Search-based Decision Ordering to Facilitate Product Line

Engineering of Cyber-Physical System

Tao Yue

1,2

, Shaukat Ali

1

, Hong Lu

1

and Kunming Nie

3

1

Simula Research Laboratory, Oslo, Norway

2

Department of Informatics, University of Oslo, Oslo, Norway

3

Launch Technology Research Academy of China Aerospace Science and Industry Corporation, Beijing, China

Keywords: Product Line Engineering, Cyber Physical System, Decision Ordering, Search Algorithms.

Abstract: Industrial Cyber Physical Systems (CPSs) are naturally complex. Manual configuration of CPS product

lines is error-prone and inefficient, which warrants the need for automated support of product configuration

activities such as decision inference and decision ordering. A fully automated solution is often impossible

for CPSs since some decisions must be made manually by configuration engineers and thus requiring an

interactive and step-by-step configuration solution. Having an interactive solution with tool support in mind,

we propose a search-based solution (named as Zen-DO) to support optimal ordering of configuration steps.

The optimization objective has three parts: 1) minimizing overall manual configuration steps, 2) configuring

most constraining decisions first, and 3) satisfying ordering dependencies among variabilities. We

formulated our optimization objective as a fitness function and investigated it along with four search

algorithms: Alternating Variable Method (AVM), (1+1) Evolutionary Algorithm (EA), Genetic Algorithm,

and Random Search (a comparison baseline). Their performance is evaluated in terms of finding an optimal

solution for two real-world case studies of varying complexity and results show that AVM and (1+1) EA

significantly outperformed the others.

1 INTRODUCTION

Cyber-Physical Systems (CPSs) are large-scale

systems of systems communicating with each other

based on digital cyber technologies, integrating

software and physical components, and interacting

with environment and human actors. CPSs are often

seen in various domains including aerospace, energy

and maritime, and healthcare. Product Line

Engineering (PLE) is gaining increasing attention of

researchers and practitioners because of its

capability to deal with the increasing complexity and

variation in software/system product lines (Frakes

and Kang, 2005). Adopting PLE has shown to be

effective for improving the quality of products and

the productivity of developing the products. It has

been reported in (Ali et al., 2012) that PLE can

effectively speed up time-to-market in many

organizations such as Boeing, Lucent, and Nokia.

Due to the inherent complexity of CPSs,

hundreds and thousands of reusable components

(e.g., electronic components, software components

or network component) are typically and integrated

and configured. Therefore automated support based

on concise abstractions of reusable artifacts becomes

crucial to the configuration process, where

abstraction plays a central role for software reuse

while automation can facilitate effective selection

and customization of reusable components. Such an

automated configuration solution heavily relies on a

large number of constraints, which can be formally

specified using e.g., the Object Constraint Language

(OCL) (OMG) to facilitate, for instance, automated

decision inference based on dependencies of

Variation Points (VPs) (i.e., configurable

parameters) and the optimization of configuration

steps. Our previous work (Nie et al., 2013b)

classifies different types of constraints that should be

explicitly captured and specified on product line or

product models to enable automation in the context

of CPS PLE.

We have proposed an interactive configuration

framework, named as Zen-Configurator (Kunming

Nie, 2013, Hong et al., 2014, Hong et al., 2015, Nie

et al., 2013), with the aim to implement at least three

functionalities: Decision Inference, Decision

Yue, T., Ali, S., Lu, H. and Nie, K.

Search-based Decision Ordering to Facilitate Product Line Engineering of Cyber-Physical System.

DOI: 10.5220/0005717006910703

In Proceedings of the 4th International Conference on Model-Driven Engineering and Software Development (MODELSWARD 2016), pages 691-703

ISBN: 978-989-758-168-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

691

Ordering and Conformance Checking. A user

interface has been developed; the decision inference

and conformance checking functionalities have been

implemented (Hong et al., 2014). The decision

ordering functionality of Zen-Configurator should

take the product line architecture model (including

constraints) as input, order configuration decisions

(VPs) in an optimized way such that overall manual

configuration steps are minimized, which is the

focus of this paper.

In the literature, different methods have been

proposed to address this problem such as applying

SAT Solvers for ordering decisions (Nohrer and

Egyed, 2011), relying on Constraint Satisfactory

Problems (CPS) solvers to derive valid feature

selection sequences (White et al., 2009), and

prioritizing features based on their selectivity (Chen

and Erwig, 2011). All these works handle relatively

simple dependencies among variabilities, i.e.,

decision or feature selection. However, based on our

previous experience of stusdying three industrial

CPS product line families (Nie et al., 2013b),

configuring CPSs require handling complex

constraints, thus indicating the insufficiency of these

work. Some configuration tools (e.g., Pure::Variants

(Beuche, 2008), Dopler (Dhungana et al., 2011),

Covamof (Sinnema et al., 2004), SPLOT (Mendonca

et al., 2009), FMP (Czarnecki et al., 2005), and

Questionnaire (La Rosa et al., 2009)) implemented

the decision ordering functionality in various ways:

based on user predefined configuration sequences,

deriving configuration sequences from dependencies

of variabilities, and simply applying depth first

strategy to traverse feature models. None of these

tools implemented the objective of minimizing

manual configuration steps—the main objective of

this work. As reported in (El-Sharkawy and Schmid,

2012), the Dopler tool suite (Dhungana et al., 2011)

is the only tool that implements the heuristic of

configuring most constraining decisions first to

reduce overall configuration effort, which aligns

with part of our objective.

In this paper, we propose a search-based solution

(named as Zen-DO) to support optimal ordering of

configuration decisions of CPS product lines. We

propose and assess a fitness function for minimizing

manual steps required to configure a product, while

fulfilling configuration ordering dependencies of

VPs to the maximum extent and starting from most

constraining configuration decisions first. We

evaluate the fitness function together with four

search algorithms: Alternating Variable Method

(AVM), Genetic Algorithms (GA), (1+1)

Evolutionary Algorithm (EA) and Random Search

(RS). RS was used as the baseline to evaluate the

performance of the other three algorithms. Two real-

world case studies and 130 artificial problems have

been used to evaluate the selected search algorithms

and the fitness function. Results show that AVM and

(1+1) EA significantly outperformed the other two

algorithms for both of the real-world case studies

and most of the artificial problems.

The rest of the paper is organized as follows. In

Section 2, we provide an overview of Zen-

Configurator and Zen-DO, and relevant background

information. Section 3 presents the formalization of

the optimization problem and the fitness function.

The empirical study and the controlled experiment

are discussed in detail in Section 5 and Section 6,

respectively. We present the overall discussion in

Section 6. We addresses the threats to validity of the

empirical study in Section 7. Section 8 discusses the

related work. We conclude the paper in Section 9.

2 OVERVIEW

In this section, we first introduce Zen-Configurator

and then the overview of Zen-DO.

2.1 Zen-Configurator

As previously discussed, in the context of CPS PLE,

there are a large number of VPs that have to be

configured correctly by conforming to a large

number of constraints. Product configuration is

therefore an error-prone and time-consuming

activity when it is totally manual. Hence, it is

important to have an interactive and semi-automated

configuration solution for CPS PLE.

