Applying Mathematical Programming to Planning Bin Location

in Apple Orchards

Marcela C. González-Araya

1

, Carolina A. Urzúa-Bobadilla

2

and Luis G. Acosta Espejo

3

1

Department of Industrial Engineering, Faculty of Engineering, Universidad de Talca,

Camino a Los Niches km 1, Curicó, Chile

2

Faculty of Engineering, Universidad de Talca, Camino a Los Niches km 1, Curicó, Chile

3

Departamento de Ingeniería Comercial, Universidad Técnica Federico Santa María,

Avenida Santa María 6400, Vitacura, Santiago, Chile

Keywords: Pome Fruit Harvest, Bin Location, Optimization Models, Mathematical Programming.

Abstract: In Chile, it has been observed that there is downtime during the apple harvest season. This is largely due to

the long distances that the workers must cover and the lack of bins in the orchards. Currently, the

administrators do not use methods that enable them to estimate the number of bins required or where they

should be located. Taking these observations into consideration, this research paper proposes a plan for bin

placement in apple orchards by applying a location model with the objective of diminishing distances covered

by the harvest personnel. With data from an orchard in the Maule Region of Chile, the number of bins to be

used is calculated taking into consideration the particular surface characteristics of the plantation and the apple

variety maturity indicators. For the spatial distribution of the bins, the capacitated p-median was used, because

better results were obtained with it in terms of reducing travel distance during the harvest and the ease of

implementing the solutions.

1 INTRODUCTION

The Chilean apple industry has had a dynamic

development which has placed Chile among the five

main apple exporters worldwide with 10% of the

market participation, equivalent to approximately

760,000 tons exported (Bravo, 2013). Currently, one

of the major challenges facing this industry is to

increase its leadership which requires better planning

and coordination in all stages of the supply chain.

However, in the Chilean fruit industry the supply

chain activities are mainly based on the experience of

its participants.

In the literature, the first authors to use

mathematical programming models to support apple

orchard management decisions were Willis and

Halon (1976). Their research developed a dynamic

programming model to determine the optimum mix

of apple varieties to be planted over the long term and

applied it to an apple orchard in Massachusetts, USA.

Other models developed for planning the fruit

industry supply chain were presented by Ortmann et

al. (2006), Masini et al. (2007), Masini et al. (2008),

Catalá et al. (2013) and Munhoz and Morabito

(2014).

In a related line of research, Ahumada and

Villalobos (2009) carried out a literature review

focused on models based on agricultural harvests for

planning supply chain production and distribution of

agro foods. Other literature reviews on mathematical

programming models to support agricultural supply

chain decisions can be found in Weintraub and

Romero (2006) and Bjorndal et al. (2012), who

dedicated a portion of their research to models in the

agricultural area; Higgins, et al. (2010), who

discussed the challenges of adopting operations

research models in the agricultural value chain; and

Shukla and Jharkharia (2013), who classified the

models used in the fresh produce supply chain in

various ways (country, year, problem context,

technique used, among others).

Several mathematical programming models

developed in Chile to support harvesting stage

decisions have been applied mainly to the forestry

industry (Palma and Troncoso, 2001, Troncoso et al.,

2002)

C. Gonzà ˛alez-Araya M., A. UrzÞa-Bobadilla C. and G. Acosta Espejo L.

Applying Mathematical Programming to Planning Bin Location in Apple Orchards.

DOI: 10.5220/0006192203450352

In Proceedings of the 6th International Conference on Operations Research and Enterprise Systems (ICORES 2017), pages 345-352

ISBN: 978-989-758-218-9

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

345

Among the fruit harvest planning in Chile, the

well-known research by Ferrer et al. (2008) proposed

a mixed integer linear programming model to

determine the plan for grape harvesting which would

minimize operating costs and maximize grape

quality. In later research done by Bohle et al. (2010)

they incorporated data uncertainty into the model

presented by Ferrer et al.(2008)which was dealt with

by robust optimization.

Regarding location model application to

agriculture, Lucas and Chhajed (2004) carried out a

review of location models based on territorial balance

theory and optimal location applied to improving the

agricultural supply chain. Found among the research

done after that of Lucas and Chhahed (2004), is the

work by Rantala (2004) who developed a mixed

integer programming model in order to design a

production-distribution system in the seed and

seedling supply chain for the purpose of evaluating

the expansion or closure of facilities (greenhouses

and cold storage).In another study, Higgins and

Laredo (2006) used two location models to improve

the sugar value chain. One of these models is a p-

median problem (Hakimi, 1964) which has an

additional restriction that limits the largest average

distance from the fields to the loading points. The

other model is similar to the capacitated clustering

problem (Osman and Christofides, 1994) which

divides the producing farms into groups and seeks to

minimize the sum of the distances from each farm to

the center of the group. These models were applied to

a sugar producing region in Australia. In a recent

study, Srinivasan and Malliga (2013) applied a p-

median model to locate collection centers for Jatropha

seeds to be used to produce oil for biofuel. The

purpose of the model was to minimize distances from

the collection centers to the demand points, thus

facilitating logistics for the growers.

