A Dwell Time-based Container Positioning Decision Support System

at a Port Terminal

Myriam Gaete G.

1

, Marcela C. González-Araya

2

, Rosa G. González-Ramírez

3

and César Astudillo H.

4

1

Programa de Magíster en Gestión de Operaciones, Facultad de Ingeniería, Universidad de Talca,

Camino a Los Niches km 1, Curicó, Chile.

2

Department of Industrial Engineering, Faculty of Engineering, Universidad de Talca,

Camino a Los Niches km 1, Curicó, Chile.

3

Facultad de Ingeniería y Ciencias Aplicadas, Universidad de Los Andes,

Mons. Álvaro del Portillo 12.455, Las Condes, Santiago, Chile.

4

Departamento de Ciencias de la Computación, Facultad de Ingeniería, Universidad de Talca,

Camino a Los Niches km 1, Curicó, Chile

Keywords: Container Terminal, Container Storage Policies, Dwell times, Stacking Strategies.

Abstract: In this article, a methodology as well as a decision support system for the container storage assignment at a

yard of a container terminal is proposed. The motivation of the proposed methodology are the cases of

container terminals where inland flows present high levels of uncertainty and variability. This situation is

typical of ports in developing countries such as is the case in Latin America where due to lack of automation,

there are many paper-based procedures and little coordination with the hinterland. The proposed methodology

is based on a dwell time segregated storage policy, considering only import containers (due to the difficulty

to determine segregation criteria for this type of containers). Dwell times are discretized in order to determine

dwell time classes or segregations, so that containers of the same segregation are assigned to close locations

at the yard. As a case study, the port of Arica in Chile is considered. A discrete-event simulation model is also

proposed to estimate potential benefits of the proposed methodology. Numerical results for the case study

show a good performance, with potential reduction of the rehandles incurred.

1 INTRODUCTION

World container port throughput increased by an

estimated 5.1% to 651.1 million TEUs (twenty-foot

equivalent units) in 2013 and global containerized

trade was projected to grow by 5.6% in 2014

(UNCTAD, 2014). Maritime ports are strategic nodes

on the international logistic chain whose current role

goes beyond the traditional functions of transferring

cargo to a more active participation and promotion of

value-added services to the port stakeholders. Ports

can be conceptualized from a logistics and supply

chain management approach and under this vision the

traditional port system is extended to an “integrated

channel management system” where the port is a key

location linking different flows and channels with the

port community (Bichou and Gray 2004). In this

context, efficient cargo handling operations are

essential, as new value-added services, as well as

better service levels, agility and predictability are

demanded by the users of the port. The productivity

of a container terminal is related to an efficient use of

labor, equipment and land, and is commonly

measured as a function of the ship turnaround time,

the transfer rate of containers and the dwell times of

the cargo at the port (Dowd and Leschine 1990; Doerr

and Sánchez, 2006; Chung, 1993).

At the port, the yard can serve as a buffer between

the arrival and departure of temporarily stored cargo

which is later loaded on a ship or dispatched to

external carriers. The efficiency of the operations at

the yard significantly impact ship turnaround times so

adequate container storage space assignment policies

and yard equipment planning are needed. In addition,

minimizing port dwell times is one of the main

objectives from the perspective of the shippers in the

port supply chain (Lee et al. 2003).

128

Gaete G. M., C. Gonzà ˛alez-Araya M., G. Gonzà ˛alez-Ramà rez R. and Astudillo H. C.

A Dwell Time-based Container Positioning Decision Support System at a Port Terminal.

DOI: 10.5220/0006193001280139

In Proceedings of the 6th International Conference on Operations Research and Enterprise Systems (ICORES 2017), pages 128-139

ISBN: 978-989-758-218-9

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Coordination of landside operations at a container

terminal is not straightforward in ports in developing

countries where there are important challenges in

terms of infrastructure development, technology

implementation and paper-based documental

procedures. Latin American and Caribbean (LAC)

ports have seen an important increase in their

participation in world foreign trade. This growth has

put pressure on the freight distribution systems that

need to develop better logistics capabilities

(Rodrigue, 2012).

In this article, the problem of defining a container

storage space allocation policy for import containers

is addressed by considering the case of a container

terminal that faces a high level of uncertainty in the

dispatching process of import containers. This

uncertainty is mainly explained by the lack of

coordination mechanisms with the hinterland, a

situation that can be very common at ports in

emerging countries.

The assignment of space at the yard for export

containers is not considered in this article. The reason

is that yard planners of container terminals have

general criteria to group export containers into

segregations (e.g., vessel, port of destination, weight,

etc.), while for import containers is more difficult to

determine. This is explained as the time in which the

containers are retrieved depends on the different

consignees of the cargo (importers) and the fulfilment

of all the procedures, resulting in more uncertainty. In

contrast, export containers are loaded to a single

vessel at the container terminal.

During the dispatching of an import container, it

is possible that other containers may be blocking the

container and should be removed to be able to reach

the required container. These non-value added

movements are refereed as “rehandles” or

“reshuffles” of containers. Rehandles represent a high

cost with no value for the container terminal, and

increase the truck turnaround times of the external

trucks at the container terminal, generating

congestion and affecting service levels of to the users

of the container terminal.

In order to assign a storage space for the import

containers in the yard, a dwell time segregated storage

policy is proposed. In this case, segregations of

import containers are defined based on dwell time

intervals, and containers of the same segregation are

assigned to close locations. The aim is to reduce

potential container rehandles at the moment that they

are retrieved from their locations at the yard. Hence,

containers with the same interval of dwell time

located at close positions in the yard, may incur in less

rehandles. In order to estimate dwell times of import

containers, classification algorithms are employed.

This is justified as the results of the estimations are

used to define import container groups based on dwell

time ranges so the precise values of the predicted

dwell times are not needed. In addition, the design of

a decision support system for the assignment of

storage space to import containers is proposed. The

aim is to assist the yard planner with a tool that may

be inter-connected with the Terminal Operator

System (TOS) of the container terminal.

As a case study, the container terminal at the port

of Arica in Chile is considered. High levels of

uncertainty for import container dispatching as well

as long dwell times are observed in the container

terminal due to the type of cargo handled; around

70% of the cargo is in-transit from Bolivia. The

political agreement between Chile and Bolivia

establishes special conditions for the in-transit cargo

where no storage fee is charged. The current practice

of the yard managers is to assign space to containers

in a semi-random fashion where containers are

located at the yard considering only the space

utilization rules that have been set to avoid unutilized

space.

In order to validate the methodology proposed in

a stochastic environment, a discrete-event simulation

model was implemented, to determine the potential

impacts in terms of rehandles of containers when are

retrieved to be dispatched to external transport

carriers.

The article is structured as follows: Section 2

presents a literature review, Section 3 describes the

methodology employed and the proposed dwell time

segregated storage policy. Section 4 presents the

architecture and components of the decision support

system for the storage space assignment of import

containers. Section 5 presents the case study as well

as the simulation model to estimate the benefits of

using the proposed support system to assign storage

space to import containers. Conclusions and

recommendations for further research are provided in

Section 6.

