Manufacturing and Optimization of Sol-gel-based TiO

2

-SiO

2

thin

Films as High Refractive Index Overlays for Long Period

Grating-based Biosensing

Palas Biswas

1

, Francesco Chiavaioli

2

, Sunirmal Jana

1

, Somnath Bandyopadhyay

1

,

Nandini Basumallick

1

, Ambra Giannetti

2

, Sara Tombelli

2

, Susanta Bera

1

, Aparajita Mallick

1

,

Francesco Baldini

2

and Cosimo Trono

2

1

Central Glass and Ceramic Research Institute, CSIR-CGCRI, 196 Raja S C Mullick Road, Kolkata 700032, India

2

Institute of Applied Physics “Nello Carrara”, CNR-IFAC, Via Madonna del Piano 10, 50019 Sesto Fiorentino, Italy

Keywords: Long Period Gratings, Sol-gel Overlay, High Refractive Index Thin Film, Refractometer, Biosensor.

Abstract: The manufacturing procedure and the optimization of high refractive index overlays for long period grating-

based sensors are reported. The overlay consists of a sol-gel-based TiO

2

-SiO

2

thin film. By carefully tuning

the overlay thickness and refractive index, it is possible to bring the LPG in the so-called transition mode

working region, and to optimize and maximize the LPG sensing performances. LPGs are here characterized

as optical refractometers, and, after a suitable functionalization of the sol-gel coated fiber surface, as

biosensors performing an IgG/anti-IgG bioassay.

1 INTRODUCTION

The optical label-free detection of chemical

compounds or biological species is based on the

modulation of the refractive index (RI) occurring at

the liquid/solid sensor interface, where the

biochemical interaction between the sensing layer

and the analyte of interest takes place (Fan, 2008).

Generally, the RI modification modulates the

evanescent wave component of the total optical

power. The literature accounts for several optical

configurations, mainly based on surface plasmon

resonance (SPR) (Homola, 2008), on localized SPR

(Willets and Van Duyne, 2007), on interferometry

(Queirós et al., 2011) or on optical resonance-based

structures (Kindt and Bailey, 2013). The substrate on

which the sensing layer is deposited is generally an

optical waveguide that allows both the interaction

light-analyte and the transport of the optical signal.

Recently, optical fiber long period gratings

(LPGs) have been proposed as a promising tool for

label-free biosensors (Chiavaioli et al., 2015; Baldini

et al., 2012). They exploit the typical peculiarities and

advantages of optical fiber sensors, such as

compactness, lightweight, intrinsic miniaturization,

high compatibility with optoelectronic devices,

remote measurement capabilities and multiplexing

thanks to the spectral modulation of the signal.

An LPG is produced by inducing periodic RI

perturbations in the core of a single-mode optical

fiber. When the light normally guided into the fiber

core interacts with the grating, the fundamental core

mode couples to co-propagating cladding modes at

well-defined resonance wavelengths (LPG

res

)

which satisfy the phase-matching condition

expressed by the characteristic equation of LPGs

(Erdogan, 1997):

res

(

m

)

= ( n

eff,core

– n

eff,clad

(

m

)

)

(1)

where is the grating period (usually in the range

from 100 m to 600 m), n

eff,core

and n

eff,clad(m)

represent the effective RIs of the fundamental core

mode (i.e. LP

01

) and the m-th cladding mode (i.e.

