was performed for complete

system, that is, insole pressure sensor connected to

the data acquisition module and the software that

displays data acquired by means of wireless

connection. Thus, the pressure employed was

associated to the color intensity of graphic element

that represents the SE.

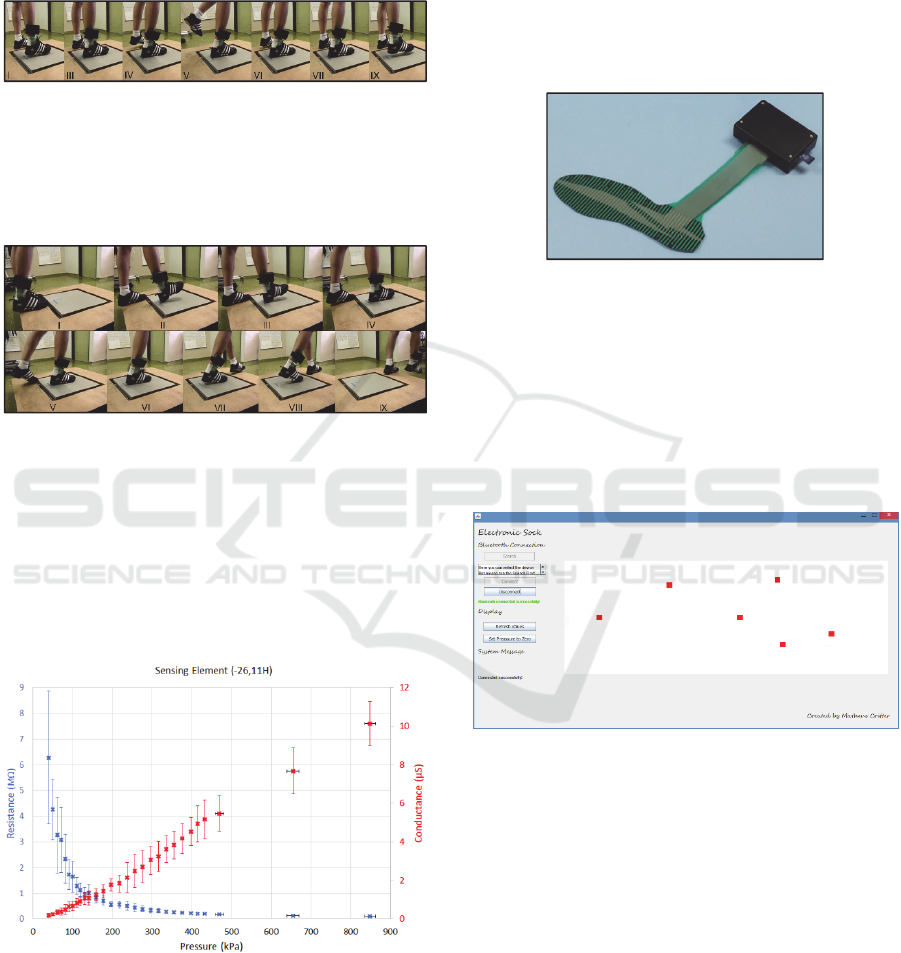

The Biomechanics Platform OR6-7-1000 (AMTI

Advanced Mechanical Technology, Inc., Watertown,

MA, USA) was used to verify the system

performance (Figure 5). This equipment presents a

sample rate equals to 240samples/s and all data are

processed by low pass filter (10.5Hz).

Figure 5: Biomechanics Platform – sign convention for the

force and moment components defined by AMTI.

A healthy subject fixed the data acquisition

module on his right leg by Velcro strap and placed the

insole sensor pressure in the right footwear. Firstly,

the load due to subject’s body mass was measured.

The verification of system performance was based

on two activities (static and dynamic). During static

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

210

activity, the subject transferred his load from the left

lower limb to the right, and returned to the initial

position; nine load levels (Fz) were considered.

Figure 6 shows 7 positions of the subject related to

this activity.

Figure 6: Subject performing static activity.

The dynamic activity was based on a step on the

platform (Figure 7). The moment applied on the Y-

axis (My) was considered to verify the transfer of the

load from the heel to the toes of the right foot.

Figure 7. Subject during dynamic activity.

