Searching the Optimal Combination of Fire Risks Reducing

Measures at Oil and Gas Processing Facilities with the use of Genetic

Algorithm

Sergey Gudin

1

, Renat Khabibulin

2

and Denis Shikhalev

2

1

Ghent University, 9000, Ghent, Belgium

2

The State Fire Academy of EMERCOM of Russia, 129366, B. Galushkina 4, Moscow, Russia

Keywords: Genetic Algorithm, Oil and Gas Processing Facilities, Quantitative Risk Assessment, Optimisation.

Abstract: The search for the combination of fire risk-reducing measures at oil and gas processing facilities is a

complicated task. There may be a large number of measures to reduce fire risks which need to be optimized,

both technically and economically. The analysis of the existing programs for risk assessment has been

conducted. The structure of database with the values of risk-reducing measures has been worked out. To

reduce the time required for this task, a genetic algorithm approach has been proposed.

1 INTRODUCTION

At present, there are a lot of quantitative risks

assessment systems, which can qualitatively

determine explosion and fire dangerous factors in the

territory of oil and gas processing facilities. As a rule,

after risks assessment procedures, risk values are

inappropriate. In these cases, some measures for

reducing risk values are required. There can be a lot

of measures for reducing risk values (installation of

alarm system, automatic fire extinguishing system, a

decrease in stored material, etc.). In most cases, one

measure is not enough. It is necessary to find a set of

measures that maximally reduce fire risk values and

do not require a lot of expenses. Fire risks values may

be different in each case of a combination of risk

values reducing measures. Each situation requires

risk assessment procedures, but risk assessment

procedure requires a lot of operations and time. So,

the number of the procedures of risks assessment will

grow in geometric progression with the amount of

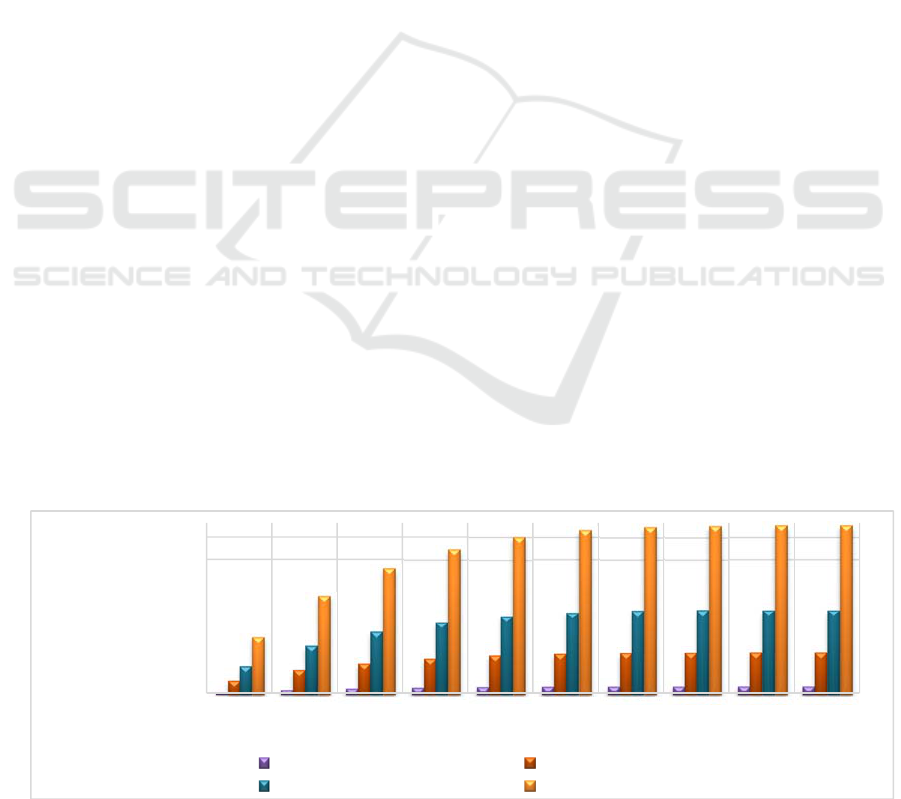

objects on the territory (figure 1). Special algorithm

for optimization of combinations of measures for

reducing risk values has been developed. In the paper

presented, the risk acceptance criteria approach when

using genetic algorithms for searching optimal

combination of fire risk-reducing measures at oil and

gas processing facilities.

Figure 1: Number of combinations of measures to ensure fire safety.

1

100000000

1E+16

1E+24

1E+32

1E+40

1E+48

1E+56

12345678910

Number of combinations

of measures to ensure fire

safety

Number of measures to ensure fire safety

1 object on the territory 5 objects on the territory

10 objects on the territory 20 objects on the territory

Gudin S., Khabibulin R. and Shikhalev D.

