Application of the Six Sigma Method for Improving Maintenance

Processes – Case Study

Michał Zasadzień

Institute of Production Engineering, Silesian University of Technology, Roosevelta 26, Zabrze, Poland

Keywords: Maintenance, Six Sigma, Improvement, Breakdown, Process, DMAIC.

Abstract: The article presents an implementation attempt of the DMAIC method used in the Six Sigma concept for the

improvement of production processes connected with maintenance. Thanks to the tools included therein

(process map, FMEA, SIPOC chart) we were able to define the: problem, i.e. which types of breakdowns

cause the most machine stoppage; precise structure of the failure removal process and its needs, owners,

resources, client-supplier relationships in particular sub-processes; source causes for overly long stoppages.

Learning the process and the causes of malfunctions allowed us to develop improvement procedures aimed

at minimising the fault removal times. The procedures developed have been implemented in the company

alongside a control plan, which will ensure supervision and their efficient functioning in the future.

1 INTRODUCTION

1.1 Maintenance

Processes connected with maintaining technical

resources used in production in good condition are

some of the key elements which affect the efficiency

of production processes, which directly influences

the company’s competitiveness on the market

(Żurakowski, 2004). Thanks to an efficient machine

park, a production company can supply its goods to

the customers in required quantity, quality and

within the agreed deadlines; it becomes a reliable

and trustworthy partner for its clients. A key element

to the production process is the availability of

machinery and equipment. Availability (operational

time) of machines and equipment which take part in

the production process is limited by several

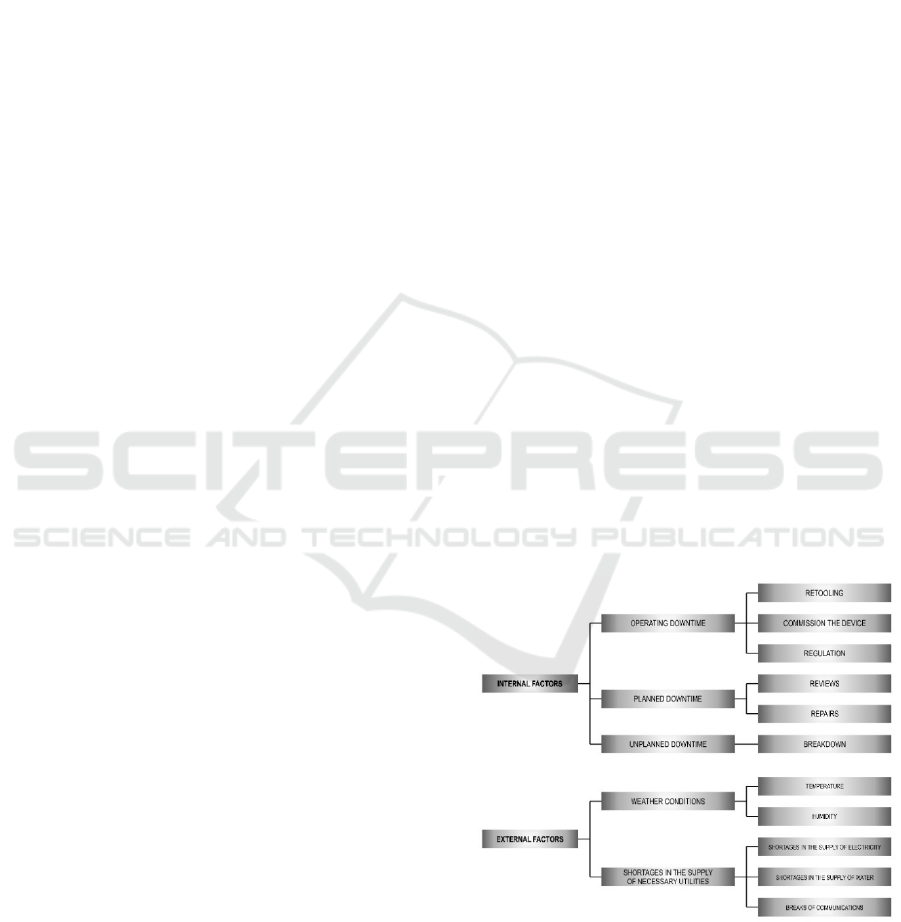

elements, which can be classified into two main

groups: stoppages caused external factors and

stoppages caused by internal factors. External

factors do not depend on the technical condition of

the machinery or the way it is operated. These

factors include stoppages caused by e.g. media

supply shortages (water, electricity,

communication), but also weather conditions which

make operation impossible (temperature in the

production hall). Internal stoppage factors depend on

the way the machines are operated and their

technical condition. These include stoppages caused

by breakdowns, inspections and renovation works,

but it is also the time needed for refitting or

calibration of the machines, launching them after a

stoppage, introducing improvements, training new

employees, etc. An example division is presented in

Figure 1.