LP

0m

), respectively. Therefore, the transmission

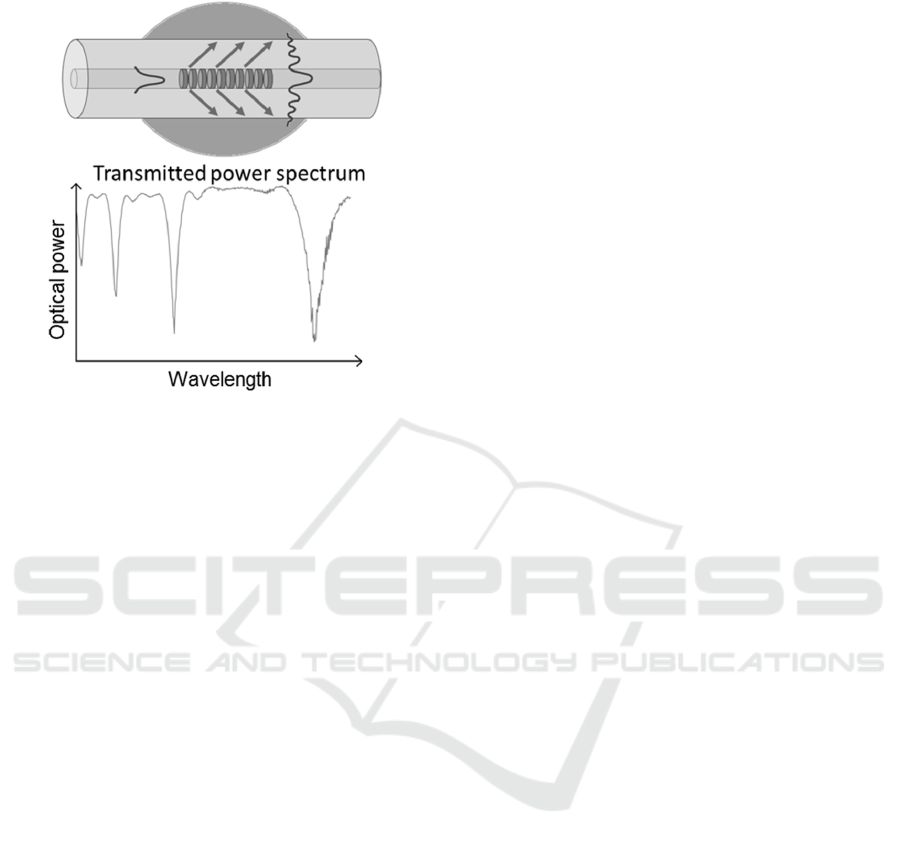

spectrum of an LPG will be characterized by one or

more attenuation bands (Figure 1), in which the

minimum of each band corresponds to the coupling

with a selective m-th cladding mode. The cladding

refractive index n

eff,clad

will therefore depend on the

RI of the surrounding medium (n

sur

) and this feature

allows to use LPGs as RI sensors.

The optical mechanism of LPG-based biosensing

can be explained considering that the binding

interactions on the fiber surface produce a change of

Biswas, P., Chiavaioli, F., Jana, S., Bandyopadhyay, S., Basumallick, N., Giannetti, A., Tombelli, S., Bera, S., Mallick, A., Baldini, F. and Trono, C.

Manufacturing and Optimization of Sol-gel-based TiO2-SiO2 thin Films as High Refractive Index Overlays for Long Period Grating-based Biosensing.

DOI: 10.5220/0005844103490355

In Proceedings of the 4th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2016), pages 351-357

ISBN: 978-989-758-174-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

351

the n

eff,clad

and, consequently, a shift of the LPG

res

.

Figure 1: LPG working principle (top) and a typical LPG

transmission spectrum (bottom).

The best RI sensitivity of a standard LPG is

reached when n

sur

is close to the RI of fiber cladding

(i.e. 1.44–1.46 RIU, RI units), thus quite far from the

RI of water or aqueous solutions (i.e. 1.33–1.34 RIU)

(Patrick et al., 1998), in which practically all the

biochemical reactions occur. To overcome this

problem, the literature accounts for a general

approach that consists in the deposition over the fiber

of a nm-thick film overlay of RI higher than the

cladding RI (Del Villar et al., 2005). In this way the

RI range in correspondence of the maximum

sensitivity can be adjusted around 1.33 RIU. In this

case, values of RI sensitivity of the order of thousands

of nm RIU

-1

can be experimentally achieved (Pilla et

al., 2012).

Sol-gel-derived coatings have been used for years

to enhance the performance of evanescent wave

sensors. The sensor manufacturing is quite simple

thanks to the dip-coating (DC) technique (MacCraith,

1993), and the possibility of doping sol-gel coatings

with high refractive index materials provides the

chance for implementing high RI (HRI) film overlays

(Smietana et al., 2015; Davies et al., 2009).

In the present paper, the manufacturing procedure

and the optimization of a sol-gel-based TiO

2

-SiO

2

thin film as HRI overlay for LPG-based biosensing

applications were investigated. The HRI overlay,

deposited by means of the DC technique along the

sensing portion containing the LPG, improved the

sensor performance in terms of volume RI sensitivity

(as optical refractometer), and of bio-layer formation

sensitivity (as biosensor). An IgG/anti-IgG assay

implemented on the fiber sol-gel coated sensing

region was used to characterize the proposed LPG-

based device as a feasible and effective biosensor.

2 MATERIALS AND METHODS

2.1 LPG Fabrication

LPGs were manufactured in a standard single-mode

fiber (SMF28e of Corning Inc.) using point-to-point

technique (Hill and Meltz, 1997) by means of a KrF

pulsed Excimer laser (Braggstar-500, TUI laser,

Germany, = 248 nm, repetition rate = 200 Hz, pulse

energy = 10 mJ) with = 342 m. The fiber was

previously hydrogen loaded at a pressure of 10.3 MPa

and a temperature of 100 °C for 48 hours to enhance

the photosensitivity. After the inscription, the fiber

was annealed at 150–170 °C for about six hours for

the stabilization of the optical characteristics of

LPGs. In order to deposit a glassy coating (e.g. a sol-

gel based thin film) over an optical fiber containing

an LPG, the grating region must be heated at around

450 °C during sintering the gel film. In general, at that

temperature, the LPG attenuation bands almost

reduce to zero. To overcome this problem, during the

grating manufacturing, the cladding mode of interest

(LP

07

) was intentionally overcoupled with a greater

coupling strength to achieve stable LPGs when heated

(Biswas, 2014). The LPGs were stabilized at 550 °C

and then gratings with a

res

of roughly 1590 nm, with

a visibility of the attenuation band of roughly -12 dB,

and with a full width at half maximum (FWHM)

bandwidth of roughly 20 nm were attained.

