Preventive Replacement Policies with Aging Failure

and Third-part Damage

Xufeng Zhao, Khalifa N. Al-Khalifa and Abdel Magid Hamouda

Department of Mechanical and Industrial Engineering, Qatar University, Doha, 2713, Qatar

Keywords:

Preventive Replacement, Maintenance Modeling, Random Failure, Third-part Damage, Aging Cycle.

Abstract:

In general, corrosions, degrading the mechanical strength of pipelines gradually with its age in a stochastic

way, is the predominant cause of pipeline leaks. In addition, the third-part damage is the leading cause of

pipeline ruptures, which occurs randomly in a statistical sense. Naturally, corrective replacement (CR) is done

immediately when the pipeline is subjected to a random failure. To reduce the failure probabilities, preventive

replacement (PR) policies are scheduled to meet the failure due to aging and the third-part damage. We model

three PR policies, using the renewal theory in reliability, and obtain their optimal solutions analytically to

minimize respective replacement cost rates. Finally, numerical examples are given to compare these policies.

1 INTRODUCTION

The pipeline systems have been increasingly con-

structed to meet the rapid development of the oil and

gas industry. Reliability assessment (Amirat, 2006),

failure probability estimation (Xie, et al., 2008), and

inspection of damage suffered for shock and corro-

sion (Sahraoui, et al., 2013) have been applied com-

monly for preventive replacement actions in pipelines

to prevent incidents.

In general, corrosions, degrading the mechani-

cal strength of pipelines gradually with its age in a

stochastic way, is the predominant cause of pipeline

leaks. In addition, the third-part damage is the lead-

ing cause of pipeline ruptures, which occurs randomly

in a statistical sense (Pluvinage and Elwany, 2008).

Naturally, corrective replacement (CR) (Barlow

and Proschan, 1965) should be done immediately

when any operating item is subjected to a random fail-

ure resulting the loss of productivity. For the pipeline

segment, the failure means leaks or ruptures referred

above. To reduce the failure probabilities, preventive

replacement (PR) policies are conducted in a common

way such that replacement actions are done preven-

tively at some thresholds or planned measurements

such as operating time, usage number, damage level,

repair cost, number of faults or repairs, etc. (Osaki,

2002).

When cracks or corrosions are located for the

pipeline segment, condition-based maintenances or

repairs with minimum reliability requirement are

usually conducted to save replacement cost, e.g.,

structural pipeline repairs using carbon composites

(Goertzen and Kessler, 2007), a carbon composite

overwrap pipeline repair system (Duell, 2008), and

carbon-fiber reinforced composites for pipeline repair

(Alexandera and Ochoa, 2010). However, we pro-

pose that the pipeline segment would still go into

a new degradation level after any repair that is ran-

domly taken place even though it is conducted per-

fectly. That is, the pipeline segment has aging cycles

degrading after repairs, and preventive replacement

should be done when it undergoes several cycles of

aging for the final renewal.

In this paper, we propose for a pipeline segment

that PR are scheduled (i) at a planned time T (0 <

T ≤ ∞) of operation, which is a classical policy called

age replacement, (ii) at the Nth (N = 1,2,···) cy-

cle of aging, where intervals for aging cycles are

random variables Y

n

(n = 1,2,···), (iii) at a number

K (K = 1,2,··· ) of damages, in order to monitor the

fatal third-part damages.

Policies (i) and (ii) are taken to meet the failure

due to aging from both determinate and indeterminate

viewpoints, meanwhile, policy (iii) is planned to mon-

itor the failure caused by the third-part damage. That

is, the pipeline should be replaced preventively before

failure at T , N, or K, whichever takes place first. We

model the above PR policies, using the renewal the-

ory in reliability (Osaki, 1992), and obtain their op-

timal solutions analytically to minimize the expected

replacement cost rates. Finally, numerical examples

Zhao, X., Al-Khalifa, K. and Hamouda, A.

Preventive Replacement Policies with Aging Failure and Third-part Damage.

DOI: 10.5220/0005737003730379

In Proceedings of 5th the International Conference on Operations Research and Enterprise Systems (ICORES 2016), pages 373-379

ISBN: 978-989-758-171-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

373

are given to compare these policies.

In mathematics, we give the following notations

to describe the above two failure modes: An item,

which is used to denote any product functioning for

missions, e.g., pipeline segment mentioned above,

fails at a time X due to aging, where X is a ran-

dom variable and has a cumulative distribution func-

tion F(t) ≡ Pr{X ≤ t} with density function f (t).

Let r(t) ≡ f (t)/F(t) denote the instant failure rate of

F(t), where Φ(t) ≡ 1 − Φ(t) for any function Φ(t).

The failure rate r (t) increases strictly with t to r(∞) ≡

lim

t→∞

r(t).

