Electrochemical Analysis of Accelerated Aging of PEDOT-PTS

Coated Screen-printed Electrodes

Nathalia Peixoto

1

, Tjerignimin Silue

1

, Catalina Vallejo-Giraldo

2

and Manus Biggs

2

1

Electrical and Computer Engineering, George Mason University, Fairfax, VA, U.S.A.

2

Centre for Research in Medical Devices (CURAM), National University of Ireland Galway, Galway, Ireland

Keywords: Implantable Electrodes, Electrode Coating, Stability of Electrode Coatings, Electrochemical Impedance

Spectroscopy, Accelerated Aging, Cyclic Voltammetry, Long-term Electrode Testing.

Abstract: We have developed a deposition method that enhances charge delivery of screen printed electrodes by up to

six times through electrochemical deposition of poly (3,4-ethylenedioxythiophene):p-toluenesulfonate

(PEDOT-PTS). In order to elucidate the effects of PEDOT-PTS deposition on the long-term electrochemical

characterization of screen-printed electrodes we characterized electrode stability with cyclic voltammetry and

impedance spectroscopy at room temperature and at 47 °C. A deposition current of 0.4 mA/cm

2

guarantees

coverage of the working electrode conductive area with no spill of the conductive polymer through the

insulating tracks. Control electrodes show charge storage capacity of 0.25 mC. PEDOT-PTS deposited

electrodes are stable for over 4 months and present cathodic charge storage capacity of 1.25 mC.

1 INTRODUCTION

The electrode interface continues to be the main

puzzle piece in the development of neural coupled

devices and implanted sensors. Current challenges are

focused on addressing the accumulation of

hypertrophic astrocytes, and the development of

electrode-investing glial scar tissue (Vallejo-Giraldo

et al., 2014), which increases impedance and prevents

electrode integration with excitable neural tissues.

The development of next-generation electrode

technologies is informed by the biological and

physico-mechanical considerations of nervous tissues

and neural interfaces (Fernandez-Yague, 2015),

which has led to advances in the fabrication of high-

density microelectrode arrays (Green et al., 2013) and

the development of biochemically modified

(Kikkawa et al., 2014) and mechanically biomimetic

neuroelectrode systems (Ware et al., 2012).

Long-term recording with implanted electrode

systems in non-human primates represents a

significant bottleneck in the development of brain-

computer-coupled devices and of novel medical

solutions to neural disorders. Although long-term

neural recording has been reported in a handful of

studies (Nicolelis et al., 2003) using traditional

electrode approaches (parylene-coated microwires),

the controversy of long-term neural recording

proliferates due to confounding variables such as

handling of the implant, chemical and mechanical

properties of implants, surgical technique, and quality

of materials implanted, among other fabrication

variables.

In order to investigate the mechanisms of

electrode failures, in vitro experiments are performed

with a subset of those variables, under controlled

environmental conditions. Previous research from our

group, for example, showed that parylene as an

insulator would age within 4 months if implanted.

However, when parylene is applied in conjunction

with ALD (atomic layer deposition) alumina, it

demonstrated a four-fold increase in lifetime

(Minnikanti et al., 2014). Furthermore, we compared

these two kinds of insulations while testing them at

relatively high temperatures, or under “accelerated

aging” conditions, which allowed us to reliably

predict the lifetime of this polymer in vivo.

Poly(3,4-ethylenedioxythiophene) (PEDOT) has

gained much attention recently (Green et al., 2013,

Kim et al., 2014, Mandal et al., 2014), given its

biocompatibility, versatility in terms of counter-ion

species and high charge storage capacity (Green et al.,

2013). Our group has previously investigated several

conductive polymers, as well as surface modifications

for biological applications (Fernandez-Yague et al.,

76

Peixoto, N., Silue, T., Vallejo-Giraldo, C. and Biggs, M.

Electrochemical Analysis of Accelerated Aging of PEDOT-PTS Coated Screen-printed Electrodes.

DOI: 10.5220/0005700600760082

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 1: BIODEVICES, pages 76-82

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2014) and in particular for the development of smart

neuroelectrode applications (Mokarian-Tabari et al.,

2015).

We hypothesized that we could apply the same

principles of testing the material lifetime of electrodes

coated with poly(3,4-ethylenedioxythiophene):p-

toluenesulfonate (PEDOT-PTS) and that

electrodeposition of this conducting polymer at the

recording surface would enhance their

electrochemical properties. In a previous report we

have shown that PEDOT was not as stable as iridium

oxide when used for stimulation (Peixoto et al.,

2009). Here we will address a PEDOT formulation

with stable counter-ions and leverage accelerated

aging and electrochemical characterization to

demonstrate stability of the superficial layers.