PLE is composed of two distinct phases: Domain

Engineering and Application Engineering. In

domain engineering, PLA modelling and constraint

specification approaches are used by a Domain

Expert to capture commonalities and variabilities in

the system architecture and design and constraints

relevant to the configuration of a valid product. In

different contexts, different modelling and

specification approaches can be used. As part of the

Zen-Configurator solution, we rely on SimPL

(Behjati et al., 2013), which is a modeling

methodology with a UML profile for specifying

commonalities and variabilities of a product line of

integrated control systems at the architecture and

design level. SimPL was developed to deal with four

types of variabilities: Cardinality, Attribute,

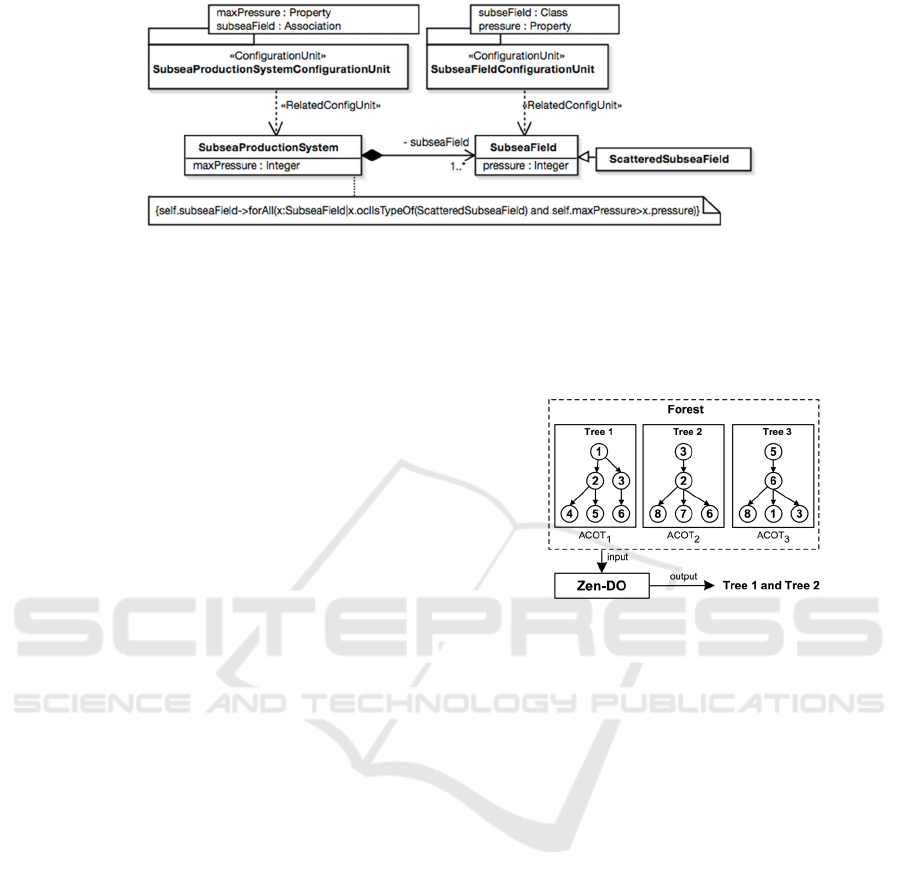

Topology and Type. As shown in Figure 1, a subsea

production system that may have more than one

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

692

Figure 1: An Example of SimPL Model (Excerpted From (Behjati et al., 2013)).

subsea fields with various types, such as scattered

subsea fields. Two template packages are

stereotyped with <<ConfigurationUnit>> and

associated to classes SubseaProductionSystem and

SubseaField to specify the VPs of each of these two

classes. As an example, we specify one OCL

constraint for this model, that is, all the subsea fields

are scattered subsea fields and the pressure of all

subsea fields is less than the max pressure of a

subsea production system.

In the application-engineering phase, Zen-

Configurator has three key functionalities (Decision

Inference, Decision Ordering and Conformance

Checking), to assist configuration engineers to

configure a product. PLA models and constraints of

the product line are considered as product line assets

stored in a repository, which are used as the input to

facilitate the automation of configuring products.

Configured products are therefore stored in the

Product Artifacts Repository. We have previously

implemented an automated and incremental

conformance checking approach, named Zen-CC, to

ensure that the manual configuration of each VP

conforms to a set of pre-defined conformance rules

specified in OCL (Hong et al., 2014).

Zen-Configurator relies on a set of algorithms

that implement a set of heuristics (e.g., determining

optimal decision orders), which are identified as key

elements to optimize the effectiveness and efficiency

of the configuration solution. These algorithms need

to access the PLA models and constraints at runtime

and therefore, it is crucial to have a lightweight

internal representation capturing sufficient

information for supporting efficient configuration. In

Zen-Configurator, we use Trees (e.g., with nodes

representing VPs and edges denoting VP

dependencies) for this purpose. Automated

transformation from the PLA models and constraints

(SimPL and OCL respectively) to Trees is needed in

Zen-Configurator. Zen-Configurator also needs to

employ search algorithms for optimal decision

ordering, which require encoding of the problem, a

fitness function to assess a solution, and parameter

settings specific to each search algorithm. The focus

of the paper is to propose such a search-based

decision ordering solution.

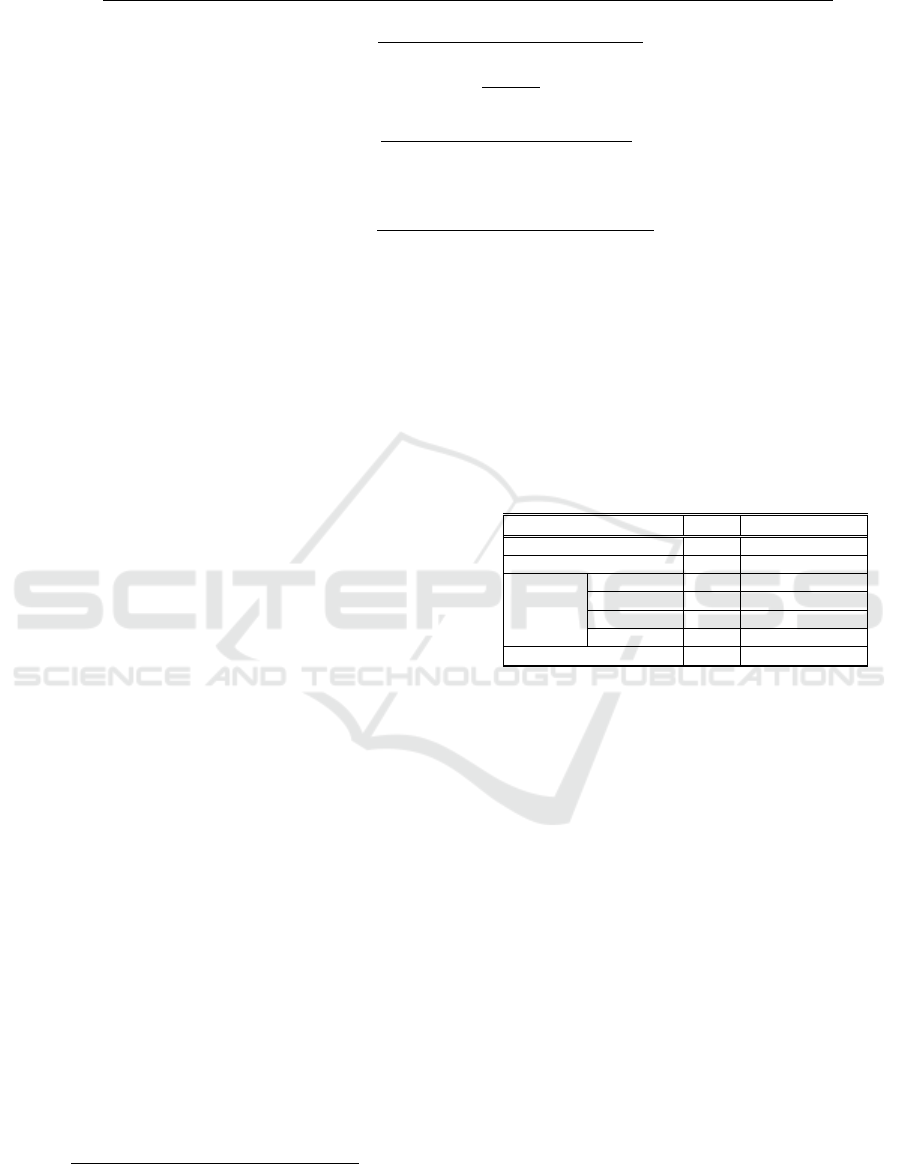

Figure 2: Illustrative Example of Zen-DO.

2.2 Zen-DO

In a typical PLE practice, a product line specification

captures commonalties and variabilities of a product

line. For example, feature models (Czarnecki et al.,

2005) are commonly used for this purpose. VP is a

configurable element of a product line specification

and it defines the place of the variability. A variant is

one of the possible choices to be bound for a VP.

VPs can be specified in different ways, including

value range, constraints, or enumeration literals,

depending on applications. When resolving a VP, a

variant is bound to the respective VP. A Constraint,

in our context, is an element of system specification

constraining one or more other elements to support

automated product configuration.

