Whispering Gallery Mode Emission of a Cylindrical Droplet Laser

Mitsunori Saito and Takuya Hashimoto

Department of Electronics and Informatics, Ryukoku University, Seta, Otsu 520-2194, Japan

Keywords: Droplet Laser, Stimulated Emission, Whispering Gallery Mode, Fluorescence, Silicone Rubber.

Abstract: A cylindrical droplet laser was fabricated in a silicone rubber by using a polyethylene-glycol solution of

rhodamine 6G. The silicone rubber provided a simple molding process for enclosing the droplet, since

silicone oil solidified at room temperature by only adding a curing agent. Polyethylene glycol dissolved a

large amount of dye molecules, yielding a fluorescent solution whose refractive index (1.46) was higher

than that of the silicone rubber (1.40). Consequently, some fluorescence rays circulated in the cylindrical

droplet owing to the total internal reflection on the side surface (the whispering gallery mode). Other

fluorescence rays made round trips in the radial or axial directions of the cylindrical droplet (the radial and

axial modes) being reflected at the side or bottom surfaces. When the droplet was excited by a green laser

pulse (wavelength: 527 nm, pulse duration: 10 ns), these emission modes competed with one another to

induce a stimulated emission. In a droplet with 2.0 mm diameter and 1.4 mm height, the whispering gallery

mode conquered the other emission modes, exhibiting a non-linear peak growth and a peak-width narrowing

when the excitation energy exceeded 20 μJ (the threshold energy of the stimulated emission).

1 INTRODUCTION

Whereas most optical devices are composed of

solids, liquids exhibit some excellent functions that

are unachievable with solids. Deformability

(fluidity) is an attractive property when creating

tunable or flexible devices. A simple fabrication

process is also an advantage of liquid devices; e.g.,

no polishing process is needed to create a droplet

with a smooth surface that acts as a microresonator

(Matsko, 2009). In a smooth droplet, which is

producible by spraying aerosol (Tzeng et al, 1984),

lightwave circulates with a low scattering loss and

generates a whispering gallery (WG) mode

(Campillo et al, 1991). In addition to fundamental

researches (Biswas et al, 1989), the WG mode

resonators have been studied extensively in various

technical fields including spectroscopy (Sasaki et al,

1997), biomedical sensing (Arnold et al, 2003), and

photonic signal control (Hara et al, 2005). Of

various applications, droplet lasers have been

studied most keenly in the last two decades (Barnes

et al, 1993). Droplets are usually suspended in air

(Kaqradag et al, 2013) or oil (Tanyeri et al, 2007),

and hence, handling difficulty and instability

become problems when creating a microlaser. These

problems are solved by enclosing a droplet in a

transparent silicone rubber (Saito et al, 2008).

Although droplets in the rubber can be handled like

a solid, their deformability (optical tunability) is

preserved owing to the flexibility of the rubber

(Saito and Koyama, 2012). Electrical tuning is also

achievable for a liquid-crystal droplet in a silicone

rubber (Humar et al, 2009).

In spherical resonators the WG modes are

excited in various planes because of the three-

dimensional symmetry. Fluorescent microspheres,

therefore, emit strong beams in various directions

even in the stimulated emission process. Although

the direction of the stimulated emission is

controllable by deforming the sphere (Schwefel et al,

2004), creation of a cylindrical or disklike droplet is

more preferable for restricting the WG mode plane.

A novel fabrication process has to be developed for

creation of cylindrical droplets. In addition,

fabricated droplets have to be enclosed in a solid

matrix, since the surface tension causes the cylinder

to deform into a sphere in free space (air or oil).

Silicone rubber seems useful for both creating and

enclosing a cylindrical droplet.