In a previous study on bin location in apple

orchards, González-Araya et al. (2009) proposed

improving their distribution by using the capacitated

p-median model (Hakimi, 1964, Garey and Johnson,

1979). This study extends the research by González-

Araya et al. (2009) by taking into consideration the

fruit maturity indicators according to variety, and also

including information about the pollinating varieties.

These new data permit better adapting to the orchard

characteristics, thus obtaining a different bin

distribution plan for each variety. In this manner, this

research proposes to improve the bin distribution in

apple orchards by applying a location model in order

to reduce distances covered by the seasonal workers

during fruit harvest. The model used is the

capacitated p-median (Hakimi 1964).

Next, the problem of bin distribution in apple

orchards is described. In Section 3 the mathematical

formulation of the model and the parameters used are

presented. In Section 4 a case study is described for

an orchard located in Chile and in Section 5 the main

results and discussion thereof are shown. Finally in

Section 6 the conclusions and future research are

presented.

2 DESCRIPTION OF THE

PROBLEM

The pome fruit harvest involves extensive surface

areas, and for this reason the orchards are divided into

sections. In this manner, each section may have its

own particular characteristics, these being: Fruit

variety; plantation density (distance between trees in

the same row and distance between rows); density

(low, medium, high), that refers to the number of trees

per hectare; year of plantation; area (hectares per

section); type of irrigation; pollinating trees; among

others. All these characteristics make it so that each

section can be worked in an independent manner

(Catalá et al., 2013). Moreover, pome fruit harvest is

characteristically seasonal; with the season beginning

once the ranges of maturity for each variety have been

reached. In Chile, the harvest generally begins in mid-

February and ends around mid-April; however, this

can vary according to the climatic conditions each

year.

The surface area planted with apples in Chile is

about 37,297 hectares where the main producing

regions are the Maule Region with 22,488 hectares

and the O’Higgins Region with 10,011 hectares,

uniting 87% of the national apple plantation surface

area (Bravo, 2013).The Maule Region is the main

apple producer in Chile with 60.3% of the planted

surface area nationally, where 18,863 hectares

correspond to red apples and 3,625 hectares to green

apples (Bravo, 2013).Orchards in this region present

an average density of 1,100 trees per hectare for red

apples and 933 trees per hectare for green apples, and

an average yield of 48.8 and 50.5 tons per hectare,

respectively (CIREN and ODEPA, 2013).

The harvest requires seasonal workers, bins in

which to put the fruit, harvest equipment (ladders,

baskets, among others) and tractors to transport the

bins. Coordinating resources during the harvest is a

complex process, where the lack of any one of them

can slow it down and affect the quality of the fruit.

The apple harvest in Chile is carried out manually

to avoid any mechanical damage, given that the

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

346

destination markets are very far away (Asia, the

United States, Europe and the Middle East). Bins with

a capacity of approximately 350 kilograms placed

between the rows of trees are used to collect the

apples in the orchard. The placement of the bins is

done according to the preferences of the tractor driver

with little coordination with those responsible for the

orchard sectors. On one hand, the drivers know the

number of bins that should be distributed in a given

section and the harvesters know which rows of apples

they should harvest. However, the way in which the

bins are distributed results in either a scarcity or an

excess of them among the rows. As well, the seasonal

workers must frequently relocate the bins as they

advance through the harvest sector. This generates

down time and a number of extra hours for the tractor

driver to collect the bins from the orchard.

3 MATHEMATICAL

FORMULATION AND

PARAMETER ESTIMATION

In this study the solutions from the capacitated p-

median model (Hakimi, 1964, Garey and Johnson,

1979) are analyzed, for the purpose of establishing a

bin location plan that would reduce travel distance for

harvest crews and that the plan would be easy to

implement.

3.1 Capacitated p-median Problem

In general terms, the problem consists of determining

where to locate the bins and assign apples to each bin,

minimizing the distance covered by the workers

during the harvest. This case can be modeled as a

capacitated p-median problem (Hakimi, 1964, Garey

and Johnson, 1979). Thus, the installations or

medians correspond to the bins and the demand areas

correspond to the apples to be harvested.