The third-part damage occurs at a non-

homogeneous Poisson process with mean-value

function H(t) ≡

R

t

0

h(u)du, where we denote

p

j

(t) ≡ [H(t)

j

/ j!]e

−H(t)

( j = 0,1,2,···) be the

probability that an exact number j of damages occur

in [0,t]. The item either fails with probability p or

continues to function with probability q = 1 − p at

each damage. Then, the damage causing the item to

be failure occurs in [0,t] with probability

F

p

(t) =

∞

∑

j=1

pq

j−1

∞

∑

i= j

[H(t)]

i

i!

e

−H(t)

= 1 − e

−pH(t)

.

In other words, the item fails at age X or at damage

p, whichever takes place first. Then, the probability

that the unit fails at age X is

Z

∞

0

F

p

(t)dF(t), (1)

and the probability that it fails at damage p is

Z

∞

0

F(t)dF

p

(t), (2)

where note that (1)+ (2)=1. Thus, the mean time to

item failure is

MTTF =

Z

∞

0

tF

p

(t)dF(t) +

Z

∞

0

tF(t)dF

p

(t)

=

Z

∞

0

F(t)F

p

(t)dt. (3)

2 REPLACEMENT MODELS

Naturally, corrective replacement (CR) is done imme-

diately when the item is subjected to a random failure

resulting the loss of productivity. To reduce the failure

probabilities for aging X and damage p, the following

preventive replacement (PR) policies are scheduled:

(a) Replacement done at a planned time T (0 < T ≤

∞) of operation, which is a classical policy called

age replacement (Barlow and Proschan, 1965)

and has been commonly conducted in real appli-

cations;

(b) Replacement done at the Nth (N = 1,2,···) cy-

cle of aging, where intervals for aging cycles are

random variables Y

n

having an identical distri-

bution G(t) ≡ Pr{Y

n

≤ t} with density function

g(t). Noting that when N = 1, the policy de-

grades to a random replacement that was newly

proposed for the uncertain need of replacement

performance. Denote G

(n)

(t) (n = 0, 1, 2, · ··)

be the n-fold Stieltjes convolution of G(t), and

G

(n)

(t)−G

(n+1)

(t) means the item has entered the

(n + 1)th aging cycle.

(c) Replacement done at a number K (K = 1,2,···)

of damages in order to monitor the fatal third-part

damages.

Policies (a) and (b) are taken to meet the failure due

to aging X from both determinate and indeterminate

viewpoints, meanwhile, policy (c) is planned to mon-

itor the failure caused by the third-part damage. That

is, the item should be replaced preventively before X

or p at T , N, or K, whichever takes place first. In

addition, the item is supposed to be replaced at fail-

ure p when the Kth damage makes the item fail with

probability p.

Let c

p

denote the cost for preventive replacement

policies at T , N and K, and c

f

(c

f

> c

p

) denote the

cost for corrective replacement at failures X and p.

Using the theory of renewal process (Osaki, 1992),

the expected replacement cost rate can be given by

the expected cost per replacement cycle divided by

the expected duration of its cycle.

Then, the probability that the item is replaced at

time T is

F(T )[1 − G

(N)

(T )]

K−1

∑

j=0

q

j

p

j

(T ), (4)

the probability that it is replaced at aging cycle N is

K−1

∑

j=0

q

j

Z

T

0

F(t)p

j

(t)dG

(N)

(t), (5)

the probability that it is replaced at damage number

K is

q

K

Z

T

0

F(t)[1 − G

(N)

(t)]p

K−1

(t)h(t)dt, (6)

the probability that it is replaced at failure for age X

is

K−1

∑

j=0

q

j

Z

T

0

[1 − G

(N)

(t)]p

j

(t)dF(t), (7)

and the probability that it is replaced at failure for

damage p is

K−1

∑

j=0

pq

j

Z

T

0

F(t)[1 − G

(N)

(t)]p

j

(t)h(t)dt, (8)

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

374

where note that (4)+(5)+(6)+(7)+(8)=1. Thus, the

mean time to replacement is

T F(T )[1 − G

(N)

(T )]

K−1

∑

j=0

q

j

p

j

(T )

+

K−1

∑

j=0

q

j

Z

T

0

tF(t)p

j

(t)dG

(N)

(t)

+ q

K

Z

T

0

tF(t)[1 − G

(N)

(t)]p

K−1

(t)h(t)dt

+

K−1

∑

j=0

q

j

Z

T

0

t[1 − G

(N)

(t)]p

j

(t)dF(t)

+

K−1

∑

j=0

pq

j

Z

T

0

tF(t)[1 − G

(N)

(t)]p

j

(t)h(t)dt

=

K−1

∑

j=0

q

j

Z

T

0

F(t)[1 − G

(N)

(t)]p

j

(t)dt. (9)

Therefore, the expected cost rate is

C(T, N,K) =

c

p

+ (c

f

− c

p

){

∑

K−1

j=0

q

j

R

T

0

[1 − G

(N)

(t)]p

j

(t)dF(t)

+

∑

K−1

j=0

pq

j

R

T

0

F(t)[1 − G

(N)

(t)]p

j

(t)h(t)dt}

∑

K−1

j=0

q

j

R

T

0

F(t)[1 − G

(N)

(t)]p

j

(t)dt

.