2 LITERATURE REVIEW AND

BACKGROUND

2.1 Main Contributions Related to

Dwell Time Estimations in the

Literature

Carlo et al., (2014) presents a review on storage yard

operations at container terminals, providing an

A Dwell Time-based Container Positioning Decision Support System at a Port Terminal

129

overview, trends and research directions. Several

contributions have been proposed, both from the

perspective of the design of the layout of the yard,

storage space policies and stacking algorithms. In

this section, we focus the attention on reviewing the

main contributions to dwell time estimations in the

literature, which is more related to port terminal

capacity and the storage space policies of the port

terminal.

Port terminal capacity is defined as the amount of

cargo that can be handled by a port per time period

(Bassan 2007). The first contributions related to

capacity analysis at the yard of a Container Terminal

are presented by (Dally 1983; Hoffman 1985;

Dharmalingam 1987), where storage capacity at the

yard is estimated as a function of container dwell

times, the number of stacking containers, and the

container storage space available expressed in TEUs,

among other factors.

Determining the factors that influence port choice

and port competitiveness is another research avenue

where cargo dwell times are identified as an

explanatory variable (De Langen 2007; Nir et al.

2003; Tongzon and Sawant 2007; Veldman and

Bückmann 2003). Arvis et al. (2010) identify dwell

time as a factor that directly affects operational costs

in the ports as it increases inventory levels and

uncertainty in the dispatching process. On the other

hand, dwell times have also been identified as an

element of port competiveness and a factor in port

choice related decisions (Magala and Sammons

2008).

From a macro-economic perspective, the impact

of port delays at Puerto Limón in Costa Rica, over the

regional economy in Central America is estimated in

(USAID, 2015). They conclude that reducing port

inefficiencies, such as long dwell times of cargo at the

ports, may improve the GDP (Gross Domestic

Product) of Costa Rica by about 0.5%. Djankov et al.

(2006) employed a gravity model to estimate the

impact that each additional day required for

dispatching cargo may have on the GDP. The

unproductive movements undertaken during quay

transfer operations are quantified by Chen et al. 2000.

They identify storage density as a factor of

unproductive movements during ship loading and

unloading operations. This refers to the number of

containers stacked in the yard and the ground slots

used for storage. Furthermore, their results show that

housekeeping moves represent the majority of

unproductive moves undertaken.

Merckx (2005) estimates dwell time impact on the

capacity of a terminal based on a sensitivity analysis,

considering five scenarios with different dwell times

and container types. The interaction among the

terminal operators and the users of the port (e.g.

importers/exporters, freight forwarders) is analyzed

by Rodrigue and Notteboom (2009) and they

conclude that the relationship and collaboration levels

could impact container dwell times at the port.

An analysis of dwell times at ports in Sub-Saharan

Africa is presented by Raballand et al. (2012). Main

findings highlight that dwell times are abnormally

long, more than 2 weeks, and also show an abnormal

dispersion which increases the inefficiencies of port

operations and, in consequence, total logistic costs.

Beuran et al. (2012) provide an analysis of the causes

of these long dwell times from the shipper

perspective, discovering the crucial importance of

private sector practices and incentives.

Moini et al. (2012) analyze the factors that

determine container dwell times in a port, employing

three data mining algorithms: (i) Naive Bayes

Algorithm (Kononenko 1990), (ii) Decision Tree

C4.5 (Quinlam 1986) and (iii) The Hybrid Bayesian

decision tree (Kohavi 1996). Estimation results are

compared in terms of four indicators: accuracy, the

Kappa coefficient, RSME and execution times. In

order to evaluate the results they provide a simulation

under different scenarios with the results obtained.

An important difference with respect to the work

presented herein, is that the authors do not use the

results to estimate container storage assignment

policies. In addition, the data mining algorithms also

differ from those proposed in this article.

Another contribution of the work presented here,

is the discretization of a continuous variable (dwell

time) for its prediction, justified by the fact that the

results are employed as criteria to segregate import

containers and assign storage space according to this

policy. In contrast, Moini et al. (2012) do not employ

classification algorithms in their approach, which is

reasonable as their aim is not to determine storage

space policies which is an important difference with

respect to the work presented here. Finally, another

contribution of this work is the simulation proposed

model that aims to measure the impact of different

storage policies in terms of the number of rehandles

incurred when containers are dispatched to external

carriers. It is important to point out that in the

literature there is no approach proposed in which the

input data of a simulation model consists of the results

obtained by the classification algorithms for dwell

time estimation.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

130

2.2 Determinant Factors of Dwell

Times

Table 1: Main Determinant Factors of Dwell Time.

Factor

Reference

Type

Frequency of the

sailing schedules

of the vessels

Merckkx (2005),

Moini et al. (2012)

Unique Value

Type of container

(e.g., empty/full,

dry/reefer, etc.),

size (20/40 TEUs)

and its contents

Merckkx (2005),

Moini et al. (2012)

Nominal

Modal split of

hinterland

connections

Merckkx (2005),

Moini et al. (2012)

Unique Value

Port Governance

and structure

Merckkx (2005),

Moini et al. (2012)

Unique Value

Location of the

Port Terminal and

the main products

(or logistic chains)

that are transferred.

Merckkx (2005),

Moini et al. (2012)

Unique Value

Terminal working

hours and business

days

Merckkx (2005),

Rodrigue and

Notteboom (2009),

Moini et al. (2012)

Unique Value

Shippers and

consignee

Rodrigue and

Notteboom (2009),

Moini et al. (2012)

Nominal

Inspections and

regulatory

procedures

Moini et al. (2012)

Unique Value

Transport corridors

Moini et al. (2012)

Nominal

Ocean carriers or

Maritime Shipping

Company and the

demurrage time for

the empty

containers

Moini et al. (2012)

Nominal

Container flow

balance (export

and import)

Moini et al. (2012)

Nominal

Freight

Forwarder/Broker

and Third Party

Logistics Company

(3PL)

Moini et al. (2012)

Nominal

The main factors considered in the literature as dwell

time determinants are presented in Table 1. The

factors are divided into two groups: unique value and

nominal value. Factors with a unique value are those

that may have a unique value at each port and this

value does not vary as a function of the cargo

transferred at the port (i.e., the frequency on the

itineraries, the location of the port terminal, etc.). This

type of factor is not considered as the results for

predicting dwell time are employed for container

space allocation policies and this is influenced by the

amount of cargo handled. On the other hand, nominal

and numerical factors correspond to factors that vary

as a function of the cargo handled, where nominal

factors are represented by strings and numerical

factors by a number. For instance, a nominal factor is

related to the name of the importer or exporter, while

the weight of a container is a numerical factor.

3 METHODOLOGY

DESCRIPTION

The dwell time segregated storage space policy is

based on generating segregations of import containers

based on dwell time intervals. In this way, containers

of the same segregation are those whose dwell time is

predicted to be at the same interval. In order to

determine the dwell time classes and estimate the

potential impact of the proposed storage space policy,

the proposed methodology is described as follows in

Table 2.

Table 2: General Methodology.

DWELL TIME BASED STORAGE SPACE POLICY

CALIBRATION

INPUT: Data Base with Historical Data on the arrival and

departure time of import containers

1. STAGE 1: Dwell time prediction by classification

algorithms

1.1. Class definition as a function of time intervals in order to

discretize the dwell time numerical variable.

