µSmartScope: 3D-printed Smartphone Microscope

with Motorized Automated Stage

Lu

´

ıs Rosado

1

, Jo

˜

ao Oliveira

1

, Maria Jo

˜

ao M. Vasconcelos

1

, Jos

´

e M. Correia da Costa

2

, Dirk Elias

1

and Jaime S. Cardoso

3

1

Fraunhofer Portugal AICOS, Rua Alfredo Allen 455/461, 4200-135 Porto, Portugal

2

Instituto Nacional de Sa

´

ude Dr. Ricardo Jorge, Rua Alexandre Herculano 321, 4000-055 Porto, Portugal

3

INESCTEC and University of Porto, Rua Dr. Roberto Frias, 4200-465 Porto, Portugal

Keywords:

Microscopy, Mobile Devices, Motorized Microscope Stage, Developing Countries, Mobile Health.

Abstract:

Microscopic examination is currently the gold standard test for diagnosis of several neglected tropical diseases.

However, reliable identification of parasitic infections requires in-depth train and access to proper equipment

for subsequent microscopic analysis. These requirements are closely related with the increasing interest in

the development of computer-aided diagnosis systems, and Mobile Health is starting to play an important role

when it comes to health in Africa, allowing for distributed solutions that provide access to complex diagnosis

even in rural areas. In this paper, we present a 3D-printed microscope that can easily be attached to a wide

range of mobile devices models. To the best of our knowledge, this is the first proposed smartphone-based

alternative to conventional microscopy that allows autonomous acquisition of a pre-defined number of images

at 1000x magnification with suitable resolution, by using a motorized automated stage fully powered and

controlled by a smartphone, without the need of manual focus of the smear slide. Reference smears slides

with different parasites were used to test the device. The acquired images showed that was possible to visually

detect those agents, which clearly illustrate the potential that this device can have, specially in developing

countries with limited access to healthcare services.

1 INTRODUCTION

The increasing interest in the development of

computer-aided diagnosis systems for disease diag-

nosis in developing countries is well known, mainly

due to the common practical difficulties experienced

in rural health facilities. The excessive workload due

to shortage of medical staff has been reported as one

of the most significant problems (Quinn et al., 2014),

fact that has been driving the development of new so-

lutions that aim to facilitate the diagnosis of several

neglected tropical diseases.

The detection of several neglected tropical dis-

eases, particularly blood stage parasites, are primarily

based on well established and widely used laboratory

techniques. The microscopic examination of smear

preparations of different human biological products

are also used to diagnosis a wide range of para-

sites, such as the usage of blood smears (e.g Malaria,

Lymphatic filariasis, African Trypanosomiasis), stool

smears (e.g. intestinal helminths) and urine smears

(e.g. Schistosomiasis) (Utzinger et al., 2012). How-

ever, reliable identification of the referred parasitic in-

fections requires in-depth train for specimen prepara-

tion and high-standard expertise for subsequent mi-

croscopic analysis. Those requirements are closely

related with the increasing interest in the develop-

ment of computer-aided diagnosis systems for this

purpose, particularly in the area of Mobile Health.

The mobile phone is currently Africa's most impor-

tant digital technology. In the year 2000 few Africans

had a mobile phone, but today about three-quarters

do (Zachary, 2015). So it becomes natural that Mo-

bile Health is starting to play an important role when

it comes to health in Africa, particularly through the

usage of solutions that allow skipping over central-

ized laboratories (Dolgin, 2015) by taking advantage

of the advanced imaging and processing capabilities

of the new generation of mobile devices.

Thus, the development of new portable micro-

scopic devices (and ideally low cost) is an area that

can greatly improve the chances of the successful de-

38

Rosado L., Oliveira J., JoÃ

ˇ

co M. Vasconcelos M., M. Correia da Costa J., Elias D. and S. Cardoso J.

ÎijSmartScope: 3D-printed Smartphone Microscope with Motorized Automated Stage.

DOI: 10.5220/0006155800380048

In Proceedings of the 10th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2017), pages 38-48

ISBN: 978-989-758-216-5

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

ployment of computer-aided diagnosis solutions for

disease diagnosis in the underserved areas (Rosado

et al., 2016). Given also the increase possibilities

coming from additive manufacturing, in this paper

we report our efforts on the development of a 3D-

printed microscope with a motorized stage, termed

µSmartScope, that can be easily coupled to a smart-

phone. The process will be to place the smartphone in

the µSmartScope along with the smear, and have the

smartphone image sensor to acquire a set of magni-

fied images autonomously. This collection of images

could then be analyzed, either automatically through

image processing approaches, or manually by a spe-

cialist on a remote location.

It worth mentioning that we took into account sev-

eral particularities of the African reality during the de-

sign of this device, like the high customs taxes and

import duties currently in practice in many African

countries; this motivated us to favor solutions easy

replicable in third world countries. Several others ad-

ditional requirements were equally considered, like

automating the device as much as possible, discard-

ing the need of considerable expertise and train of the

technician in terms of maneuvering the microscope,

or supplying the energy needed for the illumination

and/or any type of automation through the mobile de-

vice battery, thus discarding the need of an additional

power source.

This paper is structured as follow: Section 1 cor-

responds to Introduction and presents the motivation

and objectives of this work; Section 2 give a summary

of the related work found on the literature; Section 3

describes each component of the device, namely the

Optics, Illumination and Motorized Automated stage;

Section 4 details the process of Autofocusing; In Sec-

tion 5 the Results are presented; and finally the Con-

clusions are drawn in Section 6.

2 RELATED WORK

Some research has been made in the last years to

develop cell-phone based systems that provide low-

cost alternatives to conventional microscopy. The mi-

croscopy designs of the proposed systems can be sep-

arated in three different areas: lensless, on-lens and

attachment-based approaches.

The lensless approaches are based on the princi-

ples of holographic microscopy, i.e. the microscopic

images are reconstructed from the holograms cap-

tured by the cell-phone. This approach has the advan-

tage of not requiring any lenses or optical component

as well as obtaining images with large field-of-view

(FOV). However, acceptable resolutions are only ob-

tained for small magnifications (∼40x magnification,

NA= 0.65 objective) and processing power is needed

to reconstruct the image (Tseng et al., 2010; Pirnstill

and Cot, 2015).

On-lens approaches usually employ a refractive

element directly attached to the smartphone camera at

the focus, or a ball lens mounted in front of the camera

lens (Arpa et al., 2012; Cybulski et al., 2014). Despite

being a low-cost alternative, the ball lens produces a

spherical focal plane, which creates aberrations and

reduces drastically the usable FOV. Moreover, magni-

fication and radius of the ball lens are inversely linked,

so in order to achieve 1000x magnification we need a

a ball lens with radius of 0.15mm (Cybulski et al.,

2014), which can turn the mounting and alignment

process with the camera lens really challeging.