3 RESULTS

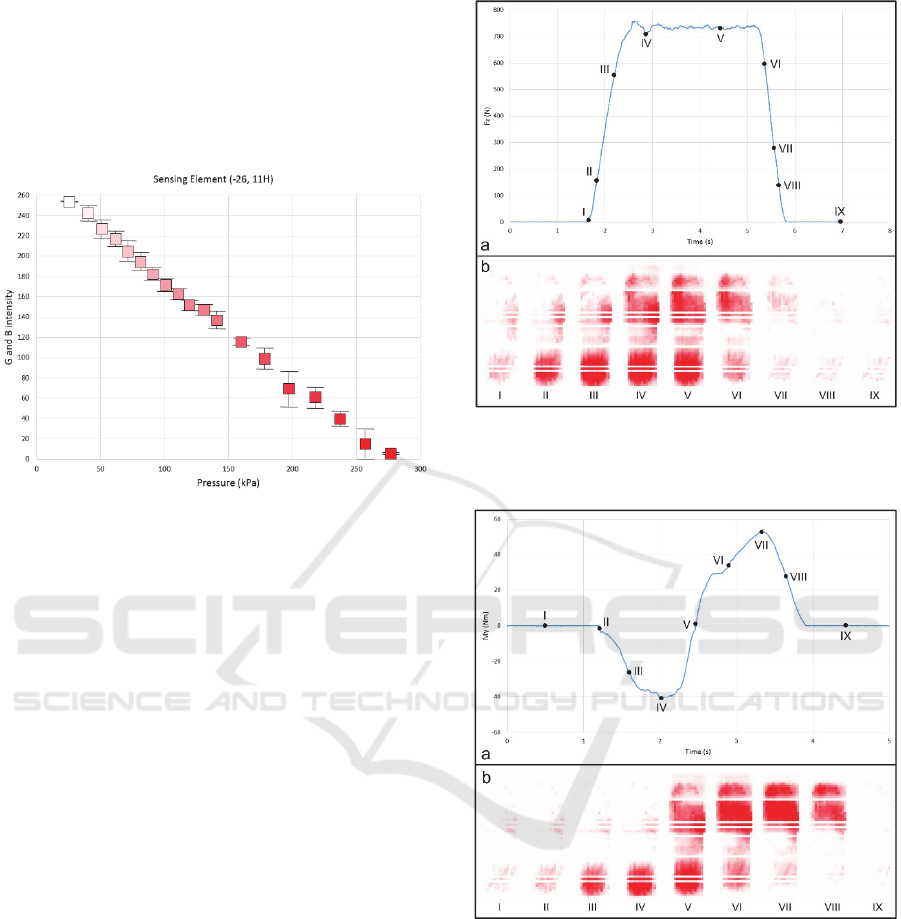

Using 100/70 Rule, the SE presented a very high R

s

to zero pressure, allowing it to be considered as an

open circuit. Thus, the C

s

becomes zero. Figure 8

shows the relationship between applied pressure and

R

s

and C

s

.

Figure 8: Characterization of SE in relation to applied

pressure and R

s

and C

s

.

For a better visualization of the other points, the

first point associated with the pressure 25.7(0.4)kPa

was not included in the graph. The respective values

of R

s

and C

s

were 24.7(14.4)MΩ and 0.06(0.05)μS.

Figure 9 shows the wearable device composed by

the data acquisition module with Medical Sensor

3000 embedded in it. The data acquisition module,

which has small dimensions (120x80x33mm) and

low weight (160g and 205g with battery), is fixed to

the user’s leg by a strap and the sensor is inserted into

the footwear during the plantar pressure mapping.

This device consumes up to 42mA and it may be used

bilaterally.

Figure 9: Wearable device: data acquisition module and

Medical Sensor 3000 (215g).

Bluetooth module HC-06 kept the connection up

20m even with two wooden walls between the

transmitter and receiver, without data loss.

In addition to the area intended for the insole

pressure sensor representation, the front panel of Java

application presents buttons related to the Bluetooth

connection and displayed data (Figure 10).

Figure 10: Front panel of Java application showing five

saturated SEs (left foot): (-26,11H), (-13,5H), (1,11T),

(8,4T), (9,16T) and (18,14T).

“Search” button allows finding paired devices.

Device services are selected through the password,

and they are listed in the scroll box. The HC-06

service must be selected and the connection is

established through the “Connect” button. Thus,

status message “Bluetooth not connected…”

becomes “Bluetooth connected successfully!”.