Zen-Configurator is an interactive configuration

tool that interacts with users, in our context

Configuration Engineers, to configure a product line

family and derive a set of family members: products.

Configuration engineers in this configuration

environment are considered as part of the

optimization as they receive feedback (on which

decisions to make first) from the tool and

configuration engineers’ manual decisions trigger

the configuration tool to dynamically find other

Search-based Decision Ordering to Facilitate Product Line Engineering of Cyber-Physical System

693

optimized configuration orders based on the

remaining VPs to be configured in the whole

configuration space (all VPs should be configured

and all constraints should be satisfied to various

extents). This kind of configuration design is called

“User-in-the-loop” (Sayyad et al., 2013).

VPs and constraints are taken as input by the tool.

Note that as we investigated in our previous work

(Nie et al., 2013b), decision ordering in such a user-

in-the-loop interactive configuration environment

relies on two types of constraints: variability

dependencies and ordering constraints. These

constraints can be either user defined, derived from

system specifications, or enforced by a particular

system development process. These constraints,

together with the product line architecture model,

contribute to the formation of the internal

representation: Forest consisting of a set of Trees,

which are necessary to formulate our optimization

problem, thereby proposing the fitness function.

Suppose we have obtained such a set of

constraints, applying each constraint will form an

ordering tree with nodes representing VPs to be

configured and edges describing which VP should

be configured before or after which other VP(s). By

applying all the identified constraints, a forest is

formed, containing a set of trees (each of which

corresponds to a constraint constraining the

configuration sequence of a set of VPs) and having

each yet-to-be configured VP covered in the forest.

In the forest, all the yet-to-be configured VPs must

be configured to obtain a product.

We then apply search algorithms to derive a set

of trees based on three heuristics: 1) covering yet-to-

be configured VPs as many as possible, 2)

minimizing the number of Abstract Configuration

Ordering Trees (ACOTs) to be contained in a

solution, and 3) minimizing the manual steps

required to configure a product. For example, as

shown in

Figure 2, Tree 1 and Tree 2 were selected

as the optimal solution given the forest, because

these two trees cover all the VPs (1-8) and form a

solution with the minimum number of trees (i.e., 2).

An optimal solution (Tree 1 and Tree 2) will be

provided to configuration engineers and they will

select any of the root nodes of these trees

(representing VP1 and VP3) to configure them

manually. The consequence of this manual

configuration is that the remaining VPs to configure

will be updated. Therefore, the forest will be

updated and the optimization process will start to

find another solution for the new updated forest.

It is important to notice that our optimization

solution is independent of any product line

specification or modeling methodology as the

optimization starts from the forest, which captures

all the required information for the optimization.

This gives us the freedom to make this work

applicable to different contexts such as combing

with feature models or architecture and design based

variability modeling methodologies. However, as an

integrated part of Zen-Configurator, a

transformation from SimPL to the internal

representation (Trees) has been implemented.

3 PROBLEM REPRESENTATION

AND FITNESS FUNCTION

3.1 Definitions

A forest F is a set of Configuration Ordering Trees

and is defined as F= {COT

1

, COT

2

, …, COT

ncot

},

where ncot is the total number of configuration

ordering trees.

VP = {vp

1

, vp

2

, …, vp

nvp

} is a set of VPs, where

nvp is the total number of VPs to be configured.

Each vp

i

in VP has an attribute Configured of type

Boolean.

Configuration Ordering Tree (COT) is a tree of

in the F forest defined above. COT = {{Node},

{Edge}}. Note that it is also possible that a COT only

constrains one node. Each node represents a VP

from VP. Each edge represents an ordering

dependency of two VPs. Edge = {e

1

, e

2

, .., e

ne

},

where each edge e

i

connects a pair of vp

k

and vp

j

from Node. Each edge e

i

has a set of attributes:

Manual and Infer of type Boolean, respectively

indicating whether a configuration step is manual or

can be automatically inferred. Such information can

only be obtained using heuristic rules, as it is

impossible to know in advance which step is manual

and which step can be automatically inferred based

on pre-defined constraints, as the whole process is

dynamic and interactive. For example, one simple

heuristic rule could be that VPs that are configurable

parameters with primitive types but are not involved

in any pre-defined constraint are most probably

required to be manually configured. Another

example is that for VPs with primitive types have

high chance to be automatically inferred when they

are involved in constraints with other VPs that are

already configured. Note that implementing these

heuristics to predict this property of a configuration

step is out of the scope of this paper and will be

automated in the future.

Each edge of a COT is also characterized with

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

694

another attribute Weight with three categories: High,

Medium and Low, each of which respectively

indicates the extent of dependency of two VPs.

There are several ways to obtain this information.

One commonly used way is to ask user’s preference

on the configuration order, which might not be

classified as Medium and Low. Some dependencies

should be classified High as configuring one VP

depends on the decision made for another VP. Such

information can be automatically obtained by

querying variability models or constraints on VPs.

Abstract Configuration Ordering Graph (ACOG)

consists of a set of nodes and edges: ACOG =

{{AbstractCOT}, {AbstractEdge}}. AbstractCOT =

{acot

1

, acot

2

, …, acot

nan

}, where each acot

i

is a COT.

AbstractEdge = {ae

1

, ae

2

, .., ae

nae

}, each ae

i

connects

a pair of acot

j

and acot

k

. Note that edges in

AbstractEdge do not have attributes.

3.2 Optimization Problem

For configuration, there is a subset of AbstractCOT:

,

,…

, based on which a set of

potential solutions

,

,…

can

be derived, where ns is the total number of solutions

and can be calculated as 2

1. For each s

i

,

there is nacot

i

belonging to S

NACOT

= {nacot

1

,

nacot

2

, …, nacot

ns

}, where 1=<nacot

i

<=n

acot

. In

addition, for each s

i

, there is vpcot

i

belonging to

S

NACOT

= {vpcot

1

, vpcot

2

, …, vpcot

ns

}, where

1=<vpcot

i

<=total number of remaining VPs. This

constraint is implemented as part of our algorithms

and we also implemented the four heuristics below.

Covering VPs that appear in the forest as many

as possible. Our aim is to find s

i

such that the

maximum number of VPs that appear in the

forest should be included in the abstract nodes of

s

i

. This is to ensure that most of the VPs in the

forest should be taken into account when making

a configuration ordering plan (a solution to

search). We define the following formula for this

aim: ∀:

,

,

. This heuristic tries to find a solution s

i

with

the maximum number of VPs.

Starting from most constraining configuration

decisions. To achieve this, a search algorithm

must guide the search towards large abstract

nodes having the largest number of VPs

connected to them. Recall that when constructing

the forest, a constraint is applied to form a tree in

the forest. Therefore, large trees (i.e., large

abstract nodes) reflect complex constraints

restricting large numbers of VPs. Hence, we

define this formula for this heuristic, which later

on is translated into a part of the fitness function:

∀:

,

, ,

meaning to find a solution s

i

with the minimum

number of abstract nodes in AbstractCOT.

Searching for a solution with the minimum

number of manual configuration steps. To

achieve this, we defined formula:

∑

1,

.∀

1,

∑

1,

.

.

Guiding the search towards the direction of

satisfying dependencies of VPs to the maximum

extent. Recall that the edges in the trees of the

forest are weighted with three categories: High

(0), Medium (1), Low (2), indicating to which

extent configuration ordering dependencies of

VPs should be satisfied while deriving a solution.

We use the following formula to formulate the

heuristic:

0,

.′′

1,

.′′

2,

.′′

∀1

1

,

0,

.′′

1,

.′′

2,

.′′

1

3.3 Fitness Function

Based on the definitions and the formulated

optimization problem, we derive the fitness function

that is used along with the six selected search

algorithms to find optimal solutions for our

optimization problem.

The fitness function (formula (1)) is composed of

four parts, which are defined in formulas (2)-(5),

respectively. These four formulas correspond to the

heuristics described in the previous section. We

applied the division method in the fitness function to

normalize values produced by formulas (2)-(5) so

that each heuristic has equal importance. n

acot

is the

total number of nodes in AbstractCOT.

∑

represents the total number of edges in AbstractCOT.