In formulating the capacitated p-median model

the following nomenclature is considered:

},...,1{ nN

the set of possible bin locations

within the sector

},...,1{ mM

the set of apple trees in the sector

d

ij

the linear distance between the apple tree i,

iM, and the possible location of the bin j, jN.

p the number of bins needed in the sector

k the maximum number of apple trees that can be

assigned to a bin,

The decision variables of the model are defined in

the following manner:

y

j

{0,1}, where y

j

= 1 if a bin is located in

position j, y

j

= 0; if not, jN.

x

ij

{0,1}, where x

ij

= 1 if apple tree i is assigned

to the bin located in j, x

ij

= 0; if not, iM, jN.

Thus, the formulation of the capacitated p-median

model is as follows:

Minimize

m

i

n

j

ijij

xd

11

(1)

s.t.

, ,1

1

n

j

ij

Mix

(2)

, ,

1

Njkyx

m

i

jij

(3)

,

1

py

n

j

j

(4)

y

j

0,1, jN, (5)

x

ij

0,1, iM, jN. (6)

The objective function (1) seeks to minimize the

sum of the distances covered by the harvesters from

each apple tree to each assigned bin. The set of

restrictions (2) guarantees that each apple tree be

assigned to a single bin, while the set of restrictions

(3) assures that a bin located in j can be assigned, at

the most, to k apple trees. The restriction (4)

establishes that p bins must be located. Finally,

restrictions (5) and (6) define the variables that must

be binary.

3.2 Estimation of Parameters Used in

the Model

The model parameters are calculated in agreement

with the description of the problem given in Section

2; those being: distance between an apple tree and the

possible bin location points; number of bins to be

located in each sector; capacity of each bin (measured

in trees), which differs according to apple variety; and

plantation characteristics by sector, that is, the

number of trees planted and fruit count before

harvest.

The potential bin locations are represented as

discrete points established midway between apple

tree rows and equidistant among the trees. The

quantity of potential locations will depend on the

Applying Mathematical Programming to Planning Bin Location in Apple Orchards

347

plantation density, the distribution of pollinating trees

and quantity of trees per row of surface area.

The distance d

ij

(in meters) between apple tree i

and the potential bin location j is obtained by

calculating the Euclidian distance, given that it is a

good approximation of the real distance covered by

the harvest workers, since, generally there are no

obstacles to covering the distance by walking in a

straight line.

The parameter p indicates the number of bins to

be located in a surface area to receive the gathered

apples. Its value is determined with the following

formula:

afbSS

FPCmTAPNp

(7)

Where:

PN

S

: kg estimated net production for a sector.

TA

S

: total trees of the variety to be harvested

planted in a sector.

P

f

: percentage of fruit on the tree with sufficient

maturity for collecting.

C

b

: Capacity of the bin selected for the harvest,

measured in kg.

m: number of apple trees in the sector.

F

a

: adjustment factor.

The adjustment factor permits defining a margin

of security in order to avoid running out of bins

during the harvest. In this case 1.1 was considered for

the F

a

. This value was obtained from the average of

the variation coefficients in the production of the

apple trees, which was 10%.

Once the p parameter has been obtained, the k

parameter is calculated. It represents the quantity of

trees it is feasible to assign to a bin when harvesting

a particular variety so the unit of measurement is

trees/bin. The formula is calculated as follows:

p

m

k

(8)

Formula (8) establishes that if the result is a

decimal, it is rounded up to the next integer, given that

k must be a whole number.

4 CASE STUDY

Data was taken from an orchard in the Maule Region,

Chile that has an apple tree plantation of more than

66 hectares. The varieties of trees occupying the most

surface area of the orchard were included, these being

Royal Gala, Early Red One and Granny Smith. Each

section of the orchard corresponds to the area where

a specific variety is planted of which the number of

hectares may vary. These sections present different

types of harvesting; the Royal Gala is harvested by

selective picking and the Early Red One and Granny

Smith are harvested by strip picking. As is described

by Gil (2004), in selective pickings, the sector must

be covered at least three times during the season since

the fruit does not mature homogeneously. In strip

picking, the sectors are covered only once, harvesting

all the fruit from the trees.

The instances of the location models were solved

using the optimization software, CPLEX 12.0,

academic version, for integer linear programming

problems.

To generate the parameters of the capacitated p-

median model it is necessary to obtain information

about the characteristics and production of the

sectors, which has to be periodically revised, and also

data about the previous and current season. The

required information for each sector is as follows:

trees planted, surface area (in hectares), location of

the pollinating trees, number of pollinating trees per

sector and per row, plantation density, year of

plantation, number of trees per row and per sector.

The required data from the previous season include

the kilograms of apples sent to a packing plant,

kilograms of apples that did not meet the required

quality parameters (discard), and the percentage of

apples to be harvested. The necessary data from the

current season are the tree load, the weight of the fruit

in kilograms, the bin capacity in kilograms, an

estimated percentage of apples that will not meet the

required quality parameters (discard), and finally, the

percentage of apples to be harvested.