1.2. Application and validation of the classification

algorithms based on a predictive model.

1.3. Identification of the interrelation among the dwell time

measure units based on a multi-classifier generation.

1.4. Performance evaluation of the classification algorithms.

2. STAGE 2: Dwell time segregated storage policy

implementation and evaluation

2.1. Segregate containers based on the dwell time classes

obtained in Stage 1.

2.2. Run the simulation model for a set of instances, testing

the performance in terms of the number of rehandles

when containers are retrieved. Compare results with

alternative storage policies that may resemble the current

practice of the container terminal under study.

Output: Policy and impact estimation if dwell-time

segregated policy is implemented.

3.1 STAGE 1: Dwell Time Prediction

by Classification Algorithms

As observed in Table 2, the first stage consists of

applying classification algorithms to predict dwell

times. For this, it is necessary to have a data base with

historical data about the containers’ arrival and

departure times at the yard. Step 1.1 is related to the

class interval definition. We consider that the classes

A Dwell Time-based Container Positioning Decision Support System at a Port Terminal

131

may be measured in three time units: hour, day and

week. Table 3 presents a more detailed description of

Step 1.2.

For the sample size definition, the formula to be

used is provided by Cochran (1986), in which the size

of the population is assumed to be an input data. For

the classification model, different classification

algorithms can be evaluated according to the specific

characteristics of the container terminal under study.

In addition, Step 1.3 consists of the definition of the

multi-classifier to determine the inter-relations

among different dwell time measure units. Step 1.4

consists of an evaluation of the results obtained by the

different classification algorithms. Four performance

metrics are considered: (i) the number of instances

classified correctly, (ii) the Kappa coefficient, (iii) the

computational time and (iv) the mean squared error in

time units (Witten et al. 2011).

Table 3: Classification algorithms based on a predictive

model.

Step 1.2 Classification algorithm application and

validation

INPUT: Data base with historical data on the arrival and

departure times of import containers

1. Sample size definition

2. Random sample of instances

3. Definition of the classification model

4. Evaluation of the classification model

5. Estimation of the prediction error

Output: Dwell time predictions.

3.2 STAGE 2: Dwell Time Segregated

Storage Policy Implementation and

Evaluation

A common practice of terminal operators is to assign

space to containers at the yard based on segregations.

In order to determine segregations of import

containers based on dwell time intervals, the

predicted dwell times and intervals found in stage 1

(see Table 2) are employed for an instance of the

container terminal under study. Then, a real time

stacking heuristic for locating the import containers

in each dwell time segregation is defined, so that

containers of the same segregation may be assigned

to close locations with the aim of reducing rehandles

when containers are retrieved.

In order to evaluate the benefits of implementing

the policy at the yard, a discrete event simulation

model is also proposed, in which the dwell-time

storage space policy is implemented to define the

location of the import containers at the yard. The

dispatching process of the import containers to

external carriers is also simulated in order to count the

number of rehandles incurred. More details will be

provided at section 5 with the case study.

4 DECISION SUPPORT SYSTEM

FOR THE ASSIGNMENT OF

STORAGE POSITIONS TO

IMPORT CONTAINERS

This section details the architecture of a decision

support system for the container position assignment

at the yard of a container terminal. The aim of the

system is two-fold: First, we enhance the capabilities

of the TOS with a module that predicts the dwell time

based on historical data. Second, we take advantage

of that prediction in order to suggest an explicit

storage location for the container under scrutiny.

When an import container is unloaded from the

vessel and is transported to the yard, the yard planner

examines the container and faces the decision of

where to store it. The yard planner uses the proposed

system to estimate the dwell time based on

characteristics associated to the container and

historical information of other containers stored in the

yard. As opposed to expert intuition, this estimation

can be used to make an informed decision. If the yard

planner desires, the system can suggest a specific

storage location for the container.

When a container is assigned to a particular

storage slot at the yard, it is stored until requested by

the consignee. There are some cases in which the

container may be relocated because it is blocking the

access to the yard crane to retrieve another container.

These movements are also referred as rehandles. One

of the objectives of the yard planner, is to reduce the

number of rehandles or relocations of containers, as

these are non-value movements that generate

additional costs and waiting times.