(10)

In particular, when the item is replaced only at fail-

ure, i.e., when T → ∞, N → ∞ and K → ∞,

C

1

≡ lim

T,N,K→∞

C(T, N,K) =

c

f

R

∞

0

F(t)F

p

(t)dt

, (11)

and when T → 0 for any N and K,

C

2

≡ lim

T →0

C(T, N,K) = ∞. (12)

3 OPTIMAL T

∗

, N

∗

AND K

∗

We have to avoid the high failure cost without any PR

in (11). Meanwhile, it is unreasonable to make fre-

quent replacements to waste PR cost, such as an ex-

treme case in (12). In order to minimize the respective

cost rates of the above three replacement policies, we

next obtain analytically optimum time T

∗

, aging cycle

N

∗

, and damage number K

∗

, respectively.

3.1 Optimal T

∗

Suppose that the item should be replaced preventively

before failure X or p at time T (0 < T ≤ ∞). Then,

putting that N → ∞ and K → ∞ in (10), the expected

cost rate is

C(T ) =

c

f

− (c

f

− c

p

)F(T )F

p

(T )

R

T

0

F(t)F

p

(t)dt

. (13)

Differentiating C(T ) with respect to T and setting

it equal to zero,

[r(T ) + ph(T )]

Z

T

0

F(t)F

p

(t)dt − [1 − F(T )F

p

(T )]

=

c

p

c

f

− c

p

. (14)

Let L(T ) denote the left-hand side of (14),

dL(T )

dT

=

dr(T )

dT

+ p

dh(T )

dT

Z

T

0

F(t)F

p

(t)dt.

Thus, if r(T ) + ph(T ) increases strictly with T , then

L(T ) increases strictly with T from 0 to

lim

T →∞

L(T ) =

Z

∞

0

F(t)F

p

(t)[r(∞) + ph(∞) − r(t) − ph(t)]dt.

Therefore, when lim

T →∞

L(T ) > c

p

/(c

f

− c

p

),

there exists a finite and unique T

∗

(0 < T

∗

< ∞) which

satisfies (14), and the resulting cost rate is

C(T

∗

) = (c

f

− c

p

)[r(T

∗

) + ph(T

∗

)], (15)

and when lim

T →∞

L(T ) ≤ c

p

/(c

f

− c

p

), T

∗

= ∞, and

the resulting cost rate is given in (11).

When F(t) = 1 − e

−αt

β

(β > 1), p

j

(t) ≡

[(ωt)

j

/ j!]e

−ωt

, and G

(N)

(t) =

∑

∞

j=N

[(t

δ

)