Figure 1: Factors affecting machine unavailability (based

on Zasadzień and Midor 2015).

From the availability period we can also

distinguish the unused time (the period when the

machine is not working despite being operational),

which depends on planning, production quantity and

314

ZasadzieÅ

ˇ

D M.

Application of the Six Sigma Method for Improving Maintenance Processes â

˘

A ¸S Case Study.

DOI: 10.5220/0006184703140320

In Proceedings of the 6th International Conference on Operations Research and Enterprise Systems (ICORES 2017), pages 314-320

ISBN: 978-989-758-218-9

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

organisation. It is not considered as either external or

internal factor, as the machine is available for work

at the time.

The occurrence of a breakdown of a machine

involved in the production process can cause delays,

endanger its operators or the natural environment; it

increases the risk of crossing delivery deadlines or

decrease in product quality. The probability of

stoppages caused by breakdowns can be minimised

by introducing advanced maintenance strategies,

which include preventive maintenance based on

inspections and preventive renovation, or predictive

maintenance, based on monitoring the technical

condition (condition based maintenance) (Legutko,

2009). Even the most technically and

organisationally advanced preventive measures

cannot reduce the probability of a breakdown to an

absolute zero.

A breakdown is a sudden and mostly unforeseen

occurrence, which is why the process of its removal

is very complex; it is necessary to act in a rush and

reorganise working schedules. It consists of

administrative, organisational and technical

activities. Reducing the breakdown removal time,

and therefore reducing the downtime of the machine

directly affects the efficiency indicators of the

production process. It is, therefore, important to

skilfully direct the main and auxiliary processes

connected with the company’s activity in order to

efficiently use the working time, materials, machines

and equipment (Mikler, 2005). The maintenance

department often operates based on no precisely

defined schedule and its priorities are set on the fly,

usually with not enough human and technical

resources available, which is why the skills of

managing working time and using it efficiently are

especially important here (Midor, Szczęśniak and

Zasadzień, 2010; Mączyński and Nahirny, 2012).

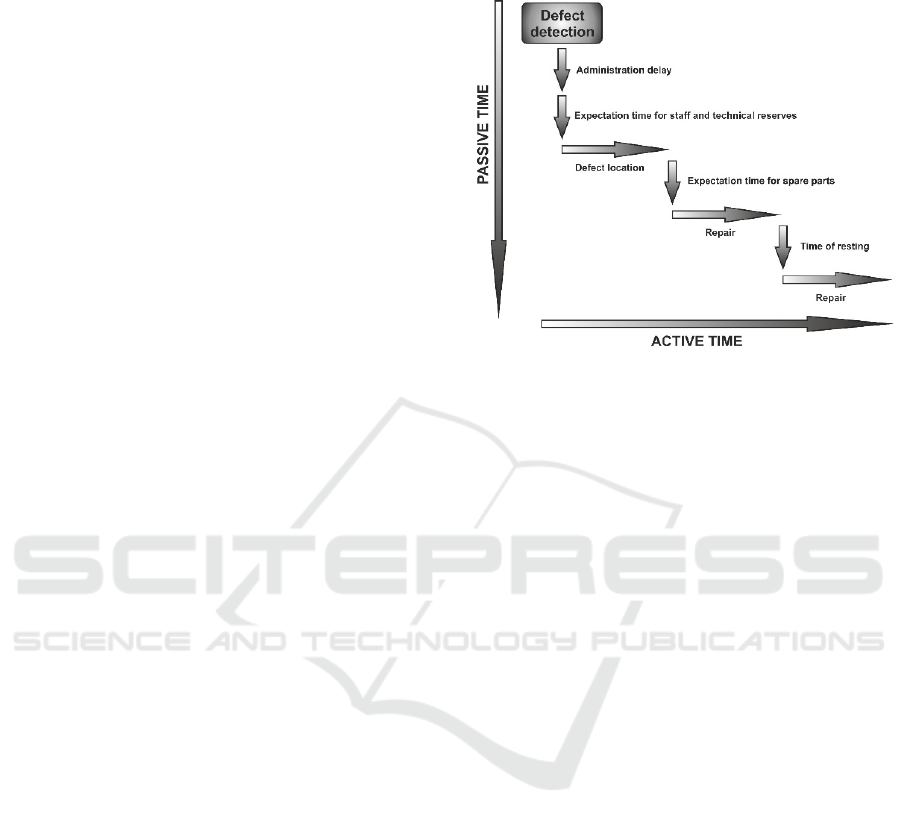

Stoppage caused by a breakdown can consist of

active and passive time, as presented in Figure 2.