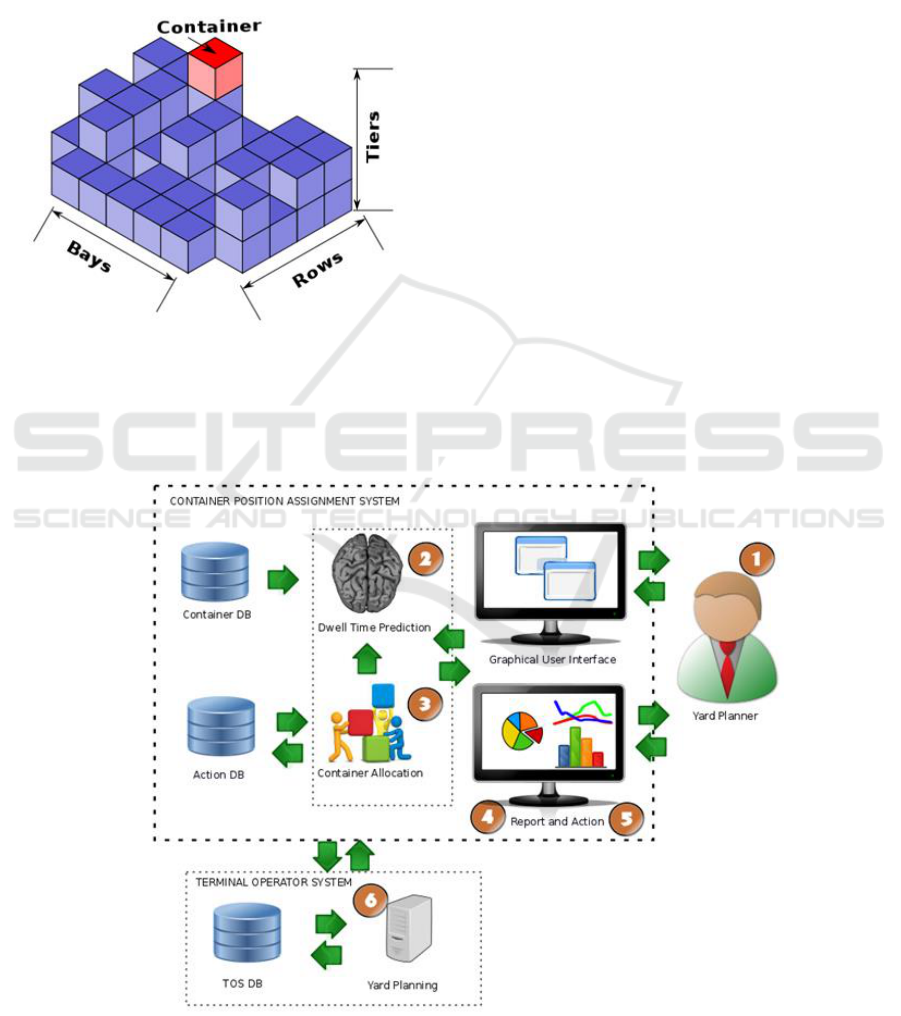

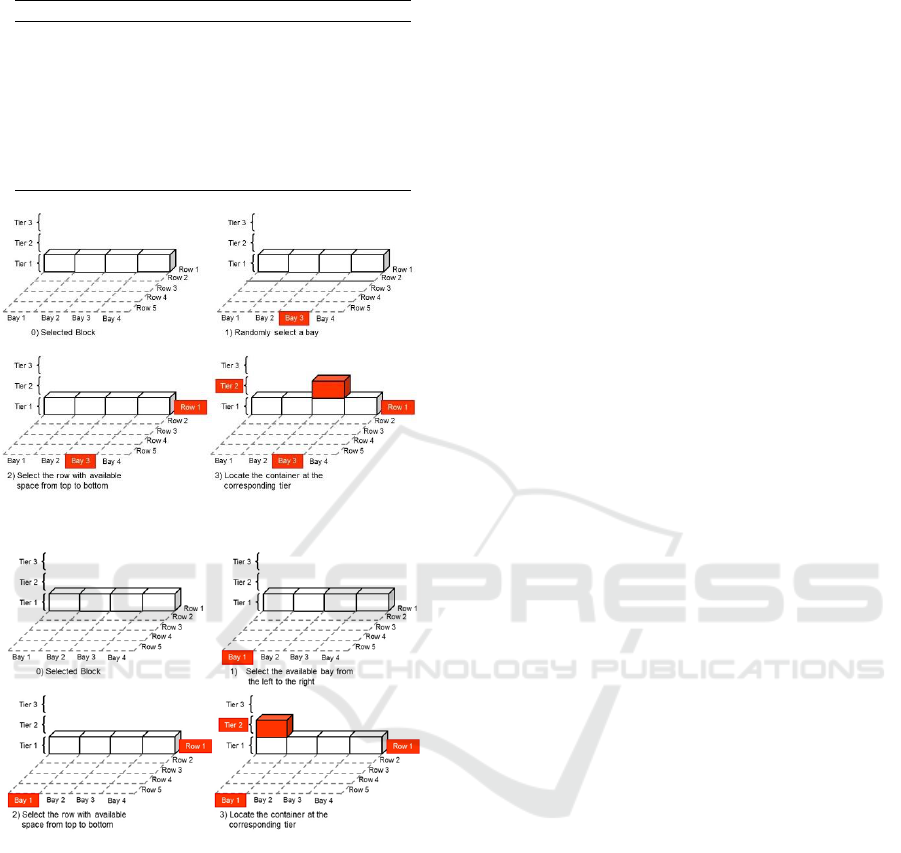

The storage space at the yard is organized as a

three dimensional matrix ordered in bays, columns

and rows (see Figure 1 for a pictorial reference). This

abstract representation is convenient for maintaining

an internal representation of the current state of the

storage space. It is possible to define algorithmic

operations for assigning a slot to a container,

requesting the coordinates of a particular container,

and analyzing if there is more containers on top of the

requested item (i.e., a container), and so on.

In order to explain the details of our proposed

architecture, we will describe a sequence of temporal

events and the relationship with each particular

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

132

module of the system. Figure 2 depicts the software

architecture for the above-mentioned decision

support system. This system is constituted by one

main module that is connected to the TOS. The TOS

corresponds to a software suite designed to manage

the resources of the container terminal and it can be

an in-house developed software or a generic

commercial product (e.g.,Navis N4 TOS).

Figure 1: BAROTI System.

The whole process begins when the import

container arrives to the port. At that moment, the yard

planner accesses the graphical user interface (GUI) to

identify the container that must be stored (labelled

with the number 1 in the Figure 2). Then, the system

connects to the TOS, retrieving statistical information

regarding the container such as the name of the

consignee, the service or vessel, type of container,

weight, etc. This information is fed to the predictor

and an estimation for the dwell time is obtained (see

number 2 in the Figure 2). This estimation is made

based on a mathematical model that use the historical

data of containers and dwell time kept in the

Container database. The planner use the dwell time

estimation to decide where to place the container.

Alternatively, the planner may request to the

system a recommendation for the location of the

incoming container to the yard. For this matters, the

system includes a special module that may suggest to

the yard planner, a storage position at the yard (see

label 3 in the Figure 2). The module internally ask for

a dwell time prediction, which is used as the input for

an internal algorithm that outputs a location. This

output location is assumed to be the best option for

storing the current container. The general assumption

is that two containers with a similar dwell time must

be located in neighbouring regions. In contrast, two

containers with a big difference in their dwell times,

are assign to different locations avoiding to interfere

to each other.

Figure 2: Container Position Assignment System architecture.

A Dwell Time-based Container Positioning Decision Support System at a Port Terminal

133

Once the dwell time prediction and/ or the storage

position of each incoming container at the yard have

been determined, the system generated a report with

this information. This report may include a graphical

representation of the yard. In this report, the location

in which the current container must be assigned is

specified (label 4 in the Figure 2). Based on this

information the yard planner may decide whether to

accept to locate the import container in the suggested

position. This action (label 5) is recorded in the

Action Database. Here, our idea is that the learning

system is generating solutions for the problem and the

human expert can validate them as being correct or

wrong, knowledge that can be further exploited to

refine the learning method of the system.

Finally (label 6), the decision made by the yard

planner is communicated to the TOS, which records

the transaction. As a final comment in this matter, we

observe that the architecture is not limited for a single

user. Rather, more than one yard planner may access

the service concurrently, which can be an

advantageous feature, as this information for

instance, could be provided to the yard crane

operators in a mobile device.

5 CASE STUDY: PORT OF

ARICA IN CHILE

The port of Arica, Chile is used in this case study

because it presents a high level of uncertainty in the

import processes and huge container dwell times. The

port of Arica occupies the 43rd position in the Latin

American containerized movements ranking

provided by UN-ECLAC; and the 6th position in the

Chilean port system, with a total of 204,174 TEUs

transferred in 2013 (Doerr 2013). The port consists

of a single multi-purpose terminal whose main

characteristic is that about 70% of the cargo

corresponds to cargo in transit from Bolivia. The port

presents special conditions for cargo handling, due to

the political agreements between Chile and Bolivia, a

reason for which the cargo has no storage fee (exports

for 60 days and imports up to 365 days). Furthermore,

the main hinterland (located in Bolivia) is more than

1000 kilometers away, in contrast with the main

Chilean ports, Valparaiso and San Antonio, whose

main hinterland (Metropolitan Region of Santiago) is

located at 120 kilometers from the ports.

The port of Arica lacks coordination of systems

with the hinterland such as appointment or booking

systems, or electronic data interchange. This fosters

the uncertainty and variability in port operations,

especially for the import processes. Long service

times (truck turnaround times) and container

rehandles are commonly observed. Under this

situation, the current practice of the yard managers is

to assign space to containers in a semi-random

fashion, where containers are located at the yard

considering only very simple rules that maximize

space utilization. A segregation-based policy for

storage space assignment of export containers has

been an efficient strategy for reducing rehandles

incurred when containers are loaded on the vessel.