j

/ j!]e

−t

δ

,

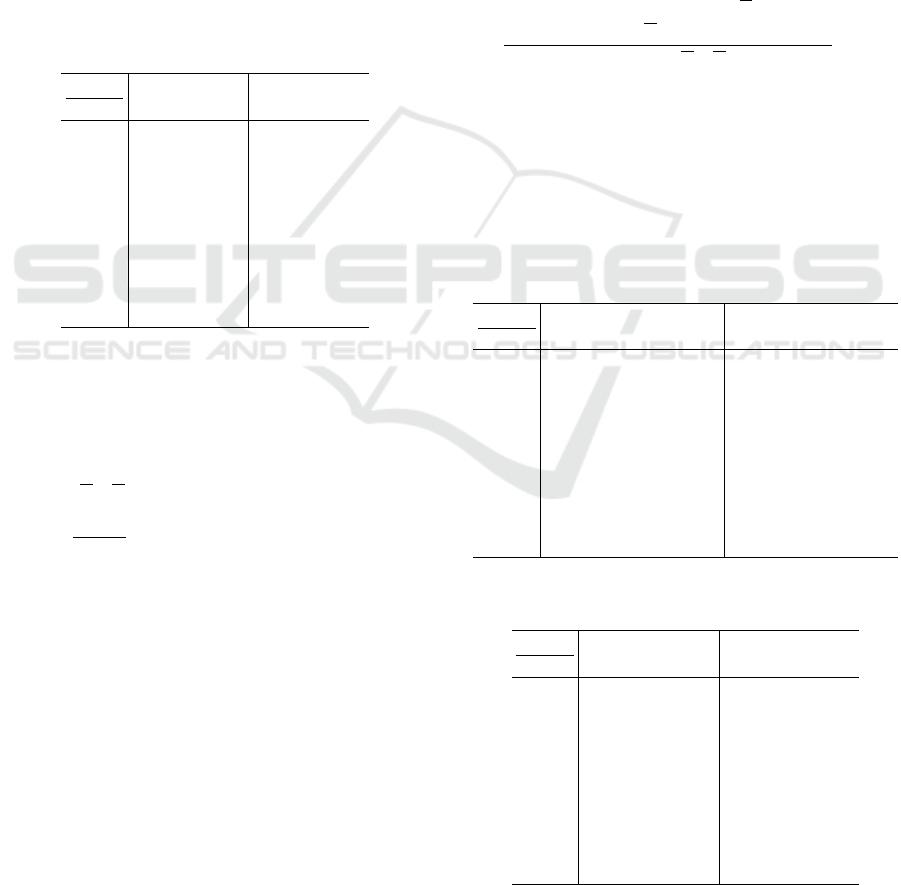

Table 1 presents optimal T

∗

and its cost rates

C(T

∗

)/c

p

when α = 2.0, β = 1.2, ω = 1.0 and δ =

0.5.

Table 1: Optimal T

∗

and its cost rates for p and c

p

/(c

f

−

c

p

).

c

p

p = 0.01 p = 0.1

c

f

− c

p

T

∗

C(T

∗

)/c

p

T

∗

C(T

∗

)/c

p

0.01 0.166 37.491 0.167 46.516

0.03 0.424 15.000 0.428 18.025

0.05 0.663 9.821 0.672 11.647

0.07 0.896 7.442 0.913 8.755

0.10 1.245 5.558 1.279 6.487

0.30 4.007 2.332 4.374 2.672

0.50 8.430 1.620 9.910 1.853

0.70 15.883 1.312 19.886 1.500

1.00 36.091 1.080 48.465 1.235

Preventive Replacement Policies with Aging Failure and Third-part Damage

375

3.2 Optimal N

∗

Suppose that the item should be replaced preventively

before failure X or p at aging cycle N (N = 1, 2, ···).

Then, putting that T → ∞ and K → ∞ in (10), the ex-

pected cost rate is

C(N) =

c

p

+ (c

f

− c

p

)

∑

N−1

j=0

{

R

∞

0

[G

( j)

(t) − G

( j+1)

(t)]

×

F

p

(t)dF(t) +

R

∞

0

[G

( j)

(t) − G

( j+1)

(t)]F(t)dF

p

(t)}

∑

N−1

j=0

R

∞

0

[G

( j)

(t) − G

( j+1)

(t)]F(t)F

p

(t)dt

.

(16)

Forming the inequality C(N + 1) −C(N) ≥ 0,

[Q

1

(N) + pQ

2

(N)]

N−1

∑

j=0

Z

∞

0

[G

( j)

(t) − G

( j+1)

(t)]F(t)F

p

(t)dt

−

N−1

∑

j=0

Z

∞

0

[G

( j)

(t) − G

( j+1)

(t)]F

p

(t)dF(t)

+

Z

∞

0

[G

( j)

(t) − G

( j+1)

(t)]F(t)dF

p

(t)

≥

c

p

c

f

− c

p

, (17)

where

Q

1

(N) ≡

R

∞

0

[G

(N)

(t) − G

(N+1)

(t)]

F

p

(t)dF(t)

R

∞

0

[G

(N)

(t) − G

(N+1)

(t)]F(t)F

p

(t)dt

,

Q

2

(N) ≡

R

∞

0

[G

(N)

(t) − G

(N+1)

(t)]F(t)F

p

(t)h(t)dt

R

∞

0

[G

(N)

(t) − G

(N+1)

(t)]F(t)F

p

(t)dt

.

Let L(N) denote the left-hand side of (17),

L(N + 1) − L(N) =

[Q

1

(N + 1) + pQ

2

(N + 1) − Q

1

(N) − pQ

2

(N)]

×

N

∑

j=0

Z

∞

0

[G

( j)

(t) − G

( j+1)

(t)]F(t)F

p

(t)dt.

Thus, if Q

1

(N) + pQ

2

(N) increases strictly with N,

then L(N) increases strictly with N to

lim

N→∞

L(N) =

Z

∞

0

F(t)F

p

(t)[Q

1

(∞) + pQ

2

(∞) − r(t) − ph(t)]dt.

Therefore, when lim

N→∞

L(N) > c

p

/(c

f

− c

p

),

there exists a finite and unique minimum N

∗

(1 ≤

N

∗

< ∞) which satisfies (17), and the resulting cost

rate is

(c

f

− c

p

)[Q

1

(N

∗

− 1) + pQ

2

(N

∗

− 1)] < C(N

∗

)

≤ (c

f

− c

p

)[Q

1

(N

∗

) + pQ

2

(N

∗

)]. (18)

In particular, when L(1) ≥ c

p

/(c

f

− c

p

), N

∗

= 1.