In regard to the data from the previous season or

that of the current season it is important to mention

that both types of data are not used at the same time.

One must select which of these information sources

to use as input for generating parameters, taking into

consideration the rigorousness of data collection in

each of the seasons and the seasonal variability of the

factors that affect the harvest (climatic conditions,

fertilizer application, fruit thinning, fruit count, tree

replacement, among others).

Applying the equations described in Section 3.1,

the ranges and input parameters of the model for a

sector are calculated with the obtained information.

The capacity parameters and number of bins used in

the model for each variety of apples is shown in Table

1, in which different harvesting methods are

observed, and hence, different input parameters.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

348

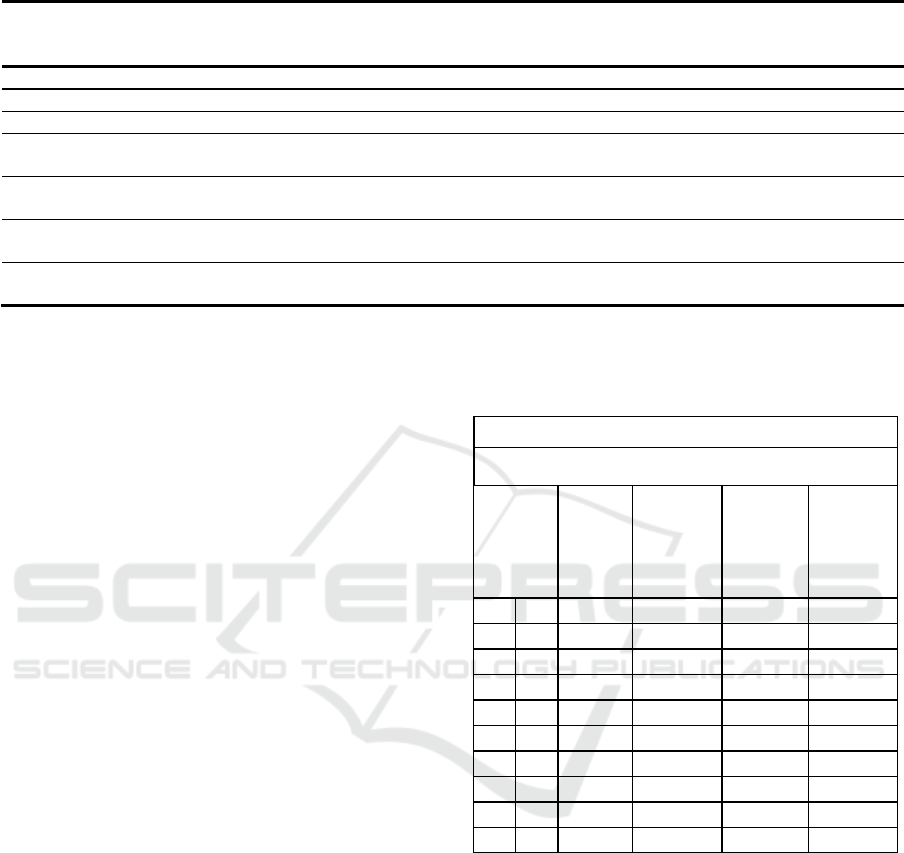

Table 1: Parameters used in the capacitated p-median location model according to apple variety by sector.

Variety Harvest Method

Percentage of

Harvest (%)

Bin Capacity

(trees/bin) (k)

Sector Surface

Area (ha.)

N° of bins to be

located per

sector (p)

Early Red One Strip picking 100 9 4.5 685

Granny Smith Strip picking 100 8 4.6 696

Royal Gala Strip picking 100 7 6.4 848

Royal Gala Selective

pickings

80 8 6.4 680

Royal Gala Selective

pickings

60 10 6.4 508

Royal Gala Selective

pickings

40 14 6.4 336

Royal Gala Selective

pickings

20 28 6.4 181

5 RESULTS AND DISCUSSION

In this section the main bin distribution proposals

obtained when applying the capacitated p-median

model are presented. The results for the Early Red

One and Royal Gala varieties that have the strip

picking and selective picking methods, respectively,

are described in greater detail.

With the information from the previous harvest

season (2010) a plan for collecting according to sector

was obtained, indicating the spatial distribution of the

bins, and the distance between the bins (metric and

practical).The practical distance is understood as the

number of trees there should be between individual

bins. It turns out that this distance is easier to explain

to the tractor drivers who distribute the bins since it is

only necessary to indicate the space (number of trees)

that should be left between containers.

To estimate the harvest plan and the average

distance covered by the seasonal workers in Sector

M13 that has the Early Red One variety, the following

information is used: 259,321 kg net weight harvested

in the 2010 season, 379 kg average bin capacity and

the strip picking harvesting method.