Searching the Optimal Combination of Fire Risks Reducing Measures at Oil and Gas Processing Facilities with the use of Genetic Algorithm.

DOI: 10.5220/0006188904890496

In Proceedings of the 9th International Conference on Agents and Artificial Intelligence (ICAART 2017), pages 489-496

ISBN: 978-989-758-220-2

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

489

2 RELATED WORKS

Risk management has become a vital topic both in

academia and practice during the past several

decades(Desheng, Shu-Heng, David, 2014). When

evaluating safety of projects, it is common to use risk

acceptance criteria to support decision-making

(Abrahamsen and Aven, 2008). However, the

analysis of the existing fire risk estimation software

(Gudin and Khabibulin, 2015) showed that the

systems of fire risks assessment do not contain special

methods and algorithms, which make it possible to

find a combination of measures for reducing fire risk

values.

One of the existing methods for solving

optimization problems is genetic algorithms used to

solve a lot of decision-making problems with great

amount of information (Xuancai et al., 2016). Many

scientists came to the conclusion that genetic

algorithms can be used in solving complex tasks

(Martorell et al., 2005; Ramirez et al., 2009). Besides,

their effectiveness as to the optimization were

highlighted in many studies (Panov and Shary, 2011;

Schaefer, 2012; Sergienko, 2009).

One of the methods of using genetic algorithms

has been already presented (Caputo et al., 2011). This

method is used in searching for the economic

optimum risk level. It is based on the minimization of

total expenses. After the experiments, the authors

show that he can solve that problem quite well.

Reduction in expenses is an important task, but the

first task is to provide fire safety, because it directly

influences the safety plant workers and people living

in residential areas.

Upon the review of the related works, it was

identified that genetic algorithm can solve the

problem of searching for the best combination of

measures for reducing fire risk values with risk

acceptance criteria.

3 GENETIC ALGORITHM FOR

FINDING COMBINATIONS IN

ORDER TO REDUCE RISK

VALUES

For the purposes of analysis of most of the events

stored in the database, comprehensive assessment of

fire risks should be conducted when analyzing each

event, except for specific associated cases. For

example, with the time that people spend in the

building, when the values of individual fire risk

would change only by factoring the probability of the

people being there. In such cases, comprehensive risk

estimation is not required, and such exceptions should

be included into the program code separately.

In general, the genetic algorithm model proposed

by John Holland (Holland, 1975) was used. For

crossing of chromosomes a method with a single

point of exchange was used. Mutation procedure was

slightly modified for searching the combination of

fire risk-reducing measures.

First of all, after crossing, there may be identical

gens in the chromosome. It is necessary to have only

unique gens in the chromosome. So, all identical gens

are going to mutate, except for one.

To add more, a special method was invented to

form the first population. It consists of 2 steps:

1) Evaluating the effectiveness of measures;

2) Generation chromosomes by using the roulette

wheel method.

To create combinations with different number of

measures added the operation for accidentally

deleting of chromosome.

3.1 Objective Function

One of the obligatory criteria of the genetic algorithm

use is an objective function presenting quantification

of the efficiency of computed solutions. The

suggested objective function consists of three

parameters:

1. The amount of fire risks calculated values

in the territory of an enterprise, which does not

exceed acceptable values (Q).

2. The parameter of average deviation of

infeasible calculated values of fire risks in the

territory of oil and gas facility and the adjacent

residential zone from the acceptable values (D).

3. Reduced cost of measures (P).

The following formula is used for the calculation

of the amount of acceptable fire risks values in the

territory of oil and gas facility:

=

+

(

)

+ ,

(1)

Where:

=

1, ≤

0, >

;

(2)

(

)

=

1, ≤

0, >

;

(3)

ICAART 2017 - 9th International Conference on Agents and Artificial Intelligence

490

(

)

=

1, ≤

0, >

;

(4)

R – Final value of an individual fire risk for the

workers of the enterprise;

J – Amount of workers on the enterprise;

I – Final value of individual fire risk for people

located in housing, social, and business or recreation

areas;

M – Amount of facilities with people in residential

zone;

S – Final value of social fire risks quantity for people

located in housing, social, and business or recreation

areas;

R

a

– Acceptable value of individual fire risk quantity

for the workers of enterprise;

I

a

– Acceptable value of individual fire risk quantity

for people located in housing, social, and business or

recreation areas;

S

a

– Final value of social fire risk quantity for people

located in housing, social, and business or recreation

areas;

α – Acceptable criterion of value as to individual fire

risk quantity for the workers of the enterprise;

β – Acceptable criterion of value of individual fire

risk quantity for people located in housing, social, and

business or recreation areas;

γ – Acceptable criterion of value of social fire risk

quantity for people located in housing, social, and

business or recreation areas;

Q – Amount of fire risks quantity acceptable within

the framework of the given case.