Our objective is to minimize f(s

i

), i.e., searching a

value of f(s

i

) closer to 0 (fittest solution).

4 EMPIRICAL STUDY

We conducted experiments to evaluate the fitness

function with the four search algorithms for

addressing our optimization problem: minimizing

the manual steps required to configure a product,

while covering the VPs, fulfilling the configuration

ordering dependencies to the maximum extent and

Search-based Decision Ordering to Facilitate Product Line Engineering of Cyber-Physical System

695

4

(1)

1

(2)

(3)

∑

1,

.

∑

(4)

∑

0,

.

1,

.

2,

.

∑

(5)

starting from most constraining configuration

decisions. Details are reported in Section 5.

In Section 4.1, we present the research questions

of the empirical study. In Section 4.2, we discuss

two case studies used in the empirical evaluation.

4.1 Research Questions

In the empirical study, we aim to investigate the

following five research questions (RQs): RQ1: Are

the search algorithms effective to solve our

optimization problem, to compare with RS? RQ2:

Among the studied search algorithms, which one

fares best in solving our optimization problem? RQ3:

How does the configuration of VPs impact the

performance of the search algorithms? RQ4. How

does the number of VPs and the number of trees

impact the performance of the search algorithms?

4.2 Case Studies

Crisis Management System (CMS): We

significantly extended the scope of Crisis

Management System (CMS) based on the

requirements defined by Capozucca et al.

(Capozucca et al., 2012), modeled the architecture of

CMS containing CMS police, rescue, traffic control

etc., as well as corresponding VPs using SimPL, and

specified ordering and conformance rules as OCL

constraints. Part of the SimPL model (Table 1) has

been presented in the CMA@MODELS 2013

workshop, evaluated by modeling experts and was

deposited to the ReDoMM repository

1

for public

access.

Subsea Control: Based on several years of

experience of conducting industry-oriented research

in subsea oil and gas and in the context of PLE

1

http://www.cs.colostate.edu/remodd/v1/content/modeling-architecture-

and-design-crisis-management-system-product-line-using-simpl

(Behjati et al., 2013, Briand et al., 2012), we

modeled the main concepts presented in Part 6

(subsea production systems) of the ISO 13628-

6:2006 standard (ISO13628-6, 2006) using SimPL.

The developed SimPL (Table 1) was further

enriched with the well-known subsea engineering

hand-book (Bai and Bai, 2012).

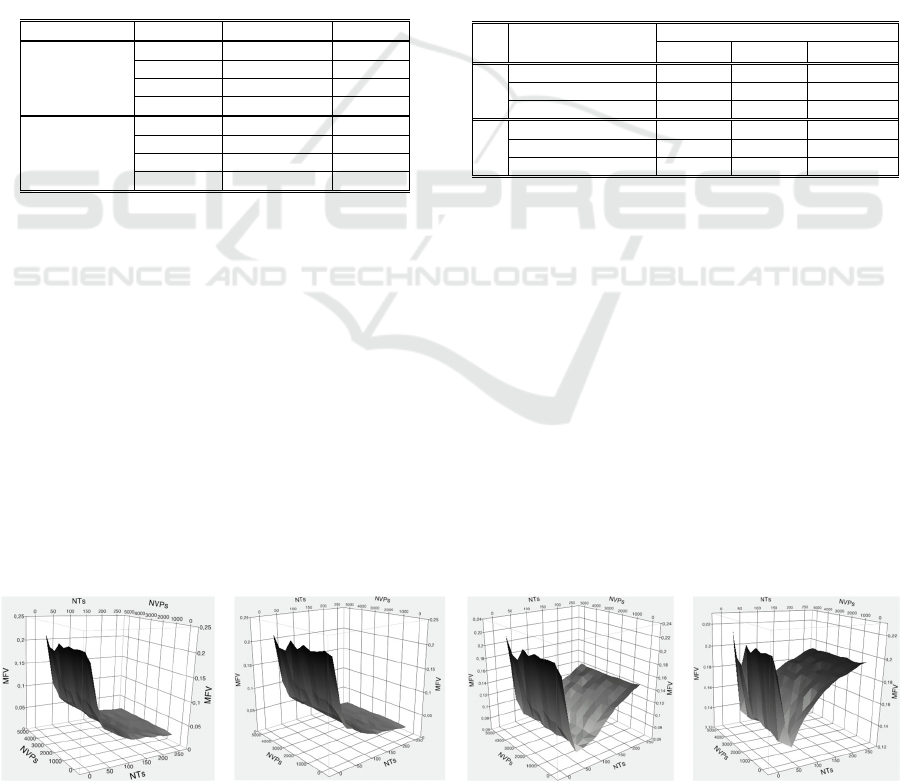

Table 1: Descriptive Statistics of CMS and Subsea

Control.

Model Elements CMS Subsea Control

Packages

30 13

Classes

188 71

VP Types Cardinality

62 13

Attribute

49 91

Topology

9 7

All

120 111

OCL Constraints

31 25

5 EVALUATING SEARCH

ALGORITHMS

This section reports the evaluation for answering

RQ1-RQ4. The experiment design and execution is

presented in Section 5.1 and analyses and results are

discussed in Section 5.2.

5.1 Experiment Design and Execution

In our experiments, we compared three search

algorithms: AVM, GA, (1+1) EA, and used RS as a

comparison baseline to assess the difficulty of the

addressed problems. AVM represents typical local

search algorithms. GA is the most commonly

applied global search algorithm. (1+1) EA has been

proved effective for software engineering problems

(e.g., see (Huihui et al., 2015, Yan et al., 2015)). In

terms of GA, we set the population size to 100 and

the crossover rate to 0.75, and a 1.5 bias for rank

selection. We use a standard one-point crossover,

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

696

and mutation of a variable is done with the standard

probability 1/n, where n is the number of variables.

5.1.1 Design of Search Problems

Real-world Configuration Problems: To answer

RQ1-RQ3, we simulated two configuration

processes of the two case studies (Section 4.2) and

evaluated the performance of the search algorithms

at each manual configuration step. Notice that Zen-

DO is invoked as a result of manual configuration of

a VP in Zen-Configurator, which can lead to the

automated decision inference of other VPs. At each

manual configuration step, a new search problem is

formed and then solved by the search algorithms. As

shown in Table 1, the VPs defined in the PLA

models of CMS and Subsea Control are 120 and 111

respectively. We simulated a large part of a

complete configuration process for each case study

and as a result, we obtained 106 search problems for

CMS and 64 search problems for Subsea Control.

Notice that during the configuration process,

instances of a cardinality VP are populated based on

the configuration value to the cardinality VP. The

populated instances usually contain attribute VPs,

which need to be further configured. In short, the

number of VPs in a product model dynamically

changes while the configuration progresses.

Artificial Problem Design: To empirically

evaluate the scalability of our approach, we created

130 artificial problems. We used a range of 100 to

4600 with an increment of 500 for the number of

VPs, and a range from 10 to 250 with an increment

of 20 for the number of trees. In total we had 10

options for the number of VPs and 13 options for the

number of trees and defined 10*13 = 130 artificial

problems.

5.1.2 Dependent and Independent Variables

We used fitness value (FV) as the main dependent

variable, which is the best fitness value obtained

after a certain number of generations by an

algorithm (2000 in our experiments). In addition, we

used two additional dependent variables: mean

fitness value (MFV

p

) for each problem and mean

fitness value for a specific number of problems

(MFV

ps

). The independent variables include: type of

search algorithm (TSA), number of VPs (NVPs), and

number of trees (NTs).

For each problem, both NVP

S

and NT

S

are fixed.

MFV

p

is calculated for each algorithm using the

formula

∑

. FV is the fitness value of

one run, while l is the number of runs (100 in our

experiments).

For MFV

ps

, there are two situations. With the

fixed NVPs and various NTs, mean fitness values are

calculated for each algorithm using the

formula MFV

,

∑∑

∗

. FV

v

is the fitness

value of one run for a given NVPs. l is the number of

runs while t is NTs. With the fixed NTs and various

NVPs, mean fitness values are calculated for each

algorithm using the formula MFV

,

∑∑

∗

.

FV

t

is the fitness value of one run for a given NTs. l

is the number of runs while v is NVPs.