The attachment-based approaches covers the ma-

jority of the solutions already reported on the liter-

ature, which requires coupling additional hardware

to the cell-phone, such as commercial lenses or illu-

mination modules (Smith et al., 2011; Switz et al.,

2014; Pirnstill and Cot, 2015). This approach usu-

ally takes advantage of complex optical elements that

allow achieving suitable resolutions at high magnifi-

cations (e.g. ∼1000x), which increases the overall

cost of the system, but is currently a requirement for

the microscopic examination of several neglected dis-

eases. With high magnifications also emerges the lim-

itation of having a small FOV, thus requiring the de-

velopment of mechanisms to move the smears in or-

der to cover a large area of the specimen. Moreover,

it was verified that the majority of reported works are

designed for a unique cell-phone model, which can

greatly compromise the adoption of the proposed so-

lution.

In this work, we present a 3D-printed microscope

that can easily be attached to a wide range of mobile

devices models. To the best of our knowledge, this

is the first proposed smartphone-based alternative to

conventional microscopy that allows autonomous ac-

quisition of a pre-defined number of images at 1000x

magnification with suitable resolution, by using a mo-

torized automated stage fully powered and controlled

by a smartphone, without the need of manual focus of

the smear.

3 µSMARTSCOPE COMPONENTS

Since we wanted to achieve a cheap and easily repli-

cable alternative to conventional microscopes that can

be attached to smartphones, most of the device is 3D-

printed (see Fig. 1). The proposed device can be di-

vided in 3 major modules: the Optics; the Illumina-

ÎijSmartScope: 3D-printed Smartphone Microscope with Motorized Automated Stage

39

tion; and the Automated Stage (see Fig. 2).

Figure 1: µSmartScope with smartphone attached and

malaria-infected blood smear inserted.

3.1 Optics

The selected commercial lenses used to construct the

µSmartScope were supplied by Bresser, a vendor that

showed a good price-quality relation for the required

optics. Particularly, we used the Planachromat 100x

oil-immersion objective (Bresser #5941500) and the

Wide Angle 10x Eyepiece (Bresser #5941700).

Figure 2: Render model of the µSmartScope used for 3D-

printing with the identification of the 3 main modules:

Optics (green); Illumination (cyan); and Automated Stage

(red).

3.2 Illumination

To allow a uniform illumination of the specimen, us-

ing just a LED is not enough because most of the light

is lost to parts of the sample that are not being cap-

tured. To counter that, in a common microscope, a

light condenser is normally used. The condenser is

a lens (or multiple lenses) that concentrates the light

from the illumination source and focus it in the part of

the sample that is being captured by the amplification

device. This device, in turn, magnifies the light beam,

allowing an uniform illumination. Since the support

materials for the lenses are 3D-printed, the minimum

resolution of the 3D-printer must be taken into con-

sideration. Several topologies of condensers can be

used with their pros and cons. One of the cheapest

options with acceptable results for our use case is the

Abbe condenser, which uses a plano-convex lens to

pre-concentrate the light into a smaller ball or half-

ball lens that, in turn, provides the final concentration

of light. This arrangement guarantees a good result

by using cheaper individual lenses instead of an ex-

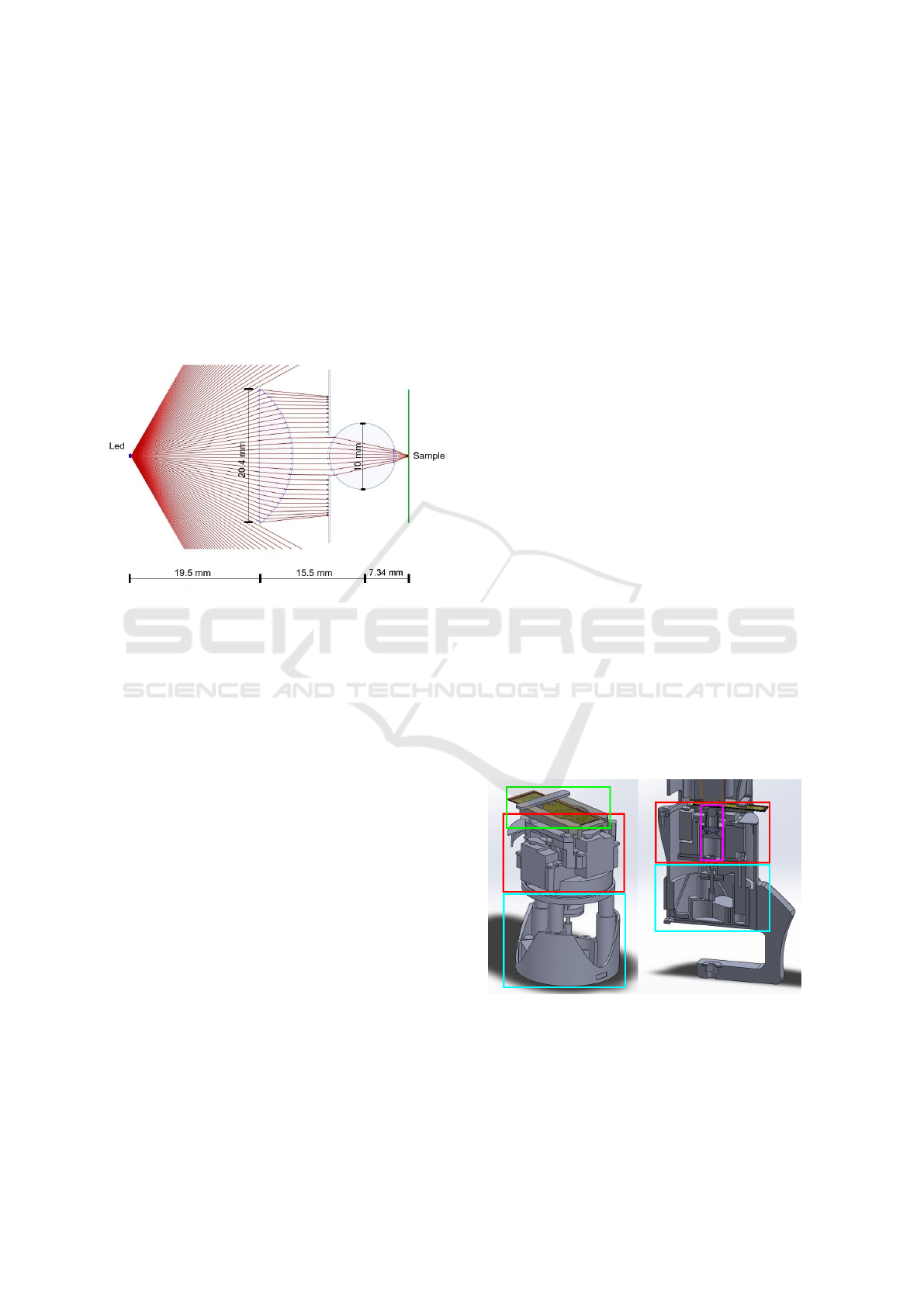

pensive, custom made, one. To design our condenser

we selected a 20.4 x 25mm plano-convex lens (Ed-

mund Optics #43483) and a 10mm N-BK7 Ball Lens

( Edmund Optics #32748). In order to calculate the

Back-Focal Length (BFL), i.e. distance on the optical

axis between last active optical surface and the spec-

imen plane (i.e. the sample), we used the following

equation (Cybulski et al., 2014):

BFL =

1

2

·

r · (2− n)

(n − 1)

, (1)

where r = 5mm is the radius of the ball lens and n =

1.517 is the Index of Refraction of the N-BK7 optical

material. This gives a BFL = 2.34mm, as shown in

Fig. 3.