Total costs of procedures implementation are

calculated according to the following formula:

=

⋅

+С

(5)

where P

i

– total costs of i-th procedure, eur/year;

K

i

– capital cost for the purposes of the procedure

implementation, eur/year;

С

ei

– exploitation costs of i-th procedure.

Adduction of this set cost parameters to the

current period is performed by multiplying them by

the coefficient of the relative cost effectiveness of

additional capital investments. (E

n

).

Parameter (D) reflects average deviation of

infeasible calculated fire risks quantities at the

protected facility and the adjacent residential area

from feasible values. The current parameter takes on

the value from 0 to 1, and it is used in cases, where

not of all the values of fire risks are feasible, and also

used in order to define points in the territory of the

facility, where all values will be most designated to

feasible values:

=

++

++

,

(6)

Where

=

∑

/

;

(7)

=

∑

/

;

(8)

=

,>

0,≤

;

(9)

А – Dimensionless parameter of the average

infeasible individual fire risks quantities in the

territory of the facility (less than R

a

) from feasible

values (R

a

);

R

z

– Value of the quantity of infeasible individual

risks in the territory of gas distributing plant;

Z – Amount of infeasible values of individual fire

risks quantity in the territory of the enterprise;

B – Dimensionless parameter of the average

infeasible values of the individual fire risks in the

territory of the facility (lesser I

a

) from feasible values

(I

a

);

I

y

– Infeasible values of the individual fire risks in

residential area;

Y – Amount of infeasible values of individual risks

quantity in the residential area;

C – Dimensionless parameter of deviation of social

risk in the residential area from feasible value.

The current criteria were correlated in a unified

object function. Because of the primary objective

within the set of procedures on the optimization of

fire risks control is safety, the highest priority goes to

parameter K, the next criterion according to priority

is economic component (P). Against the backdrop of

couple combinations of procedure parameters K and

P are equal, and the required values of fire risks are

non-subnormal, Q becomes the key parameter that

provides rectangular distribution of the risk zones in

the territory of gas and oil facilities. Therefore, the

object function in the system of fire risks

management is presented in the following way:

=

(

max

(

)

,min

(

P

)

,max

(

))

(10)

3.2 Generation of the First Population

The logical sequence of actions as to the evaluation

of the effectiveness of risk value-reducing measures

can be represented as follows:

1. Choosing a fire risk-reducing value

measure from the database.

Searching the Optimal Combination of Fire Risks Reducing Measures at Oil and Gas Processing Facilities with the use of Genetic Algorithm

491

2. Analysis of the application with regard to

the objects in the territory.

3. Calculation of fire risks values for each

suitable object with the selected measure.

4. Save results to the specified massive.

5. If all measures are considered, go to the

end, or go to step 1.

The first population is generated by using the

approach that called the “roulette wheel” (Gen and

Cheng, 1997). The value of the effectiveness of each

measure is expressed by fitness function ((

)).

The next step after the assessment of the effectiveness

of measures is to calculate the overall function of all

measures:

= (

)−

(

)

(11)

3. Calculate the probability of selection (

) for each

measures

:

=

(

)

−min

(

)

(12)

k =1,2,…,number_of_measures

4. Calculate the total probability

for each measure

(

):

=

(13)

Each measure is one gen in the chromosome, so

chromosome consists of many measures.

=(

[

1

]

,

[

2

]

,

[

3

]

,…[])

(14)

where M1, M2, M3, Mk – measures for reducing

fire risks values.

A chromosome consists of k measures. The

selection process begins with rotation of a wheel for

k times; each time, one chromosome’s gen is selected

by the following algorithm:

1. Generate a random number r from the interval

[0, 1].

2. If ≤

, then select the first measure

;

otherwise, go to the k-th measure (2≤ ≤

count_of_mesuares) such as

≤ ≤

.

3. If the selected chromosome has already been

chosen, go to step 1 or choose this measure.

The above procedures are to be repeated while

counting the population not equal to the required

number.

3.3 Fitness Function

Evaluation function matching of chromosomes is

performed in two steps:

1. Implementation of all measures contained in the

chromosome.

2. Calculate the parameters of the goal function.

Fitness function plays the role of environment and

evaluates chromosomes according to their capability

to perform optimization criterion.

3.4 Selection

For the selection, the roulette wheel approach was

chosen. The roulette wheel can be constructed as

follows:

1. Calculate the value of the function of

compliance (

) for each chromosome

.