When F(t) = 1 − e

−αt

β

(β > 1), p

j

(t) ≡

[(ωt)

j

/ j!]e

−ωt

, and G

(N)

(t) =

∑

∞

j=N

[(t

δ

)

j

/ j!]e

−t

δ

,

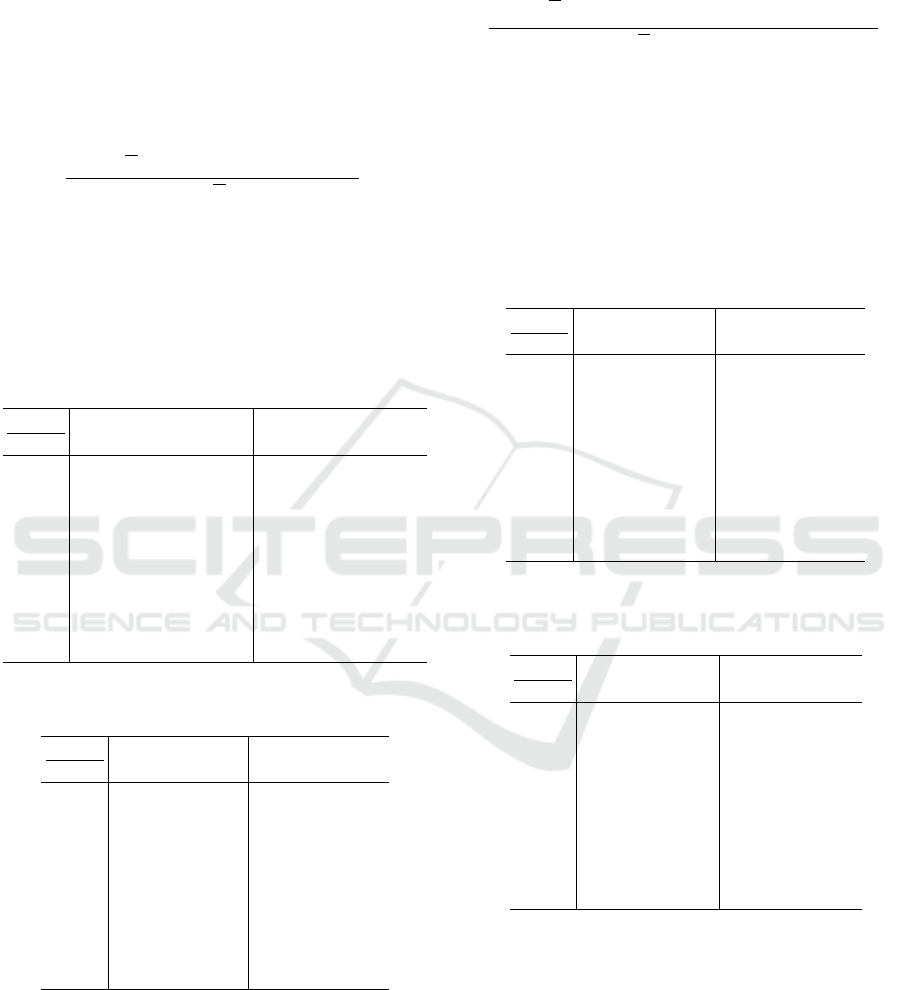

Table 2 presents optimal N

∗

and its cost rates

C(N

∗

)/c

p

when α = 2.0, β = 1.2, ω = 1.0 and δ =

0.5.

Table 2: Optimal N

∗

and its cost rates for p and c

p

/(c

f

−

c

p

).

c

p

p = 0.01 p = 0.1

c

f

− c

p

N

∗

C(N

∗

)/c

p

N

∗

C(N

∗

)/c

p

0.01 1 47.309 1 55.374

0.03 1 16.725 1 19.495

0.05 1 10.609 1 12.320

0.07 2 7.912 2 9.123

0.10 2 5.772 2 6.646

0.30 7 2.314 8 2.646

0.50 15 1.605 20 1.835

0.70 31 1.300 43 1.487

1.00 80 1.072 120 1.226

3.3 Optimal K

∗

Suppose that the item should be replaced preventively

before failure X or p at damage number K (K =

1,2,···). Then, putting that T → ∞ and N → ∞ in

(10), the expected cost rate is

C(K) =

c

f

− (c

f

− c

p

)q

K

R

∞

0

F(t)p

K−1

(t)h(t)dt

∑

K−1

j=0

q

j

R

∞

0

F(t)p

j

(t)dt

. (19)

Forming the inequality C(K + 1) −C(K) ≥ 0,

[Q

3

(K) + pQ

4

(K)]

K−1

∑

j=0

q

j

Z

∞

0

F(t)p

j

(t)dt

−

K−1

∑

j=0

q

j

Z

∞

0

p

j

(t)dF(t) + p

Z

∞

0

F(t)p

j

(t)h(t)dt

≥

c

p

c

f

− c

p

, (20)

where

Q

3

(K) ≡

R

∞

0

p

K

(t)dF(t)

R

∞

0

F(t)p

K

(t)dt

,

Q

4

(K) ≡

R

∞

0

F(t)p

K

(t)h(t)dt

R

∞

0

F(t)p

K

(t)dt

.