Despite the distances defined on Fig. 3 being

strictly respected, during the design we also had to

ensure that the center of the ball lens was both care-

fully aligned with the center of the plano-convex lens

and with the center of the objective lens.

3.3 µStage

The microscopic examination of smears usually re-

quires the visual analysis of different microscopic

fields (i.e. positions) of the smears, and the mini-

mum number of required fields depends on the dis-

ease and used magnification. For instance, accord-

ing to World Health Organization (WHO), the anal-

ysis of 100 fields of a blood sample is the minimum

needed to perform a malaria microscopy test (WHO,

1991). Currently, this process is manually performed

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

40

by trained staff and can be extenuating, requiring that

the operator takes regular breaks in order to ensure

maximum attention. In order to improve this pro-

cess, the sample movement should be performed au-

tonomously and on-demand by the smartphone. For

that, the µStage was developed, which is an automatic

stage designed to be as cheap as possible, while pro-

viding displacement up to 20mm in X/Y with reso-

lution of 500 µm and a resolution of 25 µm in the Z

axis. It was designed to be powered using the USB-

OTG connection of the smartphone.

Figure 3: Schematic of the developed condenser generated

with OpticalRayTracer® optics design software.

3.3.1 Mechanical Structure

In order to be as flexible as possible, most of the struc-

ture is modular and can be adapted without needing to

refactor the whole structure. One of our major goals

was to minimize the use of mechanical components

and try to 3D-print as many parts as possible. This re-

duces costs and facilitates replication in third world

countries, but has some disadvantages like reduced

precision and wear.

The structure is composed by a base part where

the electronic board, the Z axis actuator and the µUSB

connector are placed. In this part, there are 3 slots that

are the negatives of the tubular structures of Z axis.

Besides the base, the stage is divided in 4 functional

modules that are fully 3D printed (see Fig. 4):

• Z axis: Composed by 3 tubular structures that

slide against their negatives in the base part, the

Z axis was designed to have the highest resolution

possible within the restrictions to ensure correct

focus of the smear. Ensuring that the used 3D-

printer is correctly calibrated and parametrized is

evidently important for all µSmartScope printed

components, but particularly crucial for this mod-

ule. Obtaining the required gap between the each

tubular structure and the corresponding negative

is crucial to achieve a smooth Z axis movement,

without tilting. Moreover, a simple stepper motor

is used to provide the movement, being the cir-

cular movement translated through a M3 threaded

rod and a nut fixed in this part. A rigid piece of

heat shrink sleeve is then used to couple the step-

per with the threaded rod. This ensures that even-

tual 3D printing deviations are corrected by the

flexibility of the sleeve without compromising the

Z axis movement.

• X/Y axes: Composed by 2 parts that slide against

the Z axis module and between each other, the

precision is not high but the resolution is enough

to ensure at least 100 different microscopic fields.

It should be noted that repositioning to a specific

field location with high precision is usually not

needed in microscopic smear analysis. Cover-

ing different microscopic fields that represents the

overall specimen is by far much more important.

Two servo motors are used to provide the move-

ment, together with some rubber bands that ensure

the movement in both ways. This arrangement is

not linear since the servo movement is provided in

a 90° arc, but ensures different fields: while one

of the servo moves, the other is always static and

placed in the Z axis part.

• Illumination: The optical design of this module

was already presented in section 3.2, which passes

through the Z and X/Y axes modules.

• Smear holder - a standard microscope slide can

be fitted in the top part of the stage and hold in

place by a simple plastic piece.

Figure 4: Render model of the motorized automated stage

with the identification of the 4 modules: Z-axis (cyan); X/Y

axes (red); Illumination (purple); and Smear holder (green).

ÎijSmartScope: 3D-printed Smartphone Microscope with Motorized Automated Stage

41

3.3.2 Electronics

The power board was designed to power the 3 actu-

ators (stepper and two servos) and the illumination

LED using only the power from a USB connection

with 5V and 500 mA. Almost any modern smartphone

has USB-OTG interface that allows the connection of

USB peripherals. To be fully compatible with the

µSmartScope, it needs to support, at least, the nor-

mal power standard enumerated above. Some manu-

facturers do not use this standard in their devices and

are not supported since this devices are not capable of

powering the µStage. An image of the developed PCB

can be observed in Fig. 5, and the electronic system is

composed by:

• Stepper motor: The used stepper motor is a

28BYJ-48 5V, which is the cheapest stepper mo-

tor found in common electronic stores. This was a

major point in choosing the motor since the repli-

cation of the µSmartScope should be easy and

cheap in any part of the world. It is controlled by

a DRV8836 from Texas Instruments with current

limited to 200 mA, and capable of 512 steps per

full rotation. Since we are using a standard M3

threaded rod, we have a theoretical resolution of

around 1 µm. Furthermore, a simple push-button

switch is placed in the Z axis to provide a way to

locate the position when the device is turned on.

• Two servo motors: The used servo motors are

the Hitec HS-55 5V, which is the cheapest micro

servo motor found in common electronic stores.

Controlled directly by PWM output and limited

to 200 mA, their rotation is directly used to gen-

erate the linear movement. The servo head has a

size of 13mm meaning that this is our maximum

displacement. Using the 90° travel with 2.5° per

step, we have 36 steps available while we only

need 10 per axis;

• Illumination: Since the illumination depends of

the sample under analysis, the control board pro-

vides an output based in a power Mosfet capa-

ble of providing 150mA at 5V. This power can be

controlled by changing the PWM duty cycle of the

output.

• Control: An ATMega32u4 is used to control all

the logic of the system, which contains native

USB communications and plenty of GPIO ports

and PWM support. The native USB connection is

seen as a serial port in the smartphone using the

USB serial for Android library (Wakerly, 2012).

Moreover, an API for Android was developed to

allow interaction with the stage. This API was

made to be as simple as possible to integrate in

any app, providing every function needed to fully

control the stage (i.e. stepping in X, Y and Z axes,

as well as control the LED light).

Figure 5: Prototype PCB to control the µStage.

4 AUTOMATED FOCUS

The traditional focusing method in microscopy is usu-

ally achieved by manually adjusting the vertical posi-

tion of the smear stage, in order to obtain a focused

image of the smear. However, for screening processes

that requires the analysis of a huge amount of po-

sitions per specimen, this process clearly becomes a

cumbersome task. As an illustrative example, for the

analysis of malaria-infected blood smears, is recom-

mended the analysis of 100 different positions for a

single specimen. Thus, taking advantage of devel-

oped motorized automated stage and real time feed-

back retrieved from the smartphone camera sensor, it

became clear that is fundamental to develop an au-

tomated focus approach that ensures autonomous ac-

quisition of focused smear images.

Automated focus is a long standing topic in the

literature and several focus algorithms have been pro-

posed (Krotkov, 1988; Shih, 2007), yet the search for

the proper algorithm still remains an open topic, since

it can highly depend on the resolution of the cam-

era sensor and visual characteristics of the specimen.

