in-vitro Assessment of Expanded-Polytetrafluoroethylene Stentless

Tri-leaflet Valve Prosthesis for Aortic Valve Replacement

Guangyu Zhu

1, 2

, Masakazu Nakao

3

, Qi Yuan

1

and Joon Hock Yeo

2

1

School of Energy and Power Engineering, Xi’an Jiaotong University,

No. 28 Xian Ning West Rd., 710049, Xi’an, Shaanxi, China

2

School of Mechanical and Aerospace Engineering, Nanyang Technological University,

50 Nanyang Ave., 639798, Singapore, Singapore

3

Department of Cardiothoracic Surgery, KK Women’s and Children’s Hospital,

100 Bukit Timah Rd., 229899, Singapore, Singapore

Keywords: ePTFE, Artificial Heart Valve, Aortic Valve Replacement.

Abstract: Truly stentless polymeric valve prosthesis can be a viable alternative for aortic valve replacement (AVR). In

the present paper, the dynamic and hemodynamic performance of a novel designed expanded-

polytetrafluoroethylene (ePTFE) stentless tri-leaflet valve was assessed experimentally. The in-vitro tests

were performed under time-varying physiological pressure by using the Vivitro pulse duplicator. A high-

speed camera, a flow meter, and pressure transducers were utilized to evaluate the dynamic leaflet behaviours

and coaptation parameters. The maximum effective orifice area, mean pressure gradient, regurgitant volume,

leakage volume and energy loss of the stentless ePTFE tri-leaflet valve are 2.86 cm

2

, 9.89 mmHg, 7.09

ml/beat, 2.81 ml/beat and 129.03 mJ, respectively. The results of the current study may provide a viable option

for the future clinical application.

1 INTRODUCTION

The Ross procedure is a widely accepted surgical

option for the treating of the aortic valve failure (Ross

1967; Talwar et al. 2012; Brancaccio et al. 2014;

Oury et al. 1998). However, for the patients with a

diseased pulmonary valve or in a severe situation, the

standard AVR thus became an alternative treatment

method of the aortic valve failure.

The need for AVR is increasing for pediatric

patients. And the quest for a perfect aortic valve

substitute has been going on for more than fifty years

(Lower et al. 1960). The selection of the ideal

prosthesis for AVR is controversial (Mazzitelli et al.

1998). Multiple surgical options for AVR are

available for these patients, including stented and

stentless porcine valves, porcine valve conduits,

bovine jugular vein conduits, mechanical valves and

mechanical valve conduits. The prosthetic selection

for AVR, however, is still debatable, and all choices

have significant limitations.

The use of polymeric materials for valve leaflets

has been more than 60 years (Roe & Moore 1958).

Polymeric valves’ long-term durability and no need

of permanent anticoagulation combined the

advantages of mechanical valves and bioprosthetic

valves (Sachweh & Daebritz 2006). Among the

polymeric materials, ePTFE valves have shown good

performance in the recent clinical trials in pulmonary

sites(Miyazaki et al. 2011; Miyazaki et al. 2007).

However, there is a lack of information about the

application of ePTFE valves in aortic site. To expand

the current understanding of the performance of the

ePTFE valves in the aortic site, the dynamic and

hemodynamic performance of an ePTFE tri-leaflet

aortic valve prosthesis was assessed in this paper.

2 METHODS

2.1 Preparation of Physical Model

The design parameters of the tri-leaflet valve were

listed in Table 1.

186

Zhu G., Nakao M., Yuan Q. and Yeo J.

in-vitro Assessment of Expanded-Polytetrafluoroethylene Stentless Tri-leaflet Valve Prosthesis for Aortic Valve Replacement.

DOI: 10.5220/0006184401860189

In Proceedings of the 10th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2017), pages 186-189

ISBN: 978-989-758-216-5

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Table 1: Design parameters of the conventional tri-leaflet

valve.