5.1.3 Statistical Tests

To compare the obtained results of the search

algorithms, we applied the Wilcoxon signed-rank

test and the Vargha and Delaney statistics (Arcuri,

2011). For all pairs, we conducted two samples

Wilcoxon signed-rank test to obtain a p-value which

determines the significance of results (with the

significance level of 0.05). The Vargha and Delaney

statistics (A

) was used to calculate the effect size

measure. If A

is equal to 0.5, the two algorithms A

and B are equivalent. A

is more than 0.5 implies

that A has higher chances of obtaining higher fitness

value than B. To study the correlation between the

performance of the search algorithms and NVPs as

well as NTs, we use the Spearman’s rank correlation

coefficient.

|

|

is used to determine the

significance of results with a significance level

0.0001. If ρ is greater than 0, there is a positive

correlation; otherwise, a negative correlation exists.

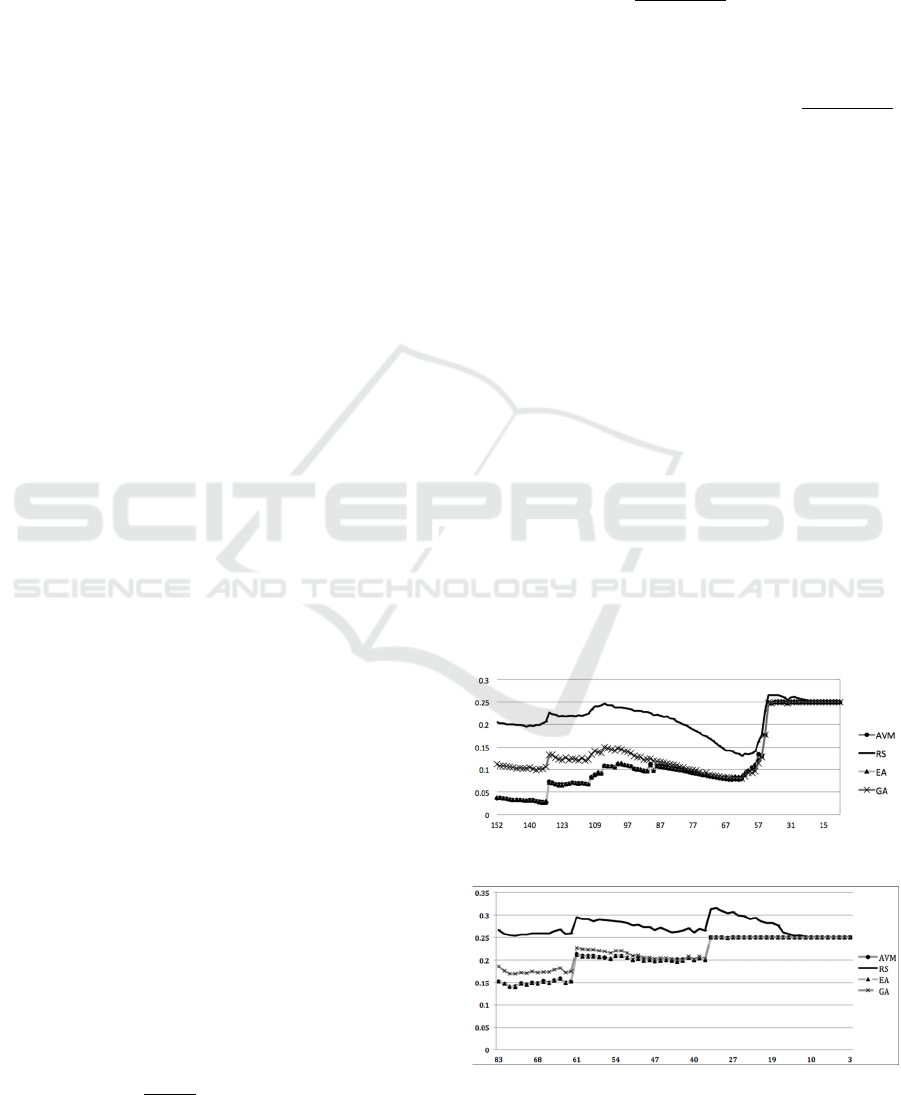

Figure 3: MFVs along with NVPs (CMS).

Figure 4: MFVs along with NVPs (Subsea Control).

Search-based Decision Ordering to Facilitate Product Line Engineering of Cyber-Physical System

697

5.1.4 Experiment Execution

Each configuration problem was repeated 100 times

for each search algorithm to counter random

variation. Each algorithm was run up to 2000

generations and the best FV obtained in the 2000

generations was recorded.

5.2 Analyses and Results

In Section 5.2.1, we report analyses and results for

the two real-world case studies for answering RQ1-

RQ3. In Section 5.2.2, we present analyses and

results for the 130 artificial problems for answering

RQ1-RQ2 and RQ4.

5.2.1 Results for the Real-World Case Study

RQ1 and RQ2: We compare RS with AVM, (1+1)

EA and GA, based on FV for each problem (Table

2). Notice that the CMS case study has in total 106

problems and the Subsea Control case study has in

total 64 problems (Section 5.1.1).

For the CMS case study, all the three search

algorithms performed significantly better than RS

for all the 106 problems (Table 1). A similar pattern

can be observed for the Subsea Control case study,

where AVM, (1+1) EA and GA performed

significantly better than RS for 64, 63 and 63

problems, respectively. We therefore can answer

RQ1 as follows: AVM, (1+1) EA and GA

significantly outperformed RS for most of the

problems suggesting the search algorithms are

effective to solve our optimization problem

compared with RS.

Regarding RQ2, for CMS, (1+1) EA

outperformed AVM for 93 problems, out of which

for 51 problems (1+1) EA performed significantly

better than AVM. There were no significant

differences observed for 48 problems. AVM

performed better than (1+1) EA for 12 problems and

only for 6 of them AVM significantly outperformed

(1+1) EA. AVM significantly outperformed GA for

105 problems and (1+1) EA significantly

outperformed GA for all the 106 problems. For

Subsea Control, (1+1) EA significantly

outperformed AVM for 59 problems and GA for all

the problems. AVM significantly outperformed GA

for 62 problems. We therefore can answer RQ2 as

follows: (1+1) EA is the best search algorithm to

solve our optimization problem followed by AVM

and GA.

RQ3: To answer RQ3, we plot the graphs shown

in Figure 3 and Figure 4, where for a given NVP

during the configuration process, the mean fitness

value is calculated for each algorithm using the

formula MFV

p

defined in Section 5.1.2. It is

important to notice that for CMS and Subsea Control

there are 106 and 64 problems respectively; the x-

axes in Figure 3 and Figure 4 should have 106 and

64 data points respectively. To avoid cluttering the

figures, only some of them are shown on the x-axis

of the figures.

Table 2: Results for the Wilcoxon signed-rank and the

Vargha and Delaney A

statistics*.

RQ Pair of Algorithms

(A vs. B)

CMS

A>B A<B A=B

1

AVM vs. RS 106/106 0/0 0/0

(1+1) EA vs. RS 106/106 0/0 0/0

GA vs. RS 106/106 0/0 0/0

2

AVM vs. (1+1) EA 6/12 51/93 48/1

AVM vs. GA 105/106 0/0 1/0

GA vs. (1+1) EA 0/0 106/106 0/0

RQ Pair of Algorithms

(A vs. B)

Subsea Control

A>B A<B A=B

1

AVM vs. RS 63/64 0/0 1/0

(1+1) EA vs. RS 64/64 0/0 0/0

GA vs. RS 63/63 0/1 1/0

2

AVM vs. (1+1) EA 0/0 59/64 5/0

AVM vs. GA 62/63 1/1 1/0

GA vs. (1+1) EA 0/0 64/64 0/0

* In columns ‘A>B’ and (‘A<B’), the values before the slashes

are the number of problems that A is significantly better (worse)

than B, while the values after the slashes are the number of

problems that A has higher probability to be better (worse) than

B. Column ‘A=B’ tells that the number of problems that there is

no difference between A and B.