In this manuscript we report on the lifetime

assessment of such coatings when used for macro

screen-printed electrodes. In order to determine

stability, we electrodeposit PEDOT-PTS on

commercially available low-cost electrodes with a

carbon layer as the active material. Those strips, as

well as control strips, were subjected to cyclic

voltammetry and electrochemical impedance analysis

for up to one month at room temperature, and

thereafter at elevated temperatures (in our case, 47

°C) for up to three months. The charge delivery

capacity of the electrodes is then evaluated, relative

to their initial value, and the robustness of coatings

determined based on that parameter and on the

stability of the modulus and phase angle in impedance

profiles.

2 METHODS

Here we describe the utilized substrates, the methods

of electrodeposition of PEDOT-PTS, and the

electrochemical methods that were utlized in order to

characterize the stability of the coatings and of non-

coated control samples.

2.1 Substrates and Solutions

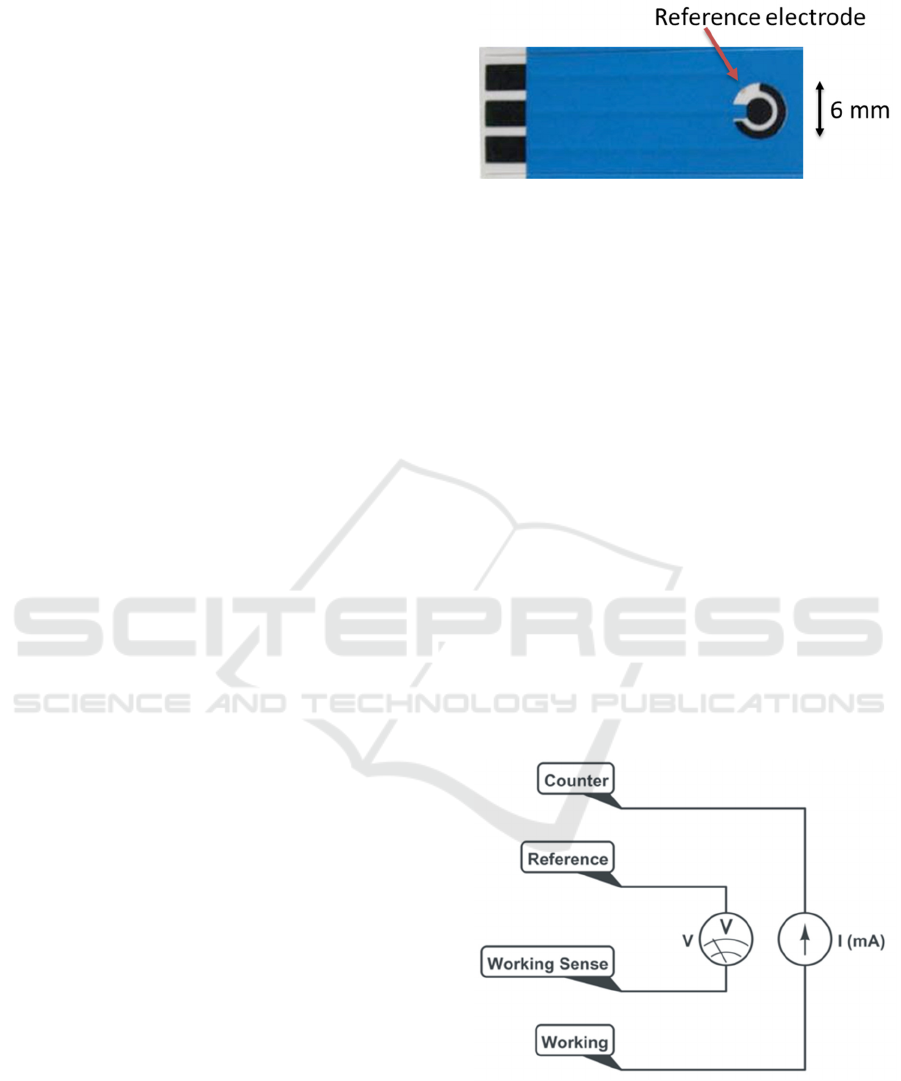

Screen-printed paper-based electrodes (Zensor,

TE100) were acquired from CH Instruments. Figure

1 shows the as-received electrodes. The counter and

working electrode are carbon-based, while the

reference electrode is a silver-silver chloride

formulation.