After applying the model, it was found that the

average distance from the trees to their assigned bin

covered by the harvest workers is 2.94 m,

approximately. Considering the 119 rows in this

sector, 685 bins should be located there in order to

collect all of the apples.

Table 2: Bin location plan in the sector with Early Red One

at 100% harvest.

Bin Location Plan

Sector: Early Red

One

Harvest method: Strip picking

Between

Rows

Number

of bins

Number

of

apple

trees

Metric

distance

Practical

distance

1 2 11 99 7.9 4

3 4 12 101 7.4 4

5 6 11 99 7.9 4

7 8 12 101 7.4 4

9 10 11 99 7.9 4

11 12 12 101 7.4 4

13 14 11 99 7.9 4

15 16 12 101 7.4 4

17 18 11 99 7.9 4

19 20 12 101 7.4 4

Part of the location plan obtained for harvesting

the Early Red One variety which has a 4.5 ha surface

area is shown in Table 2. For example, it is indicated

on this table that 11 bins (second column) should be

located between Rows 1 and 2 at a distance of 7.9 m

(fourth column) or a practical distance of 4 trees (fifth

column).As a reference, indicated in the third column

is the total number of apple trees allotted to the 11

bins for Rows 1 and 2; that is to say, the 11 bins have

the capacity to hold the fruit collected from the 99

apple trees between these two rows.

The difference between the metric and practical

distance is about 6.2%, equivalent to 0.45m, so it is

hoped that the use of the practical distance achieves

an improvement similar to that of the metric distance.

Applying Mathematical Programming to Planning Bin Location in Apple Orchards

349

In order to propose the bin distribution plan for

Sector M4 which has the Royal Gala variety, the

following information is used: 320,766 kg net weight

harvested in the 2010 season, 386 kg average bin

weight and 40% of the orchard production (a 40%

selective picking).In this application of the

capacitated p-median model the proposal described is

for a 40% selective picking, which generally

corresponds to the initial selective picking of the

season. The total surface area of the plantation

considered in this case is 6.4 ha.

According to the model results the seasonal

workers must walk an average of 8.23 m from the

apple trees to their designated bins.

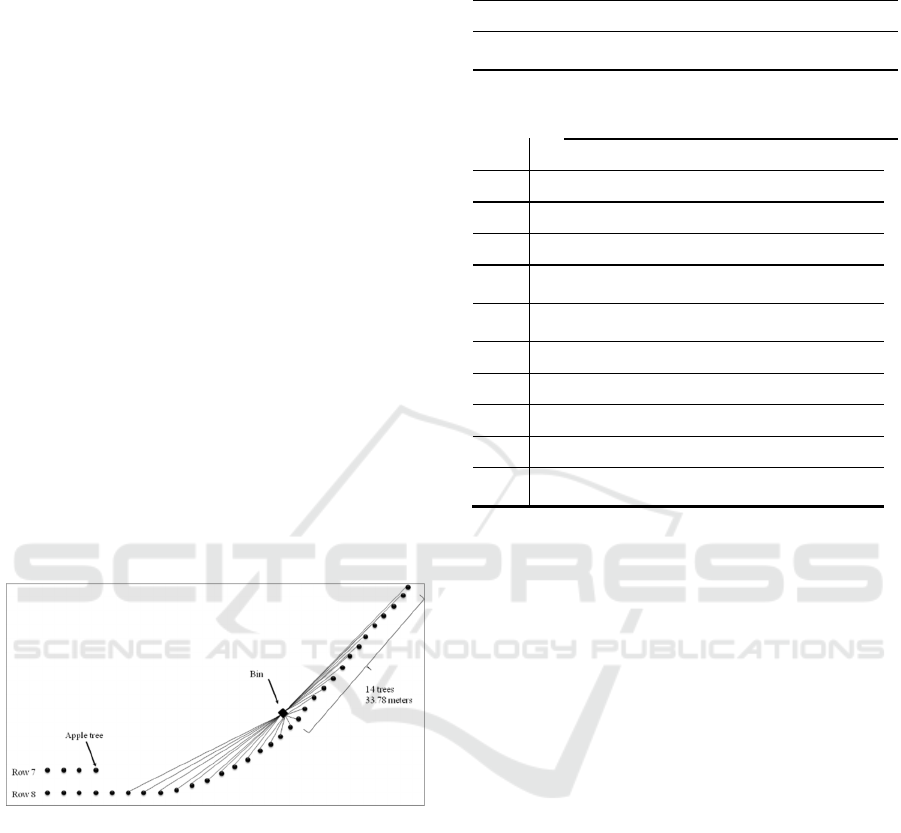

Because of the contour level irrigation system

used in the sector with this variety, it presents a

different number of trees per row. For this reason, on

occasion, locating only one bin between two rows

was proposed. This situation is shown in Figure 1,

where a bin is located between Rows 7 and 8, placing

it at the end of the longest row. In this way this bin

embraces a total of 27 apple trees at a distance of

approximately 34 m or every 14 trees. Hence, to make

the bin location operative, in each row a bin will be

placed every 17 m or every 7 trees, which

corresponds to the average distance between bins for

a 40% selective picking (see Table 3).