The length of the downtime period caused by a

breakdown can be composed of elements whose

duration depends on the organisation and

management of the maintenance department

(administrative delay, waiting for personnel and

spare parts), i.e. the so-called support capability, as

well as on ease of maintenance, i.e. the ease with

which a given machine can be brought back to an

operational condition. Ease of maintenance depends

primarily on the qualifications and competence of

employees, the machine’s structure, its technical

condition and location. Shortening the downtime

caused by a breakdown consists in, for the most part,

shortening the passive and/or active time of the

breakdown removal process.

Figure 2: Time in the defect removal process (based on

Mikler, 2005).

1.2 DMAIC

Strategies for improving production processes have

been described in literature many times (Sahno and

Shavtshenko, 2014; Soković et al., 2009). Currently,

we have at our disposal such methods and concepts

of quality management as: PFMEA, TQM, Six

Sigma and others (Tague, 2005; Andrássyová,

2013). Apart from those, many less complex tools,

such as the Pareto chart, Ishikawa diagram or 5

WHYs (Midor, 2014) are also used with much

success.

One of the elements of streamlining the

production process can be the DMAIC (Define -

Measure - Analyse - Improve - Control) method,

rooted in the automotive industry and successfully

utilised in process improvement in accordance with

the Six Sigma assumptions (Krzemień and Wolniak,

2007; Wojraszak and Biały, 2013). Six Sigma is a

complex and flexible system for achieving,

sustaining and maximising business achievements. It

is characterised by the understanding of customers’

needs and organised use of facts, data and statistical

analysis results, and is based on management,

streamlining and constantly creating new, ever better

solutions with reference to all the processes taking

place in the company. Furthermore, it is aimed at

minimising the costs of bad quality while

simultaneously increasing customer satisfaction

(Truscott, 2003)). The method is used to eliminate

the causes of defects, losses they incur and any

problems related to quality in the aspects of

production, services and management. To solve

Application of the Six Sigma Method for Improving Maintenance Processes â

˘

A¸S Case Study

315

these problems, the method employs quality tools

and statistical techniques (Eckes, 2000).

When implementing the DMAIC method, a

number of auxiliary quality improvement tools and

methods are used. The improvement cycle using the

DMAIC method consists of the following elements

(Dreachslin and Lee, 2007; Bargerstock and

Richards, 2015):

Define. In this stage a team is created which

will be responsible for the implementation of

the method. The defining phase must identify

the following elements: determining the

problem (description of the problem, time of

occurrence), scope of the project (elements of

the process the team will work on), aim of the

project (a tangible goal to achieve and sustain

in the future).

Measure. During the measurement stage

parameters and places of measurement should

be defined, i.e. the points of process quality

and its costs along with a precise reflection of

the actual state. Conducting measurements

successfully requires a statistical outlook on

the particular production processes and

problems related to them. The measurement

stage employs methods such as: descriptive

statistics, summary charts, the SIPOC method

and the process map.

Analyse. During this stage of the

methodology, by analysing the particular

parameters of the process, the team will be

able to determine the causes of the problem,

which will then need to be eliminated or

fixed. The results obtained during the

measurement stage are used in order to

investigate the correlation between causes of

defects and process variability sources. In

order to identify the causes of process

variability, which are a significant factor in

defect creation, the PFMEA analysis, the

Pareto - Lorenz chart and the Ishikawa

diagram are often used.

Improve. Improvement can otherwise be

understood as engagement in the course of

the production process, i.e. reduction of the

defect rate. It consists in searching for and

evaluating potential causes of process

variability and investigating their

correlations. Learning the multi-factor

relations allows for achieving the desired

results.

Control. The control stage takes place after

finishing the new process implementation

phase. The fundamental goal of Six Sigma is

the constant observation of the improvements

introduced to maintain a desired level of

quality. In this phase of the DMAIC the

measurement system and potential

verification process are repeated to confirm

the improvement of the process. Afterwards,

measures are taken to appoint control over

the streamlined processes; usually a so-called

control plan is created.