Generally an autofocus system includes three compo-

nents: focusing region selection, focus measurement

and peak search. In this section it will be presented

a description of those components to obtain micro-

scopic images from thin blood smears infected with

malaria parasites.

Due to lens constrains, it is not possible to obtain

the optical circle with maximal focus in the whole

area. Therefore, for each frame given by the cam-

era sensor, this automated focus algorithm considers

the central square of the previewed image, with size

equal to one third of previewed image (smallest of the

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

42

height and weight value) to be the region with maxi-

mum focus, as portrayed in Fig.7.

4.1 Focus Metric

Taking into consideration several works on the liter-

ature targeting the automatic focus for microscopic

devices using image processing, in this work we se-

lected a wide range of focus metrics already pro-

posed that where considered highly relevant for au-

tomatic focusing for testing and comparison. In de-

tail, we tested: derivative-based as the Brenner gra-

dient and the Tenenbaum gradient; statistics based,

like the normalized variance; histogram-based, as en-

tropy; and intuitive algorithms, like thresholded con-

tent (Sun et al., 2005; Liu et al., 2007). After this

comparative analysis, the standard deviation (STD) of

the Tenenbaum gradient (Tenenbaum, 1970) was con-

sidered the most discriminative focus metric to dif-

ferentiate better a focused point in the focus curve,

i.e. in the variation of the metrics while the Motor-

ized Automated Stage is ascending in the vertical axis

(see Fig.6). The Tenenbaum gradient is obtained by

convolving the previously selected central square of

the image with Sobel operators, and by summing the

square of gradient vector components:

T ENG = (G

x

(i, j)

2

+ G

y

(i, j)

2

), (2)

where G

x

and G

y

are the horizontal and vertical gradi-

ents computed by convolving the focus region image

with the Sobel operators. From the previous equation,

the STD and the mean values are extracted.

4.2 Focus Logic

The developed automated focus logic has three dis-

tinct phases: the Rough, Precise, Ending phase (see

Fig.6). The main concept behind the proposed focus

logic relies on following concept: the Motorized Au-

tomated Stage starts at a bottom position (called the

reset position), and while is going up in the Z axis

(i.e. the vertical axis), the value of the selected focus

metrics starts to increase. The usage of three differ-

ent phases in the focus logic is directly related with

the length of the Z steps. Particularly, a pre-defined

length of the Z step is a associated to each phase, so

while the stage is going up and the metric increases,

the focus logic evolves from the Rough phase (Z steps

with maximum length) to the Ending phase (Z steps

with minimum length).

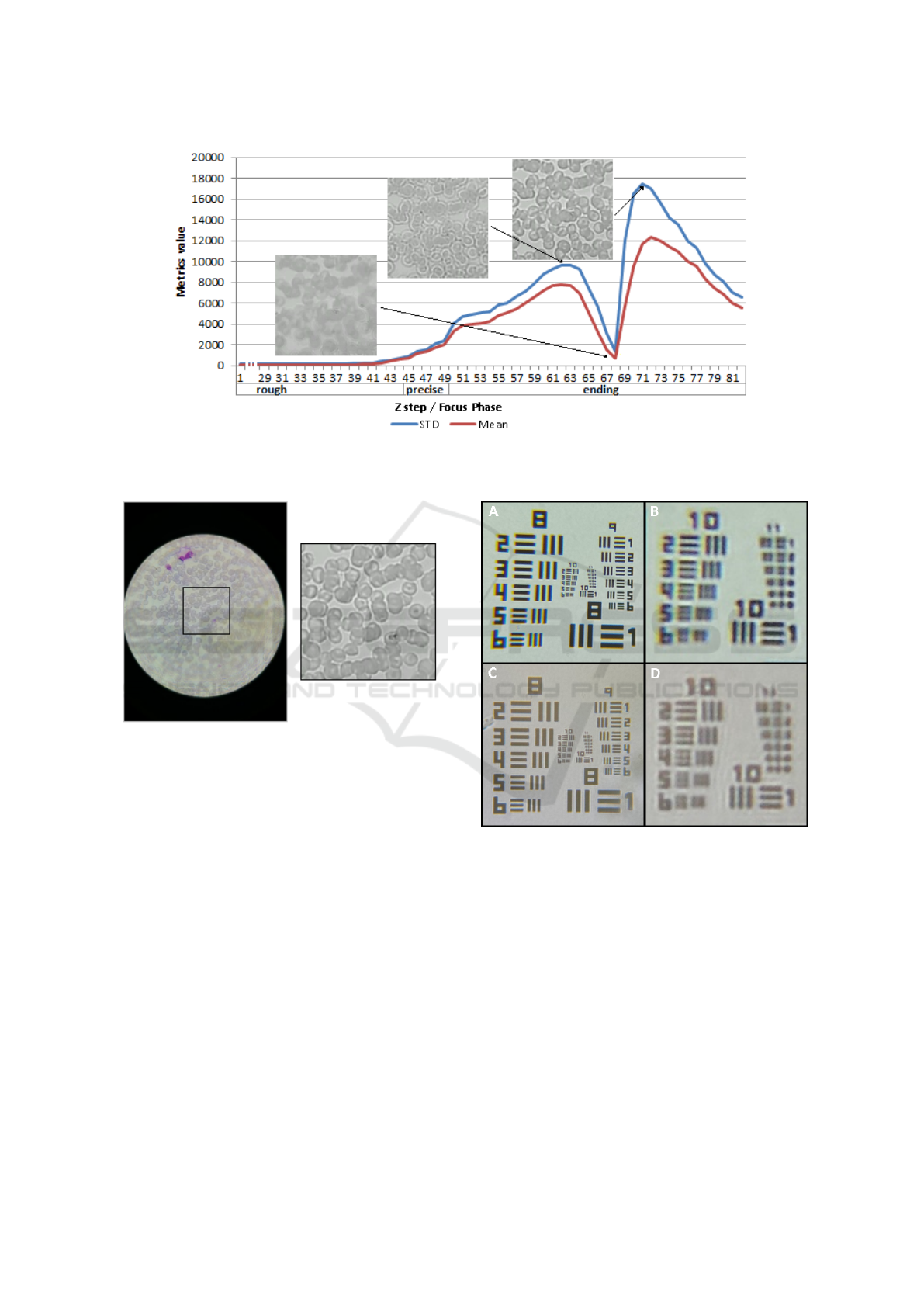

To better understand the focus logic, please see in

Fig.6 where it is presented the behavior of the Tenen-

baum metrics while the motorized stage goes up. The

first step of the algorithm consists in resetting the

stage to a predefined Z step that is below the focus

point (Rough phase). While ascending, in each Z

step an image frame is captured and the selected focus

metrics are evaluated in order to infer the next move:

either stay in the same stage and move up or go to next

stage and adapt Z step length. The focus curve for the

selected focus metric is usually composed by two lo-

cal maxima, where the second corresponds to the best

focused image region. So a threshold is dynamically

defined when the first local maximum is reached, and

a focus image is selected and saved only after this

threshold is overcome and a new maximum value ex-

ists. By doing this, we ensure that the last image saved

is the one with best focus quality, while minimizing

memory allocation of the algorithm. Moreover and

because the stage can suffer some “jumps” leading to

metrics behavior different than the one presented, we

included a failure index metric which after 3 failures

leads the motorized stage to reset.