Design Parameters Value

d

b

(mm) 25

d

c

(mm) 25

H

s

(mm) 4

H (mm) 21.9

A (mm

2

) 561.3

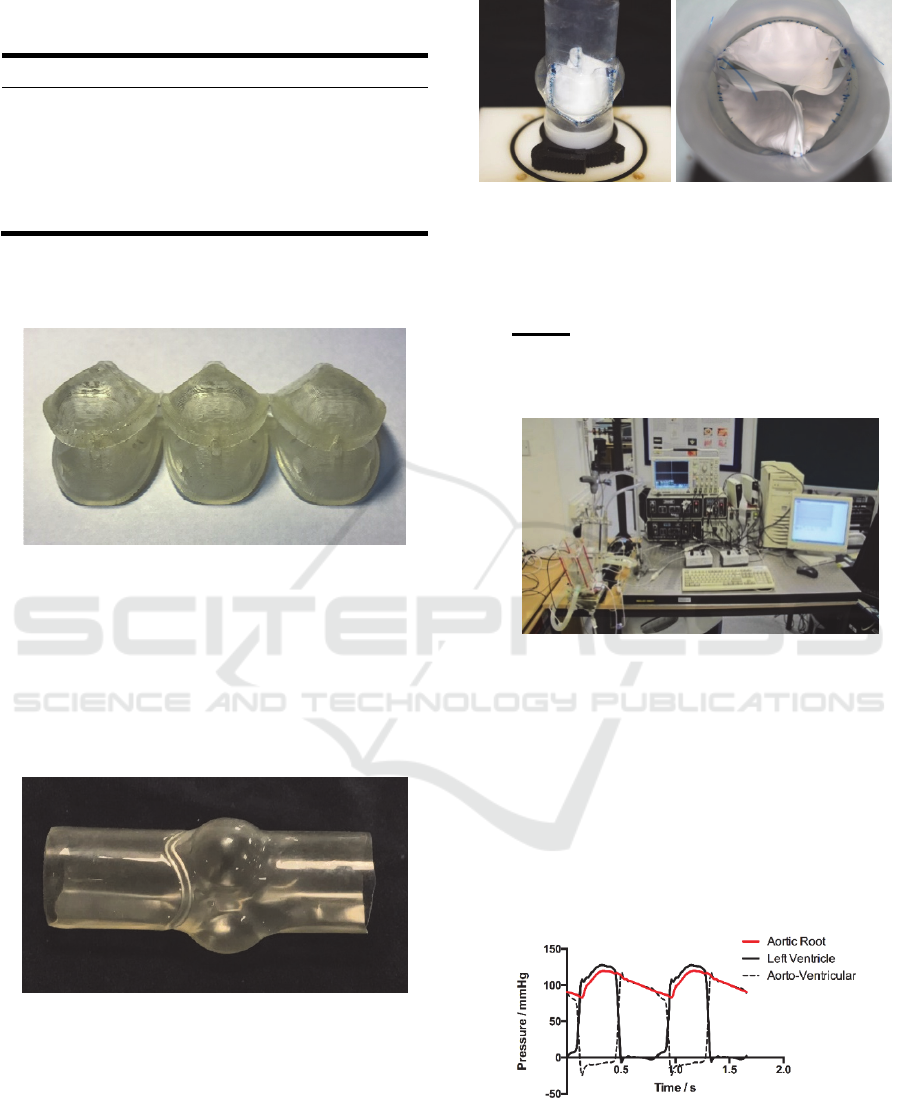

A set of resin mold based on the geometry was

fabricated by using 3D printing technology (Figure

1).

Figure 1: 3D Printed Resin Mold.

The valve leaflets were prepared by placing the

ePTFE membrane in-between the mold and cutting

along the edge. The aortic root was constructed by

using the silicon polymer (VTV, MCP-HEK Tooling

GmbH, Kaarst, Germany). Guiding lines were cast

inside the silicon conduits to guarantee the leaflets

can be properly sutured (Figure 2).

Figure 2: Silicon Conduit.

The commissures of the leaflets were sutured to

the aortic root with one running 4-0 polypropylene

suture following the guide line in the conduit (Figure

3).

Figure 3: Valved Conduit.

2.2 Experimental Set-up and Flow

Conditions

The Vivitro pulse duplicator (Vivitro Systems Inc.,

Victoria, BC, Canada) was used to generate the

physiological pressure and flow in the left ventricle

and aorta.

Figure 4: Experimental Setup.

The physiological pressure applied in the in-vitro

investigation was shown in Figure 5. The ventricular

and aortic pressures were measured at the exit of the

left ventricle and the exit of the aorta model by

pressure transducers (SPC 330A, Millar Instruments,

Inc., Houston, TX, USA), respectively. The pressures

were controlled by adjusting the resistor and piston

movement magnitude. The systolic and diastolic

pressure in the aorta is 120 mmHg and 80 mmHg,

respectively.

Figure 5: Time-varying pressure loadings measured in in-

vitro experiment.

All tests were conducted at a stroke volume of 75

ml (5.4L/min) and a heart rate of 72 beats/min. An

aqueous solution of glycerol (42% by weight) was

in-vitro Assessment of Expanded-Polytetrafluoroethylene Stentless Tri-leaflet Valve Prosthesis for Aortic Valve Replacement

187

used as the working fluid to mimics blood. The

dynamic viscosity and density of the working fluid is

3.52 mPa·s and 1038 kg/m

3

, respectively.