Let L(K) denote the left-hand side of (20),

L(K + 1) − L(K) =

Q

3

(K + 1) + pQ

4

(K + 1) − Q

3

(K) − pQ

4

(K)

×

K

∑

j=0

q

j

Z

∞

0

F(t)p

j

(t)dt.

Thus, if Q

3

(K) + pQ

4

(K) increases strictly with K,

then L(K) increases strictly with K to

lim

K→∞

L(K) =

Z

∞

0

F(t)F

p

(t)[Q

3

(∞) + pQ

4

(∞) − r(t) − ph(t)]dt.

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

376

Therefore, when lim

K→∞

L(K) > c

p

/(c

f

− c

p

),

there exists a finite and unique minimum K

∗

(1 ≤

K

∗

< ∞) which satisfies (20), and the resulting cost

rate is

(c

f

− c

p

)[Q

3

(K

∗

− 1) + pQ

4

(K

∗

− 1)] < C(K

∗

)

≤ (c

f

− c

p

)[Q

3

(K

∗

) + pQ

4

(K

∗

)]. (21)

In particular, when L(1) ≥ c

p

/(c

f

− c

p

), K

∗

= 1.

When F(t) = 1 − e

−αt

β

(β > 1), p

j

(t) ≡

[(ωt)

j

/ j!]e

−ωt

, and G

(N)

(t) =

∑

∞

j=N

[(t

δ

)

j

/ j!]e

−t

δ

,

Table 3 presents optimal K

∗

and its cost rates

C(K

∗

)/c

p

when α = 2.0, β = 1.2, ω = 1.0 and δ =

0.5.

Table 3: Optimal K

∗

and its cost rates for p and c

p

/(c

f

−

c

p

).

c

p

p = 0.01 p = 0.1

c

f

− c

p

K

∗

C(K

∗

)/c

p

K

∗

C(K

∗

)/c

p

0.01 1 44.545 1 53.545

0.03 1 15.808 1 18.808

0.05 1 10.060 1 11.860

0.07 1 7.597 1 8.883

0.10 2 5.602 2 6.511

0.30 6 2.311 7 2.645

0.50

14 1.605 17 1.835

0.70 29 1.300 37 1.487

1.00 72 1.072 99 1.226

Note that Q

1

(N) and Q

3

(K) respectively increases

with N and K to r(∞), and Q

3

(N) and Q

4

(K) respec-

tively increases with N and K to h(∞). Thus, it is easy

to conclude for the above three replacement policies

that if

Z

∞

0

F(t)F

p

(t)[r(∞) + ph(∞) − r(t) − ph(t)]dt

>

c

p

c

f

− c

p

,

then all of finite and unique T

∗

, N

∗

and K

∗

can be

found.

4 OPTIMAL (T

∗

,N

∗

), (T

∗

,K

∗

) AND

(N

∗

,K

∗

)

In order to make the functioning item more reliable

in real situations, maintenances with double PR sce-

narios, such as replacement policies scheduled for the

parts of an aircraft at a total hours of operation and

at a specified number of flights since the last major

overhaul, are commonly conducted. In this section,

we obtain numerically (T

∗

,N) for given N, (T,N

∗

)

for given T , (T

∗

,K) for given K, (T, K

∗

) for given T ,

(N

∗

,K) for given K and (N, K

∗

) for given N to mini-

mize their respective expected cost rates.

4.1 Optimal (T

∗

,N

∗

)

Suppose that the item should be replaced preventively

before failure X or p at time T (0 < T ≤ ∞) or at

aging cycle N (N = 1, 2, ···), whichever takes place

first. Then, putting that K → ∞ in (10), the expected

cost rate is

C(T, N) =

c

p

+ (c

f

− c

p

){

R

T

0

[1 − G

(N)

(t)]F

p

(t)dF(t)

+

R

T

0

[1 − G

(N)

(t)]F(t)dF

p

(t)}

R

T

0

[1 − G

(N)

(t)]F(t)F

p

(t)dt

. (22)

When F(t) = 1 − e

−αt

β

(β > 1), p

j

(t) ≡

[(ωt)

j

/ j!]e

−ωt

, and G

(N)

(t) =

∑

∞

j=N

[(t

δ

)

j

/ j!]e

−t

δ

,

Table 4 and Table 5 present optimal T

∗

for N, N

∗

for

T , and their cost rates C(T

∗

,N)/c

p

and C(T,N

∗

)/c

p

when α = 2.0, β = 1.2, ω = 1.0, δ = 0.5 and p = 0.1.