2.2 Sol-gel Preparation and Deposition

The preparation of the sol-gel was performed

according to previous literature (Chiavaioli et al.,

2015). Briefly, for the silica sol preparation, tetraethyl

orthosilicate (TEOS, reagent grade, 98%) was used at

a molar ratio water:TEOS:HCl of 2:1:0.001; for the

titania sol, tetraisopropylorthotitanate (TIOT, 97%)

was used at a molar ratio acetyl acetone:TIOT of 1:2.

The two sols were mixed by stirring for about 4 hours

and then kept to age for additional 24 hours. The Ti:Si

ratio and the total equivalent oxide weight percentage

(wt.%) were 1:1 and 7.3, respectively. To obtain a

thicker film, the viscosity of the sol was increased

from 3.2 mPa·s up to 27 mPa·s by controlling the

evaporation of the solvents through the warming of

the sol. Afterwards, the LPG was heated in a furnace

in order to allow the oxide formation in the deposited

OSENS 2016 - Special Session on Optical Sensors

352

film. At the end of the process, the attenuation band

related to the LP

07

cladding mode was recorded both

in air and in phosphate buffered saline (PBS) solution.

Considering the Ti:Si volumetric ratio (1:1), a

layer RI of ~1.7 RIU can be estimated as the mean

value between the titania RI (i.e. 1.91–1.96 RIU) and

silica RI (i.e. 1.42–1.44 RIU) (Davies et al., 2015). To

optimize the sensor performance and to reach the

optimum overlay thickness (OOT), the film thickness

was varied by changing both the sol viscosity during

the sol preparation and the withdrawal speed during

the film deposition. A single deposition step was

found to be good enough to move the selected

cladding mode to its transition region (Cusano et al.,

2006).

During the heat treatment, the temperature of the

furnace was increased from 26 °C to 450 °C at a rate

of about 1.2 °C min

-1

and then the LPG was kept at

450 °C for about 2.5 hours. Later, the furnace

temperature was slowly cooled down with the same

rate of 1.2 °C min

-1

in order to avoid any crack due to

thermal shock. At the end of the process, the LPG

wavelength of LP

07

mode was measured in air and in

phosphate buffered saline (PBS) solution.

2.3 Experimental Setup

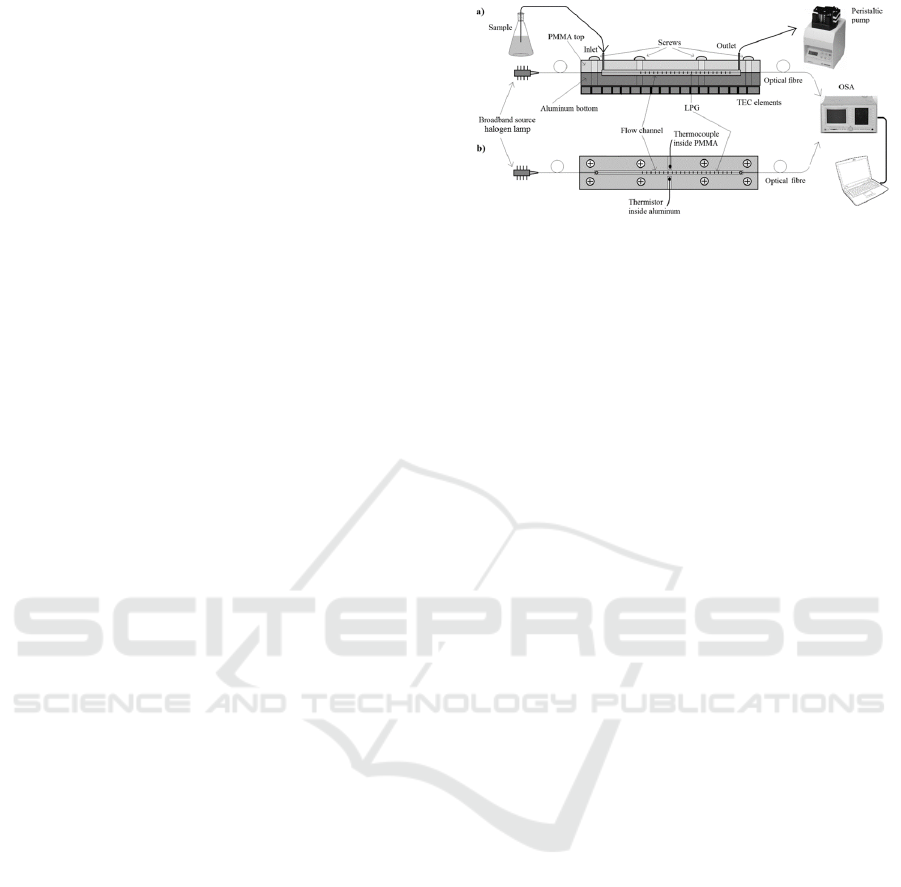

The experimental setup is detailed in Figure 2. The

flow-cell consists of two parts (Trono et al., 2011):

