Integrated Optical Devices

Fabrication of Multimode Interference Devices in Fused Silica by Femtosecond

Laser Direct Writing

Vítor A. Amorim

1,2

, João M. Maia

1,2

, D. Alexandre

1,3

and P. V. S. Marques

1,2

1

Center for Applied Photonics, INESC TEC, Rua Dr. Roberto Frias, Porto, Portugal

2

Department of Physics and Astronomy, University of Porto, Porto, Portugal

3

Department of Physics, University of Trás-os-Montes e Alto Douro, Vila Real, Portugal

Keywords: Femtosecond Laser, Laser Direct Writing, Integrated Optics, Optical Waveguide, Multimode Interference

Device, Power Splitter.

Abstract: 1xN (N=2, 3, 4) MMI power splitters were fabricated in a fused silica substrate by laser direct writing, using

a focused 515 nm amplified femtosecond laser beam, and characterized at 1550 nm. To accomplish this,

several low loss waveguides were fabricated side by side to form a multimode waveguide with the output in

a polished facet of the substrate, while a single low loss waveguide was fabricated to inject light in the

centre of the multimode waveguide. The performance of the fabricated devices was optimized by testing

three different designs.

1 INTRODUCTION

Multimode interference (MMI) devices are very

important integrated optical components that can be

used for several applications. Such devices can be

used, for instance, as optical power splitters

(Hosseini, 2011), couplers (Soldano, 1992),

wavelength division (de)multiplexers (Porque,

2000), and switches (Al-hetar, 2002; Yu, 2011).

MMI devices have clear advantages over other

power splitters, such as directional couplers and Y-

junctions. The ability to yield 1xN power splitting

with a single device, without the need for cascading

directional couplers or Y-junctions, enables a higher

compactness which is key in the fabrication of

integrated photonic circuits.

MMIs are usually composed by an input single-

mode waveguide, connected to a multimode

waveguide, and output single-mode waveguides.

Light propagating in the single-mode waveguide

arrives at the multimode waveguide where a large

number of modes is excited, due to an increase in

normalized frequency. The excited modes will then

interfere between them as they propagate in the

multimode region, since now each one has a slightly

different phase velocity. Due to this fact,

constructive interference occurs in certain locations,

depending on the multimode waveguide parameters.

These devices are usually fabricated by Planar

Lightwave Circuit technology (PLC), however, to

achieve them, many fabrication steps and a

cleanroom environment is required. Femtosecond

laser direct writing changed the way integrated

optical devices can be fabricated, eliminating many

of the problems found in planar technology. This

technique already enabled the fabrication of buried

waveguides (Eaton, 2005), Bragg gratings (Zhang,

2007), directional couplers (Eaton, 2006), Y-

junctions (Liu, 2005), integrated lasers (Calmano,

2010), among others. In 2005, Watanabe et al.

(Watanabe, 2005) reported the fabrication of MMI

devices with a longitudinal geometry inside

synthesized silica. The longitudinal geometry

involves the translation of the sample in a direction

parallel to the incident laser beam yielding very

symmetrical cross-sections, while being limited by

the objective working distance and very simple

device geometries. In 2008, Da-Yong et al. (Da-

Yong, 2008) also reported the fabrication of MMI

devices, but this time using a transversal geometry.

The transversal geometry relies on the translation of

the sample perpendicularly to the direction of the

incident beam, where only the depth of the

fabricated devices is limited, while several device

geometries can be implemented. Despite the greater

fabrication freedom, Da-Yong et al. used a low

Amorim V., Maia J., Alexandre D. and Marques P.

Integrated Optical Devices - Fabrication of Multimode Interference Devices in Fused Silica by Femtosecond Laser Direct Writing.

DOI: 10.5220/0006170602830287

In Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2017), pages 283-287

ISBN: 978-989-758-223-3

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

283

aperture objective to create the multimodal device in

a single pass, thus somewhat eliminating this

freedom in the fabrication of MMI devices.

The previous works only served as a proof of

concept, since the devices were only functional for

visible light. The work presented in this paper serves

the purpose of fabricating MMI devices with a

configurable design, working at the

telecommunication wavelengths.