Table 4: Optimal T

∗

and its cost rate for N and c

p

/(c

f

−c

p

).

c

p

N = 1 N = 5

c

f

− c

p

T

∗

C(T

∗

,N)/c

p

T

∗

C(T

∗

,N)/c

p

0.01 0.198 47.789 0.167 46.511

0.03 0.572 18.906 0.428 18.024

0.05 0.986 12.416 0.672 11.647

0.07 1.457 9.474 0.912 8.755

0.10 2.311 7.176 1.279 6.487

0.30 18.222 3.445 4.391 2.674

0.50 73.222 2.665 10.009 1.856

0.70 191.840 2.278 20.158 1.503

1.00 ∞ 1.734 49.079 1.238

Table 5: Optimal N

∗

and its cost rate for T and c

p

/(c

f

−c

p

).

c

p

T = 1.0 T = 15.0

c

f

− c

p

N

∗

C(T,N

∗

)/c

p

N

∗

C(T,N

∗

)/c

p

0.01 1 52.846 1 57.711

0.03 3 18.736 1 20.287

0.05 6 11.756 2 12.659

0.07 23 8.759 2 9.290

0.10 ∞ 6.511 3 6.743

0.30 ∞ 3.014 9 2.674

0.50 ∞ 2.315 22 1.851

0.70 ∞ 2.015 ∞ 1.499

1.00 ∞ 1.790 ∞ 1.234

Preventive Replacement Policies with Aging Failure and Third-part Damage

377

4.2 Optimal (T

∗

,K

∗

)

Suppose that the item should be replaced preventively

before failure X or p at time T (0 < T ≤ ∞) or at dam-

age number K (K = 1, 2, · ··), whichever takes place

first. Then, putting that N → ∞ in (10), the expected

cost rate is

C(T, K) =

c

p

+ (c

f

− c

p

)

∑

K−1

j=0

q

j

R

T

0

p

j

(t)dF(t)

+p

R

T

0

F(t)p

j

(t)h(t)dt

∑

K−1

j=0

q

j

R

T

0

F(t)p

j

(t)dt

. (23)

When F(t) = 1 − e

−αt

β

(β > 1), p

j

(t) ≡

[(ωt)

j

/ j!]e

−ωt

, and G

(N)

(t) =

∑

∞

j=N

[(t

δ

)

j

/ j!]e

−t

δ

,

Table 6 and Table 7 present optimal T

∗

for K, K

∗

for

T , and their cost rates C(T

∗

,K)/c

p

and C(T,K

∗

)/c

p

when α = 2.0, β = 1.2, ω = 1.0, δ = 0.5 and p = 0.1.

Table 6: Optimal T

∗

and its cost rate for K and c

p

/(c

f

−c

p

).

c

p

K = 1 K = 5

c

f

− c

p

T

∗

C(T

∗

,K)/c

p

T

∗

C(T

∗

,K)/c

p

0.01 0.173 46.768 0.167 46.512

0.03 0.469 18.299 0.428 18.024

0.05 0.781 11.943 0.671 11.647

0.07 1.128 9.073 0.912 8.754

0.10 1.748 6.840 1.278 6.486

0.30 13.067 3.244 4.422 2.677

0.50 52.892 2.510 10.339 1.867

0.70 149.037 2.173 21.277 1.518

1.00 ∞ 1.902 52.995 1.256

Table 7: Optimal K

∗

and its cost rate for T and c

p

/(c

f

−c

p

).

c

p

T = 1.0 T = 15.0

c

f

− c

p

K

∗

C(T,K

∗

)/c

p

K

∗

C(T,K

∗

)/c

p

0.01 1 52.470 1 55.486

0.03 2 18.695 1 19.457

0.05 3 11.755 1 12.251

0.07 12 8.511 2 9.084

0.10 ∞ 6.511 2 6.631

0.30 ∞ 3.014 7 2.673

0.50 ∞ 2.315 18 1.851

0.70 ∞ 2.015 ∞ 1.499

1.00 ∞ 1.790 ∞ 1.234

4.3 Optimal (N

∗

,K

∗

)

Suppose that the item should be replaced preventively

before failure X or p at aging cycle N (N = 1, 2, · · ·)

and at damage number K (K = 1,2,···), whichever

takes place first. Then, putting that T → ∞ in (10),

the expected cost rate is

C(N,K) =

c

p

+ (c

f

− c

p

)

∑

K−1

j=0

q

j

n

R

∞

0

[1 − G

(N)

(t)]p

j

(t)dF(t)

+p

R

∞

0

F(t)[1 − G

(N)

(t)]p

j

(t)h(t)dt

o

∑

K−1

j=0

q

j

R

∞

0

F(t)[1 − G

(N)

(t)]p

j

(t)dt

.