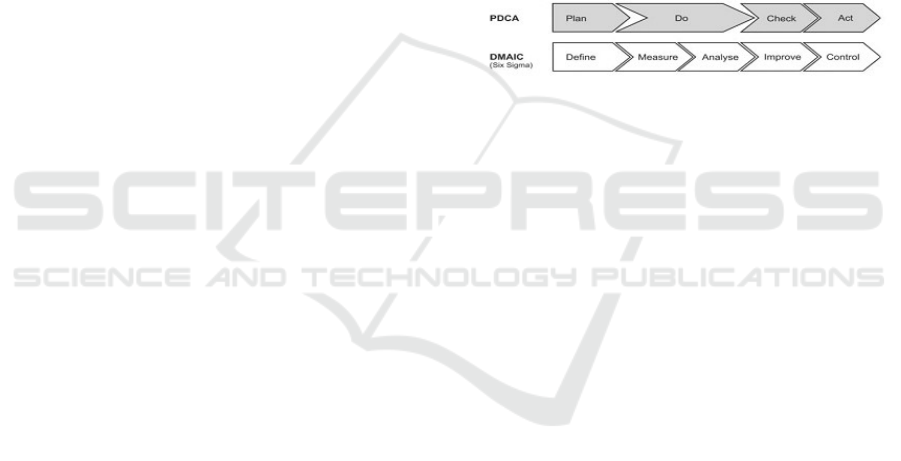

As we can infer from the above description,

based on the concepts of Six Sigma and Lean, the

DMAIC method used in management systems relies

on the principle of constant improvement and PDCA

formulated by E. Deming (Deming, 2000) and

required by the ISO 9001 series standards. A

comparison of both concepts has been presented in

the literature in many forms (George et al., 2005;

Soković et al., 2010) (fig. 3).

Figure 3: PDCA vs DMAIC.

The DMAIC methodology is used for improving

production processes, successfully contributing to

the reduction of the number of non-compliant

products and reducing production costs. The author

of this elaboration decided to introduce this method

to processes auxiliary to the production process, i.e.

to the maintenance process. The maintenance

process, as every other process, has its inputs,

outputs, clients, suppliers and can be described using

indicators, similar to the production process. The

case presented pertains to the breakdown removal

process.

2 DMAIC IMPLEMENTATION

2.1 Define

In the company which is the subject of this study the

key machines are the extruders producing HDPE

(high-density polyethylene) pipes. Due to that fact, a

total of 154 breakdowns of these machines were

analysed in the period of 32 months. This allowed us

to identify those components whose breakdowns

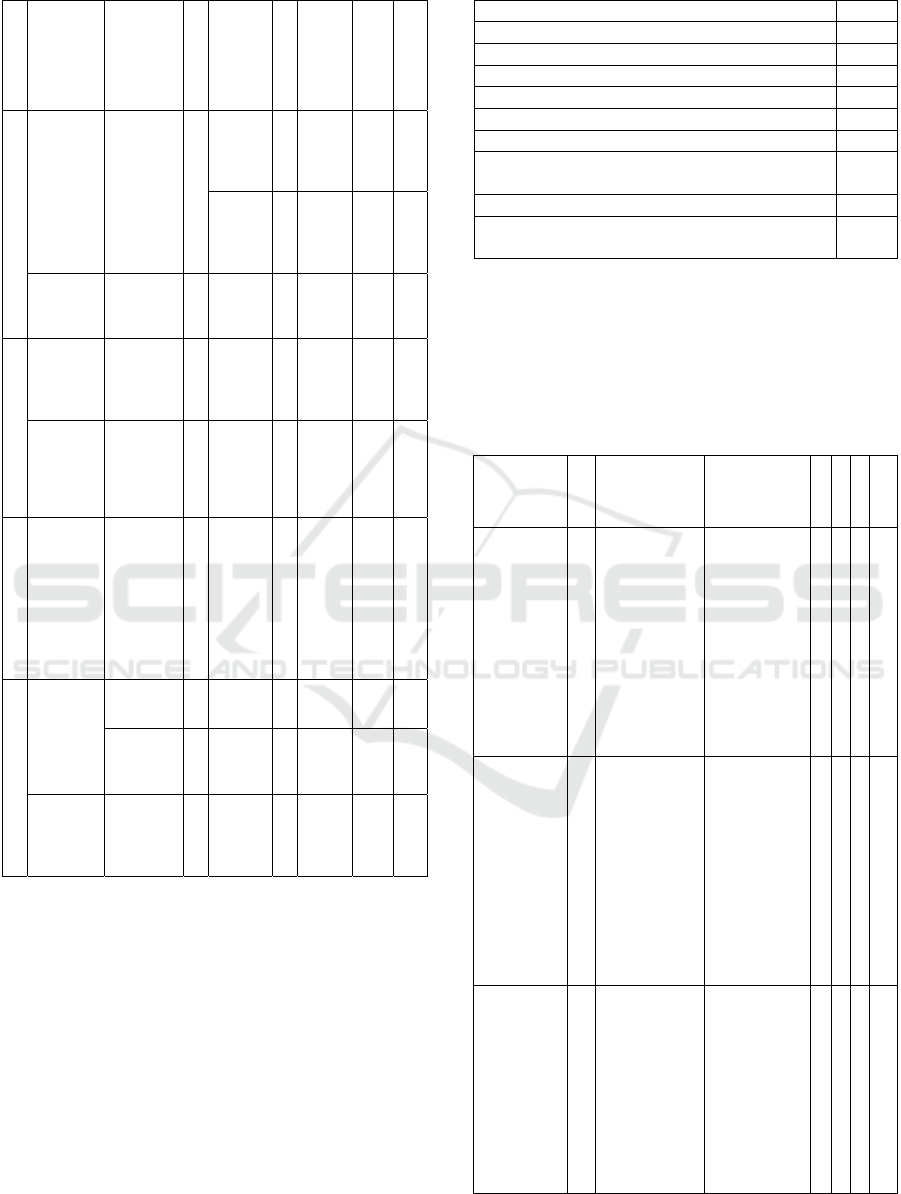

caused the longest stoppages, as presented in Table

1.