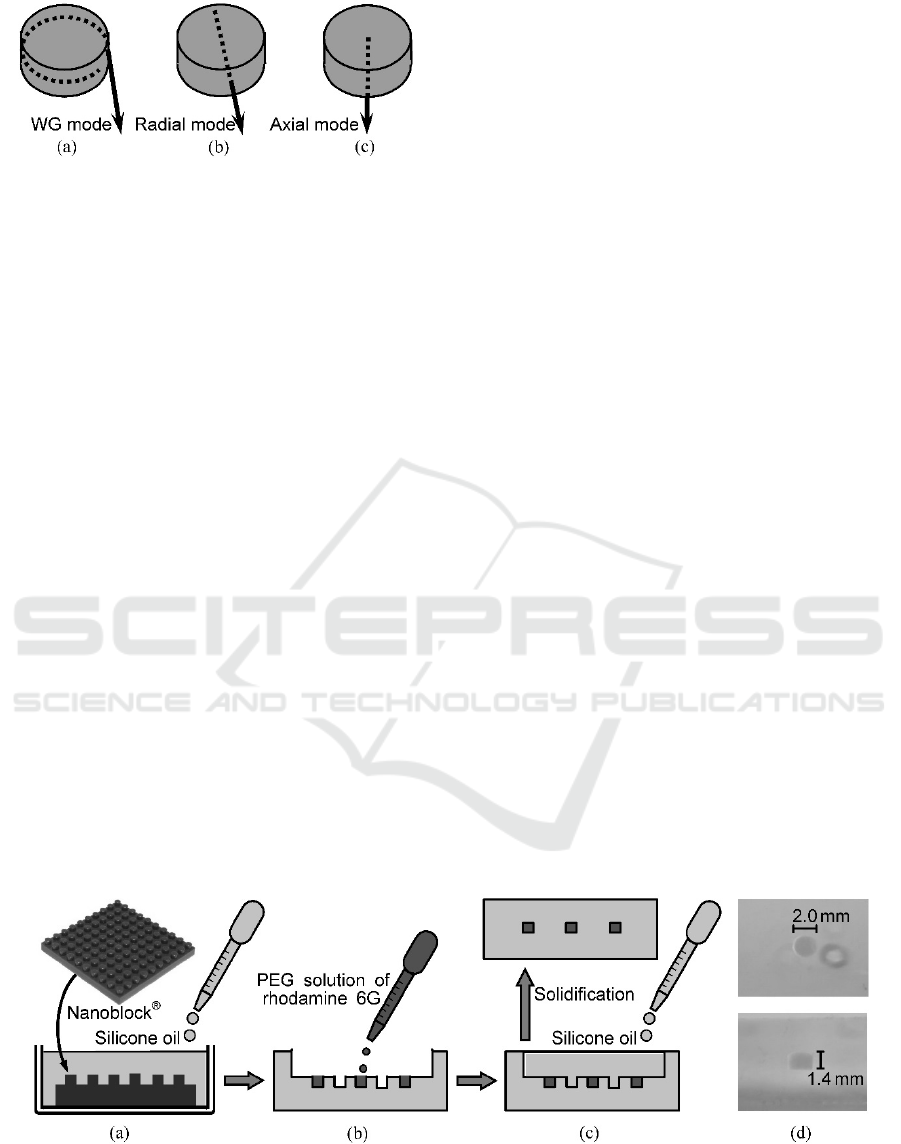

Figure 1(a) shows the WG mode in a cylindrical

droplet. Figs. 1(b) and 1(c) show two other modes in

which lightwave propagates in the radial or axial

direction. These modes compete with one another to

induce a stimulated emission; i.e., when a stimulated

emission

takes place in a certain mode, it suppresses

spontaneous emission of the other modes. (Saito and

Ishiguro, 2006). The WG mode emission is unique

32

Saito M. and Hashimoto T.

Whispering Gallery Mode Emission of a Cylindrical Droplet Laser.

DOI: 10.5220/0006089800320038

In Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2017), pages 32-38

ISBN: 978-989-758-223-3

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Schematic illustration of the emission modes in a

cylindrical droplet, i.e., (a) the whispering gallery, (b)

radial, and (c) axial modes.

to circulation-type resonators, whereas the other

emission modes are attainable with ordinary straight

waveguides. In addition, the WG mode exhibits

some attractive features for uses in sensors and

communications, e.g., a strong coupling with a

surrounding field or neighboring resonators. It is

preferred from this viewpoint to promote the

stimulated emission in the WG mode. The stimula-

ted emission occurs in a mode that has a higher gain

and/or a lower loss than the other modes. The

roughness of the cylinder surface causes a serious

optical loss to the WG mode in comparison with the

other modes, since circulating light suffers scattering

at every reflection occasion. A large gain, which is

related to the dye concentration and the droplet size,

promotes a stimulated emission in the radial or axial

mode, since lightwave is amplified strongly in a

round trip between the opposing surfaces. These

conditions have to be examined carefully to promote

the WG mode emission.

In this study, we fabricated cylindrical droplets

in a silicone rubber by using a molding technique.

Then

we measured fluorescence spectra by exciting

a cylindrical droplet from either the flat bottom or

the curved side. Spectral measurements were

conducted at various positions of the droplet to

evaluate the emission intensity of the three modes.