All characterizations were performed with

electrodes immersed in phosphate buffered saline

(Sigma-Aldrich, St. Louis, MO) at 7.4 pH.

Figure 1: As-received screen-printed electrodes. The active

areas are carbon black and silver/silver-chloride. The tabs

on the left allow for electrical connection through alligator

clips. The active areas are the ring (6mm outer diameter),

the center circle (3 mm diameter), and the reference

electrode, silver/silver-chloride. The Ag/AgCl is identified

by the red arrow. An electrically insulating polymeric cover

is identified in blue.

2.2 Electrochemical Deposition

The electrodeposition of PEDOT-PTS films was

conducted under ambient conditions. A solution of

0.05 M EDOT (Sigma Aldrich, Ireland) and 0.1 M

PTS (Sigma Aldrich, Ireland) was prepared in a 50:50

vol% mixture of acetonitrile and DI water. The

electrolyte solution containing the monomeric EDOT

was placed in an in-house fabricated electrochemical

cell system, as shown in Figure 2. The cell was

connected to a Princeton Applied Research

electrochemical potentiostat/galvanostat model 2273.

The electrochemical apparatus consisted of a four

electrode set-up and galvanostatic electrodeposition

was performed with 0.03 and 0.64 mA, and

providing current densities of 0.4 and 9.014 mA cm

-2

Figure 2: Four-electrode set-up for electrodeposition of

PEDOT-PTS onto Zensor TE100 electrodes under

galvanostatic conditions. Current is first adjusted according

to electrode surface area and then it is applied between

working and counter electrodes, while voltage is measured

between the sensor (working sense) and reference

electrodes.

Electrochemical Analysis of Accelerated Aging of PEDOT-PTS Coated Screen-printed Electrodes

77

respectively, over a constant electrodeposition time of

450 seconds. When the deposition was completed,

each electrode was soaked in deionized water for 24

h to remove excess electrolyte and unreacted EDOT

monomer.

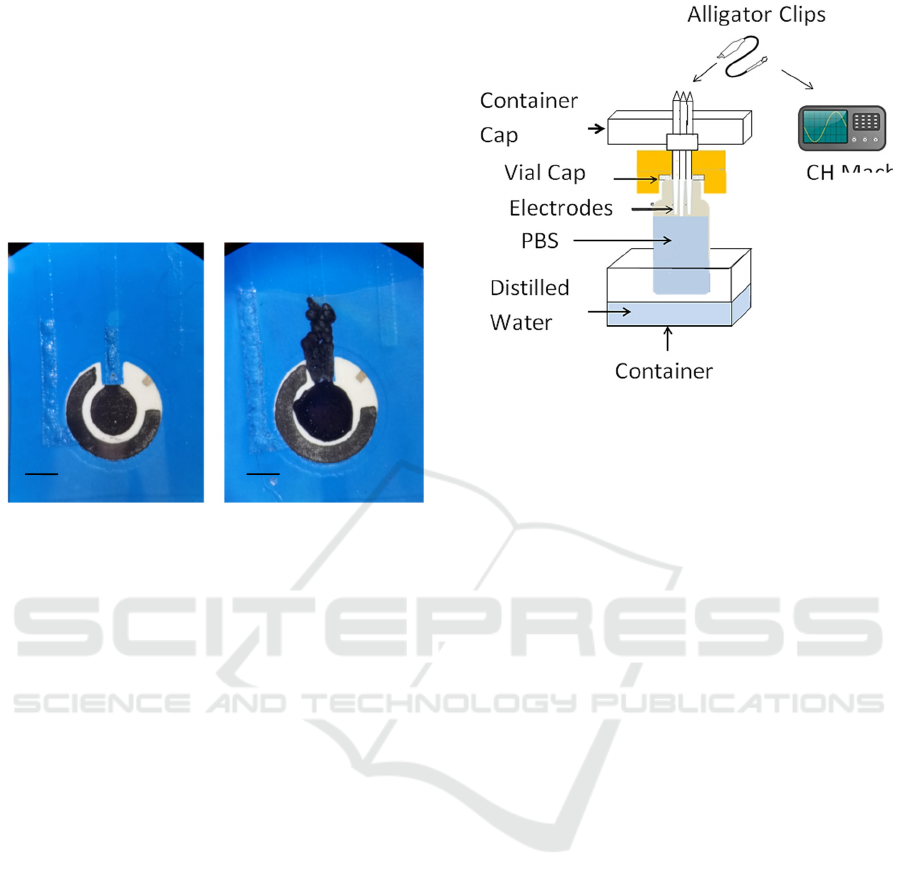

Figure 3 shows magnified images of working

electrode following PEDOT-PTS electrodeposition.