As can be seen in the above table (Tab. 1), the

breakdown that caused the longest downtime was

the damaged connector of extruder head heater. In

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

316

the examined period of time the downtime due to

this failure lasted more than 130 hours (7

breakdowns of this type), and the average time of

downtime was 18 hours, therefore, it was decided

that the problem should be subjected to analysis. The

aim was to reduce the total duration of downtime

caused by this failure by reducing the average

downtime duration and the number of breakdowns.

Table 1: Extruder component stoppages analysed.

Failure

Average

downtime

duration

[h]

Total

downtime

duration

[h]

Damaged heater supply

connector

18.69 130.83

Incorrect caterpillar track

haul-off

14.19 103.49

Pipe surface corrugation 10.19 71.31

Leak of oil from

transmission gear

9.50 37.99

Crown brush failure 17.80 35.59

Error on controller display 22.83 2.83

No heating 0.98 20.64

Fuse blown 0.48 20.30

Destroyed basket for

granulated product

18.60 18.60

No granules haul 1.61 12.88

Failure of ozone exhaust 0.42 7.48

Damaged frequency

invertor

7.34 7.34

Leak of mass from the

head

1.08 4.32

Leak in heat exchanger 3.81 3.81

No cooling 0.16 2.28

Saw failure 0.22 1.55

Printer failure 0.50 1.00

Clogged head sieve 0.44 0.88

Calibrator failure 0.24 0.72

Vacuum pump 0.21 0.21

Damaged air duct 0.03 0.03

Extractor failure 0.01 0.02

Drive system failure 0.02 0.02

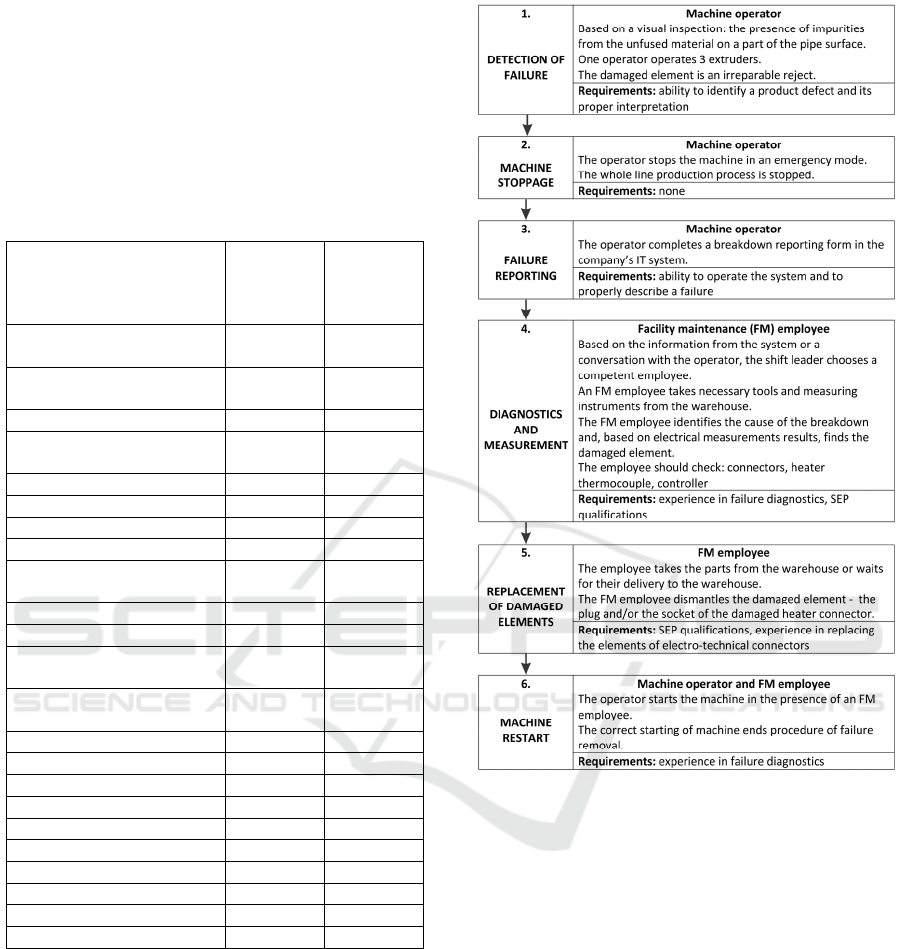

2.2 Measure

Based on the information obtained from the

production and maintenance employees, a map for

the process of identifying and removing failures of

the extruder head heater connector was created. The

process map has been presented in Fig. 4.