2 SAMPLE PREPARATION

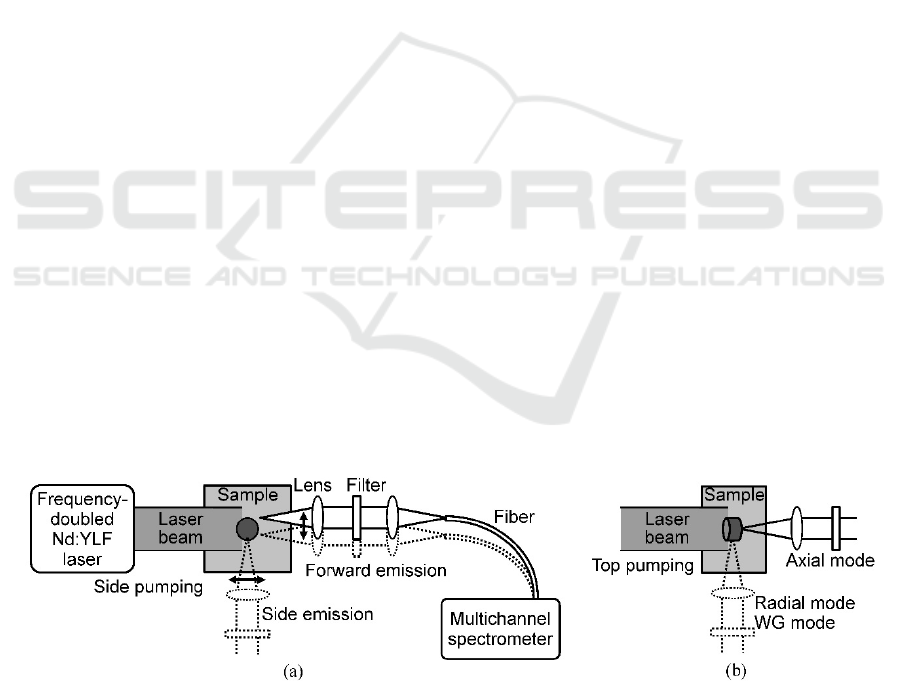

Figure 2 shows the fabrication process of the

cylindrical droplets. A piece of building blocks, i.e.,

Nanoblock

®

(Kawada Co., Ltd., 2012), which had

bumps with 2.0 mm diameter and 1.4 mm height,

was used as a mold for creating cylindrical pits on a

silicone surface. As Fig. 2(a) shows, this plastic

plate was placed on the bottom of a plastic case (30

mm square), and then, the case was filled up with

silicone oil containing a curing agent (Shin-Etsu,

KE103). The curing agent promoted a bridging

reaction between silicone (polydimethylsiloxane)

molecules, and consequently, the oil solidified in 8 h.

As Fig. 2(b) shows, the silicone rubber that was

taken out of the case had a pit array corresponding to

the bumps of the plate.

A solvent for preparing a dye solution has to be

selected carefully. A solvent consisting of a large

molecule is preferred, since molecules of ordinary

solvents, e.g., methanol and toluene, disperse into

the silicone rubber through a large free volume in

the flexible matrix (Saito et al, 2015). A high index

of refraction is another requirement for the solvent,

since the total internal reflection at the droplet

surface is essential to generate the WG mode. The

solubility of dye molecules is of course an important

issue. Taking into account these requirements for the

solvent,

we selected polyethylene glycol (PEG)

with a molecular weight of 300. This solvent has a

refractive index of 1.46, which is higher than that of

the silicone rubber (1.40). Rhodamine 6G (Tokyo

Chemical Industry) was dissolved into PEG at a

concentration of 10

-3

mol/l. As Fig. 2(b) shows, this

dye solution was put into some selected pits on the

silicone rubber. The other pits were left empty to

avoid optical interaction between neighboring

droplets.

Figure 2: Fabrication process of cylindrical droplets. (a) A plastic plate with cylindrical bumps (Nanoblock®) is fixed on

the bottom of a plastic case, and silicone oil with a curing agent is poured until it fills the entire case. (b) After solidification

(8 h), the silicone rubber is taken out of the case. Then a dye solution is put into some selected pits that have been created

by the bumps. (c) The silicone oil with the curing agent is poured into the hollow of the rubber surface to enclose the dye

solution. (d) Top and side views of a droplet in the silicone rubber.

Whispering Gallery Mode Emission of a Cylindrical Droplet Laser

33

Finally, silicone oil with the curing agent was

poured on the concave of the silicone rubber, as

shown in Fig. 2(c). When solidification was comple-

te (8 h later), a silicone rubber containing cylindrical

droplets was obtained. The micrographs in Fig. 2(d)

show the top and side views of a cylindrical droplet

that is enclosed in the silicone rubber.