5 RESULTS

In this section we present the obtained results in terms

of Resolution, Field of View and Illumination of the

obtained images using the µSmartScope, as well as an

analysis of the µStage performance in terms of steps

precision/resolution and power consumption.

5.1 Resolution

The magnified images of the smears obtained with

the µSmartScope must have an appropriate resolution

over a sufficiently large area, so a conclusive deci-

sion about the presence of a specific infectious agent

can be made. The 1951 USAF resolution test chart

is a resolution test pattern conforming to MIL-STD-

150A standard, set by US Air Force in 1951. It is still

widely accepted to test the resolving power of optical

imaging systems such as microscopes, cameras and

image scanners. One example is the READY OPTICS

USAF 1951 Microscope Resolution Target, which is a

target embedded in a standard microscope slide, suit-

able for oiled objectives and oiled condensers. In

terms of resolution, the target allows to check a mini-

mum spacing between lines of 0.197 nm.

Microscopic images of the READY OPTICS

USAF 1951 Microscope Resolution Target with

1000x magnification were acquired the µSmartScope

and with the Bresser Microscope-5102000-Erudit

DLX (see Fig. 8). Both systems use similar objec-

tives and eyepieces, so the main goal is to evaluate

image resolution of the µSmartScope.

ÎijSmartScope: 3D-printed Smartphone Microscope with Motorized Automated Stage

43

Figure 6: Focus curve of the Tenenbaum metrics for the central square of the image, i.e. variation of the metrics while the

Motorized Automated stage is ascending in the vertical axis.

Figure 7: Focused image obtained using the µSmartScope,

and respective central square used by the automated focus

algorithm.

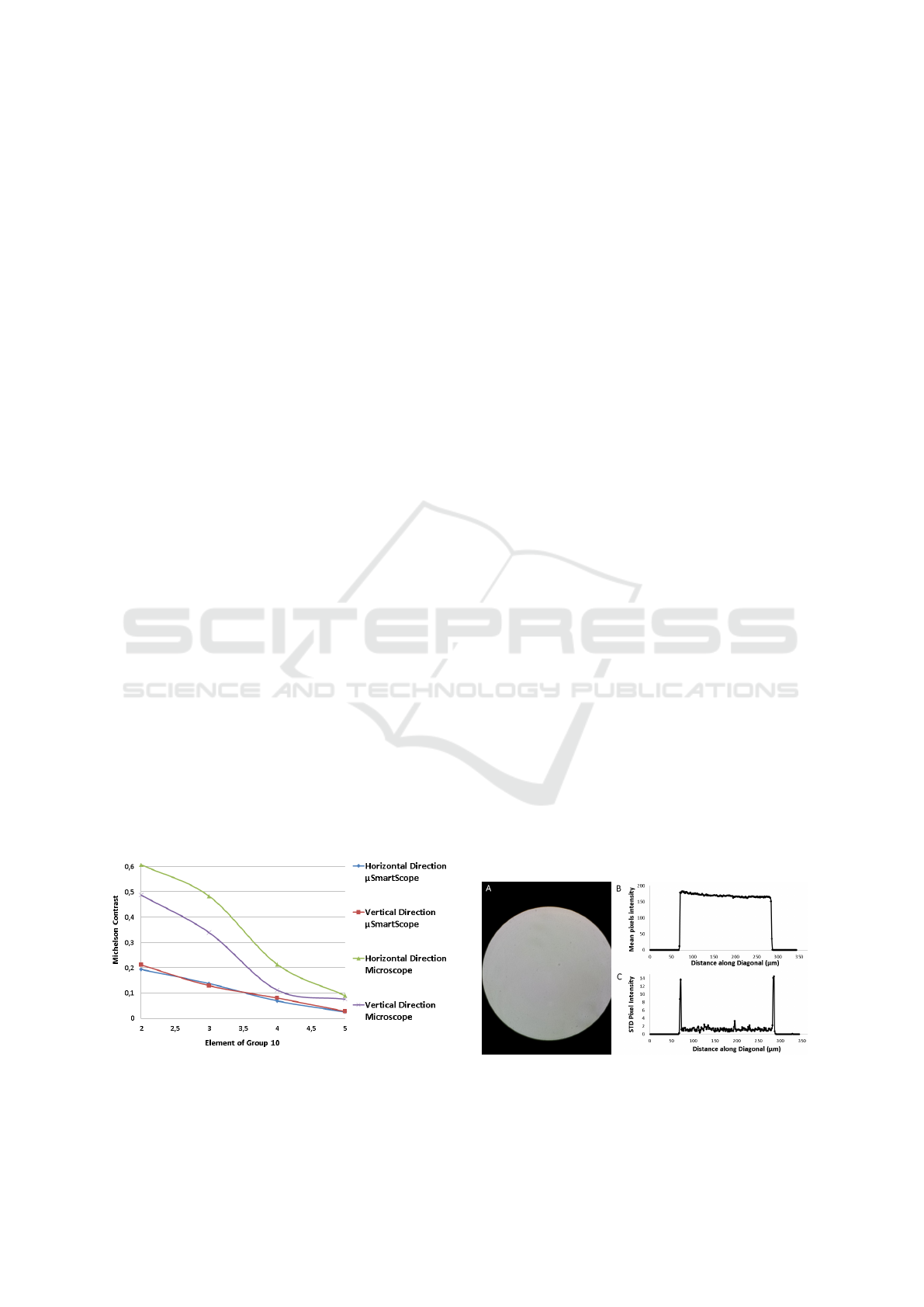

To determine the resolution of the µSmartScope

and compare it to the resolution of the Bresser Com-

mercial Microscope, the images acquired with the

separate systems were converted to grayscale and the

analysis focused on Group 10, which was the small-

est resolvable group. In order to determine the small-

est resolvable Element of Group 10 in both horizontal

and vertical orientations, the images were firstly con-

verted to grayscale and a line for each of the 6 bars of

that Element were drawn. Each line starts and ends

in a background pixel, and intersects perpendicularly

the respective bar. All pixel values of each line were

used to calculate the Michelson contrast, which was

assigned to the respective bar. In each direction of

each Element, the bar with minimum Michelson con-

trast was selected for analysis purposes (see Fig. 9).

It was defined that an Element is considered re-

solvable on a particular direction if the minimum

Figure 8: Images of READY OPTICS USAF 1951

microscope resolution target: A) acquired using

the µSmartScope; B) Detail of Group 10 using the

µSmartScope; C) acquired using Bresser Microscope -

5102000 - Erudit DLX 20x-1000x; D) Detail of Group 10

using the Microscope.