“Set Pressure to Zero” button allows the user to

calibrate the system, setting the reference values, and

the “Refresh Values” button to refresh the pixel

values in the image. The “Disconnect” button

disconnects the system from the Bluetooth device.

For complete system, the sensor saturated at

A Low Cost Wireless System to Monitor Plantar Pressure using Insole Sensor: Feasibility Approach

211

296.4(1.9)kPa, that is, the color intensity of graphic

element became bright red (255,5,5) from this value

during the five measures. In figure 11, the marker

represents the graphic element generated by Java

application. Its color was obtained from the mean

(approximated to integer) of the green and blue

intensity values.

Figure 11: Color of graphic element according to the

employed pressure. Mean and SD were approximated to

integer values.

Synchronized data from the Biomechanics

Platform and the wearable device allowed relating the

plantar pressure with the force and the moment for

static and dynamic activities, respectively. Also

synchronized, the camcorder captured the activity

images. For better visualization, all images of right

foot plantar pressure were mirrored.

As a reference value, the load due to subject’s

body mass resulted in 735.2N applied on Z-axis (Fz)

of Biomechanics Platform. This value was achieved

during static activity, as shown in figure 12 (points IV

and V).

Point I indicates initial contact of right foot with

the platform. The points II and III show the

progressive loading up to the full contact, indicated

by the baseline (points IV and V). In contrast, points

VI, VII and VIII characterize the process of unloading

up to no contact between the foot and the platform

(point IX).

For the step on the platform, the plantar pressure

was associated with applied moment on Y-axis (My).

According to the figure 13, the heel strike occurred in

point II; from there, the pressure applied by heel

increased up to the maximum value (point IV). After

this, the pressure began to be distributed, achieving

the foot flat phase (point V).

Figure 12: Load transfer from the left lower limb to the

right: a) Force measured by Biomechanics Platform; b)

Plantar pressure detected by the wearable device.

Figure 13: Load transfer from the heel to the toes: a)

Moment measured by Biomechanics Platform; b) Plantar

pressure detected by the wearable device.

Following this phase, the pressure exerted by the

heel decreased, while the pressure of the toes and

metatarsal region increased, characterizing the

transfer of the load (points VI and VII). The point

VIII showed the foot on heel off phase – on the verge

of toe off phase.

Points I and IX demonstrated the plantar pressure

for the foot at the limit of no contact and in swinging,

respectively.

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

212

4 DISCUSSION

The apparatus built for characterization of the SE

allowed application of loads with high repeatability

up to about 480kPa, as showed in figure 8. Thus, it

can be considered an effective tool for this pressure

range because the SE practically reached the

saturation at this value, although the manufacturer

informs that the pressure capacity is 850kPa (Medical

Sensor 3000).

Considering the mean values, the relationship

between R

s

and pressure is a power function with a

negative exponent. Moreover, a linear fitting is

suitable to the relationship between C

s

and pressure,

facts that are in agreement with the manufacturer and

other studies about flexible pressure sensors

(Yaniger, 1991; Kalamdani, Messom and Siegel,

2006; Flexiforce® Force Sensor Design &

Integration Guide, 2015).

The analysis of the SE showed that for low

pressures, the repeatability of R

s

is poor. According

to the manufacturer, this behavior can be attributed to

the use of a standard multimeter, since most do not

provide a constant voltage. Woodburn and Helliwell

(1996) also reported poor repeatability of the sensor.

This feature has become better from 150kPa.

However, the data acquisition module uses the C

s

,

which presents opposite behavior in relation to R

s

, to

determine the output of electronic circuit. Thus,

repeatability and linearity can be attributed to the

complete system, being confirmed by the results

obtained in workbench tests (Figure 11).

In relation to modified voltage divider, the

transistors used presents low electrical resistance (up

to about 8Ω), when they operate like closed switch.

This value is much lower than R

s

, not interfering in

the performance of the circuit. R

aux

was employed to

ensure rapid discharge of transistor drain voltage,

avoiding interference between adjoining SEs.

The design and development of the entire graphic

platform for visualization and data acquisition also

follows the porting concept. Therefore, the software

for interface and Bluetooth connection was

implemented in Java Programming Language, which

is able to execute the same procedure on different

operating systems (e.g. Windows, Linux). This

feature occurs because Java applications run in a

virtual machine.