3 EXPERIMENT

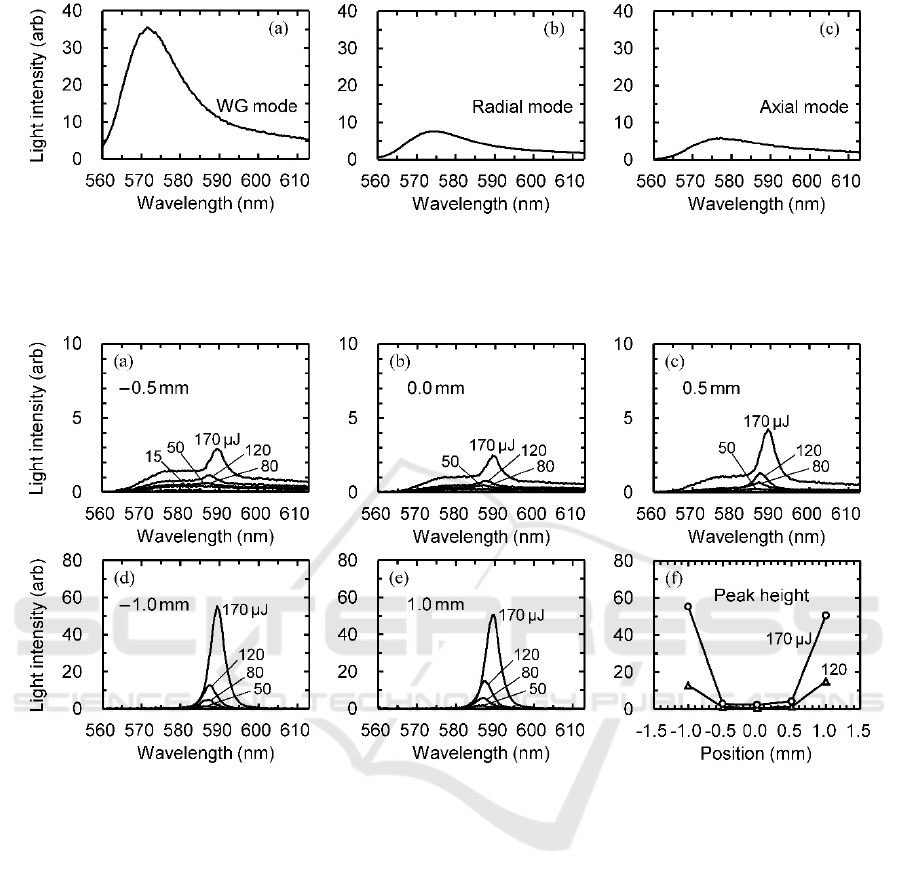

Fluorescence spectra of the droplets were measured

by using an optical system shown in Fig. 3(a). The

pump light was a frequency-doubled Nd:YLF laser

of 527 nm wavelength. A single pulse of 10 ns

duration was shot at the occasion of a trigger signal

input. The pulse energy was adjusted between 15

and 170 μJ by using an attenuator. The laser beam

diameter was ~4 mm, and hence, the beam irradiated

the entire droplet with a nearly uniform intensity

distribution. Fluorescence was collected by a lens

system consisting of two convex lenses and a long-

pass filter that cut off the pump light. The collected

light was transmitted through an optical fiber (core

diameter: 400 μm) and detected by a multichannel

spectrometer.

Measurements were conducted in

either the forward or side direction, and the detection

point was changed by moving a micropositioner on

which the lens system and the fiber were mounted.

When the fluorescence was picked up at the cylinder

edge, the WG mode emission was detected. The

radial mode emission was measured by moving the

pickup point to the cylinder center. The radial mode

emission was measureable from the cylinder top or

bottom (flat surface). As Fig. 3(b) shows,

measurements were also conducted by irradiating

the pump light from the cylinder top.

4 RESULTS

First, fluorescence was measured by irradiating the

pump beam from the cylinder top, as shown in Fig.

3(b). Figures 4(a) and 4(b) show fluorescence

spectra that were measured at the edge or the center

of the curved surface, corresponding to the WG and

radial modes, respectively. Figure 4(c) shows a

spectrum of the axial-mode emission that emerged

from the cylinder bottom (the flat surface). The

radial- and axial-mode emissions exhibit a similar

broad spectrum, which usually appears in a

spontaneous emission process. In comparison with

these spectra, the fluorescence peak of the WG-

mode emission is higher and narrower. This fact

indicates that the stimulated emission takes place in

the WG mode. The stimulated emission, however,

seems to be in its early stage, since the peak

narrowing is still insufficient (FWHM: ~20 nm).

Next, the pump light was irradiated on the side

surface of the cylinder, as shown in Fig. 3(a).