In this manuscript we discuss results pertaining to the

0.4 mA/cm

2

current deposition, as the higher current

showed polymeric coating of the plastic insulation.

Figure 3: As-deposited screen-printed electrodes. PEDOT-

PTS coated electrodes using a current density of 0.4 mA

cm

-2

(left) and PEDOT-PTS coated electrodes using a

current density of 9.014 mA cm

-2

(right). These magnified

images show details of the surface of the counter and

working electrodes immediately after deposition.

Horizontal scale: 3 mm.

2.3 Characterization Techniques

Control electrodes (carbon-based) as well as PEDOT-

deposited electrodes were immersed in PBS and

characterized over time at 24 °C (room temperature)

and at 47 °C. The temperature controller was filled

with Aluminium beads and temperature was logged

over time with a temperature data-logger.

Temperature variation from the heated experiments

(47 °C) was within 1 °C over the course of

experiment. A common problem with long-term

experiments is the evaporation of the media. We

resolved evaporation issues as follows: (a) dental

cement was used on the cap of vials; (b) Teflon tape

used around the threads; (c) a wet environment was

created inside a beaker in order to raise the water

vapor pressure and to allow for temperature control

through a bead bath. Figure 4 shows a schematic of

the setup built and used throughout the

characterization experiments.

Electrochemical characterization was performed

using a 16 channel multiplexer attached to a

CHI660D potentiostat (CH instruments, Bee Cave,

TX). The potentiostat, the electrodes, and all cables

were kept inside a Faraday cage. The potentiostat is

Figure 4: The experimental setup used for long-term

characterization of coated and control electrodes. Dental

cement was used to seal screen-printed electrodes into

electrode cells following PEDOT-PTS deposition. In order

to prevent evaporation, vials were filled with phosphate

buffered saline. Electrodes were inserted through the vial

caps and secured with dental cement. Alligator clips and

multi-stranded wires were used to contact the three

electrodes to the potentiostat, and the whole vial was kept

inside a container with distilled water in order to prevent

evaporation. An external environment with saturated

humidity guaranteed that no evaporation took place over

three months.

connected to a PC, kept outside the cage, through a

USB cable. Cyclic voltammetry (CV) is an

electrochemical method that entails the application of

a voltage between the counter and the working

electrode from -0.7 V to 0.7 V while measuring the

current through the working electrode, in reference to

the silver/silver-chloride electrode. While this test is

usually performed continuously, here we ran five

periods, at a scan rate of 50 mV/s. Each electrode

therefore undergoes five CV cycles and then one EIS

test. We have the capability of running up to 16

channels, but we only used 6 of those (3 controls and

3 experimental strips) in order to demonstrate the

stability of the coatings for up to two months.

Once a voltammetry cycle was recorded, the current

was integrated over half of the period of the voltage

applied (for example, from -0.7 V to 0.7 V, or from

0.7 V to -0.7 V) and the charge transferred could be

obtained. Because this test was done at low scan rates,

it was possible to calculate the charge storage

capacity of the electrode. More specifically, because

integration was applied over the cathodic half of the

period, the resulting plot can be referred to as the

cCSC (cathodic charge storage capacity), given in

Coulombs.