2. Calculate the overall function of the population

concerned:

= (

) −

−

=1,

(15)

k =1,2,…,pop_size

3. Calculate the probability of selection (

) for each

chromosome

:

=

(

)−

=1,

(16)

k =1,2,…,pop_size

4. Calculate the total probability (

) for each

chromosome (

):

=

,=1,2,…,_

(17)

The selection process begins with the rotation of

a wheel pop_size times; each time one chromosome

is selected by the following algorithm:

1. Generate a random number r from the interval

[0, 1].

2. If ≤

, then select the first chromosome

;

otherwise choose the k-th chromosome (2≤ ≤

_) such that

≤ ≤

.

3.5 Crossing and Mutation

For crossing of chromosomes, a method with a single

ICAART 2017 - 9th International Conference on Agents and Artificial Intelligence

492

point of exchange is used. In accordance with this

method, one point of exchange is randomly selected,

with respect to which parts of chromosomes are

swapped-parents. For this purpose, it generates the

integer in the interval [1, count_of_chromosomes],

which is the point of gene exchange.

Mutation consists of the change in one or more

genes with mutation probability equal ratio. If we

suggest different number of measures in

combinations, there is a little probability of removing

one gen from a chromosome.

4 ANALYSIS

The analysis of the received model was performed on

the basis of estimating the fire risk of a standard

facility in gas and oil industry (gas distribution plant),

in the territory of which propane-butane fraction was

major circulated substance.

In order to create the model of enterprise

optimization combination according to the reduction

of fire risks calculated values on the territory of the

current oil and gas enterprise, the list of suggested

procedures to reduce fire risks with provisional

capital and exploitation total costs from base value

has been formed (table 1).

Efficiency analysis as to the model has been

conducted in several stages, with the use of the

presented object function. During the first stage, Q

and D parameters of the object function, along with

the use of each procedure separately, were estimated

(table 2).