Figure 1: Bin location between rows 7 and 8 in the sector

with the Royal Gala variety and the contour irrigation

system.

The difference between the estimated metric and

practical distances is 3.8%, equivalent to 0.65 m. As

with the Early Red One variety, guiding the bin

distribution using the practical distance is simpler for

the tractor drivers.

For the bin location plans with different

percentages of selective picking it was observed that

the greater the percentage of selective picking, the

lesser the average distance at which bins should be

located. Following, Table 4 shows the results for

apple varieties with a larger number of hectares

planted in the orchard.

Table 3: Bin location plan for the Royal Gala variety at a

40% selective picking harvest.

Bin Location Plan

Sector: Royal Gala

Harvesting method: 40% selective

picking

Between N° N° of Metric Practical

Rows

of

bins

Apple

trees

distance Distance

2 3 3 48 19.2 8

3 4 4 48 14.4 6

5 6 3 38 15.0 6

6 7 13 193 18.4 7

7 8 1 16 Locate at the end or

beginning of the row

11 9 139 19.0 8

11 12 4 52 15.6 6

14 15 13 195 18.6 7

17 18 2 27 15.6 6

18 19 14 214 18.9 8

19 20 1 16 Locate at the end or

beginning of the row

Table 4 indicates how many bins are needed for

the complete harvest in a determined sector according

to the percentage of mature fruit, the bin location

every certain number of rows and the distances

between them determined by the number of trees.

It is worth mentioning that according to Gil

(2004) it is recommended to do at least three selective

pickings during the harvest season for the Royal Gala

variety (sector M4), which implies covering the

surface area planted with this variety three times.

However, during the study season, only selective two

pickings were carried out in the orchard for this

variety; one 60% selective picking and the remaining

40% was harvested by strip picking. Thus, it is

estimated that the location plan proposed for the 60%

selective picking reduced the average distance

covered by 0.46 m, implying a 5.73% reduction in the

average distance covered. Similarly, for the 40%

selective picking the average distance covered was

reduced by 1.81 m, which means an 18.03% reduction

in the average distance covered.

So, when the capacitated p-median model is

applied, it is possible to reduce distances covered by

the harvest personnel, where the average reduction is

approximately 16%. This reduction in distances

covered would allow improving the apple harvest

productivity.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

350

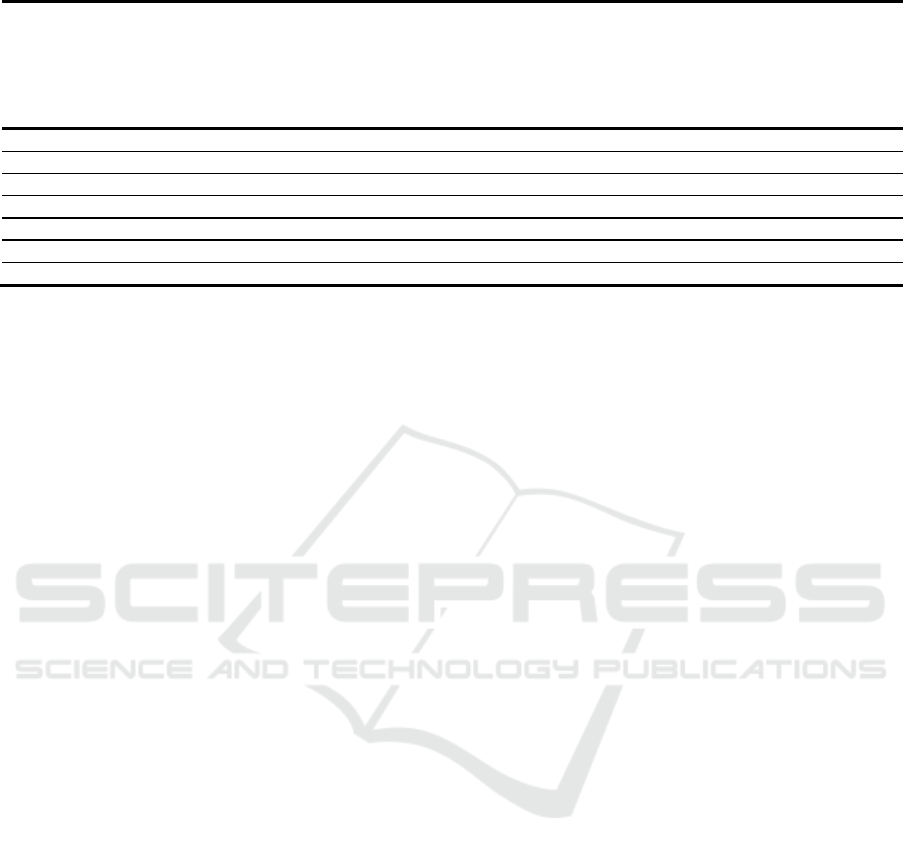

Table 4: Summary of the results for bin location according to apple variety by sector.