2 FABRICATION

The femtosecond laser system used in the fabrication

of these devices was a Satsuma HP fibre amplified

laser. The second harmonic beam at λ = 515 nm with

an approximate 250 fs pulse duration was focused

inside the fused silica substrate 50 µm below the

surface with a 0.55 NA aspheric lens, as seen in

figure 1.

Figure 1: Schematic of device fabrication using the

transverse writing geometry.

The conditions determined to be optimal for low loss

optical waveguides were used: the writing beam

polarization was oriented to be parallel to the

scanning direction, a pulse energy of 250 nJ (at 500

kHz) was used, and a sample scanning velocity of

400 µm/s utilized. These exposure conditions

yielded waveguides as seen in figure 2 (a), with total

insertion losses of 1.1 dB, for 2.5 cm long

waveguides, and a mode diameter of 12.3 µm x 7.1

µm (see figure 2 (b)), resulting in coupling losses of

0.37 dB per facet and propagation losses of 0.14

dB/cm.

A schematic of the fabricated MMI devices is

shown in figure 3 (a). Three designs were tested in

this work, two where the MMI is written

longitudinally (figure 3 (b)) and one where the MMI

Figure 2: Cross-sectional image (a) and mode field

distribution (b) of the fabricated waveguides.

is written transversely (figure 3 (c)). In the case of

the longitudinal MMIs the first design is based on

the writing of longitudinal waveguides from border

A to B with a given waveguide separation, while the

second is based on the writing of the longitudinal

waveguides from border A to the fifth waveguide

from the centre, followed by the ones from border B

to the fifth waveguide from the centre and then

writing the central waveguides alternately from the

closest to the borders until the centre is reached. For

the transversal MMIs the waveguides are written

from border A to B in sequence, from the input to

output with a given separation distance. It should be

noticed that the number of waveguides in this last

design is far superior to the ones required in

longitudinal designs. All MMI devices were

fabricated in a way that the output plane is placed

exactly on the polished facet of the substrate.

Figure 3: Schematic of the fabricated devices (a), as well

as the longitudinal (b) and transversal (b) fabrication

designs employed to optimize the device behaviour.

3 EXPERIMENTAL RESULTS

For higher splitting ratios it is normal that wider

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

284

MMI devices are required in order to separate the

lobes. With this in mind, 50 µm wide MMIs were

studied in this work. Since these devices behavior is

highly dependent on width and femtosecond laser

direct writing has a finite resolution, it is to be

expected that while doing N writings with a given

waveguide separation S the total width is larger than

NxS. To compensate the final devices were written

with 47.5 m.