The library swing allowed the implementation of

the GUI to display the insole pressure area and to

control the Bluetooth connection. Although swing is

one of the most extensive libraries, its classes and

methods also guarantee compatibility among

computers with different screen resolutions, keeping

the high level of porting both for the execution and

for the visualization of the experiments.

It is important to mention that unlike swing, the

BlueCove is not inherent in the Java development

platform. This library is originally an Intel research

project for Bluetooth communication and it is

currently maintained as an open-source project. In

addition, the computer, which runs the application,

must have Bluetooth capabilities, such as the

hardware and driver installed correctly.

About verification of performance through

activities realized by subject, the system was effective

to characterize the foot pressure applied during both

conditions.

For static activity, the system presented rapid

response, identifying a variation of about 700N in 1s,

with intermediate values also characterized (Figure

12, points I, II, III and IV). In addition, the system

represented the load transfer from the left lower limb

to the right in an appropriate manner. At the moment

that the load was fully applied to the right limb, the

system indicated a higher pressure in the region of the

fifth metatarsal (Figures 6 and 12, point IV). When

the position of the subject was stabilized, the pressure

was distributed throughout the metatarsal region and

the hallux (Figures 6 and 12, point V).

The dynamic activity can be considered a partial

gait cycle, and some phases are identified through

pressure distribution pattern. Considering the right

lower limb, the subject performed the stance phase of

the gait cycle. According to the figures 7 and 13, point

II marks the initial contact (heel strike) and loading

response phase includes point V (foot flat). Midstance

is related to point VI, being followed by the terminal

stance. In this phase occurs heel off (point VIII), and

the stance phase is finished with preswing (toe off).

Finally, the range of pressure measured by the

system is suitable for many applications, e.g., the

mean value of plantar pressure during walking is

140kPa (Keijsers, 2013).

5 CONCLUSIONS

In this paper, the development and application of a

system to monitor plantar pressure based on a

wearable device were described. According to the

preliminary results, this system is effective to show

the interaction between the foot and floor in static and

dynamic conditions, like standing and walking,

respectively. Thus, this system is a feasible auxiliary

tool for clinical, orthopaedics and rehabilitation

analysis. Low cost, high resolution insole flexible

pressure sensor, easy wearability, no discomfort,

A Low Cost Wireless System to Monitor Plantar Pressure using Insole Sensor: Feasibility Approach

213

wireless data transfer, software porting and real-time

visualization of pressure mapping are outstanding

features of this device in relation to other self-

constructed and commercial systems. However, the

sensor is sensitive to temperature and it is necessary

to disassemble the data acquisition module to change

the sensor, e.g., to use a sensor with other size.

ACKNOWLEDGEMENTS

We thank the support by grants from São Paulo

Research Foundation (FAPESP) and National

Council for Scientific and Technological

Development (CNPq).

REFERENCES

Bellizzi, M., Rizzo, G., Bellizzi, G., Ranieri, M., Fanelli,

M., Megna, G. and Procoli, U. (2011), Electronic

baropodometry in patients affected by ocular torticollis,

Strabismus, vol. 19, pp. 21–25.

Castro, M. C. and Cliquet, A. Jr. (2000), Artificial

sensorimotor integration in spinal cord injured subjects

through neuromuscular and electrotactile stimulation,

Artif Organs, vol. 24, pp. 710–717.

Chapman, J. D., Preece, S., Braunstein, B., Höhne, A.,

Nester, C. J., Brueggemann, P. and Hutchins, S. (2013),

Effect of rocker shoe design features on forefoot plantar

pressures in people with and without diabetes, Clin

Biomech, vol. 28, pp. 679–685.

Crea, S., Donati, M., De Rossi, S. M., Oddo, C. M. and

Vitiello, N. (2014), A wireless flexible sensorized

insole for gait analysis, Sensors, vol. 14, pp. 1073–

1093.

Flexiforce® Force Sensor Design & Integration Guide,

Tekscan, Inc., 2015.

Girard, O., Eicher, F., Micallef, J. P. and Millet, G. P.

(2010), Plantar pressures in the tennis serve, J Sports

Sci, vol. 28, pp. 873–880.

Hills, A. P., Hennig, E. M., McDonald, M. and Bar-Or, O.