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

78

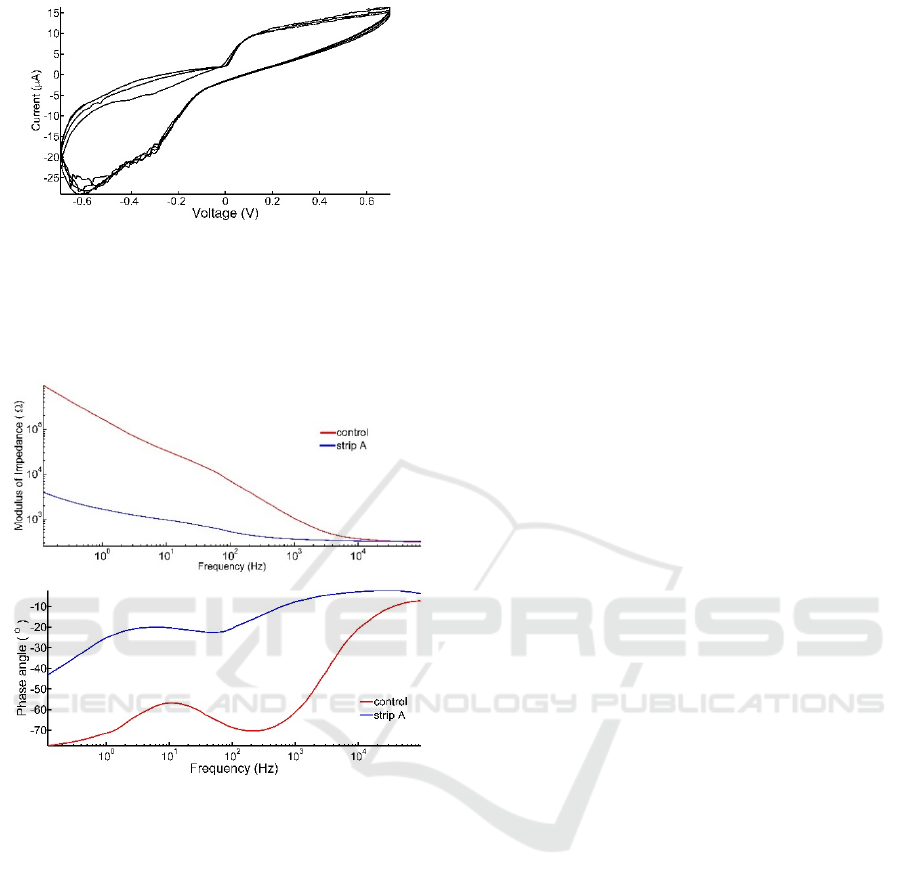

Figure 5: Five cycles of voltammetric spectra of control

non-coated carbon electrodes characterized at room

temperature, in PBS, with a three-electrode setup, voltage

range from -0.7 V to 0.7 V. Current is shown in micro

Amperes. Cyclic voltammetry profile was stable for over

one week (data not shown).

Figure 6: Electrochemical impedance spectroscopy of

control and coated electrodes characterized at room

temperature, in PBS, with a three-electrode setup. Both

impedance modulus (top graph) and phase angle (bottom

graph) show a typical profile for carbon black in the control

electrode (red curves). For lower frequencies, the

electrochemical cell is capacitive (with angles approaching

90 degrees), while for higher frequencies the characteristic

resistive phase is seen. This profile was stable over one

week (testing period, data not shown). Strip A, in blue,

shows lower impedance modulus and a more resistive phase

angle than the control electrode.

Electrochemical impedance spectroscopy (EIS)

was implemented with a 20 mVrms sinusoidal

voltage signal with frequency varying from 0.1 Hz to

100 kHz. Both the modulus and phase were then

recorded for one sweep of frequency. Subsequently

the electrode was subjected to another cyclic

voltammetry (CV) and impedance spectroscopy

(EIS) cycle. Throughout 24 hours at least 80 cycles of

these two tests were recorded.

Figure 5 shows a typical CV spectrum for a

control electrode. Following one week a similar

profile was obtained.

While the CV shows how much charge an

electrode could deliver, the impedance profile

facilitated the generation of the characteristic circuit

component that better describes the interface between

the coating and the electrolyte. Figure 6 shows the

capacitive nature of the carbon-electrolyte interface at

lower frequencies, and the resistive interface at higher

frequencies.

3 RESULTS

“As-received” non-coated electrodes (n=10) were

used as control substrates in order to determine the

stability of the cathodic charge storage capacity. This

was calculated as a function of the surface area of the

working electrode (7 mm

2

), and found to be

0.25±0.10 mC. Due to excessive PEDOT-PTS

deposition on the insulated regions when using a

current density of 9.014 mA cm

-2

,

we have

characterized further only electrodes coated with

PEDOT-PTS electrodeposited with a current density

of 0.4 mA cm

-2

, which were assessed for long-term

stability in vitro.