Segregating export containers is commonly done

based on the vessel´s characteristics and the

corresponding route. These characteristics are

considered when the stowage plan is generated and

hence, rehandles are potentially minimized. In

contrast, the criteria for segregating import containers

are not so straightforwardly determined, especially if

high levels of uncertainty on the dispatching times are

observed.

In this paper a methodology to implement a dwell

time segregated policy for assigning space to import

containers is proposed. The policy considers

segregating containers based on predicted dwell time

intervals. In order to evaluate the different

classification and multi-classification algorithms

employed, the following metrics have been

considered: (i) number of instances correctly

classified, (ii) accuracy, (iii) Kappa´s coefficient; (iv)

the mean squared error; (v) the mean error in time

units” and (vi) the mean error for categorized factors.

A data base with container movements for the

years 2011, 2012 and August 2013 is included, with

a total of 151,640 import containers. Seven factors

were considered: (1) size of the container (20/40), (2)

type of container (Dry, Reefer, High Cube, etc.), (3)

the status of the container (full or empty), (4) weight,

(5) ship where the container is unloaded, (6)

consignee or customer, and (7) the cargo’s port of

origin.

The first four factors correspond to characteristics

of the container. The factors are numerical (size of

container and weight) and nominal (type, status, ship,

port of origin, consignee). The only dual attribute is

dwell time, and the nominal variable consignee has

the largest number of classes (about 5000 to 7000). It

is important to mention that the weight and port of

origin are factors not previously employed in the

literature (see Table 1).

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

134

5.1 Results Obtained with the

Classification Algorithms

For the classification model, non-supervised

classification algorithms were employed as they

allow working with known classes. These algorithms

follow an opposed strategy than supervised

algorithms (Astudillo et al. 2014; Astudillo and

Oommen 2014). This is justified by the fact that

classes are known, since they are determined in the

step 1.1 of the proposed methodology (see Table 1).

The applied offline algorithms are Naive Bayes, Lazy

Learning, and Rules Induction Learning. Table 4

summarizes the classification algorithms evaluated:

Table 4: Classification Algorithms evaluated.

Algorithms

Reference

K nearest neighbors (KNN)

Cover and Hart

(1967)

Naive Bayes (NB)

Kononenko (1990)

One Rule (OneR)

R.C. Holte (1993)

Incremental Reduced Error

Pruning (IREP) or Repeated

Incremental Pruning to

Produce Error Reduction

(RIPPER or JRip)

Fürn Kranz (1994)

K*

Cleary and Trigg

(1995)

Decision Table (DT)

Kohavi (1995)

Zero Rule (ZeroR)

Witten and Frank

(2000)

Dwell times were measured in days, as this is the

commonly used time unit in port Terminals. The year

2011 data was used to generate the model and the

2012 data was used to evaluate it. Data for 2013 was

used only for the simulation model described in

section 4.2. The algorithms were implemented in

JAVA version 1.6.0_25, using the software WEKA

(Waikato Environment for Knowledge Analysis) in a

personal computer with a processor Intel Core 7, and

8 GB of RAM.

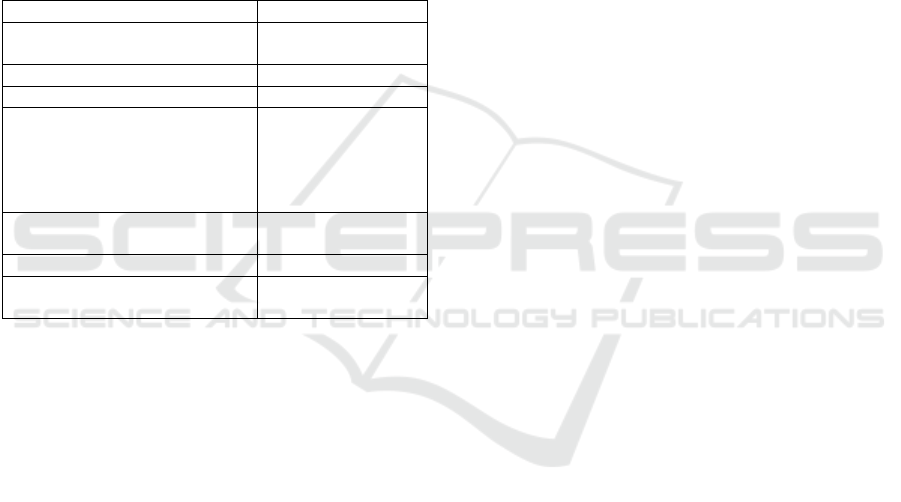

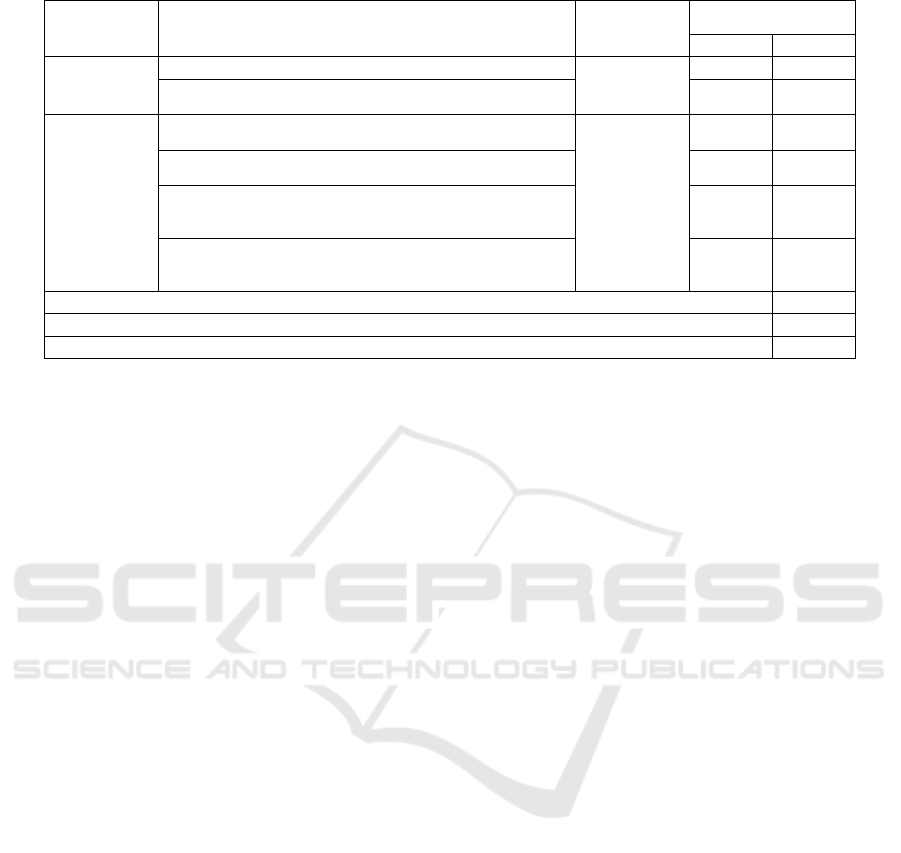

Table 5 summarizes the results found with each

algorithm. The classification algorithm that obtained

a larger number of correctly classified instances, best

accuracy, Kappa´s coefficient values and root mean

squared error is the K*. The JRip algorithm obtained

the best error values. On the other hand, the K*

algorithm had longer computational times (twice as

much as JRip).