the upper one is a 4 mm thick PMMA transparent

layer, and the bottom one is a 6 mm thick aluminium

layer placed in thermal contact with a thermo electric

cooler (TEC) element. The flow cell is 80 mm long,

15 mm wide, and 10 mm high, and the flow-channel

total volume is roughly 50 L. The temperature

stabilization section of the flow cell makes use of a

thermistor, inserted into the aluminium bottom part as

close as possible to the flow channel, which acts as a

feedback element on the Peltier elements that are

driven by a suitable controller (ILX Lightwave LDC-

3722B TEC controller). The optical fiber containing

the LPG is glued at both the edges of the flow cell and

a thermocouple (Lutron TM-917) records the

temperature of the sensing environment during the

measurements. Each sample contained into the flask

is pumped inside the flow cell by means of a

peristaltic pump (Gilson Minipuls 3). The light is

launched by a broadband superluminescent diode

(SLD) INPHENIX IPSDD1503. The transmitted

spectrum is acquired by an optical spectrum analyzer

(OSA) Anritsu MS9030A – MS9701B (0.1 nm

spectral resolution).

Figure 2: schematic view of the experimental setup.

Longitudinal cross section (a) and top view (b) of the flow-

cell.

2.4 Data Processing

The optical bandwidth of the OSA is set at 20 nm with

the central wavelength roughly corresponding to the

expected LPG

res

. After recording the spectrum, the

procedure firstly evaluates the starting LPG

res

that

is the wavelength corresponding to the minimum of

the data set; then the fitting using the Lorentzian

function is carried out (normally a correlation greater

than 0.996 can be obtained) and provides the final

LPG

res

with an error of 7 pm – 8 pm. The whole

procedure is performed every 20 s, which is the

sensing system acquisition time. For each

experimental point, the minimum wavelength is

acquired at least 15 times. Therefore, each

experimental point is characterized by its own mean

value and the respective standard deviation. In this

way, the experimental standard deviation takes into

account the noise sources coming from not only the

extraction procedure of the LPG

res

but also all the

other noise sources related to the experimental setup

(e.g. temperature fluctuations). In addition, each

experimental point is recorded when the flow is

stopped, thus the temperature fluctuations can be

maintained lower than 0.05 °C during the measuring

time.

2.5 Bioassay Protocol

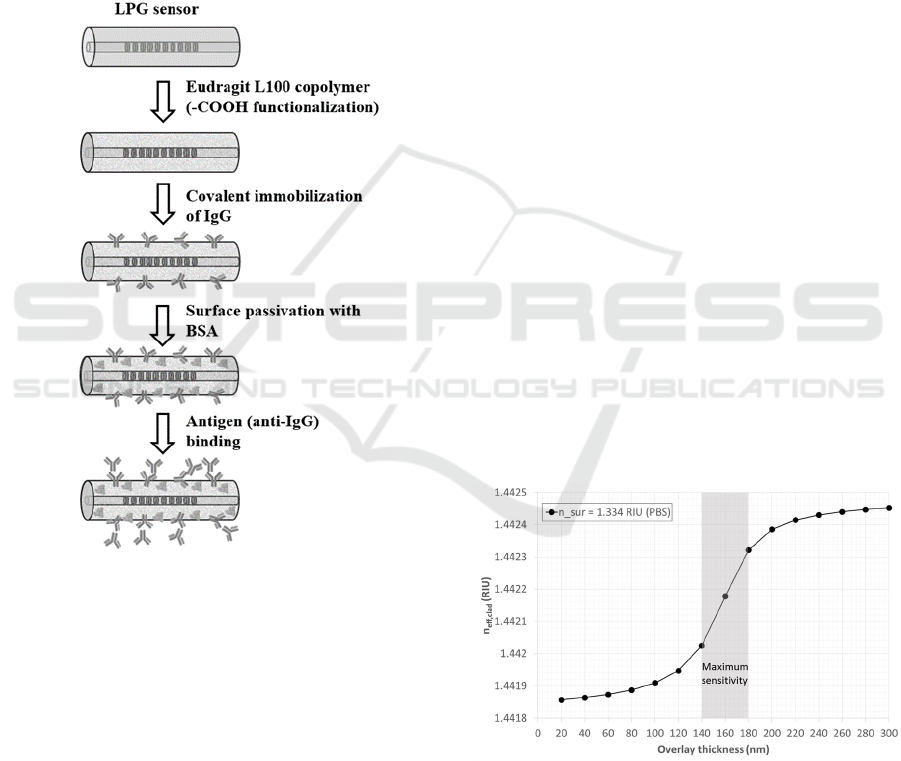

The step-by-step protocol followed to implement the

bioassay (Chiavaioli et al., 2014) is depicted in Figure

3. The functionalization of the optical fiber in

correspondence of the LPG was achieved by the

deposition of a layer of a methacrylic

acid/methacrylate copolymer (Eudragit L100) for

antibody immobilization.