Figure 4: Failure removal process map.

2.3 Analyse

Based on the information collected in the process of

identifying all the process steps and creating a

process map, a modified PFMEA matrix was

developed to identify potential causes and effects of

delays during the process of removing a failure of

extruder head heater and estimate their importance

for the process. For the needs of the case study, a

scale from 1 to 4 was adopted, where 1 means a

positive situation and 4 – a negative one (Table 2).

Application of the Six Sigma Method for Improving Maintenance Processes â

˘

A¸S Case Study

317

Table 2: PFMEA matrix.

Process stage

Problem

Cause

Importance

Effect

Occurrence

Current

prevention

Effectiveness

of prevention

IOE

1.

Failure

detected too

late

Connector

burnt during

work

4

Line

stoppage.

3

Observat

ion of the

product

by the

operator

4 48

Possibility

of further

defects

1

Observat

ion of the

product

by the

operator

4 16

Failure

occurs after

extruder

refitting

Connector

damaged in

the process o

f

refitting

3

Line

stoppage

3

N

one 4 36

3.

Too long

time of

recording the

failure in the

system

Insufficient

knowledge o

f

the IT system

1

FM is not

aware of

the failure

3

Training

of a

newly

employe

d worker

2 6

FM does not

know the

failure

details

Inaccurate

description o

f

failure

3

FM

employee

does not

have the

sufficient

equipment

4

N

one 4 48

4.

Incorrect

diagnostics

Having

identified the

cause of the

failure, the

employee

does not

control the

remaining

elements of

the system

4

Long

duration o

f

failure

removal

2

N

one 4 32

5.

Long waiting

time for the

parts

Lack of parts

in the

warehouse

4

Prolonged

failure

removal

1

N

one 4 16

Long

searching for

parts in the

warehouse

3

Prolonged

failure

removal

2

N

one 4 24

Long

duration of

damaged

elements

replacement

Waiting for

the head

temperature

to go down

4

Prolonged

failure

removal

4

N

one 4 64

The analysis conducted by means of the PFMEA

tool revealed which of the analysed causes of the

problems was the most important for the process of

failure removal. Table 3 contains the analysis

synthetic results.

For further works aimed at improving the

process, problems whose IOE was at least 40, i.e.

three most important items: waiting for the head

temperature to go down, connector burnt during

work – line stoppage and inaccurate description of

the failure were selected.