PEDOT-PTS films deposited at a current density

of 0.4 mA cm

-2

were immersed in PBS and analysed

at room temperature for one month, along with three

control strips. During this time, approximately 2,000

runs were performed on each electrode. In order to

analyze the impedance changes of each electrode, EIS

runs for each experimental condition were combined

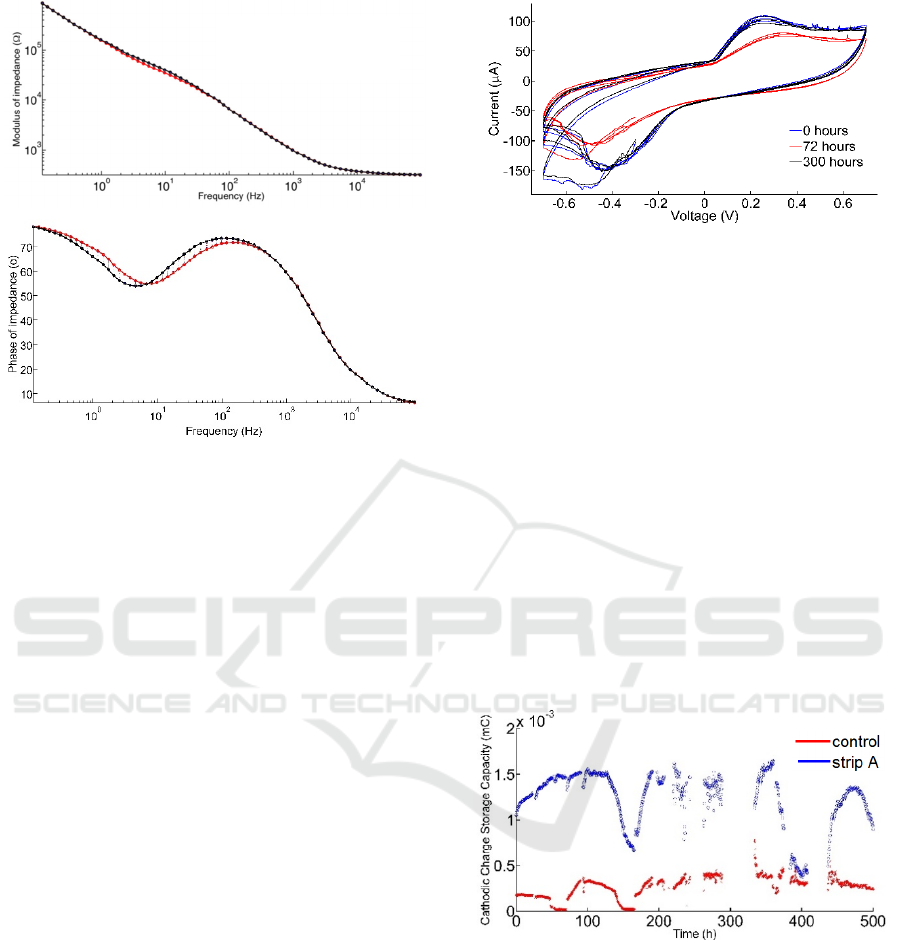

and a mean plot obtained. Figure 7A shows an

example of a twenty-four hour interval, for PEDOT-

PTS coated electrodes. The stability of the modulus

of impedances over time is within one fold for low

frequencies (up to 1 Hz) and it is statistically

insignificant for frequencies above 10 Hz. Figures 7A

and 7B also demonstrate the effects of PEDOT-PTS

deposition on the modulus and phase of the low

frequency impedance spectrum, reducing the

modulus of impedance to less than 10 kΩ at

frequencies less than 1 Hz. This is in conjunction with

a 30 degree angle on the phase of impedance,

indicating a more resistive electrode-electrolyte

interface.

While the EIS results demonstrated repeatable

profiles, the CV spectra presented noise at voltages

above 0.4 V and below -0.4 V. However, the profiles

were significantly different to those of the non-coated

carbon control electrodes (Figure 4), indicating an

Electrochemical Analysis of Accelerated Aging of PEDOT-PTS Coated Screen-printed Electrodes

79

Figure 7: Overlay of electrochemical impedance

spectroscopy measurements (modulus) and of phase

measurements for PEDOT-PTS coated electrodes. The

measurements were obtained at t=0 and after 24 hours at

room temperature, in PBS, with a three-electrode setup. The

modulus of impedance was stable across all frequencies

tested (0.1 Hz through 100 kHz) (top graph). The phase was

observed to increase by up to 10 degrees between the

beginning and end of the test (lower graph).

increased charge transfer capacity (over 1 mC at room

temperature), a higher surface area, and a more

electrically active material. Figure 8 shows CVs taken

at three different times during a 600-hour run at 47°C.

Offsets in current are not considered when calculating

the cathodic charge storage capacity. In order to

measure cCSC the average current per cycle of the

voltage is first subtracted from the current.