Once the LPG was functionalized, the optical

fiber was placed inside the temperature-stabilized

flow cell. All the steps for the implementation of the

bioassay were performed using the flow cell

Manufacturing and Optimization of Sol-gel-based TiO2-SiO2 thin Films as High Refractive Index Overlays for Long Period Grating-based

Biosensing

353

connected to a peristaltic pump and keeping the

temperature of the flow cell at 23 °C. The preparation

of the biolayer consisted of the following steps

(Figure 3): activation of –COOH (carboxylic) groups

by cross-linking chemistry (1-Ethyl-3-[3-

dimethylaminopropyl] carbodiimide hydrochloride

(EDC) and N-hydroxysuccinimide (NHS)), covalent

immobilization of mouse IgG (1000 mg L

-1

in PBS),

washing with PBS for removing the un-reacted

antibodies, and surface passivation with bovine serum

albumin (BSA) (3% in PBS) in order to block the

remaining activated carboxylic groups and to prevent

non-specific adsorption onto the surface.

Figure 3: schematic representation of the biolayer

preparation on the fiber surface and of the antibody-antigen

binding phase.

The assay was performed in human serum spiked

with increasing concentrations of goat anti-mouse

IgG ranging from 1 µg L

-1

up to 100 mg L

-1

. Serum

was used at a final dilution of 1:10 (v/v) in PBS.

3 RESULTS

3.1 Thickness Optimization

The LPG RI sensitivity can be significantly enhanced

when covered with an overlay of a material having RI

higher than the one of the fibre. In these conditions,

the selected cladding mode starts to be guided by the

overlay and the LPG is working in the so-called

transition mode region (Del Villar et al., 2005). The

overlay thickness and RI must be precisely controlled

in order to reach the optimum overlay thickness

(OOT), which occurs when the cladding mode

resonance wavelength is positioned at the centre

between the original value and that one of the next

lower cladding mode (LP

06

in this case). The

behaviour of the LP

07

cladding mode as a function of

the thickness of the sol–gel overlay was calculated

considering sol-gel RI of 1.698 RIU and PBS buffer

(1.334 RIU) as surrounding medium. The simulated

curve, reported in Figure 4, demonstrates that the

sensors can work around the most sensitive linear

region when the overlay thickness is comprised

between 140 and 180 nm. In this way, the LP

07

mode

will be in the transition region when the surrounding

medium is PBS buffer, and the sensor will show a

higher sensitivity as a function of the biochemical

interaction of the target biomolecule with the sensing

layer.

Based on these simulations, the thickness of the

sol–gel-based TiO

2

-SiO

2

film overlay was optimized

by varying the viscosity of the sol and the withdrawal

speed during the film deposition. Three different

batches were realized, changing the sol viscosity

(batch A: 3.2 mPa·s; batch B: 27 mPa·s; batch C: 24.5

mPa·s) and the withdrawal speed (batch A: 2.5 mm

sec

-1

; batch B: 2.2 mm sec

-1

; batch C: 2.95 mm sec

-1

).

The corresponding wavelength shift for the LP

07

mode due to the film deposition was 8, 13.5 and 20

nm for batch A, batch B and batch C, respectively.

Figure 4: simulated curve, n

eff,clad

vs. overlay thickness

(1.698 RIU) considering the LP

07

mode PBS buffer as

surrounding medium.