(2001), Plantar pressure differences between obese and

nonobese, Int J Obes Relat Metab Disord, vol. 25, pp.

1674–1679.

Hsiao, H., Guan, J. and Weatherly, M. (2002), Accuracy

and precision of two in-shoe pressure measurement

systems, Ergonomics, vol. 2, pp. 537–555.

Keijsers, N. (2013), The Science of Footwear, R. S.

Goonetilleke, Ed. Boca Raton, USA: CRC Press.

Kaercher, C. W., Genro, V. K., Souza, C. A., Alfonsin, M.

Berton, G. and Filho J. S. C. (2011), Baropodometry on

women suffering from chronic pelvic pain – a cross-

sectional study, BMC Womens Health, vol. 11.

Kalamdani, A., Messom, C. and Siegel, M. (2006), Tactile

sensing by the sole of the foot part II: calibration and

real-time processing, Proceedings of 3rd International

Conference on Autonomous Robots and Agents.

Koch, M., Lunde, L. K., Ernst, M., Knardahl, S. and

Veiersted, K. B. (2016), Validity and reliability of

pressure-measurement insoles for vertical ground

reaction force assessment in field situations, Applied

Ergonomics, vol. 53, pp. 44–51.

Ledoux, W. R., Shofer, J. B., Cowley, M. S., Ahroni, J. H.,

Cohen, V. and Boyko, E. J. (2013), Diabetic foot ulcer

incidence in relation to plantar pressure magnitude and

measurement location, J Diabetes Complications, vol.

27, pp. 621–626.

McPoil, T.G., Cornwall, M.W. and Yamada, W. (1995), A

comparison of two in-shoe plantar pressure

measurement systems, Lower Extremity, vol. 2, pp. 95–

103.

Medical Sensor 3000 data sheet, Tekscan, Inc., Boston,

USA.

Melvin, J. M. A., Preece, S., Nester, C. J., and Howard, D.

(2014), An investigation into plantar pressure

measurement protocols for footwear research, Gait

Posture, vol. 40, pp. 682–687.

Motha, L., Kim, J. and Kim, W. S. (2015) Instrumented

rubber insole for plantar pressure sensing, Organic

Electronics, vol. 23, pp. 82–86.

Podoloff, R. M., Benjamin, M. H., Winters, J. and Golden,

R. F. (1991), Flexible tactile sensor for measuring foot

pressure distributions and for gaskets, U.S. Patent 5

033 291.

Price, C., Parker, D. and Nester, N. (2016), Validity and

repeatability of three in-shoe pressure measurement

systems, Gait Posture, vol. 46, pp. 69–74.

Robinson, C. C., Balbinot, L. F., Silva, M. F., Achaval, M.

and Zaro, M. A. (2013), Plantar pressure distribution

patterns of individuals with prediabetes in comparison

with healthy individuals and individuals with diabetes,

J Diabetes Sci Technol, vol. 7, pp. 1113 – 1121.

Saito, M., Nakajima, K., Takano, C., Ohta, Y., Sugimoto,

C., Ezoe, R., Sasaki, K., Hosaka, H., Ifukube, T., Ino,

S. and Yamashita, K. (2011), An in-shoe device to

measure plantar pressure during daily human activity,

Med Eng Phys, vol. 33, pp. 638–645.

Smith, B. T., Coiro, D. J., Finson, R., Betz, R. R. and

McCarthy, J. (2002), Evaluation of force-sensing

resistors for gait event detection to trigger electrical

stimulation to improve walking in the child with

cerebral palsy, IEEE Trans Neural Syst Rehabil Eng,

vol. 10, pp. 22–29.

Tan, A. M., Fuss, F. K., Weizman, Y., Woudstra, Y. and

Troynikov, O. (2015), Design of low cost smart insole

for real time measurement of plantar pressure, Procedia

Technology, vol. 20, pp. 117–122.

Test & Measurement - Impossible Insights Made Possible

Through Minimally Invasive Force & Pressure

Measurement, Tekscan, Inc., 2014.

Woodburn J. and Helliwell, P. S. (1996), Observations on

the F-Scan in-shoe pressure measuring system, Clin

Biomech, vol. 11, pp. 301–304.

Yaniger, S. I. (1991), Force sensing resistors: a review of

the technology, Electro. Int., pp. 666–668.

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

214