Fluorescence

was measured in the forward direction.

Figures 5(a)‒5(e) show the fluorescence spectra that

were measured at several different positions by

moving the pickup lens system laterally. The

position that is designated as 0.0 mm corresponds to

the cylinder center (the radial mode), and ±1.0 mm

corresponds to the edge (the WG mode). The pump

light energy was varied between 15 and 170 μJ. As

Figs. 5(d) and 5(e) show, a fluorescence peak grew

nonlinearly as the pump energy increased. The peak

width (FWHM) decreased to ~4 nm at 170 μJ. These

facts indicated that a stimulated emission took place

in the WG mode. The ‘red-shift’ of the fluorescence

peak, which commonly takes place in the stimulated

emission process of dye lasers, is also visible in the

spectrum

(the peak shift to 590 nm at 170 μJ). By

contrast, a weak, broad fluorescence peak appeared

Figure 3: Optical setup for fluorescence measurements. A pump laser beam (4 mm diameter) irradiated a droplet (2 mm

diameter, 1.4 mm height) from (a) the side (curved surface) or (b) the top (flat surface). Fluorescence was picked up by

using a confocal lens system and a glass fiber (core diameter: 400 μm), and measured by a multichannel spectrometer. A

color filter was inserted to attenuate the residual pump laser beam. As the arrows show, this pickup system was moved

laterally to measure the fluorescence at the center or the edge of the droplet. Measurements were conducted in both forward

and side directions.

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

34

Figure 4: Fluorescence spectra that were measured by the top pumping configuration (Fig. 3(b)). (a) The WG- or (b) radial-

mode emission was measured from the droplet side by adjusting the pickup position to the edge or the center, respectively.

(c) The axial-mode emission was measured in the forward direction. The pulse energy and duration of the pump laser were

170 μJ and 10 ns, respectively.

Figure 5: (a‒e) Fluorescence spectra that were measured in the forward direction during the side pumping process (Fig.

3(a)). Measurements were conducted at (b) the droplet center (0.0 mm), (d, e) the edges (±1.0 mm), and (a, c) the halfway

points (±0.5 mm). The numerals beside the spectra denote the pump energies. (f) The position dependence of the peak

height.

in the other positions (0 and ±0.5 mm), as shown in

Figs. 5(a)‒5(c). The peak that emerged unnaturally

at 590 nm seemed to be caused by scattering of the

WG-mode emission, since both the spectral shape

and the pump-energy dependence of this peak

resembled those in Figs. 5(d) and 5(e). Figure 5(f)

shows the position dependence of the spectral peak

height. The fluorescence intensities at the central

portions (the radial mode) were negligible in

comparison with those at the edges (the WG mode).

The fluorescence in the axial direction was even

weaker (below the detection limit). As these facts

indicated, only a spontaneous emission took place in

the radial and axial modes.