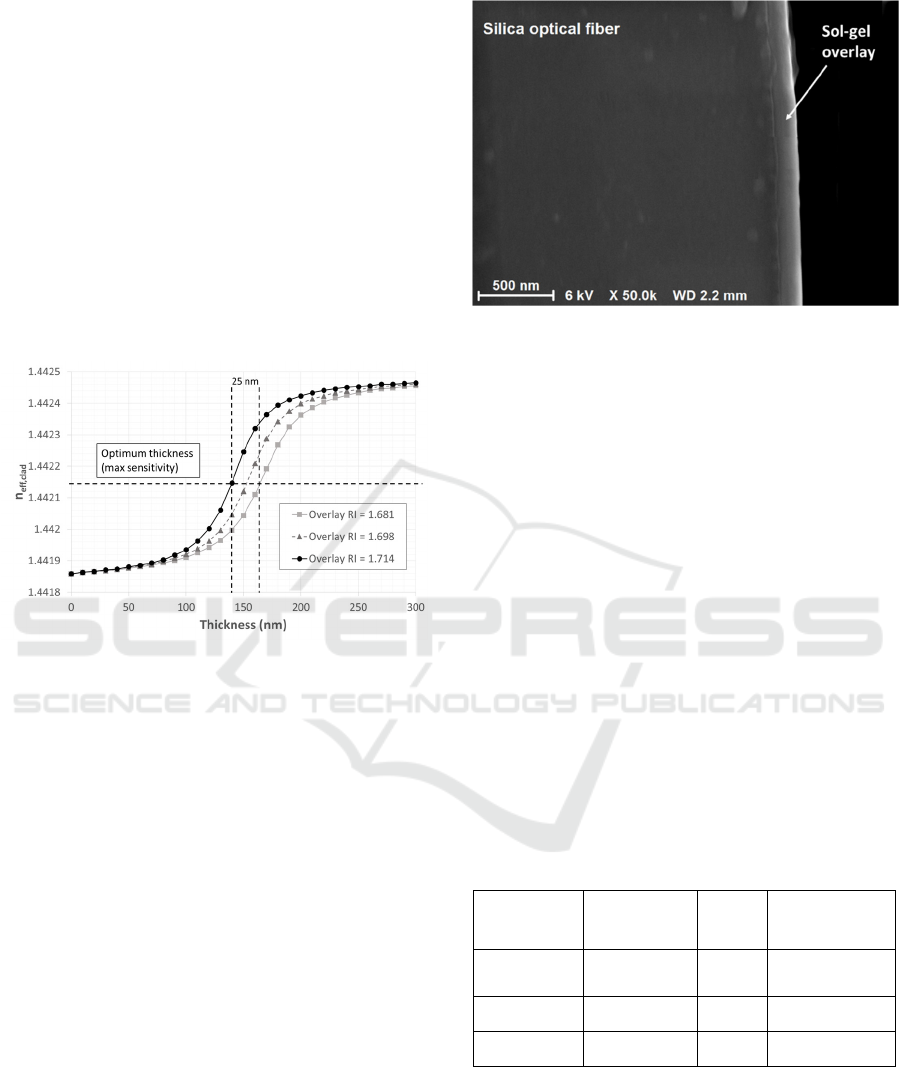

The overlay RI can also slightly vary from the

desired value depending on:

-the sol composition;

OSENS 2016 - Special Session on Optical Sensors

354

-the ageing time of the sol that can directly

influence the viscosity of the sol:

-the withdrawal speed during dip coating;

-the thermal curing temperature.

In order to evaluate the sensor response

dependence on this parameter, the effective RI of the

LP

07

mode was simulated as a function of the overlay

thickness, considering a ±1% change in the overlay

RI (1.681, 1.698 and 1.714 RIU) and considering PBS

as surrounding medium. The results are shown in

Figure 5. The ±1% variation of overlay RI slightly

changes the sensitivity without shifting the sensor

from the most sensitive region. Considering a ±1%

variation of the overlay RI, a tolerance on the overlay

thickness of about 25–35 nm is expected.

Figure 5: Simulated curves (overlay thickness vs n

eff,clad

)

used for studying the influence of a change of 1% in the

overlay RI (1.698 RIU, triangles grey dotted line; 1.681

RIU, squares, grey line; 1.714 RIU, circles, black line)

considering the LP

07

mode when the surrounding medium

is the PBS buffer.

The film overlay was analysed by means of a field

emission scanning electron microscope (FESEM;

Supra 35VP, Carl Zeiss). Figure 6 shows an image of

the cross-section of an optical fiber coated with the

sol-gel based TiO

2

-SiO

2

film overlay (sensor of batch

C). The thickness of the deposited sol-gel film

overlay was estimated to be (159 ± 10) nm

(Chiavaioli et al., 2015).

3.2 Bulk Refractive Index Sensitivity

For the RI characterization, the LPGs were immersed

in NaCl-in-water solutions of known RI: from 0.1%

wt., 1.333 RIU up to 0.6% wt., 1.334 RIU with step

of 0.1% wt. Each measurement was taken at stable

temperature of 23 °C with fluctuations lower than

0.03 ºC. This allows to discard the contribution

coming from the thermo-optic effect acting on

solutions (roughly -8 x 10

-5

RIU °C

-1

). After each

Figure 6: FESEM image of the cross-section of the optical

fiber coated with sol-gel based TiO

2

-SiO

2

film overlay

(batch C).

measurement, the fiber was washed with deionized

water in order to remove any remaining NaCl on the

overlay surface.

A comparison considering the same cladding

mode was carried out for three different LPGs (not

coated, batch A and B) in the RI range between 1.333

RIU and 1.334 RIU.