Michelson contrast was 0.1. Thus, Element 3 was

defined as the minimum resolvable Element for the

µSmartScope, which gives a minimum resolution of

0.388µm on both directions. For the Bresser Commer-

cial Microscope, Element 4 was selected as the min-

imum, which corresponds to a resolution of 0.345µm

for both directions. Although the µSmartScope

present a slightly lower resolution, it is clear on Fig. 9

that both directions have a more homogenous behav-

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

44

ior in terms of resolution, while in the Bresser Micro-

scope there is an evident discrepancy between the re-

solving power on different directions. The lower val-

ues of Michelson contrast for the µSmartScope might

be caused by the limitation in terms of the maximum

power rate of the smartphone, since both the illumina-

tion and motorized automated stage must be powered

by USB-OTG. Thus the power that feeds the LED is

limited, which diminishes the intensity of the LED

and consequently the image contrast.

5.2 Field of View

Resolution and field of view are inversely linked in

standard laboratory microscopes. In order to obtain

microscopic fields with both high magnification and

resolution, the usage of objectives with higher nu-

merical aperture is required, which results in smaller

Field of Views (FOV) (Pirnstill and Cot, 2015). To

determine the FOV of the µSmartScope, images of

the READY OPTICS USAF 1951 Microscope Res-

olution Target were acquired and used to estimate

the pixel-microns relationship. The exact distances

between bars of a specific Element is given by the

specifications of the resolution target, particularly El-

ement 2 and 3 of Group 8 corresponds to 1.740µm and

1.550µm, respectively. By measuring the number of

pixels between bars of this 2 Elements on the acquired

image, a relationship of 0.085 µm/pixel was obtained

for Element 2 and 0.084 µm/pixel for Element 3. So

we considered the average value, i.e. a relationship of

0.0845 µm/pixel. Furthermore, the number of pixels

for the vertical and horizontal axis that passes through

the center of the visible optical circle of the acquired

image were determined. These values were then com-

bined with the previously calculated µm/pixel rela-

tionship, in order to estimate the FOV of the visible

optical circle, with 214.38µm and 206.87µm for the

vertical and horizontal axis, respectively.

Figure 9: Minimum Michelson contrast for USAF Resolu-

tion Target Elements of Group 10.

5.3 Illumination

In order to evaluate the uniformity of the illumina-

tion of the LED coupled to the proposed condenser,

an image was acquired with a blank microscope slide

(see Fig. 10.A). A diagonal line scan was consid-

ered to evaluate the variation of pixels intensity along

this line. A total of 200 pixel boxes were considered,

equally spaced and with size 10x10. For each of those

boxes the mean and standard deviation were collected

(see Fig 10.B and 10.C). Despite small pixel inten-

sity variations probably caused by dust or components

floating in the immersion oil, this results demonstrate

that we can achieve a substantially uniform illumina-

tion with low noise with the proposed set up.

5.4 µStage

The µStage was analyzed in terms of precision and

resolution of the X/Y and Z steps, as well as in terms

of power consumption.

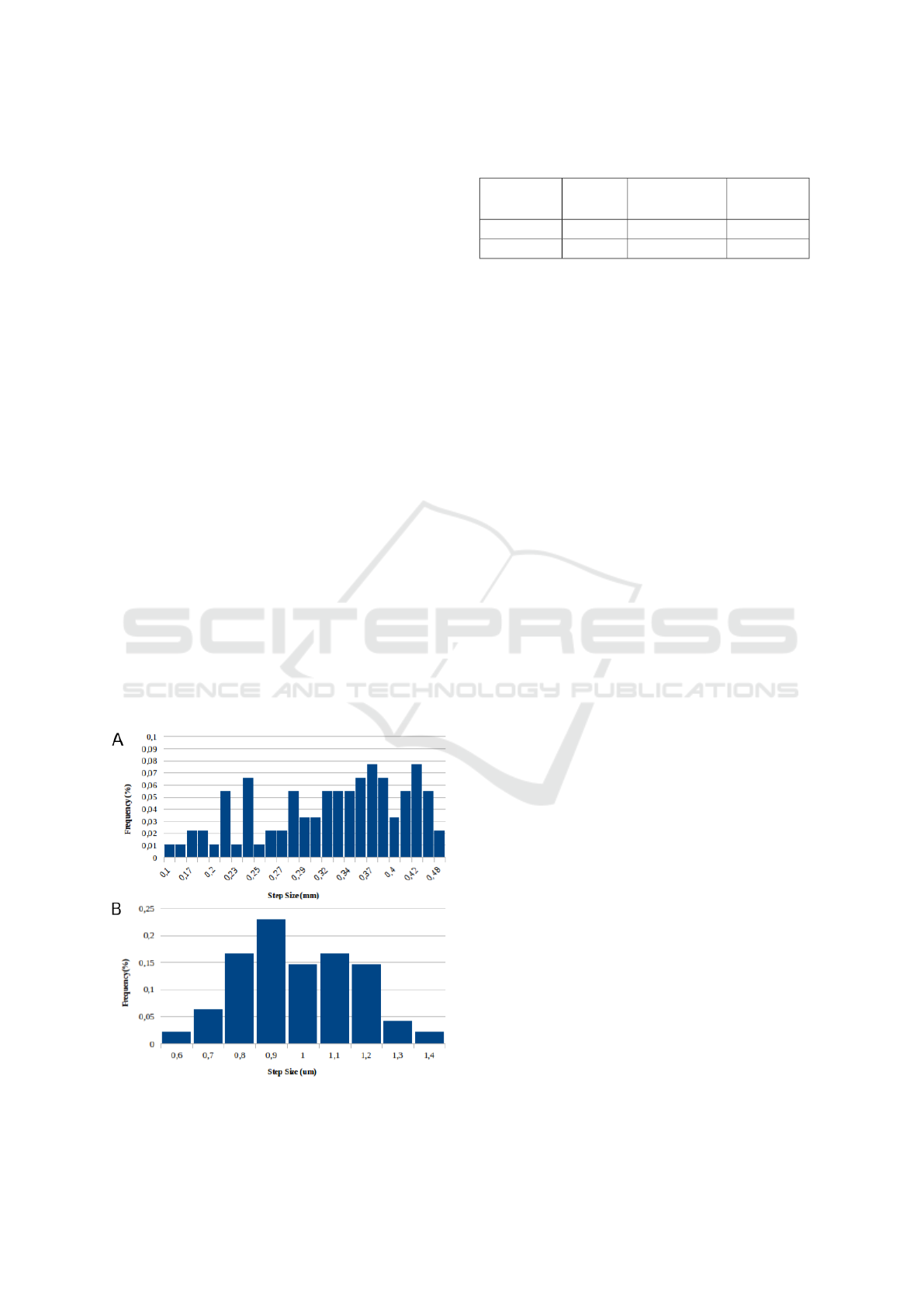

5.4.1 Precision and Resolution

While testing the usage of the µStage, we found out

that the precision of each axis is affected by the fact

that all moving parts are 3D printed. Since plastic im-

perfections and particles can be present in the sliding

portions of the parts, this leads to different displace-

ments in each step. In Fig. 11 is presented the results

for the displacement of the X, Y and Z axis, where

100 steps were taken and each one measured using a

digital caliper (Mitutoyo Absolute) with resolution of

0.01mm ± 0.02mm. Each measure was grouped per

value and the frequency plotted.