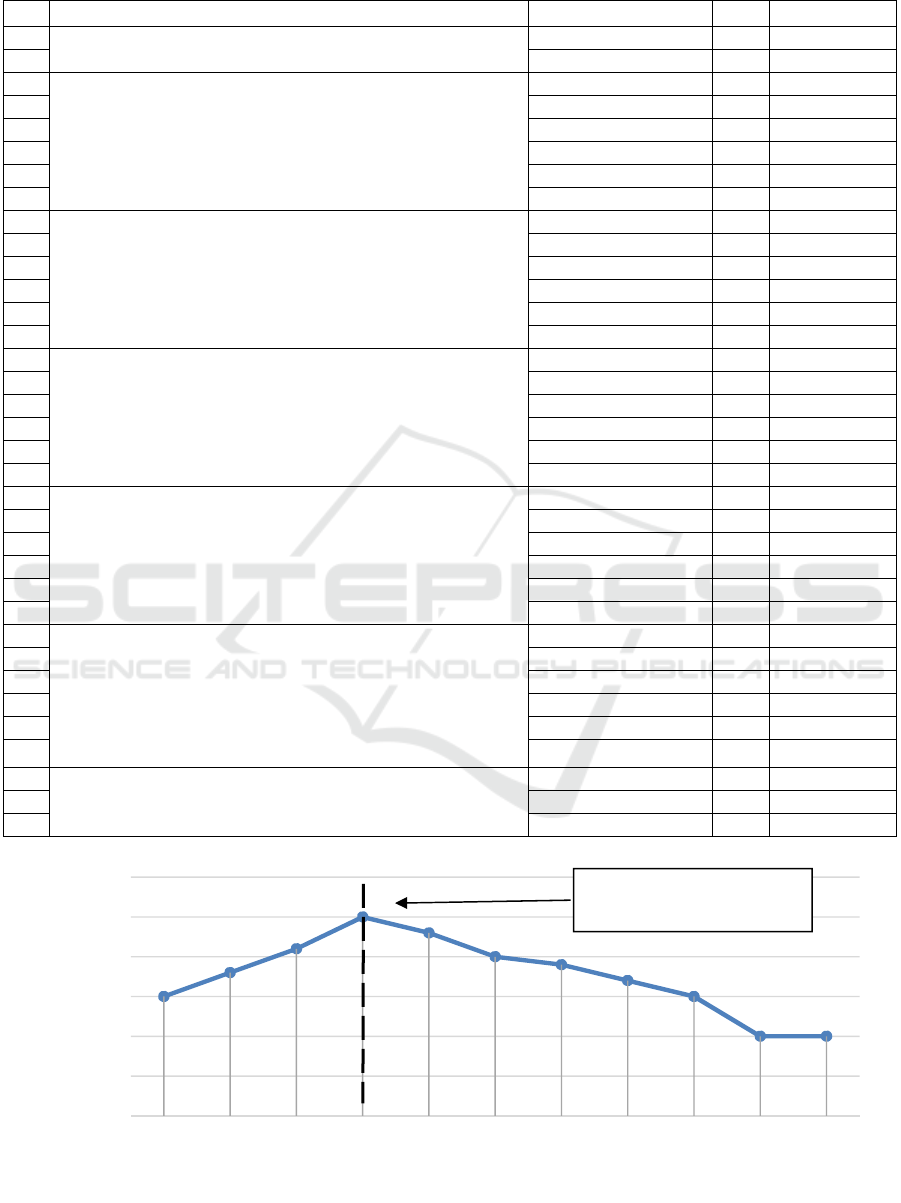

On the next stage the search of procedures

combinations with the help of suggested model was

conducted in order to analyze and select the best

parameters. As search stopping criterion was chosen

situation when combination includes only one

procedure. After the range of computing experiments

the following optimal parameters where defined:

– crossing percentage: 80;

– mutation percentage: 30;

– possibility of gene deletion from the

chromosome (procedures from the set): 75.

In order to create high variability of procedures

combination high crossing (80%) and mutation (30%)