Another variable that can change the device

performance is the refractive index distribution

inside the multimode waveguide. The BPM

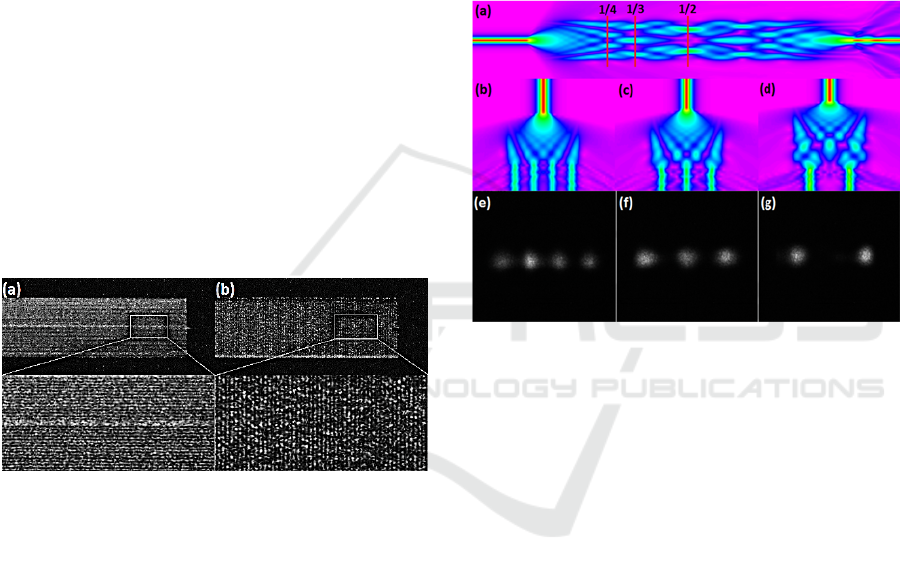

simulations made in this work to support the device

fabrication were obtained with a uniform refractive

index distribution, and, as such, the separation

between fabricated waveguides was controlled in

order to obtain, as close as possible, the simulations

refractive index distribution. In figure 4 longitudinal

and transversal MMI devices with a waveguide

separation of 1 µm are displayed. From the figure it

is possible to observe that with a waveguide

separation of 1 µm the modification is not uniform

since individual writing tracks are still observable.

Due to this fact the separation between fabricated

waveguides was reduced to 0.5 µm.

Figure 4: Dark field microscopy image of a longitudinal

(a) and transversal (b) MMI device fabricated with a

waveguide separation of 1 µm.

To fabricate power splitters with multimode

waveguides three values are required, namely

multimode waveguide width, length, and working

wavelength (device refractive index is also

important but not critical). The width was set to 50

µm, working wavelength to 1550 nm, but device

length is an unknown for the different splitting

ratios. To determine the device length BPM

simulations were made with Rsoft (see figure 5 (a)

to (d)) using a 2D model and a 7x10

-3

refractive

index difference. In this work 1x4, 1x3 and 1x2

power splitters were investigated and the device

length was found to be, through simulation, roughly

690, 900 and 1350 µm, respectively. With the

fabrication parameters set above, several MMI

devices were fabricated using the three designs

specified in section 2. All these designs were tested

in an effort to improve the device symmetry and

decrease stresses originated by the fabrication

process. The first longitudinal design and the

transversal design showed very similar results in

terms of modal distribution (first longitudinal design

results are displayed in figure 5 (e) to (g)), while the

second longitudinal design did not show the

simulated behavior but rather random distributions.

It should be noted that the CCD from which the

modal distributions were measured does not have a

uniform sensitivity over its area, explaining why

unequal distribution is observed.

Figure 5: Figure showing the simulated behaviour and the

results obtained with the first longitudinal design for 50

µm width devices. First the 1:1 MMI behaviour is

simulated (a) and the 1:4 (b), 1:3 (c) and 1:2 (d)

simulations obtained for a length of 690, 900 and 1350 µm

respectively. From these simulated lengths the 1:4 (e), 1:3

(f) and 1:2 (g) behaviour was obtained experimentally.

These results can be explained by the microscope

images in figure 6. From the top view images, in

bright and dark field, it is possible to see that the

second longitudinal design is not as uniform as the

others. In the cross section view this becomes

obvious since the guiding region is much more

irregular. Apart from this, it is also interesting to

notice that the other two designs have problems. In

the first longitudinal design all MMI devices

fabricated had a crack in the corner of border B (last

waveguide to be written). This probably happens

due to stress accumulation on this corner, resulting

from the fact that waveguides were written from

border A to B. On the transversal design some

problems can also be identified by the dark field

image. This design was implemented since it avoids

the stress build-up but another problem arises due to

hardware communication times. At border B more

light is visible than at border A due to the laser being

Integrated Optical Devices - Fabrication of Multimode Interference Devices in Fused Silica by Femtosecond Laser Direct Writing

285

Figure 6: Top and cross section view microscopy images of the fabricated longitudinal and transversal MMI devices with a

waveguide separation of 0.5 µm.

ON while decelerating, which causes an increased

alteration of the local properties. Another interesting

fact is the stress concentration on the top region of

the MMI device, seen in the Differential Interference

Contrast (DIC) images, and also the higher light

scattering in this region for the longitudinal design

when compared with the transversal design.