For the X and Y steps, a clear variation of the step

size is depict in Fig 10.A. This behavior is mainly

caused by the non-linear movement of the servo (pre-

viously described in section 3.3.1), as well as by the

Figure 10: Illumination uniformity analysis for Prototype:

a) Original image; b) Mean pixel intensity of the 10x10

pixel boxes on the diagonal direction; c) Standard deviation

of the 10x10 pixel boxes on the diagonal direction.

ÎijSmartScope: 3D-printed Smartphone Microscope with Motorized Automated Stage

45

imperfections of the printed parts. Nevertheless, we

obtained an average displacement of 330µm with a

standard deviation of 81µm, which proved to be a suit-

able approach for our solution. Taking into account

that the main goal of the X and Y steps is to displace

the smear into a different position and acquire an im-

age of a new microscopic field, the average displace-

ment provided by this approach is marginally higher

than the FOV determined in section 5.2, which con-

sequently means that we are obtaining a new micro-

scopic field every time we take a X or Y step.

Regarding the Z axis, our caliper is not able to

measure such small steps. To estimate the average

step size, one full revolution of the motor was con-

sidered (which corresponds to 512 steps), and the re-

spective displacement was measured 100 times. This

distance was then divided by the number of steps, in

order to estimate the travel of a single step. As we

can see in Fig 10.B, the steps are less dispersed, but

a significant variability is still verified. Each step cor-

responds to an average of 0.98µm with a standard de-

viation of 0.18µm, which gives an indication that our

steps in the Z axis are within the theoretical values.

Although we have a small step-size in the Z axis,

we observed that the movement is not smooth and

the variability in the step size leads to some “jumps”

while focusing the microscopic field. At 1000x mag-

nification this can have a significant impact in obtain-

ing the ideal focus point of the smear. It worth noting

that this is the reason why we can not simply move

Figure 11: Frequency of measured step size values after 100

repetitions. A) X and Y axes; B) Z axis.

Table 1: Power consumption test results.

Smartphone

Average

Current

(mA)

Average Power

Consumption

(W)

Autonomy

(min)

Samsung S5 208.64 1.043 164

Nexus 5 201.34 1.006 149

the Z axis to a specific pre-defined position that corre-

sponds to the focus point, in order to focus the spec-

imen. Thus, the automatic focus methodology pro-

posed on section 4 plays a critical role in the com-

pensation of this irregular behavior, and consequently

in the acquisition of focused images autonomously.

It worth noting that the overall image acquisi-

tion process involves: autonomous control of the Z

axis for autofocusing, capture the image in the fo-

cus point, and autonomous control of the X/Y axes to

the next microscopic field (where this process restarts

if we want to acquire a new image). We tested the

autonomous acquisition of 100 images using a LG

Nexus 5, which took in average 80 seconds per im-

age, and 94 of the images were considered focused.

5.4.2 Power Consumption

In order to ensure that we never go over the maxi-

mum power rate of the smartphone, the whole sys-

tem power consumption is always under 400mA at

5V. This is achieved by allowing only one actuator

moving at any given time. In Table 1, the power con-

sumption of the system can be observed together with

the autonomy for the tested smartphones. The profile

tested was as close as possible to the real one, i.e. the

smartphone was acquiring views continuously with

the screen off and in flight mode until it shut down

due to low battery.

It worth noting that we are currently using the

smartphone battery to simultaneously powering the

actuators of the µStage, the LED light, acquired data

continuously with the optic sensor and process each

acquired frame for the automatic focus of the smear.

Considering the current battery capacity of smart-

phones, this obviously represents a huge burden in

terms of power consumption, and it is clear that the

current autonomy of the system is low for a day of

continuous use. As an alternative, one can consid-

erer the usage of at least two smartphones to allow

the acquisition of images 24h per day, or the usage of

a power bank coupled to a OTG splitter cable, which

we are considering to include in the next version of

the µSmartScope system.

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

46

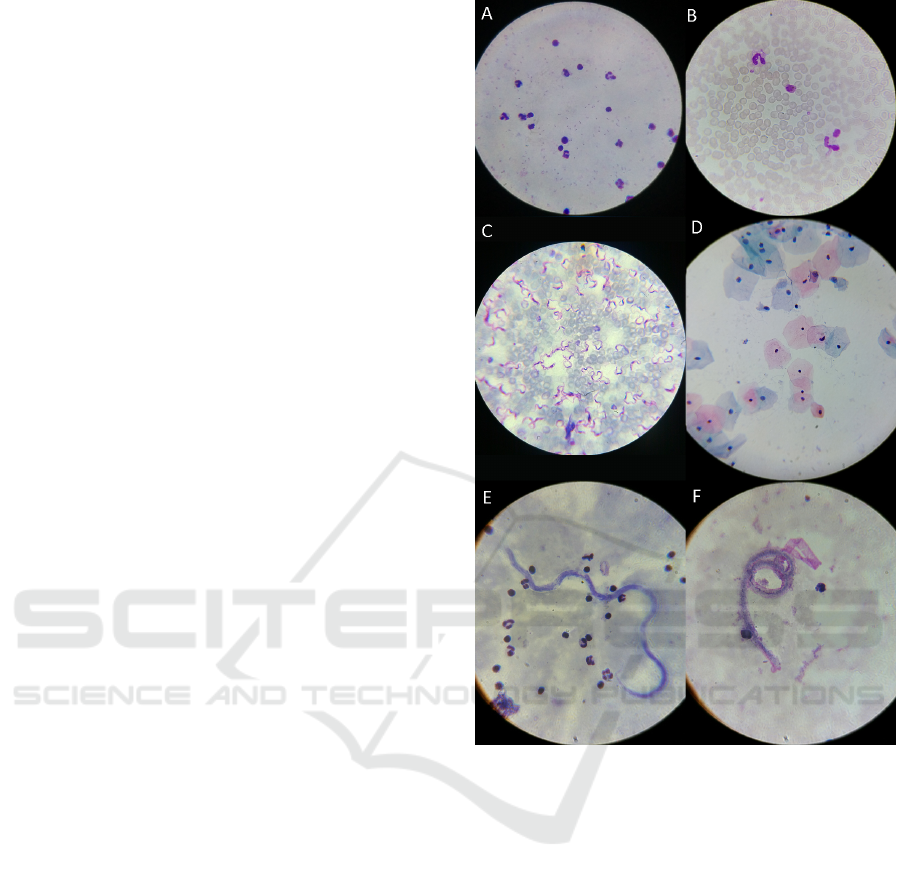

5.5 Applicability Examples

The µSmartScope was used to acquire microscopic

images of reference blood smears with different para-

sites, which are responsible for the most relevant ne-

glected tropical diseases that can be detected through

microscopic examination (see Fig 12). Particu-

larly, the following smears were used: thick blood

smear infected with malaria parasites (P.falciparum

species); thin blood smear infected with malaria par-

asites (P.ovale and P.malariae species); thin blood

smear infected with Chagas parasites (Trypanosome

cruzi species); and thick blood smear infected with

Lymphatic Filariasis parasites (Brugia malayi and

Wuchereria bancrofti species).