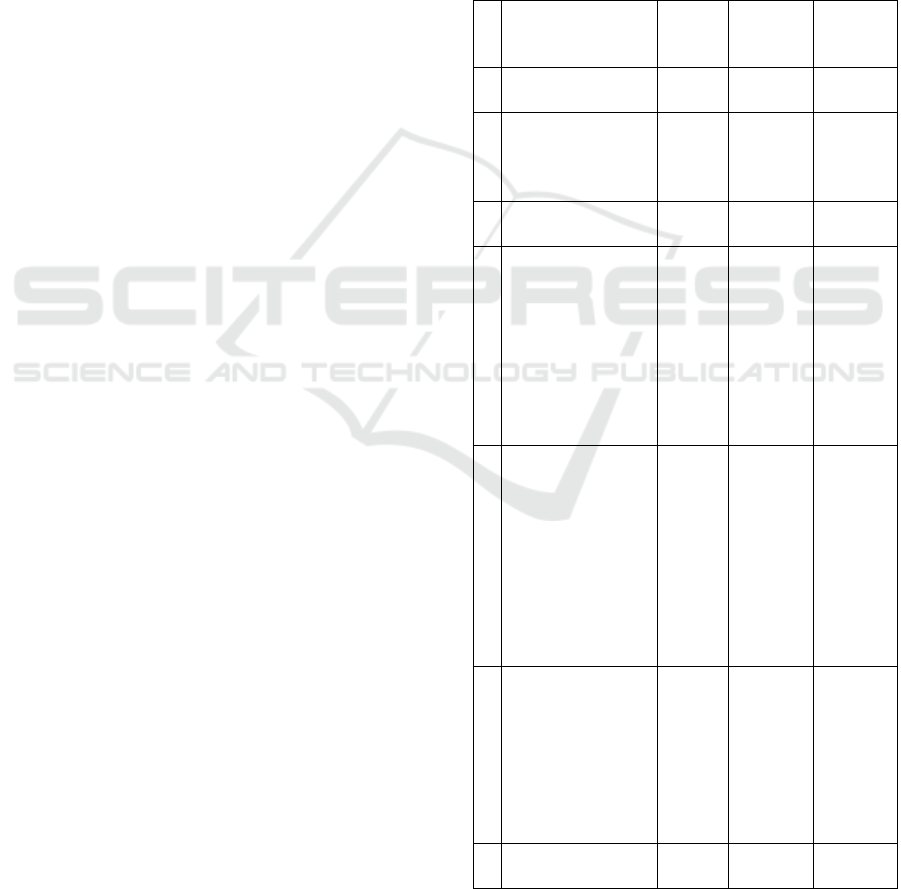

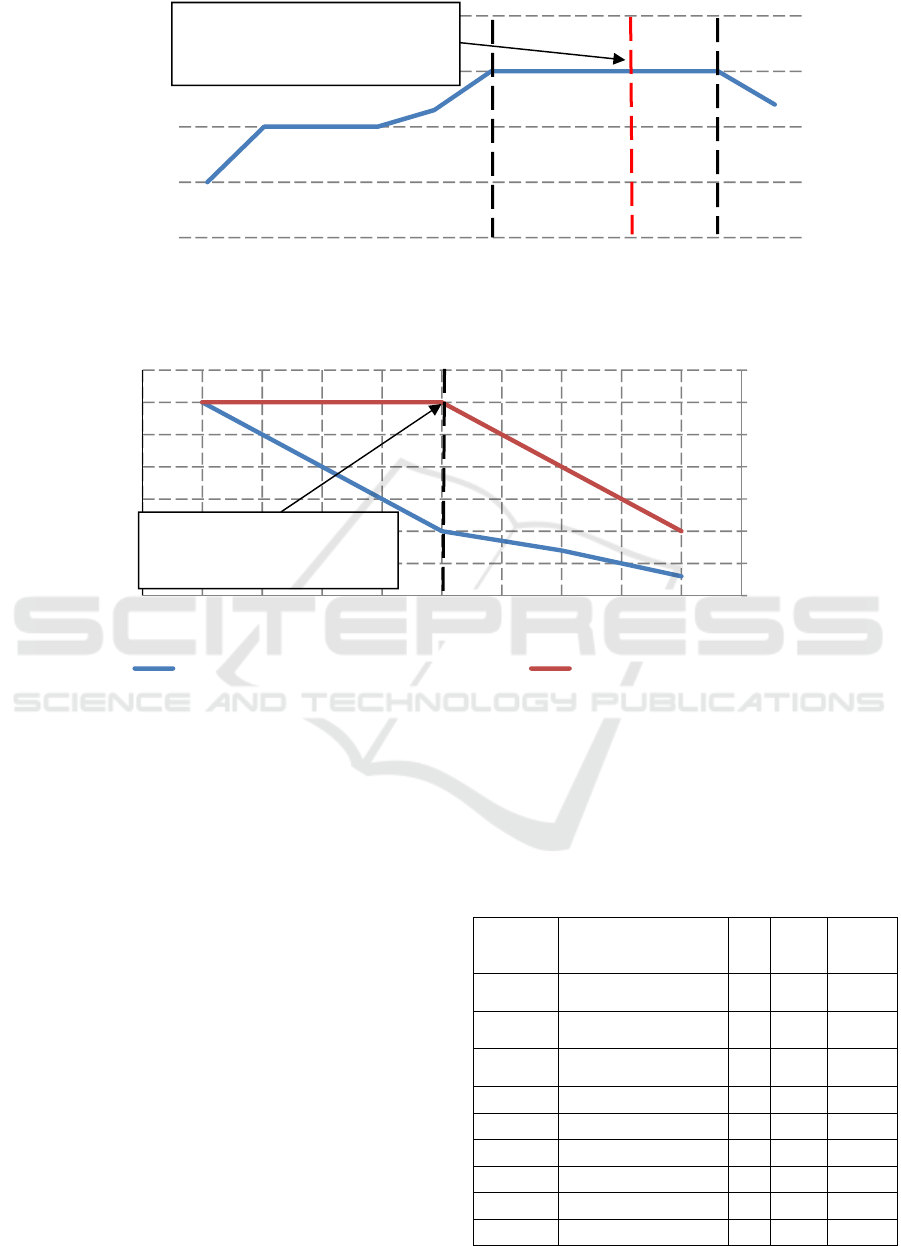

percentage was chosen (figure 2, 3). After the range

of experiments it was discovered that possibility of

gene deletion from the chromosome (procedures from

the set) significantly influence the time of selection

and in this case the quality of the selected

combinations do not change up to the particular

moment (figure 4). Therefore the possibility of gene

deletion from the chromosome was defined equal to

75%.

Mutation of 30% of specimens was chosen,

because in this value, the variability of the suggested

combination of the procedures significantly increases

and causes the increase in the quality of the algorithm

work results. The use of value under 30% causes the

decrease in the observed combinations variability and

the quality of results. According to the increase in the

variability, the decrease in the algorithm quality is

also observed (figure 3).

Table 1: Procedures of value of fire risks quantity reduction

in the territory of gas distribution plant.

№ Procedure of

reduction of value of

quantity of fire risk

K, run

С

ei

,

eur/year

P,

eur/year

1 Reduce filling

degree on 15 %.

0 X X

2 Reduce the

probability of

unstable unit

presence by 20%

0 0.3X 0.3X

3 Install automatic fire

alarm unit

0.3X 0.1X 0.16X

4 Install automatic fire

extinguishing unit or

water spray unit

under the control by

independent

organization

(irrespective of the

type of the fire

extinguishing unit)

X 0.3X 0.5X

5 Install automated

automatic fire

extinguishing unit

(water or foam) or

waterspray unit

without control of

performance

capability by

independent

organization

0.6X 0.15X 0.27X

6 Install other types of

automatic fire

extinguishing unit

without the control

of performance

capability by

independent

organization

0.5X 0.1X 0.2X

7 Install flanging 30

m

2

0.15X 0.01X 0.04X

Searching the Optimal Combination of Fire Risks Reducing Measures at Oil and Gas Processing Facilities with the use of Genetic Algorithm

493

Table 2: List of possible procedures and parameters of object function using Q and D parameters.