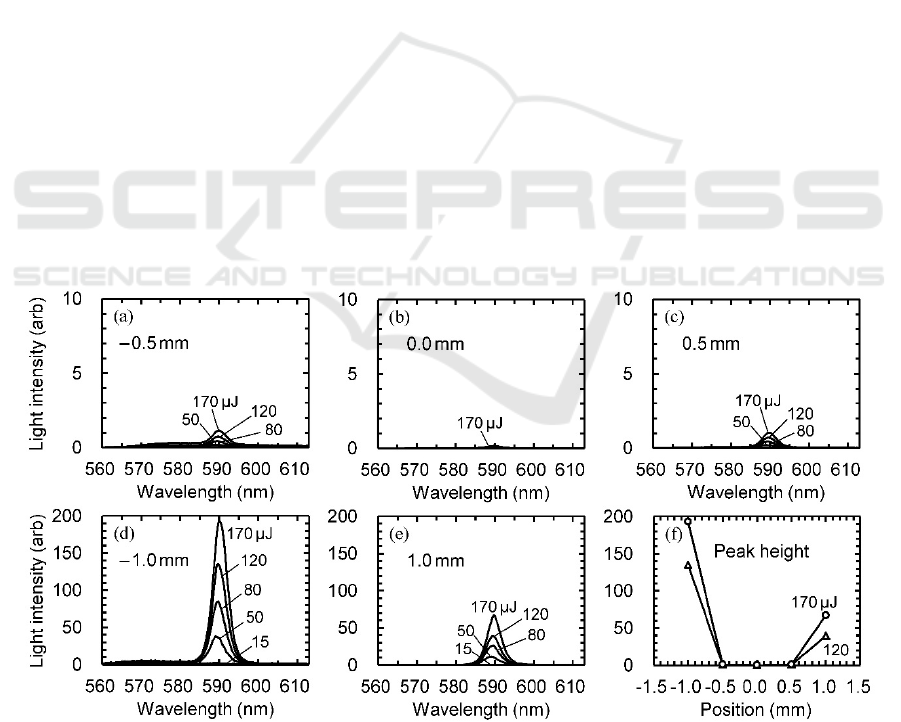

As the dotted lines in Fig. 3(a) illustrate,

fluorescence measurements were conducted in the

side direction as well. Figures 6(a)‒6(e) show the

fluorescence spectra that were measured at various

positions on the cylinder side. As Fig. 6(e) shows, a

narrow peak is visible at the edge (1.0 mm) that is

distant from the position of the pump light

irradiation (‒1.0 mm). The peak height and width

are close to those measured in the forward direction

(Figs. 5(d) and 5(e)). This is a reasonable result,

since the WG mode usually yields the same

emission intensity in all directions along the curved

cylinder surface. As Fig. 6(d) shows, however,

strong peaks emerged at the irradiated edge. The

peak height is three-fold higher than those measured

at the other edges. As Figs. 6(a)‒6(c) show, the

fluorescence spectra at the central portions (0 and

±0.5 mm) are also different from those measured in

Whispering Gallery Mode Emission of a Cylindrical Droplet Laser

35

the forward direction (Figs. 5(a)‒5(c)). The peak at

590 nm is thought to be caused by the scattered WG-

mode light. If this peak is excluded, the radial-mode

emission is weaker in the side direction than the

forward direction. These phenomena are discussed

in the following section. Figure 6(f) shows the peak

heights that were measured at various positions. The

fluorescence emission is localized at the cylinder

edges, indicating occurrence of a strong WG-mode

emission.

5 DISCUSSION

Let us consider the mode competition on the basis of

the experimental results. The absorbance of the

pump light is higher than 90% in the current droplet.

This fact indicates that the dye molecules are excited

more strongly on the irradiation side than the

opposite side. When the pump light is irradiated

from the top (Fig. 3(b)), the excitation is

comparatively uniform or axially symmetrical in the

droplet, and accordingly, all modes are excited

evenly. As Fig. 4 shows, therefore, this excitation

method yields no absolute winner of the

competition; i.e., all modes emit spontaneous

emission although symptoms of stimulated emission

are visible in the WG mode. By contrast, when the

cylinder side is irradiated (Fig. 3(a)), the central

portion of the droplet receives a small pump energy,

whereas a semi-periphery on the irradiation side

absorbs a strong energy. This is the reason that the

axial-mode emission is negligible when the pump

light is irradiated from the side. It follows that the

side pumping is more preferable than the top

pumping for promotion of the WG-mode emission.

The radial emission at the droplet center (0.0

mm) is stronger in the forward direction (Fig. 5(b))

than the side direction

(Fig. 6(b)). This phenomenon

is also explained by the non-uniformity of excitation.

The radial-mode light that emerges in the forward

direction passes through the irradiation point where

strong excitation takes place. The radial-mode light

in the side direction, however, passes the region

apart from the excitation point. This difference in the

excitation strength causes the anisotropy in the

radial-mode emission.

As mentioned earlier, the WG mode usually

emits fluorescence uniformly along its optical path

(the periphery). If a portion of the optical path is

excited strongly, however, the circulating light is

amplified strongly at that portion. Since the outward

radiation is proportional to the circulating light

intensity, the WG-mode emission possibly becomes

strong at around the excitation point. This is the

reason that the strong fluorescence peak emerges at

the irradiation edge (Fig. 6(d)). This local radiation

enhancement seems useful to extract a light energy

efficiently at a specific point. If the circulating light

is confined strongly in the droplet, i.e., if the WG

Figure 6: (a‒e) Fluorescence spectra that were measured in the direction perpendicular to the pump beam axis, i.e., the

downward direction in Fig. 3(a). Measurements were conducted at different positions; i.e., (b) the droplet center (0.0 mm),

(d) the pumping side (‒1.0 mm), (e) the opposite side (1.0 mm), and (a, c) the halfway points (±0.5 mm). The numerals

beside the spectra denote the pump energies. (f) The position dependence of the fluorescence peak height.