3 RESULTS

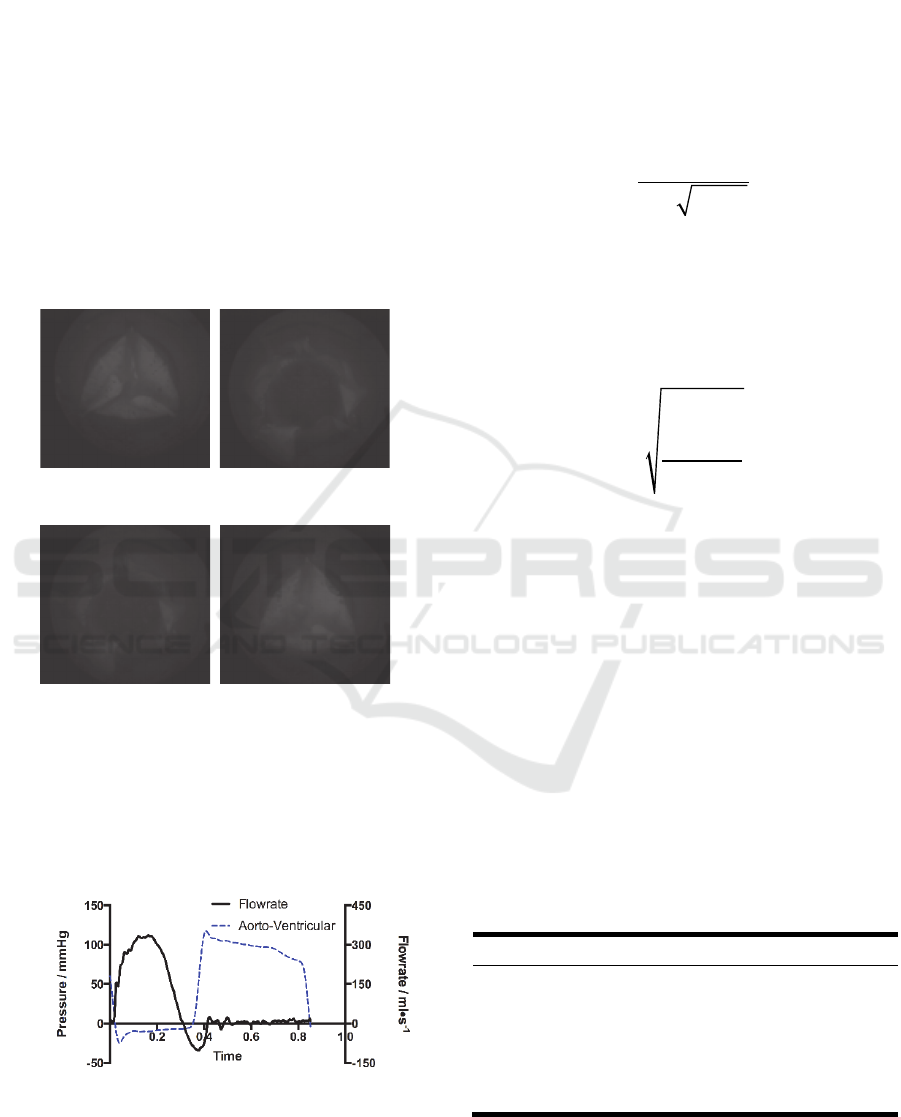

To analyze the structural dynamics, key frames from

the film that recorded by the high-speed camera were

extracted (Figure 6). The start point of the record was

defined as t = 0. The opening of the leaflets begins at

t = 0.024s. The opening stage, fully open stage,

closing stage of the valve are 0.12s, 0.132s, and

0.136s, respectively. The leaflets of the valve closed

fully at 0.38s.

t=0.024s t=0.124s

(a) Pre-open (b) Fully opened

t=0.244s t=0.380s

(c) Pre-close (d) Fully closed

Figure 6: Dynamic deformation of the valve leaflets.

The mean trans-valvular pressure of the proposed

valve during the systolic phase is 9.89 mmHg. The

trans-valvular pressure and the aortic flow of the

valves are shown in Figure 7.

Figure 7: Aortic flow rates over one cardiac cycle.

The regurgitant volume (V

R

) and leakage volume

(V

L

) was 7.09 ml and 2.81 ml per cycle, respectively.

Thus the regurgitant fraction (RF) can be calculated

by using the Equation 1:

RF = (V

R

+V

L

)/V

F

×100% (1)

Where V

R

is the regurgitant volume, V

L

is the

leakage volume and V

F

is the forward volume.

The equation from ISO: 5840:2005 (ISO:

5840:2005) was applied to evaluate the maximum

EOA (Equation 2):

A

EO

Q

RM S

51.6 P /

(2)

Where

A

EO

is the orifice area of the valve (cm

2

),

P

is the mean systolic transvalvular pressure

gradient (TPG) in mmHg,

is the working fluid

density (g/cm

3

), and

Q

RM S

is the root mean square

volumetric flow rate (ml/s) (Equation 3).