(24)

When F(t) = 1 − e

−αt

β

(β > 1), p

j

(t) ≡

[(ωt)

j

/ j!]e

−ωt

, and G

(N)

(t) =

∑

∞

j=N

[(t

δ

)

j

/ j!]e

−t

δ

,

Table 8 and Table 9 present optimal K

∗

for N, N

∗

for

K, and their cost rates C(N,K

∗

)/c

p

and C(N

∗

,K)/c

p

when α = 2.0, β = 1.2, ω = 1.0, δ = 0.5 and p = 0.1.

Table 8: Optimal K

∗

and its cost rate for N and c

p

/(c

f

−

c

p

).

c

p

N = 1 N = 5

c

f

− c

p

K

∗

C(N,K

∗

)/c

p

K

∗

C(N,K

∗

)/c

p

0.01 1 49.245 1 53.503

0.03 1 18.224 1 18.797

0.05 2 12.015 1 11.855

0.07 2 9.133 1 8.881

0.10 4 6.918 2 6.508

0.30 32 3.350 7 2.647

0.50 ∞ 2.632 18 1.839

0.70 ∞ 2.325 38 1.492

1.00 ∞ 2.094 104 1.232

Table 9: Optimal N

∗

and its cost rate for K and c

p

/(c

f

−

c

p

).

c

p

K = 1 K = 5

c

f

− c

p

K

∗

C(N

∗

,K)/c

p

K

∗

C(N

∗

,K)/c

p

0.01 1 49.245 1 54.974

0.03 1 18.224 1 19.382

0.05 2 11.788 1 12.263

0.07 3 8.873 1 9.213

0.10 ∞ 6.650 1 6.925

0.30 ∞ 3.176 ∞ 2.648

0.50 ∞ 2.481 ∞ 1.849

0.70 ∞ 2.184 ∞ 1.506

1.00 ∞ 1.960 ∞ 1.250

5 CONCLUSIONS

We have considered two failures of aging and the

third-part damage in pipeline segments, where aging

failure time is a random variable with cumulative dis-

tribution F(t), and the third-part damage occurs at a

non-homogeneous Poisson process and cause pipeline

failure with probability p. The proposed three preven-

tive replacement models, i.e., policies done at time T

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

378

and at the Nth aging cycle are planned to meet fail-

ures due to aging, and the policy done at number K

of third-part damage is planned to monitor the fatal

damage with p, have been formulated using the re-

newal theory in reliability. The three PR policies have

been optimized to minimize their respective replace-

ment cost rates, and their optimal joint PR polices

with two variables have also been obtained. Numeri-

cal examples have been given to shown the analytical

optimum solutions.

ACKNOWLEDGEMENTS

This paper was made possible by PDRA Grant #

PDRA1-0116-14107 from the Qatar National Re-

search Fund (a member of The Qatar Foundation).

The findings achieved herein are solely the respon-

sibility of the authors.

REFERENCES

Amirat, A., Mohamed-Chateauneuf, A., Chaoui, K., 2006.

Reliability assessment of underground pipelines under

the combined effect of active corrosion and residual

stress. International Journal of Pressure Vessels and

Piping, 83, 107-117.

Alexander, C., Ochoa, O., 2010. Extending onshore

pipeline repair to offshore steel risers with carbon-

fiber reinforced composites. Composite Structures,

92, 499-507.

Barlow, R. E., Proschan, F., 1965. Mathematical Theory of

Reliability, Wiley, New York.

Duell, J. M., Wilson, J. M., Kessler, M. R. 2008. Analysis of

a carbon composite overwrap pipeline repair system.

International Journal of Pressure Vessels and Piping,

85, 782-788.

Goertzen, W. K., Kessler, M. R., 2007. Dynamic mechani-

cal analysis of carbon/epoxy composites for structural

pipeline repair. Composites Part B: Engineering, 38,

1-9.

Pluvinage, G., Elwany, M. H., 2008. Safety, Reliability and

Risks Associated with Water, Oil and Gas Pipelines,

Springer, Netherlands.

Osaki, S., 1992. Applied Stochastic System Modeling,

Springer-Verlag, Berlin.

Sahraoui, Y., Khelif, R., Chateauneuf, A., 2013. Mainte-

nance planning under imperfect inspections of cor-

roded pipelines. International Journal of Pressure

Vessels and Piping, 104, 76-82.

Xie, L., Wang, Z., Hao, G., Zhang, M., 2008. Failure prob-

ability estimation of long pipeline. In: Pham, H. (Ed),

Recent Advances in Reliability and Quality in Design,

Springer, 239-251.

Preventive Replacement Policies with Aging Failure and Third-part Damage

379