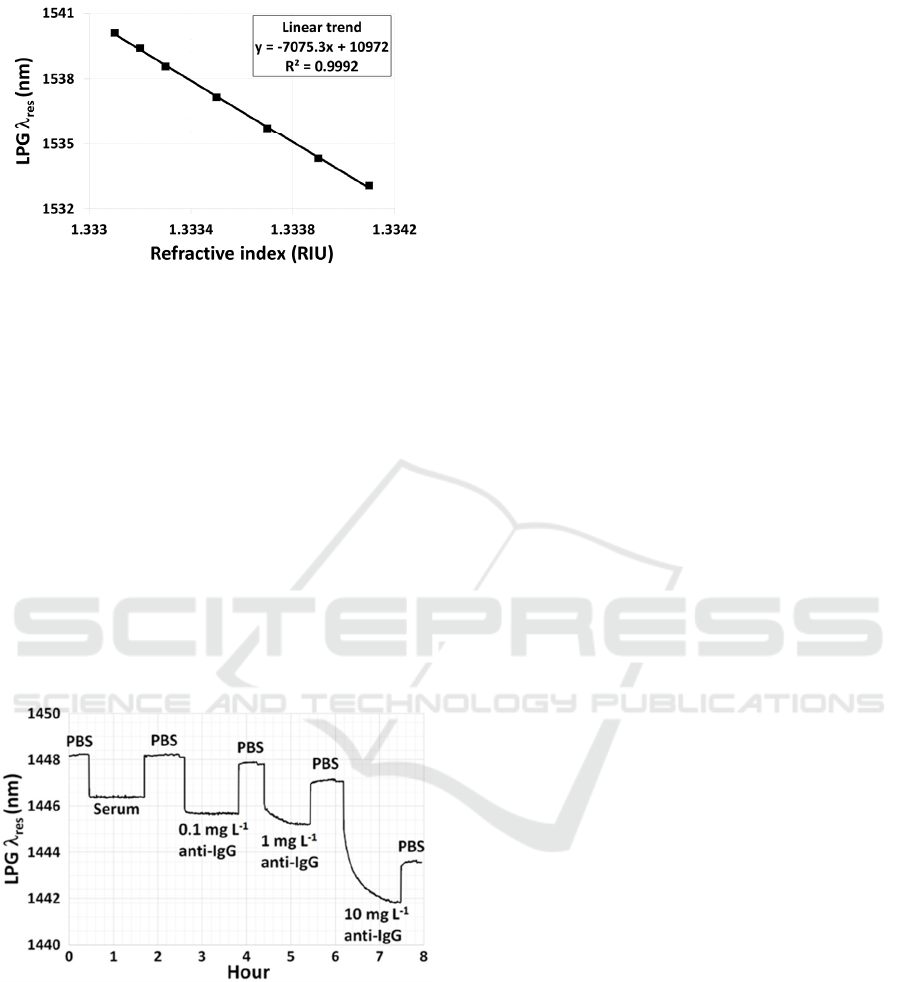

The results are summarized in table 1, while the

sensor response curve for a coated LPG of batch B is

reported in Figure 7. It is worth pointing out that the

sensitivity was evaluated considering the slope of the

linear regression approach of the sensor response

curve (Figure 7 as an example), whereas the

resolution was attained considering three times the

standard deviation divided by the sensitivity (Trono

et al., 2011).

Table 1: Comparison of the results achieved using different

sol-gel based titania-silica coated LPGs and conventional

not-coated LPG (same LP

07

mode order) in terms of volume

RI characterization.

Batch

Sensitivity

(nm RIU

-1

)

(pm)

Resolution

(RIU)

not coated

LPG

-29.8 8 8.1 x 10

-4

A -2044.5 10 1.5 x 10

-5

B -7075.3 11 4.6 x 10

-6

As shown in Table 1, there is a great improvement

(both sensitivity and resolution), going from a simple

not coated LPG to a coated LPG. Moreover, by

optimizing the thickness of the film overlay with

values around 130–175 nm considering PBS as

surrounding medium (RI of 1.334 RIU), it is possible

to achieve very good performances.

Manufacturing and Optimization of Sol-gel-based TiO2-SiO2 thin Films as High Refractive Index Overlays for Long Period Grating-based

Biosensing

355

Figure 7: LPG wavelength shift (batch B) as a function of

the external volume refractive index.

3.3 Bioassay

The performances of sol-gel coated LPGs were

evaluated also by carrying out an IgG/anti-IgG

immunoassay on the functionalized surface of the

fiber. The sol-gel based TiO

2

-SiO

2

coated LPG of

batch C was used in this measurement. The

sensorgram achieved by spiking the antigen (from 0.1

mg L

-1

up to 10 mg L

-1

) in human serum is reported

in Figure 8. The duration of the whole immunoassay,

including the antibody immobilization step, was of

several hours, but the long-term stability of the

sensing system (Trono et al., 2011), guarantees the

absence of any disturbance coming from long-term

drifts.

Figure 8: Response of a sol-gel based TiO

2

-SiO

2

coated

LPG of batch C in human serum. Sample spiked with the

antigen (anti-IgG) at 0.1 mg L

-1

, 1 mg L

-1

and 10 mg L

-1

.

A limit of detection (LOD), defined as three times

the standard deviation of the blank measurement, of 8

g L

-1

was attained (Chiavaioli et al., 2015). The

LOD is nine-fold lower than that achieved in the same

experimental conditions (i.e. human serum) but using

a not coated LPG (Chiavaioli et al., 2014).