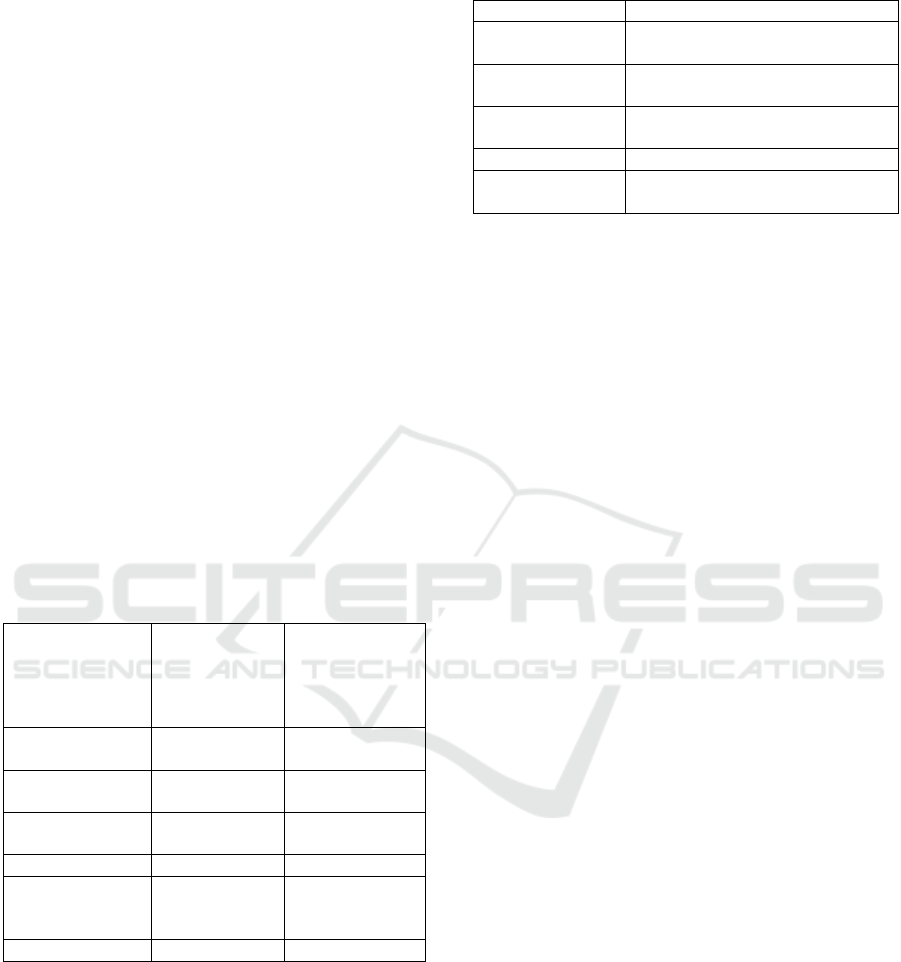

Table 3: PFMEA analysis results.

Cause IOE

Waiting for the head temperature to go down 64

Connector burnt during work – line stoppage 48

Inaccurate description of failure 48

Connector damaged in the process of refitting 36

Incorrect diagnostics 32

Long searching for parts in the warehouse 24

Connector burnt during work – possibility of

further defects

16

Lack of parts in the warehouse 16

Too long waiting for the failure to be recorded

in the system

6

2.4 Improve

At the further stage of analysis, improvement actions

for all the important problems were proposed. Their

synthetic summary has been given in Table 4.

Table 4: Improvement actions.

Cause

IOE

Improvement

actions

Benefits I O E

IOE

Waiting for

the head

temperature

to go down

64

Introducing a

system of

doubled

heads. A

spare head is

waiting at the

quick

replacement

station.

No need to

wait for the

head to cool

down.

Replacement

of the head

for a cold one

enables an

immediate

failure

removal.

4 2 2 16

Connector

burnt

during

work – line

stoppage

48

Installing a

system of

product

surface

monitoring

with software

for image

analysis.

No need for

the operator

to observe

the pipe

surface.

Automatic

alarm

initiation in

case of

surface

defects.

4 2 2 16

Inaccurate

description

of failure

48

Introducing a

uniform base

for failure

reporting in

the IT system

and training

of machine

operators in

failure

identification.

FM

employees

receive

reliable and

precise

information

enabling their

faster

preparation

for work.

3 1 2 6

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

318

The introduced improvement actions allowed a

considerable reduction of IOE values for the

analysed problems.

An estimation of the costs involved in the

improvement actions has revealed that the cheapest

solution is improving the process of failure

reporting, as the enterprise has a possibility of

modifying the IT system. Introducing a spare head at

the extruder workstation required constructing and

making trolleys for fast head replacements. Since the

company manufactures its products on a mass scale,

the expensive heads are stored in the company’s

warehouses. The most costly improvement action is

introducing a system for product surface quality

monitoring. It has been decided that such a system

will be implemented in the places where operators

have a hindered access, i.e. where observation of the

process is difficult.

2.5 Control

After implementing the actions planned, the values

of duration of downtimes due to failures of heaters

in extruder heads are monitored on a regular basis

and their causes analysed according to the schedule

contained in Table 5.

Table 5: Process monitoring.

Element of

control

Duration of

downtimes due

to heater

connectors’

failures

Elements of

downtime

duration

Control limit

Downtime

duration <10 h

None

Frequency of

control

1/half year 1/half year

Control system

Records in IT

system

Failure removal

reports

Control method Figures Charts

Response plan

Meeting with

production

managers

Meetings with

FM shift leaders

Person in charge FM manager FM manager

At the last stage of creating a control plan,

standardization (Table 6) was taken into

consideration, aimed at maintaining the standards

which the process of failure removal improvement is

based on.

Table 6: Standardization.

Person in charge Undertaken actions

Quality engineer

Instructions on head replacement

using a fast exchange trolley

Quality engineer

Instructions for pipe surface

control

Production

manager

Operators’ training in product

surface observation

Quality engineer Failure reporting instructions

FM manager

Training for operators in failure

reporting and diagnostics

Training actions are undertaken in the event new

workers are employed and any important changes

have been made in the instructions and procedures.

3 CONCLUSIONS

The aim of the undertaken actions has been

achieved. The duration of downtimes caused by

failures of extruder head heater connectors was

reduced. The period of results verification lasted 8

months. During that time there were two such

failures and downtime duration decreased from 18 to

9 hours. This process will be further monitored.

DMAIC is a long-term method and despite being

very extended and time-consuming, it guarantees

proper identification of problems and their effects

for the maintenance process. It ensures developing

and implementing effective improvement actions

and, what is most important, it guarantees that the

implemented actions will be continued in the future.