After one month of electrochemical analysis at room

temperature, both controls and PEDOT-PTS coated

electrodes presented profiles which are not

statistically different from the profiles recorded

during the initial tests (as shown in figure 7 for

impedance profiles). In order to force the aging of the

electrodes, the temperature of electrolyte was

increased to 47 °C and the cathodic charge storage

capacity was assessed for up to two months. At this

elevated temperature, the main qualitative difference

noted was electrical noise. The impact on the EIS and

CV however was minimal. In order to quantify

stability, we measured the cCSC for over 1,500

voltammetric cycles. Figure 9 shows a summary of

these plots obtained from PEDOT-PTS coated and

non-coated electrodes. The standard deviation was

not plotted on this graph for clarity.

Figure 8: Cyclic voltammetry for PEDOT-PTS coated

electrodes characterized at 47°C. Electrodes were

immersed in PBS, and the CV recorded using a three-

electrode setup, with a scan rate of 50 mV/s. The

voltammetry was performed against the reference electrode

potential. The blue curve was taken at 0 h (first cycle

recorded), red curve at 72 hours, and black curve at 144

hours.

Each electrode was characterized approximately 3

times per hour, for up to 500 hours. There were two

interruptions due to power outages, one around the

300-hour mark, and one around the 420-hour mark.

This means that we are reporting on approximately

400 hours (non-consecutive). Approximately 1,000

files were generated per electrode and each files was

used to extract one cCSC, which was then plotted

along the time axis (Figure 9). The mean and standard

deviation of the cCSCs for control and PEDOT-PTS

electrodes was recorded as 0.26±0.12 mC; 1.25±0.30

mC, respectively.

Figure 9: Cathodic charge storage capacity over time for

control (red) and PEDOT-PTS coated electrodes (blue and

black). The charge storage capacity indicates the stability

of the cyclic voltammetry through a combined mean data

point. Each number corresponds to a full cycle of a CV

performed on the electrode from -0.7 V to 0.7 V at 50 mV/s,

against a reference electrode. These experiments were

performed in PBS held at 47°C.

4 DISCUSSION

Recently, several groups have demonstrated the

t=0 (black)

t=24h (red)

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

80

successful deposition of PEDOT-PTS on Platinum

substrates for electrical stimulation in neural

prosthetics applications (Green et al., 2012, Green et

al., 2013) or as conductive films electro-sprayed onto

glass substrates (Kim et al., 2104). To our knowledge,

this is the first report of a PEDOT-PTS film

successfully deposited on Carbon substrates, on

commercially available screen-printed electrodes.

We have successfully designed a coating protocol

for PEDOT-PTS thin films that can be adjusted in

order to obtain varying charge delivery capacities.

The charge storage capacity of the films showed a

five to seven fold increase over the commercially

available carbon coating, and given the surface area

of the working electrode (7 mm

2

), and the highly non-

uniform surface, the cathodic charge storage capacity

of 0.25±0.10 mC was not surprising. A usual side

effect of thin film coatings, and in particular for

PEDOT electrodes, is the splitting of layers, also

known as delamination, over time. Factors that affect

delamination are the dynamic range of the voltage

applied during CV tests, the temperature at which the

characterizations are performed, the surface

roughness and the electrostatic interaction at the

material interface.

Delamination can usually be visualized on the

surface of the electrode seen as cracks when it is

substantial (Green et al., 2012), and it is a significant

concern in implantable applications since coating

technologies can be important to preserve

biocompatibility during chronic recording or

stimulation (Vallejo-Giraldo et al.). Critically, when

during the onset of delamination, electrochemical

methods can point to subtle or microscopic defects

that are not readily found microscopically. With the

combination of cyclic voltammetry and impedance

spectroscopy profiles, it was possible to ascertain

over time, the stability of the interface between the

working electrode or the electrode coating and an

electrolyte.

By characterizing electrodes over several months

we demonstrated that the charge and the impedance

can vary around a mean value but remained stable in

vitro. Robustness of the PEDOT-PTS could then be

demonstrated at room temperature and when

subjected to accelerated aging at elevated

temperatures. In can be hypothesized that for

applications utilizing implantable PEDOT-PTS

coated electrodes, a similar robust behavior can be

expected. The original motivation for electrochemical

analysis at 47 °C was derived from the hypothesis that

in general, for every 10 degree increase in

temperature, it can expected that the lifetime of the

polymer will decrease by a factor of two. In other

words, given that 10 days is the mean time to failure

cited in the literature for implanted PEDOT-PTS

coatings (Green et al, 2012), it could be expected that

the carbon-based electrodes investigated in this study

would fail within 5 days.