Variety Sector

Percentage

Harvested (%)

N° of bins to be

located per

Sector (p)

N° of rows

between which

bins are to be

located

Average

practical

distance for

locating a bin

(number of

trees)

Early Red One M13 100 685 2 4

Granny Smith M8 100 696 2 4

Royal Gala M4 100 848 2 3

Royal Gala M4 80 680 2 4

Royal Gala M4 60 508 2 5

Royal Gala M4 40 336 4 7

Royal Gala M4 20 181 4 14

6 CONCLUSIONS

The capacitated p-median model was applied to the

sectors of larger size in an orchard located in the

Maule Region, Chile, where parameters representing

the characteristics of each sector were used.

Therefore, the model is flexible in that it adapts to the

conditions in a specific surface area, taking into

account different input sources. Moreover, it permits

the use of various bin capacities, making it adaptable

to other types of pome fruit harvest.

In this study a bin location plan was proposed

for harvesting the Early Red One, Granny Smith and

Royal Gala varieties, which resulted in a reduction in

the average distance covered between the apple trees

and their specific container of 16.48%, 28.38% and

11.88%, respectively. This reduction in the distances

covered would permit an increase in worker

productivity and a reduction in harvest operational

costs. However, given that there was no study done

on harvest times and associated costs, it was not

possible to estimate these effects.

The suggested location model can be applied to

the harvest of pollinating trees as well, considering

these trees represent 11% of the plantation area.

The harvesting process reflects several

opportunities for research intended to improve its

operation. For example, the system used to determine

the fruit load is not based on any statistical procedure

to validate its reliability. Therefore, a study could be

done based on the particular characteristics of each

sector keeping in mind the respective maturity

indicators (such as fruit color), and the associated

agro climatic variables.

The plantation characteristics of each sector are

important parameters to consider for the harvest so

maintaining up-to-date information about these

parameters is necessary for making good decisions.

However, not all the orchards consistently carry out

this activity. In the case of the study orchard, the exact

distribution of the pollinating trees within a sector is

unknown to the administration; they have only an

estimated ratio of pollinating trees per sector, which

is approximately 11%. According to what was

observed for the analyzed varieties, the distribution of

the pollinating trees depends on the variety planted in

the sector. Also, it should be taken into account that

the harvest of these pollinating trees does not occur at

the same time as that of the main variety, which

involves planning a different harvest in the same

sector.

In future research it is recommended to study the

operations involved in harvesting the pollinating trees

with stationary bins and bin-carrying carts since it

could improve the assignment of machinery for the

harvest and reduce its cost. This is relevant since, as

previously mentioned, the pollinating trees represent

approximately 11% of the trees planted in a sector.

Thus, for the largest sector in the orchard (sector M4)

with 6.4 hectares planted with approximately 5,690

apple trees in all, the 11% pollinating trees

corresponds to 626 apple trees which must be

harvested. This illustrates the complexity of harvest

planning for this sector. Moreover, this difficulty

increases considering that during the season several

sectors are harvested at the same time.

Finally, other research opportunities arise from

the development of simulation models to plan the

machinery needed for the harvest and the application

of vehicle routing models for the purpose of

minimizing distances and fuel costs for the tractors

used for collecting and placing the bins in the orchard.

Applying Mathematical Programming to Planning Bin Location in Apple Orchards

351

REFERENCES

Ahumada, O., Villalobos., J.R., 2009. Application of

planning models in the agri-food supply chain: A

review. Eur. J. Oper. Res. 195, 1-20.

Bjorndal, T., Herrero, I., Newman, A., Romero, C.,

Weintraub, A., 2012. Operations research in the natural

resource industry. Int. Trans. Oper. Res. 19, 39–62.

Bohle, C., Maturana, S., Vera, J., 2010.A robust

optimization approach to wine grape harvesting

scheduling. Eur. J. Oper. Res. 200, 245–252.

Bravo M., J., 2013. Manzana: una temporada de alto valor

de exportaciones. Publicación de la oficina de estudios

y políticas agrarias – ODEPA. Ministerio de

Agricultura, Gobierno de Chile, Chile.