A multi-classifier algorithm for dwell time

predictions was also proposed, and it was trained

using the information from the historical data base.

Results are presented in Table 6, where it can be

observed that the KNN algorithm obtained the larger

number of correctly classified instances, accuracy and

error values, with a computational time of 40 seconds.

As observed in previous tables, the algorithms

without the multi-classifier obtained better results in

general. On the other hand, the accuracy values are

always lower than 10%, which is explained due to the

variability of the ship and consignee factors in the

data base. For dwell time predictions, the average

error is about 7 days, which is high, but under current

operations, managers of the port of Arica are not able

to estimate container dwell times, hence in the long

run, it is expected that this number can be reduced.

5.2 Impact Assessment of the Proposed

Policy via a Discrete Events

Simulation Model

A simulation model of the import processes at the port

of Arica is proposed in order to evaluate the impact

of the storage policies in terms of the number of

rehandles incurred. For comparison purposes, a

storage policy was implemented considering two

variants of the stacking strategy of containers without

the dwell time segregation policy. This allows to

emulate the current practice of the port managers.

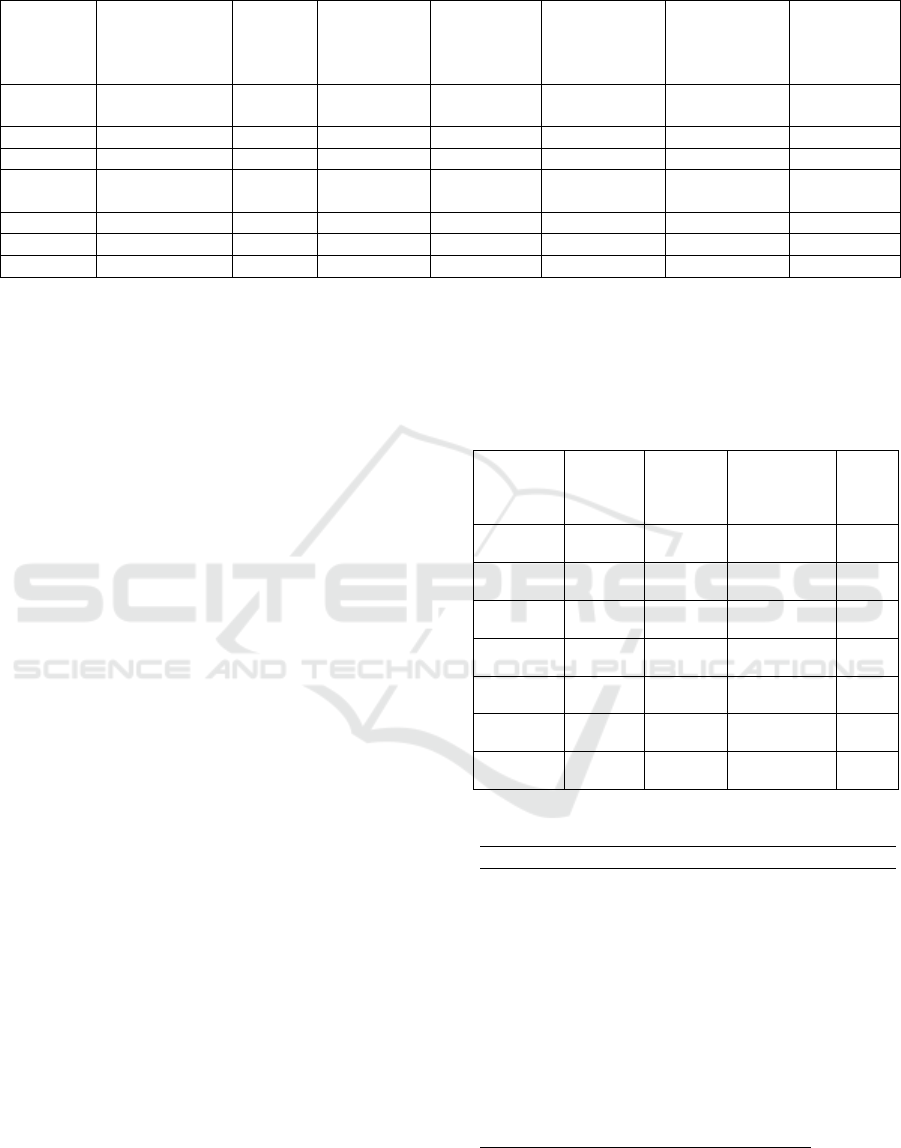

Table 7 outlines the general procedure for the

general stacking strategy implemented based on the

dwell time segregations policy. Table 8 outlines the

procedure for the non-segregation storage policy that

employs two stacking strategies: Semi-random and

Sequential, which are illustrated respectively in

Figure 3 and Figure 4.

The instance implemented considered the

movements of containers in the years 2012 and 2013.

The yard of the port terminal consists of 19 blocks for

import containers with a total of 4820 TEU slots. In

order to predict the dwell times, the JRip and multi-

classifier algorithms were implemented. The real

arrival of containers at the port during each year is

taken from the data base. For the random stacking

strategies, five replicates were run. For the sequential

stacking strategies, no replicates were tested given

that the solution obtained is the same since the arrival

of containers does not change. For the random

stacking strategies standard deviation values were in

the range of 140 to 444 rehandles. The simulation

model was implemented in the software ExtendSim

OR version 9.0 and run in a personal computer with

Intel Core 7 and 8Gb RAM. Table 9 presents the

results obtained.

A Dwell Time-based Container Positioning Decision Support System at a Port Terminal

135

Table 5: Results obtained with the classification algorithms.

Algorithms

Number of

correctly

classified

instances

Accuracy

Kappa´s

coefficient

Mean

squared error

Rootmean

squared error

Computational

Time

(seconds)

Error (days)

Naive

Bayes

3,875.8 ± 188.4

6.77%

0.031 ± 0.002

0.058 ± 0.000

0.069 ± 0.000

34.1 ± 2.9

7.88 ± 0.67

OneR

2,365.9 ± 103.3

4.13%

0.019 ± 0.003

0.058 ± 0.000

0.098 ± 0.000

34.1 ± 3.9

8.51 ± 0.20

ZeroR

2,942.3 ± 167.6

5.14%

0.000 ± 0.000

0.058 ± 0.000

0.068 ± 0.000

62.4 ± 4.9

8.21 ± 0.93

Decision

table

3,254.6 ± 256.3

5.68%

0.013 ± 0.005

0.058 ± 0.000

0.068 ± 0.000

27.4 ± 1.6

7.12 ± 0.44

K*

4,116.7 ± 88.1

7.19%

0.038 ± 0.002

0.058 ± 0.000

0.067 ± 0.000

109.0 ± 3.4

7.42 ± 0.10

KNN, K=1

3,966.6 ± 135.2

6.93%

0.035 ± 0.002

0.058 ± 0.000

0.070 ± 0.000

31.1 ± 10.5

8.07 ± 0.17

JRip

2,760.6 ± 164.1

4.82%

0.002 ± 0.001

0.058 ± 0.000

0.068 ± 0.000

36.6 ± 4.1

6.94 ± 0,88

As observed in Table 9, the average number of

rehandles incurred for both 2012 and 2013 are always

lower for the segregated dwell time policies

employing any type of stacking strategy.