For both case studies, as shown in Figure 3 and

Figure 4 along with the configuration of the VPs,

(1+1) EA, AVM and GA are consistently better than

RS, until the value of NVPs reaches less than 30 (for

CMS) and 15 (for Subsea Control). The reason for

this may be explained by the dynamic change of the

forest itself. Along with the configuration of VPs,

the trees in the forest are becoming smaller and there

may be fewer trees in the forest. So in order to cover

as many as possible the remaining VPs, more trees

are selected, which subsequently leads to higher

fitness values. In addition, along with the

configuration, the remaining trees may have a higher

percentage of manual steps and a higher percentage

of low weight, both of which contribute to higher

fitness values. In other words, we think when

reaching the point of having less number of VPs to

configure, there is no much space for optimization.

(1+1) EA and AVM performed in a very similar

pattern for all the problems. GA performed worse

than AVM and (1+1) EA when the value of NVPs is

larger than 70 (for CMS) and 50 (for Subsea

Control). This is mostly because GA uses both

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

698

mutation and crossover operators to explore more

search space as compared to (1+1) EA that uses only

mutation operator and thus GA needs more

generations (greater than 2000) to obtain better

solutions for problems with a large number of VPs.

We also calculated the Spearman’s rank

correlation between MVPs for each search algorithm

with increasing NVPs. Results (Table 3) show that

for all the algorithms except for RS, along with the

increase of NVPs, MVPs decreases. Therefore, the

performance of all the algorithms in terms of finding

optimal solutions increases. Notice that the results

are consistent with what we can observe from Figure

3 and Figure 4 along with the decrease of NVPs,

MPVs increases in general. Therefore, the

explanation described above applies to here as well.

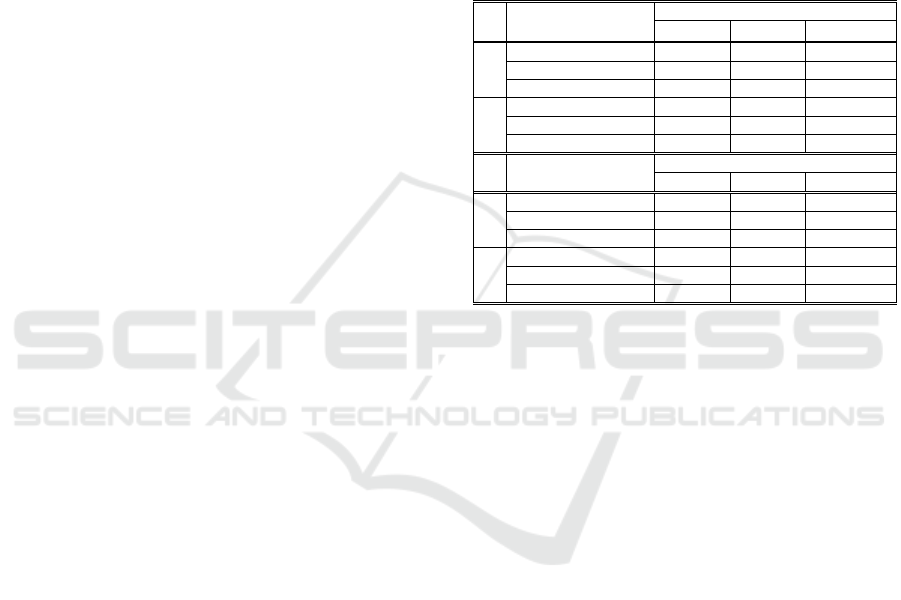

Table 3: Results of the Spearman’s correlation analysis

with the increasing NVPs.

Case Study Algorithm Spearman’s ρ Prob>|ρ|

CMS

AVM -0.8167

<.0001

(1+1) EA -0.8156

<.0001

GA -0.3412

0.0003

RS -0.2943

0.0022

Subsea Control

AVM -0.8756

<.0001

(1+1) EA -0.8713

<.0001

GA -0.7966

<.0001

RS 0.1458 0.2502

5.2.2 Results for the Artificial Problems

RQ1 and RQ2: To answer RQ1 and RQ2, we

compared the selected search algorithms with RS

and then compared each pair of them based on MFV

for each algorithm and each of the 130 artificial

problems. From Table 4, one can see that 1) AVM,

(1+1) EA and GA significantly outperformed RS for

most of the artificial problems (RQ1), 2) (1+1) EA

and AVM significantly outperformed GA for most

of the problems (RQ2) and 3) AVM is significantly

better than (1+1) EA for 62 problems while (1+1)

EA is significantly outperformed AVM for 50

problems (RQ2).

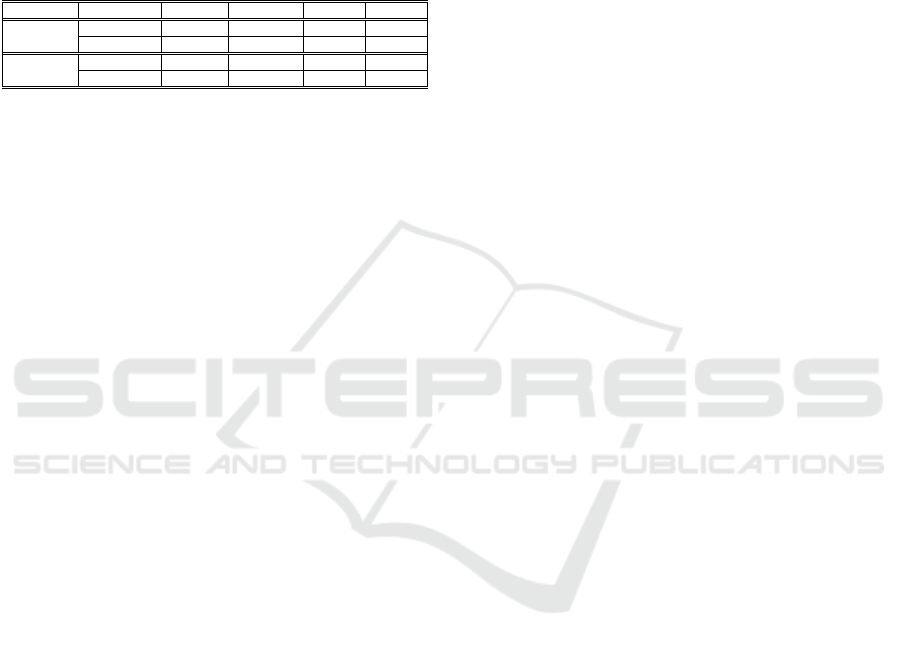

RQ4: Recall that RQ4 aims to study the impact

of the increasing number of VPs and trees on the

performance of the search algorithms. We therefore

plot surface plots as shown in Figure 5 for each

algorithm. In each plot, MFVs decrease when the

color of curves goes from black to white.

From Figure 5, we can observe that (1+1) EA

and AVM performed in a very similar pattern:

achieving very low MFVs when NTs is over 150 and

performing worse when NTs is getting smaller. The

performance of GA is the best when NTs is around

100. Its performance degraded when NTs increases

over 150. This might be because more generations

are required for GA to get better solutions when the

number of trees is large since the problems are

getting more complex. The performance of RS

follows a similar pattern as GA but RS achieved

much worse MFVs when NTs is over 100 than GA.

Table 4: Results for the Wilcoxon signed-rank test and the

Vargha and Delaney A

statistics.

RQ

Pair of Algorithms

(A vs. B)

CMS

A>B A<B A=B

1

AVM vs. RS 122/123 6/7 2/0

(1+1) EA vs. RS 129/130 0/0 1/0

GA vs. RS 130/130 0/0 0/0

2

AVM vs. (1+1) EA 62/70 50/58 18/2

AVM vs. GA 111/112 14/16 5/2

GA vs. (1+1) EA 0/5 120/120 10/5

When NTs decreases below 100, the

performance of all the algorithms degrades

significantly. This might be because along with the

configuration, the remaining trees may have a higher

percentage of manual steps and a higher percentage

of low weight, both of which will make a higher

fitness value. In other words, we think when

reaching this point, there will be no much space for

optimization, as we discussed previously.

To further analyze the correlation between the

performance and NTs and NVPs, we conducted the

Spearman correlation analysis. Results are presented

in Table 5. For AVM and (1+1) EA, NTs has a

significant negative correlation with MFVs,

implying that increasing NTs leads to the

improvement of the performance of these two

(1+1) EA AVM GA RS

Figure 5: Surface Plots of MFVs, NVPs and NTs.