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

36

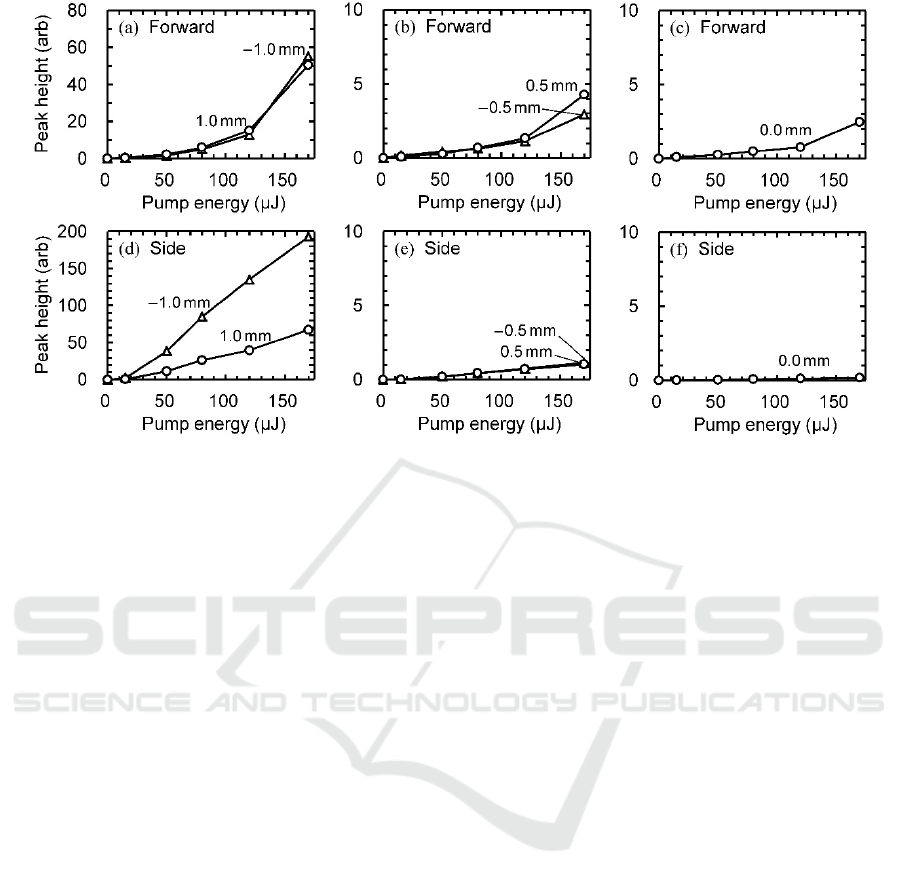

Figure 7: The pump-energy dependence of the fluorescence intensity (peak height). (a)‒(c) and (d)‒(f) correspond to the

data that were shown in Figs. 5 and 6, respectively. (a) and (d) show the data for the WG-mode emission. (c) and (f) show

the data for the radial-mode emission.

mode is weakly coupled to the outer electromagnetic

field, the outward radiation loss is small, and hence,

the circulating light propagates to the opposite side

with a small attenuation. If this is the case, the

intensity of the WG-mode emission becomes the

same at all positions; i.e., no local radiation

enhancement takes place. From this viewpoint, it is

preferable to enclose a droplet in a silicone rubber,

since

a small difference in their refractive indices

enhances a coupling efficiency between the WG

mode and the outer field.

Figures 7(a)‒7(c) show the pump-energy

dependences of the fluorescence peak height, which

were plotted on the basis of the experimental results

in Fig. 5 (the forward direction). As Fig. 7(a) shows,

the WG-mode emission exhibits a nonlinear peak

growth when the pump energy exceeds 50‒100 μJ.

Although similar nonlinear characteristics are visible

at the other positions (Figs. 7(b) and 7(c)), the

spectral peaks at these positions are attributed to the

scattering of the WG-mode light. Figure 7(d) shows

the peak heights of the WG mode that were

measured in the side direction (Figs. 6(d) and 6(e)).

At the irradiated edge (‒1.0 mm), the stimulated

emission takes place when the pump energy exceeds

~20 μJ. As regards the opposite edge (1.0 mm), the

threshold is not clear, i.e., the gradient of the curve

increases gradually as the pump energy increases.

This gradual increase is similar to those of the

curves in Fig. 7(a). The plots in Figs. 7(e) and 7(f)

also show a similar dependence (gradual increase)

on the pump energy. It is therefore assumed that

these emission peaks are caused by scattering of the

WG mode light.

In the current experiments, the silicone rubber

proved to be useful for both shaping a cylindrical

droplet and providing a suitable refractive index.

PEG is also a promising solvent, since it induces

random

lasing in the translucent solid phase (Saito

and Nishimura, 2016). With these useful materials,

we are currently planning new experiments, which

include spectral tuning by sample deformation, near-

field coupling of the cylindrical droplets, and

bistable laser emission owing to the phase transition

in PEG.