Furthermore, the gap between the average number of

rehandles for the non-segregated and segregated

policies is around 13%. Comparing the best stacking

strategy in each period for the segregated and non-

segregated policies, a 6% and a 37% gap were

obtained for the 2012 and 2013 periods respectively.

In order to estimate the economic impact of the

dwell time segregated storage policy, the period

between January and April 2012 is considered. A total

of 16,867 rehandles were incurred at present

conditions. If the dwell time segregated and

sequential stacking strategy is employed, the total

number of rehandles incurred is 14,051, with an

approximate 17% reduction. If the cost of each

rehandle is estimated as 10 dollars, it represents

potential savings of about USD $28,000 for the

container terminal.

For further implementing the proposed decision

support system, the port terminal requires to develop

a module that may be interconnected with its TOS. It

will be necessary that the port terminal develop a

historical data base (Container DB in Figure 2 in

section 4) with the characteristics of import

containers that have been stored in the yard for at least

2 years and update periodically this database or in real

time. The information required considers the

characteristics of containers, its cargo, and

destination in the hinterland, as well as the dwell

times. This information will be the input data for the

prediction system. It will be also required to maintain

a data base registering the decisions taken by the yard

planner in order to analyse the performance of the

proposed system.

We estimate that implementing the proposed

support system will not alter the current operations of

the port terminal, and is not intended to replace the

yard planner tasks. The aim of the proposed system is

to support yard planner decisions and derive

recommendations that will make easier this job and

may lead to more efficient operations in the long run.

Table 6: Multi-classifier results.

Algorithms

N° of

correctly

classified

Instances

Accuracy

Computational

Time

(seconds)

Error

(days)

Naive

Bayes

3,226.9 ±

122.6

5.63%

79.9 ± 1.5

7.47 ±

0.20

OneR

1,309.6 ±

87.9

2.28%

19.4 ± 0.9

8.75 ±

0.25

ZeroR

3,216.4 ±

262.9

5.62%

31.1 ± 9.3

7.29 ±

0.41

Decision

table

2,992.7 ±

380.5

5.23%

55.2 ± 4.6

7.18 ±

0.42

K*

3,183.5 ±

98.7

5.56%

114.7 ± 1.6

7.63 ±

0.17

KNN,

N=85

3,608.0 ±

394.8

6.30%

38.7 ± 4.9

6.92 ±

0.19

JRip

3,153.1 ±

351.8

5.51%

61.4 ± 8.8

7.27 ±

0.47

Table 7: Segregated stacking strategy.

Dwell time Segregated Stacking Strategy

INPUT: Dwell time predictions for each container and dwell

time classes; Yard layout and inventory

1. Define the segregation of containers based on the dwell

time class predictions

2. Assign to each block a segregation of containers. One block

can contain either a single or several segregations.

3. Once a container arrives, assign it to the corresponding

segregation block.

4. Define the location of the container in the block based on

the Semi-random or Sequential stacking strategies.

5. If a container arrives and there is no available space in the

block corresponding to the segregation, then randomly select a

block and repeat step 4.

OUTPUT: container location.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

136

Table 8: Non-segregated stacking strategy.

Non-Segregated General Stacking Strategy

INPUT: Yard layout and inventory

1. Randomly select a block with available space.

2. Define the location of the container in the block based on

the Semi-Random or Sequential stacking strategies.

3. If a container arrives and there is no available space in the

predetermined block, then randomly select a block and repeat

step 4.

OUTPUT: container location.

Figure 3: Semi-random stacking strategy illustration.

Figure 4: Sequential stacking strategy illustration.

6 CONCLUSIONS AND

RECOMMENDATIONS FOR

FURTHER RESEARCH

Ship turnaround times are an important productivity

indicator for a port terminal. Efficient container

handling is needed during the loading and unloading

operations. Among several factors that affect the

performance of the ship service, the yard operation

efficiency is a key element. In addition, for those

terminals in which land is very restricted, the

planning and scheduling of resources at the yard

(space and equipment) are even more critical.

A common practice among yard managers for

storage space assignment consists of defining

segregations or groups of containers with common

characteristics. Export container segregations depend

on the vessel´s loading sequence, which is based on

the vessel´s route, weight and characteristics of the

container, among other factors. On the other hand,

segregating import containers is more complex. This

is more difficult if the port terminal has no hinterland

coordination mechanisms and high levels of

uncertainty on the times when import container will

be requested.

In this article a dwell time segregated storage

space policy for import containers is proposed. In

addition, the design of a decision support system for

the yard planner based on the proposed storage policy

is proposed. The focus of this article was import

containers, due to the difficulty to determine the

criteria to segregate them. As pointed out before, this

relies on the high levels of uncertainty on the

dispatching times, and the fact that an important

number of rehandles are incurred during this process.

For the proposed policy, dwell times of import

containers are predicted by classification algorithms.

Then, containers are segregated based on dwell time

classes. Import containers of the same dwell time

class are assigned to close locations at the yard.

As a case study, we consider the particular case of

the port of Arica in Chile. This port presents special

conditions for cargo handling. More than 70% of the

cargo transferred by the port of Arica corresponds to

transit cargo of Bolivia. Due to the political

agreements maintained between Chile and Bolivia,

there exists a high uncertainty in the dispatching

processes of the import containers at the port. In order

to evaluate the potential benefits in the daily

operations of the yard, a discrete event simulation

model is also implemented. Numerical results of the

simulation model show that a dwell time segregated

storage policy with a sequential stacking strategy

provides a significant reduction in the number of

rehandles incurred. Considering the real number of

containers handled by the port for a specific instance

data set, around to 17% reduction in rehandles is

obtained by the proposed policy. Finally, it is worthy

to mention that the implementation of the decision

support system proposed may provide a valuable tool

for the yard planner.

A Dwell Time-based Container Positioning Decision Support System at a Port Terminal

137

Table 9: Numerical Results: Rehandles per time period and stacking strategy.

Storage Policy

Stacking Strategy

Average per

policy (DT vs

NS)

Rehandles per period

2012

2013

Non-

segregated

policy (NS)

Non-segregated random stacking strategy

45840.6

48611.8

43083.6

Non-segregated sequential stacking strategy

48756

42911

Dwell time

segregation

policy (DT)

Dwell time segregated and random stacking strategy (JRip)

39768.76

45785.8

37423.8

Dwell time segregated and sequential stacking strategy (JRip)

45343

36531

Dwell time segregated and radom stacking strategy (multi-

classifier and KNN, N=84)

46377.4

27909

Dwell time segregated and sequential stacking strategy (multi-

classifier and KNN, N=84)

45337

26986

Gap (Avg NS - Avg DT)/Avg DT

13.25%

Gap (Best NS - Best DT) /Best DT [2012]

6.74%

Gap (Best NS - Best DT) /Best DT [2013]

37.11%

Current practices of the managers follow a semi-

random assignment of containers at the yard, given

the limitations of data and uncertainty in the

dispatching times of import containers. Hence, the

proposed support system will not change significantly

their current operations but in turns, will provide

recommendations to the yard planners for the

assignment of spaces to containers, without replacing

the personnel.