4 CONCLUSIONS

The manufacturing procedure and the optimization of

high refractive index sol-gel-based TiO

2

-SiO

2

thin

film overlay for LPG-based sensors have been

discussed. The sol-gel characteristics (composition

and viscosity) and the withdrawal speed during the

dip-coating technique have been chosen in order to

have the best combination of RI and thickness.

Sensors with overlay thickness of 130–160 nm and RI

of 1.7 RIU were manufactured and characterized. The

LPG sensors performances were evaluated, as optical

refractometer, with the volume refractive index

characterization, and as biosensor, with the IgG/anti-

IgG bioassay. The best performance was achieved

with an overlay thickness of roughly 159 nm, with a

bulk refractive index sensitivity of roughly 7000 nm

RIU

-1

, a resolution of the order of 10

-6

RIU in water

environment (refractometer), and a LOD of 8 g L

-1

(5.3 x 10

-11

M) in serum matrix (biosensor).

ACKNOWLEDGEMENTS

This research study was supported by the Joint

Research Proposal (No.22/EU/Italy/CNR/proj./2012)

under CNR, Italy−CSIR, India Bilateral S&T

Programme, entitled “Development of Long Period

Grating (LPG) based immunoassay for bio-sensing

applications”. F. Chiavaioli wishes to thank the

Italian Minister of University and Research (MIUR)

under the grant N. RBFR122KL1. S.Tombelli wishes

to thank the European Community for the project

Hemospec (FP7-611682).

REFERENCES

Baldini, F., Brenci, M., Chiavaioli, F., Giannetti, A., Trono,

C., 2012. Anal. Bioanal. Chem., 402, 109–116.

Biswas, P., Basumallick, N., Dasgupta, K.,

Bandyopadhyay, S., 2014. J. Lightwave Technol., 32,

2072−2078.

Chiavaioli, F., Biswas, P., Trono, C., Bandyopadhyay, S.,

Giannetti, A., Tombelli, S., Basumallick, N., Dasgupta,

K., Baldini, F., 2014. Biosens. Bioelectron., 60, 305–

310.

Chiavaioli, F., Biswas, P., Trono, C., Jana, S.,

Bandyopadhyay, S., Basumallick, N., Giannetti, A.,

Tombelli, S., Bera, S., Mallick, A., and Baldini F. 2015,

Anal Chem, DOI: 10.1021/acs.analchem.5b01841.

Cusano, A.; Iadicicco, A.; Pilla, P.; Contessa, L.;

Campopiano, S.; Cutolo, A.; Giordano, M., 2006. Opt.

Express, 14, 19–34.

OSENS 2016 - Special Session on Optical Sensors

356

Davies, E.; Viitala, R.; Salomäki, M.; Areva, S.; Zhang, L.;

Bennion, I. J., 2009. Opt. A: Pure Appl. Opt., 11,

015501.

Del Villar, I., Matías, I. R., Arregui, F. J., Lalanne, P., 2005.

Opt. Express, 13, 56–69.

Erdogan, T. J., 1997. Opt. Soc. Am. A, 14, 1760–1773.

Fan, X., White, I. M., Shopova, S. I., Zhu, H., Suter, J. D.,

Sun, Y., 2008. Anal. Chim. Acta, 620, 8–26.

Hill, K. O., Meltz, G. J., 1997. J. Lightwave Technol., 15,

1263–1276.

Homola, J., 2008. Chem. Rev., 108, 462–493.

Kindt, J. T., Bailey, R. C., 2013. Curr. Opin. Chem. Biol.,

17, 818–826.

MacCraith, B. D., 1993. Sens. Actuators B, 11, 29–34.

Patrick, H. J., Kersey, A. D., Bucholtz, F., 1998. J.

Lightwave Technol., 16, 1606–1612.

Pilla, P., Trono, C., Baldini, F., Chiavaioli, F., Giordano,

M., Cusano, A., 2012. Opt. Lett. 2012, 37, 4152–4154.

Queirós, R. B., Silvia, S. O., Noronha, J. P., Frazão, O.,

Jorge, P., Aguilar, G., Marques, P. V. S., Sales, M. G.

F., 2011. Biosens. Bioelectron., 26, 3932–3937.

Smietana, M., Koba, M., Brzozowska, E., Krogulski, K.,

Nakonieczny, J., Wachnicki, L., Mikulic, P.,

Godlewski, M., Bock, W. J., 2015. Opt. Express, 23,

8441–8453.

Trono, C., Baldini, F., Brenci, M., Chiavaioli, F., Mugnaini,

M., 2011. Meas. Sci. Technol., 22, 075204.

Willets, K. A., Van Duyne, R. P., 2007. Annu. Rev. Phys.

Chem., 58, 267–297.

Manufacturing and Optimization of Sol-gel-based TiO2-SiO2 thin Films as High Refractive Index Overlays for Long Period Grating-based

Biosensing

357