6 CONCLUSIONS

A fabrication process of a cylindrical droplet laser

was established by using a molding technique of a

silicone rubber. A stimulated emission in the WG

mode was realized by exciting the droplet (2.0 mm

diameter and 1.4 mm height) with a green laser

pulse (10 ns, 20 μJ). The excitation from the curved

surface was effective for both suppression of the

other emission mode and efficient extraction of the

WG mode emission. The combination of silicone

rubber and polyethylene glycol can be extended to

creation of various composite materials and devices

including a flexible microresonator and a droplet

laser array.

Whispering Gallery Mode Emission of a Cylindrical Droplet Laser

37

ACKNOWLEDGEMENTS

This research was supported by Japan Society for

the Promotion of Science (15K04642).

REFERENCES

Matsko, A. B., ed., 2009. Practical Applications of

Microresonators in Optics and Photonics, CRC Press.

Boca Raton, Florida.

Tzeng, H.-M., Wall, K. F., Long, M. B., Chang, R. K.,

1984. Laser emission from individual droplets at

wavelengths corresponding to morphology-dependent

resonances. Opt. Lett. 9(11). p. 499–501.

Campillo, A. J., Eversole, J. D., Lin, H.-B., 1991. Cavity

quantum electrodynamic enhancement of stimulated

emission in microdroplets. Phys. Rev. Lett. 67(4). p.

437–440.

Biswas, A., Latifi, H., Armstrong, R. L., Pinnick, R. G.,

1989. Time-resolved spectroscopy of laser emission

from dye-doped droplets. Opt. Lett. 14(4). p. 214–216.

Sasaki, K., Fujiwara, H., Masuhara, H., 1997. Optical

manipulation of a lasing microparticle and its

application to near-infrared microspectroscopy. J. Vac.

Sci. Technol. B, 15(6). p. 2786–2790.

Arnold, S., Khoshsima, M., Teraoka, I., Holler, S.,

Vollmer, F., 2003. Shift of whispering-gallery modes

in microspheres by protein adsorption. Opt. Lett. 28(4).

p. 272–274.

Hara, Y., Mukaiyama, T., Takeda, K., Kuwata-Gonokami,

M., 2005. Heavy photon states in photonic chains of

resonantly coupled cavities with supermonodispersive

microspheres. Phys. Rev. Lett. 94(20). p. 203905-1–4.

Barnes, M. D., Ng, K. C., Whitten, W. B., Ramsey, J. M.,

1993. Detection of single rhodamine 6G molecules in

levitated microdroplets. Anal. Chem. 65(17). p. 2360–

2365.

Kaqradag, Y., Aas, M., Jonáš, A., Anand, S., McGloin, D.,

Kiraz, A., 2013. Dye lasing in optically manipulated

liquid aerosols. Opt. Lett. 38(10). p. 1669–1671.

Tanyeri, M., Perron, R., Kennedy, I. M., 2007. Lasing

droplets in a microfabricated channel. Opt. Lett.

32(17). p. 2529–2531.

Saito, M., Shimatani, H., Naruhashi, H., 2008. Tunable

whispering gallery mode emission from a

microdroplet in elastomer. Opt. Express, 16(16). p.

11915–11919.

Saito, M., Koyama, K., 2012. Spatial and polarization

characteristics of a deformed droplet laser. J. Opt.

14(6). p. 065002-1–6.

Humar, H., Ravnik, M., Pajk, S., Muševič, I., 2009.

Electrically tunable liquid crystal optical

microresonators. Nature Photon. 3. p. 595–600.

Schwefel, H. G. L., Rex, N. B., Tureci, H. E., Chang, R.

K., Stone, A. D., Ben-Messaoud, T., Zyss, J., 2004.

Dramatic shape sensitivity of directional emission

patterns from similarly deformed cylindrical polymer

lasers. J. Opt. Soc. Am. B, 21(6). p. 923–934.

Kawada Co., Ltd. (Japan), 2012. What’s Nanoblock?

http://www.diablock.co.jp/kawada/en/nanoblock/about.

Saito, M., Ishiguro, H., 2006. Anisotropic fluorescence

emission of a dye-doped fibre ring that is pumped by a

ring laser beam. J. Opt. A: Pure Appl. Opt. 8(1). p.

208–213.

Saito, M., Nishimura, T., Hamazaki, T., 2015. Fade-

resistant photochromic reactions in a self-healable

polymer. Opt. Express, 23(20). p. 25523–25531.

Saito, M., Nishimura, Y., 2016. Bistable random laser that

uses a phase transition of polyethylene glycol. Appl.

Phys. Lett. 108(13). p. 131107-1–4.

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

38