Search-based Decision Ordering to Facilitate Product Line Engineering of Cyber-Physical System

699

algorithms. For GA, a positive (but not significant)

correlation was discovered, while a significant

positive correlation was obtained for RS. When

looking into NVPs, a significant positive correlation

with MFVs for (1+1) EA was obtained, implying

that it increasing NVPs leads to the degradation of

the performance of (1+1) EA.

Table 5: Results of the Spearman’s correlation analysis

with the increasing NVPs and NTs.

Variable Measure AVM (1+1) EA GA RS

NTs ρ

-1 -1 0.4396 0.5659

Prob>|

ρ

|

<0.0001 <0.0001

0.1329

0.0438

NVPs ρ

0.6242 0.7212 0.4545 -0.1152

Prob>|

ρ

| 0.0537

0.0186

0.1869 0.7514

6 OVERALL DISCUSSION

Based on the results of the empirical study, we

suggest using either AVM or (1+1) EA together with

our fitness function to solve the decision-ordering

problem, since these two algorithms exhibit the best

performance as compared to the other algorithms.

Recall that the mechanism of Zen-DO is based

on ordering dependencies of VPs, which can be

identified by querying the product line architecture

and design model and from constraints explicitly

capturing such dependency information. Therefore,

if a product line has a larger number of such

ordering dependencies specified, Zen-DO will

perform more effectively. In other words, it is

important to document/specify ordering

dependencies as product line assets and associate

them (via suitable mechanisms) to VPs specified in

the product line architecture and design model in the

first place, to enable effective, automated decision

ordering. In our Zen-Configurator tool, the SimPL

methodology should be used to model the product

line architecture and design and OCL should be used

to specify constraints, which can naturally integrate

with the SimPL model.

7 THREATS TO VALIDITY

Regarding construct validity, we applied the

effectiveness measure: fitness value, which is

comparable across all the algorithms. In addition, the

number of generations was used in all the search

algorithms as the stopping criterion. Random

variations inherent in the search algorithms are the

the most probable conclusion validity threat. To

tackle it, we ran each experiment repeatedly 100

times to reduce the chance that the results were

obtained by chance.

In our experiments, we used only one

configuration setting for the search algorithms,

which might form a possible threat to internal

validity. It is however worth noting that these

settings conform to common guidelines (Arcuri and

Fraser, 2011) and our experience of applying search

algorithms for addressing other software engineering

optimization problems.

We ran our experiments on the 130 artificial

problems of different complexity to test the

scalability of the algorithms. However, one may say

that the results may not be generalized to other case

studies. Such threat to external validity is common

to all empirical studies. In the future, we plan to

evaluate our approach with more case studies.

8 RELATED WORK

As concluded in (Rabiser et al., 2012, El-Sharkawy

and Schmid, 2012), an automated configuration

solution should support product configuration with

the ultimate objective of improving both the quality

of configured products and the productivity of a

configuration process. Especially for CPSs,

hundreds and thousands of configuration parameters

with complicated constraints among them have to be

correctly configured, as reported in our previous

work (Nie et al., 2013b). Automated solutions for

configuring CPSs is therefore critically required to

support, automated consistency checking, decision

inference, etc., among which decision ordering has

been recognized as one of the most important

functionalities.

8.1 Literature Review

In (Nohrer and Egyed, 2011), an approach was

proposed to optimize user guidance during decision

making with the aim to automatically order

decisions to minimize user input while giving users

freedom to make decisions that are most important

to them. SAT was used to reason about the impact of

an answer given by a user and the ideal order of the

remaining decisions. Note that this method considers

two types of dependencies among questions and

answers. For CPSs, as we reported in (Nie et al.,

2013b) we encountered very complicated constraints

as in some cases, configuring a VP is not just

making a Boolean choice but also providing a value

or selecting a type.

The authors of (White et al., 2009) proposed an

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

700

approach to derive a valid sequence of feature

selections, while accounting for resource constraints

such as budgetary constraints, in the context of

multi-step feature model configuration process,

which was formally formulated and mapped to CSP.

CSP solvers were then applied

to solve the problem.

An approach is proposed in (Chen and Erwig, 2011)

to identify feature selection sequences by

prioritizing features that have high selectivity, such

that the overall efficiency of the feature selection

process can be improved. Each feature is associated

with a value called selectivity, indicating the impact

of selecting a feature on the selection and removal of

other features. Feature models are translated to

algebraic expressions to compute the selectivity.

Guo et. al (Guo et al.) proposed a GA based

approach to automatically optimize feature

selections with resource constraints such as cost,

CPU and memory. Evaluation results show that the

proposed search based approach achieved promising

optimal solutions.

Notice that all the above mentioned related work

address decision ordering issues in the context of

feature models or decision models. Therefore,

constraints considered are relatively simple

dependencies among variabilities. To configure

CPSs, there exist a large number of complicated

constraints on VPs with various types, considering

that a configured product is typically an operational

CPS system. Methods for decision/feature selection

cannot meet the needs of configuring CPSs. Zen-DO

aims to address the similar kind of challenges, but in

the context of CPSs and because of their enormous

complexity, we aimed for a scalable optimization

solution and search algorithms seem to be a proper

candidate for such a solution.

To compare with these related work, an approach

proposed by Sayyad et al. in (Sayyad et al., 2013) is

most closely related to our work. Their objective is

to support feature model based automated

configuration of product lines by accounting for user

preferences. Five optimization objectives were

defined and implemented, including minimizing rule

violations, the number of deselected features, and

the number of features that was not used before,

known defects and cost. With these five objectives,

the author investigated a series of well-known multi-

objective evolutionary optimization algorithms and

concluded, based a set of extensive and well-

designed experiments, that search algorithms in

SBSE should be carefully selected and tailored for

studying complex product line

configuration/decision space.

8.2 Configuration Tool Review

We reviewed 16 product configuration tools, among

which six of them provide decision ordering support:

Pure::Variants (Beuche, 2008), Dopler (Dhungana et

al., 2011), Covamof (Sinnema et al., 2004), SPLOT

(Mendonca et al., 2009), FMP (Czarnecki et al.,

2005) and Questionnaire (La Rosa et al., 2009). We

classify the approaches for these tools into three

categories: User Defined, Dependency Based and

Depth First approaches.

The User Defined approach relies on users to

predefine configuration sequences. Some modeling

methodologies have feature attributes (FMP and

Pure::variants) or specific annotations (Covamof

using Procedural Knowledge (Hotz et al., 2004)) to

facilitate the specification of such additional

information on top of variability models (mostly

feature models). The Dependency Based ordering

approach relies on the dependency or constraints

defined as part of the product line models to derive

valid configuration sequences of VPs. Dopler,

Questionnaire and SPLOT implement this approach.

The Depth First strategy is implemented in FMP to

guide the configuration process by traversing feature

models with a predetermined order (depth-first).

Note that one of them implemented algorithms to

minimize manual configuration steps.

El-Sharkawy and Schmid (El-Sharkawy and

Schmid, 2012) categorized configuration problems

into several categories, among which ensuring

correct configuration is considered as the one that

received the most attention in the past. To ensure

correct configuration, different approaches have

been taken, including validation of (partial)

configurations, optimization based on, e.g.,

minimizing costs of resulting systems, value

propagation to reduce the number of manual

configuration steps, root analysis support for invalid

configurations, and dependency based prioritization

of configuration sequences. Our work follows into

the last category of minimizing the amount of work

that needs to be done by recommending a

configuration ordering to users. Several heuristics

based on analyzing dependencies among variabilities

are summarized in the paper: 1) analyzing the

impact of a decision on possible products that can be

derived based on the current configuration

(Benavides et al., 2005), 2) identifying local feature

selection decisions to make such that reducing the

impact of a decision on other parts of the feature

hierarchy (Czarnecki and Kim), and 3) configuring

most constraining decision first to reduce the amount

of decisions to make manually.