The described case study has proved that it is

possible to effectively use quality engineering

methods and tools for maintenance process

improvement. This allows increasing the availability

of machines as well as shortening the duration of

downtimes and failure removal.

ACKNOWLEDGEMENTS

This article was prepared within the statutory

research titled “Production engineering methods and

tools for development of smart specializations”,

work symbol 13/030/BK_16/0024 performed at

Silesia University of Technology, Institute of

Production Engineering.

Application of the Six Sigma Method for Improving Maintenance Processes â

˘

A¸S Case Study

319

REFERENCES

Andrássyová Z., Žarnovský J., Álló Š., Hrubec J. 2013.

Seven new quality management tools, Advanced

Materials Research. vol. 801, special issue, pp. 25-33.

Bargerstock A.S., Richards S.R. 2015. Case Study:

Application of DMAIC to Academic Assessment in

Higher Education Quality Approaches, Higher

Education, vol. 6, no. 2, pp. 31-40.

Deming W.E. 2000. The New Economics for Industry,

Government, Education, 2

nd

edition. MIT Press.

Cambridge.

Dreachslin J.L., Lee P.D. 2007. Applying Six Sigma and

DMAIC to Diversity Initiatives, Journal of Healthcare

Management, vol. 52, no. 6, pp. 361-367.

Eckes G. 2000. The Six Sigma Revolution, John Wiley &

Sons, Inc. New York.

George M., Rowlands D., Price M., Maxey J. 2005. Using

DMAIC to improve speed, quality, and cost. In The

Lean Six Sigma Pocket Toolbook: A Quick Reference

Guide to Nearly 100 Tools for Improving Process

Quality, Speed, and Complexity, McGraw-Hill, pp. 1-

26.

Krzemień E., Wolniak R. 2007. Analysis of process of

constant improvement of six sigma. In Current trends

in commodity science. Proceedings of the 9th

International Commodity Science Conference (IGWT),

ed. R. Zieliński. Poznan University of Economics

Publishing House. Poznan, pp. 227-232.

Legutko S. 2009. Development trends in machines

operation maintenance, Eksploatacja i Niezawodnosc

– Maintenance and Reliability, no. 2, pp. 8-16.

Mączyński W., Nahirny T. 2012. Efektywność służb

utrzymania ruchu jako składowa efektywności

przedsiębiorstwa. In Innowacyjność procesów i

produktów, ed. R. Knosala, Oficyna Wydawnicza

PTZP. Opole, pp. 203-213.

Midor K. 2014. An analysis of the causes of product

defects using quality management tools, Management

Systems in Production Engineering, no. 4, pp. 162-

167.

Midor K., Szczęśniak B., Zasadzień M. 2010. The

identification and analysis of problems within a scope

of cooperation between traffic maintenance

department and production department. Scientific

Journals Maritime University of Szczecin, vol. 96, no.

24, pp. 48-52.

Mikler J. 2005. Strategie Utrzymania Ruchu: przegląd i

analiza, Seminar Protech.

Sahno, J., Shevtshenko, E. 2014. Quality improvement

methodologies for continuous improvement of

production processes and product quality and their

evolution. In Proceedings of 9th International

DAAAM Baltic Conference Industrial Engineering,

Tallinn University Of Technology, Tallinn, pp. 181-

186.

Soković M., Jovanović J., Krivokapić Z., Vujović A.

2009. Basic Quality Tools in Continuous Improvement

Process, Strojniški vestnik - Journal of Mechanical

Engineering, no 5, pp. 1-4.

Sokovic M., Pavletic D., Kern Pipan K. 2010. Quality

Improvement Methodologies – PDCA Cycle, RADAR

Matrix, DMAIC and DFSS, Journal of Achievements

in Materials and Manufacturing Engineering, vol 43,

issue 1, pp. 476-483.

Tague N.R. 2005. The Quality Toolbox , ASQ Quality

Press, Milwaukee, 2

nd

edition.

Truscott W. 2003. Six Sigma: Continual Improvement For

Businesses, Butterworth Heinemann. New York.

Wojtaszak M., Biały W. 2013. Measurement system

analysis of attribute or continuous data, as a one of the

first steps in Lean Six Sigma projects. In Systems

supporting production engineering, ed. J.

Kaźmierczak. PA NOVA. Gliwice, pp. 144-162.

Zasadzień M., Midor K. 2015. Innovative application of

quality management tools in a hard coal mine. In

Proceedings of 15th International Multidisciplinary

Scientific GeoConference SGEM 2015, book1, vol. 3,

pp. 415-422.

Żurakowski F. 2004. Funkcjonowanie przedsiębiorstwa.

Zarządzanie, Wydawnictwa Szkolne i Pedagogiczne.

Warszawa.

.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

320