№ Procedure Object Q D

1

Reduce possibility of the object’s presence by 20 %

Road tank 16 781561535748

2 Railway tank 16 779786139413

3

Reduce filling degree by 15 %.

Road tank 16 779307110031

4 Railway tank 16 779307110031

5 Separator 16 779307110031

6 Tank 100 m

3

16 779307110031

7 Tank 50 m

3

16 779307110031

8 Tank 100 м

3

(group 2) 16 779307110031

9

Install automated automatic fire extinguishing unit (water or

foam) or water spray unit without the control of performance

capability by independent organization

Road tank 16 779307110031

10 Railway tank 16 779307110031

11 Separator 16 779307110031

12 Tank 100 m

3

16 779307110031

13 Tank 50 m

3

16 779307110031

14 Tank 100 m

3

(group 2) 16 779307110031

15

Install automatic fire alarm unit

Road tank 16 788404842408

16 Railway tank 16 781226809106

17 Separator 16 790786801193

18 Tank100 m

3

17 870910212155

19 Tank 50 m

3

17 953271699395

20 Tank 100 m

3

(group 2) 17 974221794362

21

Install automatic fire extinguishing unit or water spray unit under

the control by independent organization (irrespective of the type of fire

extinguishing unit)

Road tank 16 779307110031

22 Railway tank 16 779307110031

23 Separator 16 779307110031

24 Tank100 m

3

16 779307110031

25 Tank 50 m

3

16 779307110031

26 Tank 100 m

3

(group 2) 16 779307110031

27

Install other types of automatic fire extinguishing unit without the

control of performance capability by independent organization

Road tank 16 779307110031

28 Railway tank 16 779307110031

29 Separator 16 779307110031

30 Tank100 m

3

16 779307110031

31 Tank 50 m

3

16 779307110031

32 Tank 100 m

3

(group 2) 16 779307110031

33

Install flanging 30 m

2

Road tank 16 779307110031

34 Railway tank 16 779307110031

35 Separator 16 779307110031

Figure 2: Correspondence of Q parameter average value with mutation possibility.

15,50

16,00

16,50

17,00

17,50

18,00

18,50

1 102030405060708090100

Average value of Q parameter

Possibility of mutation, %

The maximum value

of the goal function

ICAART 2017 - 9th International Conference on Agents and Artificial Intelligence

494

Figure 3: Correspondence of Q parameter average value with crossover possibility.

Figure 4: Correspondence of procedures combinations and number of feasible risks on the territory of the enterprise (Q)

selection with possibility of their chromosome gene deletion.

After selecting the procedures as to the reduction

of fire risks of the calculated values with the use of

the suggested model, the list of possible combinations

was defined. A table was formed with the lists of the

most efficient combinations with various quantity of

procedures (table 3).

Procedures selection time amounted a little bit

more than 21 min. The suggested model was always

finding procedures combination with high value of

objective function, though during the process of

combination selection options are possible with

greater amount of procedures, but with lower value of

objective function. For example: when procedures

No. 3, 4, 5, 6, 1, 16, 21, 24, 10, 11 were combined,

then the parameters of the objective function were

equal to: Q=16, D=0,78, P=3,2X. Despite the fact that

in table 4 with various quantity of procedures only

one option of a procedure set is presented, the

program can output multiple alternate options of

combinations with high value of objective function

according to the required quantity of procedures in

one combination.

Table 3: Rating of procedures combinations as to the

decrease in fire risks calculation values at various quantities

of solutions in them.

Quantity

of

solutions

Numbers of solutions

according to table 3

Q D P

10

7, 8, 1, 2, 15, 18, 19,

26, 27, 33

18 0 2,42X

9

7, 8, 1, 2, 15, 18, 19,

26, 27

18 0 2,38X

8

5, 1, 15, 17, 18, 19, 22,

24

18 0 2,24X

7 7, 1, 2, 15, 18, 19, 26 18 0 1,88X

6 5, 1, 15, 18, 19, 22 18 0 1,58X

5 5, 16, 18, 20, 10 18 0 1,05X

4 1, 15, 16, 19 18 0 1,03X

3 5, 15, 16 18 0 0,62X

2 7, 15 17 0,98 0,46X

15

16

17

18

19

0 102030405060708090100

Average value of Q

parameter

Possibility of crossover, %

15

15,5

16

16,5

17

17,5

18

18,5

0

10

20

30

40

50

60

70

25 50 75 85 95

Value of Q and D parameters

Time of procedure

selection, min

Possibility of gene deletion, %

Time of procedure selection, min Value of objective funtion

Maximum variability with

the maximum value of the goal

function

The maximum value of the

goal function with the

minimum time

Searching the Optimal Combination of Fire Risks Reducing Measures at Oil and Gas Processing Facilities with the use of Genetic Algorithm

495

5 CONCLUSIONS AND FUTURE

WORK

The model of procedures for the management of fire

risks at oil and gas facilities was presented with the

use of genetic algorithms with modifications for

solving the assigned task:

1. Instead of the use of binary row, the

chromosome is used, the genes of which serve as

identifier of the procedures.