Q

RMS

Q

2

(t )dt

t

1

t

2

t

2

t

1

(3)

Derived from Bernoulli equation, the energy loss

of the left ventricular that associated with the valve

prosthesis was calculated by integrating the aorto-

ventricular pressure times flow rate with respect to

the time (Bernacca et al. 2002; Claiborne et al. 2013;

Burriesci et al. 2010) (Equation 4):

1

0

0.1333 ( ) ( )

t

L

t

EptQtdt

(4)

Where

E

L

is the energy loss (mJ), to be the

range of a cardiac cycle,

p

is the aorto-ventricular

pressure difference (mmHg) and

Q

(t)

(ml/s) is the

volume flow. The calculated parameters are listed in

Table 2.

Table 2: In-vitro results of the hemodynamic parameters.

Parameters Values

RF (%) 14.37

TPG (mmHg) 9.89

E

L

(mJ) 129.03

Q

RMS

(ml/s) 456.0

EVOA (cm

2

) 2.86

t

0

t

1

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

188

4 DISCUSSION AND

CONCLUSIONS

The current study was aimed to assess the

performance of the ePTFE tri-leaflet valve. The

dynamic and hemodynamic performance of the valve

were in-vitro evaluated under in-vitro conditions.

As the well-accepted industry standard, ISO

5480:2055 provides a full set of criterions for

evaluating a valve design (ISO 5480:2055). The

criterions that related with the current study were

listed in Table 3.

Table 3: Minimum performance requirements for aortic

valve prosthesis.

Valve size

(TAD, mm)

25

A

EO

(cm

2

) ≥1.20

RF (%) ≤15

The EOA and RF of the valve that tested in this

study are all satisfied the criterions of the standard.

This validated that the proposed ePTFE valve design

could be a viable choice for AVR operations.

ACKNOWLEDGEMENTS

This study was supported by Singapore National

Medical Research Council

(NMRC/CIRG/1435/2015) and China Postdoctoral

Science Foundation (2016M600781)

REFERENCES

Bernacca, G.M. et al., 2002. Hydrodynamic function of

polyurethane prosthetic heart valves: influences of

Young’s modulus and leaflet thickness. Biomaterials,

23(1), pp.45–50.

Brancaccio, G. et al., 2014. The Ross procedure in patients

aged less than 18 years: the midterm results. The

Journal of thoracic and cardiovascular surgery, 147(1),

pp.383–388.

Burriesci, G. et al., 2010. Design of a novel polymeric heart

valve. Journal of medical engineering and technology,

34(1), pp.7–22.

Claiborne, T.E. et al., 2013. In vitro evaluation of a novel

hemodynamically optimized trileaflet polymeric

prosthetic heart valve. Journal of biomechanical

engineering, 135(2), p.021021.

ISO 5840:2005 - Cardiovascular implants -- Cardiac valve

prostheses.

Lower, D. et al., 1960. Autotransplantation of the pulmonic

valve into the aorta. The Journal of Thoracic and

Cardiovascular Surgery, 39, pp.680-687.

Mazzitelli, D. et al., 1998. Aortic valve replacement in

children: are we on the right track?. European Journal

of Cardio-Thoracic Suregery, 13(5), pp.565-571.

Miyazaki, T. et al., 2011. Expanded polytetrafluoroethylene

conduits and patches with bulging sinuses and fan-

shaped valves in right ventricular outflow tract

reconstruction: Multicenter study in Japan. The Journal

of thoracic and cardiovascular surgery, 142(5),

pp.1122–1129.

Miyazaki, T. et al., 2007. Expanded polytetrafluoroethylene

valved conduit and patch with bulging sinuses in right

ventricular outflow tract reconstruction. The Journal of

thoracic and cardiovascular surgery, 134(2), pp.327–

332.

Oury, J.H. et al., 1998. The Ross procedure: Current

registry results. Annals of Thoracic Surgery, 66(6),

pp.S162-S165.

Roe, B.B. and Moore, D., 1958. Design and fabrication of

prosthetic valves. Experimental medicine and surgery,

16(2-3), pp.177–182.

Ross, D., 1967. Replacement of aortic and mitral valves

with a pulmonary autograft. The Lancet, 290(7523),

pp.956–958.

Sachweh, J.S. and Daebritz, S.H., 2006. Novel

“biomechanical” polymeric valve prostheses with

special design for aortic and mitral position: a future

option for pediatric patients?. ASAIO journal, 52(5),

pp.575–580.

Talwar, S. et al., 2012. Aortic valve replacement with

biological substitutes in children. Asian cardiovascular

and thoracic annals, 20(5), pp.518–524.

in-vitro Assessment of Expanded-Polytetrafluoroethylene Stentless Tri-leaflet Valve Prosthesis for Aortic Valve Replacement

189