Search-based Decision Ordering to Facilitate Product Line Engineering of Cyber-Physical System

701

According to the study of El-Sharkawy and

Schmid (El-Sharkawy and Schmid, 2012), Dopler

(Rabiser et al., 2007) is the only tool that

implemented the heuristic: “most constraining

decisions” should be configured first with the aim to

minimize the number of decisions that must be made

manually and therefore reducing the overall

configuration effort. Our solution also includes this.

9 CONCLUSIONS

Due to the enormous complexity of Cyber-Physical

Systems (CPSs), manual configuration of products

based on a large number of various types of

constraints in CPSs is a complicated and error prone.

However, not all the steps in the configuration can

be automated and some decisions must be taken by

users. To this end, in this paper, we presented our

search-based approach to identify an optimal set of

decisions with the objectives to reduce overall

manual configuration steps, configure most

constraining decisions first, and satisfy ordering

dependencies among VPs to the maximum extent.

This objective was implemented as a fitness function

used by the search algorithms to find an optimal

solution. We empirically evaluated four search

algorithms with the fitness function on two real-

world case studies and 130 artificial problems.

Results show that Alternating Variable Method

(AVM) and (1+1) Evolutionary Algorithm (EA)

significantly outperformed the others.

REFERENCES

Cyber-Physical Systems (CPSs) [Online]. Available:

http://cyberphysicalsystems.org/.

Ali, S., Yue, T., Briand, L. & Walawege, S. 2012. A

Product Line Modeling and Configuration

Methodology to Support Model-Based Testing: An

Industrial Case Study. In the 15th international

conference on Model Driven Engineering Languages

and Systems, 2012.

Arcuri, A. 2011. It really does matter how you normalize

the branch distance in search-based software testing.

Software Testing, Verification and Reliability.

Arcuri, A. & Fraser, G. 2011. On Parameter Tuning in

Search Based Software Engineering. International

Symposium on Search Based Software Engineering

(SSBSE).

Bai, Y. & Bai, Q. 2012. Subsea engineering handbook,

Gulf Professional Publishing.

Behjati, R., Yue, T., Briand, L. & Selic, B. 2013. SimPL:

A Product-Line Modeling Methodology for Families

of Integrated Control Systems. Information and

Software Technology, 55, 607-629.

Benavides, D., Trinidad, P. & Ruiz-Cortés, A. Automated

reasoning on feature models. Advanced Information

Systems Engineering, 2005. Springer, 491-503.

Beuche, D. 2008. Modeling and building software product

lines with pure:: variants. Software Product Line

Conference, 2008. SPLC'08. 12th International, 2008..

Briand, L., Falessi, D., Nejati, S., Sabetzadeh, M. & Yue,

T. 2012. Research-based innovation: a tale of three

projects in model-driven engineering. Model Driven

Engineering Languages and Systems. Springer.

Capozucca, A., Cheng, B. H., Georg, G., Guelfi, N.,

Istoan, P., Mussbacher, G., Jensen, A., Jézéquel, J.-M.,

Kienzle, J. & Klein, J. 2012. Requirements Definition

Document for a Software Product Line of Car Crash

Management Systems. University of Nice Sophia

Antipolis, I3S CNRS, Technical Report.

Chen, S. & Erwig, M. Optimizing the product derivation

process. Software Product Line Conference (SPLC),

2011 15th International, 2011. IEEE, 35-44.

Czarnecki, K., Antkiewicz, M., Kim, C. H. P., Lau, S. &

Pietroszek, K. fmp and fmp2rsm: eclipse plug-ins for

modeling features using model templates. Companion

to the 20th annual ACM SIGPLAN conference on

Object-oriented programming, systems, languages,

and applications, 2005.

Czarnecki, K. & Kim, C. H. P. Cardinality-based feature

modeling and constraints: A progress report.

Dhungana, D., Grünbacher, P. & Rabiser, R. 2011. The

DOPLER meta-tool for decision-oriented variability

modeling: a multiple case study. Automated Software

Engineering, 18, 77-114.

El-Sharkawy, S. & Schmid, K. Supporting the effective

configuration of software product lines. Proceedings

of the 16th International Software Product Line

Conference-Volume 2, 2012. ACM, 119-126.

Frakes, W. B. & Kang, K. 2005. Software reuse research:

Status and future. Software Engineering, IEEE

Transactions on, 31, 529-536.

Guo, J., White, J., Wang, G., Li, J. & Wang, Y. A genetic

algorithm for optimized feature selection with resource

constraints in software product lines. Journal of

Systems and Software, 84, 2208-2221.

Hong, L., Tao, Y., Ali, S., Kunming, N. & Li, Z. 2014.

Zen-CC: An Automated and Incremental

Conformance Checking Solution to Support

Interactive Product Configuration. Software Reliability

Engineering (ISSRE), 2014 IEEE 25th International

Symposium on.

Hong, L., Tao, Y., Shaukat, A. & Li, Z. 2015. Model-

based Incremental Conformance Checking to Enable

Interactive Product Configuration. accetped in

Information and Software Technology.

Hotz, L., Krebs, T. & Wolter, K. Combining software

product lines and structure-based configuration—

methods and experiences. Proceedings of the

Workshop on Software Variability Management for

Product Derivation, at Software Product Line

Conference (SPLC), 2004.

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

702

Huihui, Z., Tao, Y., Shaukat, A. & Chao, L. 2015.

Facilitating Requirements Inspection with Search-

Based Selection of Diverse Use Case Scenarios. 9th

EAI International Conference on Bio-inspired

Information and Communications Technologies

(formerly BIONETICS).

ISO13628-6 2006. Petroleum and natural gas industries-

Design and operation of subsea production system-

Part 6:Subsea production control systems.

La Rosa, M., Van Der Aalst, W. M., Dumas, M. & Ter

Hofstede, A. H. 2009. Questionnaire-based variability

modeling for system configuration. Software and

Systems Modeling, 8, 251-274.

Mendonca, M., Branco, M. & Cowan, D. SPLOT:

software product lines online tools. Proceedings of the

24th ACM SIGPLAN conference companion on

Object oriented programming systems languages and

applications, 2009. ACM, 761-762.

Nie, K., Yue, T. & Ali, S. Towards a Search-based

Interactive Configuration of Cyber Physical System

Product Lines. Demos/Posters/StudentResearch@

MoDELS, 2013a. 71-75.

Nie, K., Yue, T., Ali, S., Zhang, L. & Fan, Z. Constraints:

The Core of Supporting Automated Product

Configuration of Cyber-Physical Systems. ACM/IEEE

16th International Conferene on Model Driven

Engineering Languages and Systems (MODELS),,

2013b.

Nohrer, A. & Egyed, A. Optimizing user guidance during

decision-making. Software Product Line Conference

(SPLC), 2011 15th International, 2011. IEEE, 25-34.

OMG Accessed: 2015. OCL 2.0 Specification,

http://www.omg.org/spec/OCL/2.2/.

Rabiser, R., Dhungana, D. & Grünbacher, P. Tool support

for product derivation in large-scale product lines: A

wizard-based approach. Workshop on Visualisation in

Software Product Line Engineering (ViSPLE), IEEE

Computer Society, 2007. 119-124.

Rabiser, R., Grünbacher, P. & Lehofer, M. A qualitative

study on user guidance capabilities in product

configuration tools. The 27th IEEE/ACM

International Conference on Automated Software

Engineering, 2012.

Sayyad, A. S., Menzies, T. & Ammar, H. 2013. On the

Value of User Preferences in Search-Based Software

Engineering: A Case Study in Software Product Lines.

Software Engineering (ICSE), 2013 35th International

Conference on.

Sinnema, M., Deelstra, S., Nijhuis, J. & Bosch, J. 2004.

Covamof: A framework for modeling variability in

software product families. Software product lines, 25-

27.

White, J., Dougherty, B., Schmidt, D. C. & Benavides, D.

Automated reasoning for multi-step feature model

configuration problems. The 13th International

Software Product Line Conference, 2009. Carnegie

Mellon University, 11-20.

Yan, L., Tao, Y., Shaukat, A. & Li, Z. 2015. Zen-

ReqOptimizer: A Search-based Approach for

Requirements Assignment Optimization. Accepted in

Empirical Software Engineering (EMSE).

Search-based Decision Ordering to Facilitate Product Line Engineering of Cyber-Physical System

703