Furthermore, to highlight the versatility of the de-

veloped system, a liquid-based Pap smear with high

grade squamous lesions was also tested, which is as-

sociated with precancerous changes and high risk of

cervical cancer. For the analysis of this smear, a mag-

nification of 400x is required, so we had to adapt

the optical set up of the µSmartScope, which con-

sisted in the simple procedure of changing the Bresser

Planachromat 100x oil-immersion objective for the

Bresser Planachromat 40x (Bresser #5941540).

To finalize, considering the acquired images and

the feedback received by the specialists that helped

us collect the smears, we can state that very promis-

ing results were obtained. For all the tested smears,

the detection of the considered blood parasites and the

precancerous cells on the cervix was considered pos-

sible through images acquired via the µSmartScope.

6 CONCLUSIONS

In this paper, we present a 3D-printed microscope that

can easily be attached to a wide range of mobile de-

vice models. This is the first proposed smartphone-

based alternative to conventional microscopy that al-

lows autonomous acquisition of a pre-defined number

of images at 1000x magnification with suitable res-

olution, by using a motorized automated stage fully

powered and controlled by a smartphone, without the

need of manual focus of the smear.

All the components of the proposed device are de-

scribed and properly evaluated. In terms of the Op-

tical Module, a minimum resolution of 0.388µm was

determined, with a FOV of 214.38µm and 206.87µm

for the vertical and horizontal axis that passes through

the center of the visible optical circle, respectively.

Regarding the Illumination Module, the LED light

coupled to the proposed condenser demonstrated to

achieve an uniform illumination suitable for bright-

Figure 12: Images of different smears acquired with the

µSmartScope: a) Thick blood smear infected with malaria

parasites (P.falciparum species); b) Thin blood smear

infected with malaria parasites (P.ovale and P.malariae

species); c) Thin blood smear infected with Chagas par-

asites (Trypanosome cruzi species); d) Liquid-based Pap

smear with high grade squamous lesions; e) Thick blood

smear infected with Lymphatic Filariasis parasites (Brugia

malayi species); f) Thick blood smear infected with Lym-

phatic Filariasis parasites (Wuchereria bancrofti species).

Images a), b) and c) were acquires with a LG Nexus 5, while

images d), e) and f) with a Samsung Galaxy S5. All images

were acquired with magnification of 1000x, except image

d) which has magnification of 400x.

field microscopy. In terms of the Motorized Auto-

mated Stage (µStage), we achieved an average reso-

lution of 330µm (with a standard deviation of 81µm)

for the X and Y steps and an average resolution of

0.98µm (with a standard deviation of 0.18µm) for the

Z steps.

Several smears infected by different blood para-

sites responsible for the most relevant neglected tropi-

ÎijSmartScope: 3D-printed Smartphone Microscope with Motorized Automated Stage

47

cal diseases were used to test the device. The acquired

images showed that it was possible to detect those

agents through images acquired via the µSmartScope,

which clearly illustrate the huge potential that this de-

vice can have, specially in developing countries with

limited access to healthcare services.

As future work, we want to tackle several of the

detected issues in order to achieve a more robust ver-

sion of the µSmartScope system. In particular, we

want to solve the significant negative impact of oc-

casional plastic imperfections (originated by the 3D

printing process) in the precision of the µStage, as

well as the currently low autonomy of the system for

continuous usage.

ACKNOWLEDGEMENTS

We would like to acknowledge the financial sup-

port from North Portugal Regional Operational Pro-

gramme (NORTE 2020), Portugal 2020 and the Euro-

pean Regional Development Fund (ERDF) from Eu-

ropean Union through the project ’Deus ex Machina:

Symbiotic Technology for Societal Efficiency Gains’,

NORTE-01-0145-FEDER-000026.

REFERENCES

Arpa, A., Wetzstein, G., Lanman, D., and Raskar, R. (2012).

Single lens off-chip cellphone microscopy. pages 23–

28. IEEE.

Cybulski, J. S., Clements, J., and Prakash, M. (2014). Fold-

scope: Origami-Based Paper Microscope. PLoS ONE,

9(6):e98781.

Dolgin, E. (2015). Portable pathology for Africa. IEEE

Spectrum, 52(1):37–39.

Krotkov, E. (1988). Focusing. International Journal of

Computer Vision, 1(3):223–237.

Liu, X., Wang, W., and Sun, Y. (2007). Dynamic evaluation

of autofocusing for automated microscopic analysis of

blood smear and pap smear. Journal of microscopy,

227(1):15–23.

Pirnstill, C. W. and Cot, G. L. (2015). Malaria Diagnosis

Using a Mobile Phone Polarized Microscope. Scien-

tific Reports, 5:13368.

Quinn, J., Andama, A., Munabi, I., and Kiwanuka, F.

(2014). Automated Blood Smear Analysis for Mobile

Malaria Diagnosis. In Mobile Point-of-Care Monitors

and Diagnostic Device Design, Devices, Circuits, and

Systems.

Rosado, L., Costa, J. M. C. d., Elias, D., and Cardoso, J. S.

(2016). A Review of Automatic Malaria Parasites

Detection and Segmentation in Microscopic Images.

http://www.eurekaselect.com, 14(1):11–22.

Shih, L. (2007). Autofocus survey: a comparison of algo-

rithms. In Electronic Imaging 2007, pages 65020B–

65020B. International Society for Optics and Photon-

ics.

Smith, Z. J., Chu, K., Espenson, A. R., Rahimzadeh, M.,

Gryshuk, A., Molinaro, M., Dwyre, D. M., Lane,

S., Matthews, D., and Wachsmann-Hogiu, S. (2011).

Cell-Phone-Based Platform for Biomedical Device

Development and Education Applications. PLoS

ONE, 6(3):e17150.

Sun, Y., Duthaler, S., and Nelson, B. J. (2005). Autofocus-

ing algorithm selection in computer microscopy. In

2005 IEEE/RSJ International Conference on Intelli-

gent Robots and Systems, pages 70–76. IEEE.

Switz, N. A., D’Ambrosio, M. V., and Fletcher, D. A.

(2014). Low-Cost Mobile Phone Microscopy with a

Reversed Mobile Phone Camera Lens. PLoS ONE,

9(5):e95330.

Tenenbaum, J. M. (1970). Accommodation in computer vi-

sion. phd dissertation. Technical report, DTIC Docu-

ment.

Tseng, D., Mudanyali, O., Oztoprak, C., Isikman, S. O.,

Sencan, I., Yaglidere, O., and Ozcan, A. (2010). Lens-

free microscopy on a cellphone. Lab on a Chip,

10(14):1787–1792.

Utzinger, J., Becker, S. L., Knopp, S., Blum, J., Neu-

mayr, A. L., Keiser, J., and Hatz, C. F. (2012). Ne-

glected tropical diseases: diagnosis, clinical manage-

ment, treatment and control. Swiss Medical Weekly,

142:w13727.

Wakerly, M. (2012). Usb serial for android.

WHO, W. H. O. (1991). Basic malaria microscopy.

Zachary, G. (2015). Technology alone won’t improve health

in Africa [Spectral lines]. IEEE Spectrum, 52(1):7–7.

BIODEVICES 2017 - 10th International Conference on Biomedical Electronics and Devices

48