The robustness of the screen-printed electrodes

was a further unexpected result observed in this

exploration and the polymeric insulating coating did

not delaminate over the course of three months (total

test time) indicating the potential applications of these

cost-effective devices for implantable devices.

Future studies will focus on the miniaturization of

the deposition area and on validating the stability of

PEDOT-PTS coated electrodes in neuronal-glial

culture maintained for over three months, while

leveraging the electrodes for stimulation and

recording of extra-cellular activity.

5 CONCLUSIONS

PEDOT-PTS films, when deposited on Carbon-based

substrates, enhance the electrode-electrolyte interface

through increasing the charge delivery with a constant

surface area. The potential of this coating approach

for neuroelectrode applications is further validated

through the coating persistence and delamination was

not observed for up to two months in age-accelerated

conditions. We intend to test miniaturized electrodes

with the same coating process, and with neuronal-

glial cultures, in order to further characterize

PEDOT-PTS for biological applications.

ACKNOWLEDGEMENTS

We acknowledge the participation of our summer

students, Kevin Luu (UCSD) and Jose Pahuacho

Palomino (GMU), who performed some of the

experiments discussed here. M.J. Biggs is a Science

Foundation Ireland, Starting Investigator SIRG

COFUND fellow (grant agreement no.

11/SIRG/B2135), and a funded investigator through

the Science Foundation Ireland Centre for Research

in Medical Devices (CÚRAM) (Grant agreement no.

13/RC/2073).

REFERENCES

Fernandez-Yague, Marc A., et al. "Biomimetic approaches

in bone tissue engineering: integrating biological and

physicomechanical strategies." Advanced drug delivery

Electrochemical Analysis of Accelerated Aging of PEDOT-PTS Coated Screen-printed Electrodes

81

reviews 84 (2015): 1-29.

Green, Rylie A., et al. "Substrate dependent stability of

conducting polymer coatings on medical electrodes."

Biomaterials 33.25 (2012): 5875-5886.

Green, R. A., et al. "Performance of conducting polymer

electrodes for stimulating neuroprosthetics." Journal of

neural engineering 10.1 (2013): 016009.

Kikkawa, Y. S., T. Nakagawa, L. Ying, Y. Tabata, H.

Tsubouchi, A. Ido and J. Ito (2014). "Growth factor-

eluting cochlear implant electrode: impact on residual

auditory function, insertional trauma, and fibrosis." J

Transl Med 12: 280.

Kim, Seul-Gi, et al. "Highly conductive PEDOT: PTS films

interfacially polymerized using electro spray deposition

and enhanced by plasma doping." Japanese Journal of

Applied Physics 53.3 (2014): 035501.

Mandal, Himadri S., et al. "Improving the performance of

poly (3, 4-ethylenedioxythiophene) for brain–machine

interface applications." Acta biomaterialia 10.6 (2014):

2446-2454.

Minnikanti, Saugandhika, et al. "Lifetime assessment of

atomic-layer-deposited Al2O3–Parylene C bilayer

coating for neural interfaces using accelerated age

testing and electrochemical characterization." Acta

biomaterialia 10.2 (2014): 960-967.

Mokarian-Tabari, P., C. Vallejo-Giraldo, M. Fernandez-

Yague, C. Cummins, M. A. Morris and M. J. P. Biggs

(2015). "Nanoscale neuroelectrode modification via

sub-20 nm silicon nanowires through self-assembly of

block copolymers." Journal of Materials Science-

Materials in Medicine 26(2).

Nicolelis, Miguel AL, et al. "Chronic, multisite,

multielectrode recordings in macaque monkeys."

Proceedings of the National Academy of Sciences

100.19 (2003): 11041-11046.

Peixoto, Nathalia, et al. "Charge storage: stability measures

in implantable electrodes." Engineering in Medicine

and Biology Society, 2009. EMBC 2009. Annual

International Conference of the IEEE. IEEE, 2009.

Vallejo-Giraldo, Catalina, Adriona Kelly, and Manus JP

Biggs. "Biofunctionalisation of electrically conducting

polymers." Drug discovery today 19.1 (2014): 88-94.

Ware, Taylor, et al. "ThreeDimensional Flexible

Electronics Enabled by Shape Memory Polymer

Substrates for Responsive Neural Interfaces."

Macromolecular materials and engineering 297.12

(2012): 1193-1202.

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

82