4 CONCLUSIONS

The fabrication of multimode interference devices,

working at 1550 nm, was shown to be possible in

fused silica with the femtosecond laser direct writing

technique. Power splitting was achieved with

experimental results proving to be in good

agreement with BPM simulations. Splitters with a

splitting ratio of 1x4, 1x3 and 1x2 were fabricated

with a 50 µm width and a length of the multimode

section of 690, 900 and 1350 µm, respectively.

ACKNOWLEDGEMENTS

Vítor Amorim acknowledges the support of Calouste

Gulbenkian Foundation through the Stimulus to

Scientific Research Program (Grant no. 141773).

This work was also supported by Project

"NanoSTIMA: Macro-to-Nano Human Sensing:

Towards Integrated Multimodal Health Monitoring

and Analytics/NORTE-01-0145-FEDER-000016" is

financed by the North Portugal Regional Operational

Programme (NORTE 2020), under the PORTUGAL

2020 Partnership Agreement, and through the

European Regional Development Fund (ERDF).

REFERENCES

Hosseini, A, Kwong, D, Zhang, Y, Subbaraman, H, Xu, X

& Chen, R 2011, ‘1xN multimode interference beam

splitter design techniques for on-chip optical

interconnections’, IEEE Journal on Selected Topics in

Quantum Electronics, vol. 17, no. 3, pp. 510-515.

Soldano, L, Veerman, F & Smit, M 1992, “Planar

Monomode Optical Couplers Based on Multimode

Interference Effects”, Journal of Lightwave

Technology, vol. 10, no. 12, pp. 1843-1850.

Porque, J, Coudray, P, Charters, R, Kribich, K, Etienne, P

& Moreau, Y 2000, ‘WDM based on multimode

interferencecoupler built in an organic-inorganic

material’, Optics Communications, vol. 183, no. 1, pp.

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

286

45-49.

Al-hetar, A, Supa’at, A, Mohammad, A & Yulianti, I

2008, ‘Multimode interference photonic switches’

Optical Engineering, vol. 47, no. 11, pp. 112001.

Yu, F, Yamamoto, K, Piao, X & Yokoyama, S 2011,

‘Multimode interference waveguide switch of electro-

optic polymer with tapered access waveguides’,

Physics Procedia, vol. 14, pp. 25-28.

Eaton, S, Zhang, H & Herman, P 2005, ‘Heat

accumulation effects in femtosecond laser-written

waveguides with variable repetition rate’, Optics

Express, vol. 13, no. 12, pp. 4708-4716.

Zhang, H, Eaton, S & Herman, P 2007, ‘Single-step

writing of Bragg grating waveguides in fused silica

with an externally modulated femtosecond fiber laser’,

Optics Letters, vol. 32, no. 17, pp. 2559-2561.

Eaton, S, Chen, W & Zhang, L 2006, ‘Telecom-Band

Directional Coupler Written With Femtosecond Fiber

Laser’, Photonics Technology Letters, vol. 18, no. 20,

pp. 2174-2176.

Liu, J, Zhang, Z, Chang, S, Flueraru, C & Grover, C 2005,

‘Directly writing of 1-to-N optical waveguide power

splitters in fused silica glass using a femtosecond

laser’, Optics Communications, vol. 253, pp. 315-319.

Calmano, T, Siebenmorgen, J, Hellmig, O, Petermann, K

& Huber, G 2010, ‘Nd:YAG waveguide laser with 1.3

W output power, fabricated by direct femtosecond

laser writing’, Applied Physics B, vol. 100, no. 1, pp.

131-135.

Watanabe, W, Note, Y & Itoh, K 2005, ‘Fabrication of

multimode interference waveguides in glass by use of

a femtosecond laser’, Optics Letters, vol. 30, no. 21,

pp. 2888-2890.

Da-Yong, L, Yan, L, Yan-Ping, D, Heng-Chang, G, Hong,

Y & Qui-Huang, G 2008, ‘Transverse Writing of

Multimode Interference Waveguides inside Silica

Glass by Femtosecond Laser Pulses’, Chinese Physics

Letters, vol. 25, no. 7, pp. 2500-2503.

Integrated Optical Devices - Fabrication of Multimode Interference Devices in Fused Silica by Femtosecond Laser Direct Writing

287