Catalá, L.P., Durand, G.A., Blanco, A.M., Bandoni, J.A.,

2013. Mathematical model for strategic planning

optimization in the pome fruit industry. Agr. Syst. 115,

63–71.

CIREN – Centro de Información de Recursos Naturales,

ODEPA – Oficina de Estudios y Políticas Agrarias,

2013. Catastro Frutícola, Principales Resultados,

Región del Maule, Junio 2013, Chile.

Ferrer, J.,MacCawley, A., Maturana, S., Toloza, S., Vera,

J., 2008. An optimization approach for scheduling wine

grape harvest operations. Int. J. Prod. Econ. 112, 985–

999.

Garey, M.R., Johnson, D. S. (Eds), 1979. Computers and

intractability: a guide to the theory of NP-

completeness. W.H. Freeman and Co. San Francisco,

USA.

Gil S., G. F. (Ed.), 2004. Fruticultura: Madurez de la fruta

y manejo poscosecha: frutas de climas templado y

subtropical y uva de vino, 2. Ediciones Universidad

Católica de Chile, Santiago de Chile, Chile.

González-Araya, M., Acosta-Espejo, L., Ferreira, M., 2009.

Una Propuesta de Optimización en el Proceso de

Cosecha de Manzanos. In Anales del XLI Simpósio

Brasileiro de Pesquisa Operacional. Porto Seguro,

Brasil.

Hakimi, S.L. 1964. Optimum location of switching centers

and the absolute centers and medians of a graph. Oper.

Res. 12:450–459.

Higgins, A.J., Laredo., L., 2006. Improving harvesting and

transport planning within a sugar value chain. J. Oper.

Res. Soc. 57, 367–376.

Higgins, A.J., Miller, C.J., Archer, A.A., Ton, Τ., Fletcher,

C.S., McAllister, R.R.J., 2010. Challenges of

operations research practice in agricultural value

chains. J. Oper. Res. Soc. 61, 964–973.

Lucas, M.T., Chhajed, D., 2004. Applications of location

analysis in agriculture: a survey. J. Oper. Res. Soc. 55,

561–578.

Masini, G.L., Blanco, A. M., Petracci, N.C., Bandoni, J.A.,

2007. Supply chain tactical optimization in the fruit

industry. In: Papageorgiou, L., Georgiadis, M. (Eds.),

Supply Chain Optimization, Volume 4, Part II. John

Wiley & Sons, New York, pp. 121– 172.

Masini, G.L., Blanco, A.M., Petracci, N.C., Bandoni, J.A.,

2008. Optimal Operational Planning in the Fruit

Industry Supply Chain. In: Ferruh E. (Ed.),

Optimization in Food Engineering. CRC Press, Taylor

and Francis Group, pp. 703–746.

Munhoz, J.R., Morabito, R., 2014. Optimization

approaches to support decision making in the

production planning of a citrus company: A Brazilian

case study. Comput. Electron. Agric. 107, 45-57.

Ortmann, F.G., Vuuren, J.H., van Dyk, F.E., 2006.

Modeling the South African fruit export infrastructure:

a case study. ORiON. 22 (1), 35–57.

Osman, I.H., Christofides. N., 1994.Capacitated clustering

problems by hybrid simulated annealing and tabu

search. Int. Trans. Oper. Res. 1, 317–336.

Palma, C., Troncoso, J., 2001. Asignación óptima de

equipos en faenas de cosecha forestal. Revista El

Bosque. 22, 65-73.

Rantala, J., 2004. Optimizing the supply chain strategy of a

multi-unit Finnish nursery company. SilvaFenn. 38 (2),

203–215.

Shukla, M., Jharkharia, S., 2013.Agri-fresh produce supply

chain management: a state-of-the-art literature review.

Int. J. Oper. Prod. Man. 33 (2), 114–158.

Srinivasan, S.P., Malliga, P., 2013. An Optimal Jatropha

Seed Warehouse Location Decision Using Myopic and

Exchange Heuristics of P Median. In: Dou R. (Ed.),

Proceedings of 2012 3rd International Asia Conference

on Industrial Engineering and Management Innovation

(IEMI 2012). Springer-Verlag, Berlin Heidelberg.

Troncoso, J., Garrido, R., Ibacache, X., 2002. Modelos de

localización de instalaciones: Una aplicación para la

producción y logística forestal. Revista El Bosque. 23,

57–67.

Weintraub, A., Romero, C., 2006. Operations Research

Models and the Management of Agricultural and

Forestry Resources: A Review and Comparison.

Interfaces. 36 (5), 446–457.

Willis, C., Hanlon, W., 1976. Temporal model for long-run

orchard decisions. Can. J. Agr. Econ. 24 (3), 17–28.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

352