As further research additional factors that may

affect dwell time predictions should be analyzed,

such as the cargo transported in the container. For

instance, we could differentiate containers with cargo

of a single or several consignees.

The problem addressed in this article is at the

tactical decision level. Hence, another research

avenue would be to develop real time stacking

strategies based on the dwell time segregated policy.

Furthermore, impact assessment for different types of

yard equipment could be another research project to

be developed (reachstackers vs RTG vs straddle-

carriers, etc.). Finally, ship turnaround times can be

also considered as a performance metric for the

different stacking strategies and a sensitivity analysis

to determine the most significant factors determining

dwell times for the port of Arica is another research

avenue.

REFERENCES

Arvis, J-F, G. Raballand and J-F, Marteau. 2010. “The cost

of being landlocked: logistics costs and supply chain

reliability”. In Directions in development trade 55837,

Washington DC: The World Bank.

Astudillo, C.A., M. Bardeen, and C. Cerpa, 2014. Editorial:

data mining in electronic commerce - support vs.

confidence. Journal of Theoretical and Applied

Electronic Commerce Research, 9(1): I-VIII.

Astudillo, C.A. and B.J., Oommen, 2014. “Topology-

oriented self-organizing maps: a survey.” Pattern

Analysis and Applications, 17(2): 1 26.

Bassan, S. 2007. “Evaluating seaport operation and

capacity analysis—preliminary methodology”,

Maritime Policy & Management, 34(1): 3 19.

Beuran, M., M.H. Mahihenni, G. Raballand and S. Refas.

2012. “The impact of demand on cargo dwell time in

ports in SSA.” Policy research working paper 6014,

Africa Region: The World Bank.

Bichou, K., and R. Gray. 2004. “A logistics and supply

chain management approach to port performance

measurement”, Maritime Policy & Management, 31(1):

47 67.

Carlo, H.J., Vis, I.F.A., Roodbergen, K.J. (2014). “Storage

yard operations in container terminals: Literature

overview, trends, and research directions.” European

Journal of Operational Research, 235: 412-430.

Chen, T., K. Lin and Y-C, Juang. 2000. “Empirical studies

on yard operations part 2: quantifying unproductive

moves undertaken in quay transfer operations”,

Maritime Policy & Management, 27(2): 191 207.

Chung, K. C. 1993. “Port Performance Indicators”. In

Infrastructure Notes: Transportation, water and urban

development. Transport No. PS-6. The World Bank.

Cochran, W.G., 1986. Sampling techniques, New York:

John Wiley & Sons.

Dally, H.K. 1983. Container handling and transport: A

manual for current practice, London: CS Publications.

De Langen. 2007. “Port competition and selection in

contestable hinterlands: The case of Austria”. European

Journal of Transport and Infrastructure Research 7(1):

1 14.

Dharmalingam, K. 1987. Design of storage facilities for

containers- a case study of port Louis Habour, Maritius.

Ports and Harbors, 32(9): 27 31.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

138

Djankov, S., C., Freund, and C.S., Pham, 2006. “Trading on

time”. In Policy research working paper 3909,

Washington DC: The World Bank.

Doerr, O. 2013.“Latin American and the Caribbean

container port throughput, Ranking 2013”.

Infrastructure Services Unit, Santiago Chile: UN-

ECLAC.

Doerr, O. and R. Sánchez. 2006. “Indicadores de

productividad para la industria portuaria: aplicación

en América Latina y el Caribe”. Serie Recursos

naturales e infraestructura, 112, Santiago Chile: UN-

ECLAC.

Dowd, T.J., and T.M. Leschine. 1990. “Container terminal

productivity: a perspective”, Maritime Policy &

Management, 17(2): 107 112.

Hoffman, P. 1985. Container facility planning: a case

description. Port management textbook

containerization, Institute of shipping economics and

logistics, 353-364.

Kohavi, R. 1996. “Scaling up the accuracy of Naive-Bayes

classifiers: A decision-tree hybrid”, In Proceedings of

the second international conference on knowledge

discovery and data mining, 202 207.

Kononenko I., 1990. “Comparison of inductive and Naive

Bayesian learning approaches to automatic knowledge

acquisition’.” In: Current trends in knowledge

acquisition, edited by B. Wielinga, J. Boose, B. Gaines,

G. Schreiber, and M. van Someren. Amsterdam: IOS

Press.

Lee, T-W, N.K. Park., and D-W, Lee. 2003. “A. simulation

study for the logistics planning of a container terminal

in view of SCM”, Maritime Policy & Management,

30(3): 243 254.

Magala, M., and A. Sammons, A. 2008. “A new approach

to port choice modelling”. Maritime Economics and

Logistics, 10(1-2): 9 34.

Merckx, F. 2005. “The issue of dwell time charges to

optimize container terminal capacity.” In Proceedings

of the International Association of Maritime

Economists annual conference 2005, Limassol, Cyprus.

Moini, N., M. Bolie, M., S. Theofanis, and W. Laventhal.

2012. “Estimating the determinant factors of container

dwell times at seaports.” Maritime Economics &

Logistics. 14: 162 177.

Nir, A-S, K., Lin and G-S, Liang. 2003. “Port choice

behaviour: from the perspective of the shipper”.

Maritime Policy and Management, 30(2): 165 73.

Quinlam, J.R., 1986. “Induction of decision tree”, Machine

learning 1: 81 106.

Raballand, G., S. Refas, M. Beuran, and G. Isik. 2012.

“Why does cargo spend weeks in Sub-Saharan African

ports? Lessons from six countries” In Directions in

Development, Washington DC: The World Bank.

Rodrigue, J.P. 2012. “The benefits of logistics investments:

opportunities for Latin America and the Caribbean”,

In: Technical Notes IDB-TN-395, edited by Mary

Paden, 1-65, Washington, DC: Inter-American

Developing Bank.

Rodrigue, J.P., and T. Notteboom. 2009. “The

terminalization of supply chains: reassessing the role of

terminals in port/hinterland logistical relationships”.

Maritime Policy& Management. 36(2): 165 183.

Tongzon, J.L. and L. Sawant. 2007. “Port choice in a

competitive environment: from the shipping lines'

perspective”. Applied Economics, 39(4): 477 492.

UNCTAD. 2014. “Review of maritime transport 2014”.

United Nations Publications. ISBN 978-92-1-112878-

9.

USAID. 2005. “The broad economic impact of port

inefficiency: A comparative study of two ports”. U.S.

Agency for International Development, reported by

Nathan Associates, Washington, DC. Accessed in:

http://pdf.usaid.gov/pdf_docs/PNADC612.pdf.

Veldman, S., and E. Bückmann. 2003. “A model on

container port competition: an application for the West

European container hub-ports”. Maritime Economics

and Logistics, 5(2): 3 22.

Witten, I., E. Frank, and M.A., Hall. 2011. Data mining:

practical machine learning tools and techniques.

Morgan Kaufmann series in data management systems:

Elsevier.

A Dwell Time-based Container Positioning Decision Support System at a Port Terminal

139