2. The primary population is generated

according to a specific algorithm.

3. In order to create the set from various quantity

of procedures, a changed mutation operation is used

consisting of random deletion of one of the

chromosome-s gene.

The efficiency of the model obtained was tested

in information system “FireRisks”. As a result, it was

concluded that one of the main advantages of the

suggested approach is the significant decrease in

calculation operations, which, in turn, solves the issue

of optimizing fire risks management procedures at the

facilities with the use of modern information systems.

The offered model also possesses high variability

of suggested variants, except for the significant

reduction in the required time for conducting the

variable combination of procedures on fire risk

calculated values decrease.

At present, unification is conducted of the created

models into a single system of intellectual support of

decision-making in the field of fire risks management

at oil and gas complex facilities.

The way forward is to create algorithms using

CMA Evolution Strategy, Differential evolution and

Simulated Annealing to compare the effectiveness of

the obtained models in the management of fire risks

in the oil refining facilities.

REFERENCES

Desheng Dash Wu, Shu-Heng Chen, David L. Olson,

Business intelligence in risk management: Some recent

progresses, Information Sciences, Volume 256, 20

January 2014, Pages 1-7, ISSN 0020-0255,

http://dx.doi.org/10.1016/j.ins.2013.10.008.

Abrahamsen, E. B., & Aven, T. (2008). On the compliance

of risk acceptance criteria with normative theories for

decision-making. Reliability Engineering & System

Safety, 93(12), 1906-1910. doi:http://dx.doi.org/

10.1016/j.ress.2008.03.021.

Gudin, S. V., Khabibulin, R. Sh., Rubtsov, D. N. Problems

of decision-making in fire risks management in the

territories of oil processing facilities using modern

software products // Fire and Explosion Safety. —

2015. — № 6 (62). — pp. 40-45. DOI:

10.18322/PVB.2015.24.12.40-45.

Xuancai Zhao, Qiuzhen Lin, Jianyong Chen, Xiaomin

Wang, Jianping Yu, Zhong Ming, Optimizing security

and quality of service in a Real-time database system

using Multi-objective genetic algorithm, Expert

Systems with Applications, Volume 64, 1 December

2016, Pages 11-23, ISSN 0957-4174,

http://dx.doi.org/10.1016/j.eswa.2016.07.023.

Martorell, S., Villanueva, J. F., Carlos, S., Nebot, Y.,

Sánchez, A., Pitarch, J. L., & Serradell, V. (2005).

RAMS+ C informed decision-making with the

application to multi-objective optimization of technical

specifications and maintenance using genetic

algorithms. Reliability Engineering & System Safety,

87(1), 65-75.

Ramirez, A. J., Knoester, D. B., Cheng, B. H., & McKinley,

P. K. (2009). Applying genetic algorithms to decision-

making in autonomous computing systems. The paper

presented during the Proceedings of the 6th

international conference on Autonomous computing.

Panov N.V., Shary S.P. (2011). Interval evolutionary

algorithm search the global optimum - News of Altai

State University, №. 12.

Schaefer I.A. (2012). Investigation on the efficiency of

genetic algorithm constrained optimization - Youth and

Science: Proceedings of the VIII All-Russian scientific

and technical conference of students, graduate students

and young scientists dedicated.

Sergienko R. B. (2009) Efficacy co-evolutionary genetic

algorithm constrained optimization. Herald of Siberian

State Aerospace University. Academician M.F.

Reshetnev № 3.

Caputo, A. C., Pelagagge, P. M., & Palumbo, M. (2011).

Economic optimization of industrial safety measures

using genetic algorithms. Journal of Loss Prevention in

the Process Industries, 24(5), 541-551.

Holland J.N (1975). Adaptation in Natural and Artificial

Systems. Ann Arbor, Michigan: Univ. Michigan Press.

Gen, M., & Cheng, R. (2000). Genetic algorithms and

engineering optimization (Vol. 7). John Wiley & Sons.

ICAART 2017 - 9th International Conference on Agents and Artificial Intelligence

496